Professional Documents

Culture Documents

INBAL Geral

Uploaded by

Alisson Gustavo KalilOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

INBAL Geral

Uploaded by

Alisson Gustavo KalilCopyright:

Available Formats

Model 733DX-04AR01

F06-02-01

Hydraulic Actuation, Local Resetting

Deluge Valve, Pressure Control

Series700D/DG/DX - 04/14AR01

General Description

The I nbal Pr e s s ur e Cont r ol ,

Hydraulically Actuated Deluge Valve is

specifically designed for use in fire

protection systems which require

pressure control, actuated by a detection

and release system of wet pilot sprinklers

and/or hydraulic manual control. The

Inbal Valve, when in operation,

automatically reduce a higher inlet

pressure to a preset delivery pressure

which remains steady and unattached by

the variations or fluctuations in the

pressure inlet line.

The I nbal Pr e s s ur e Cont r ol ,

Hydraulically Actuated Deluge Valve is

used for automatic or manual hydraulic

operation. The wet pilot line functions as

a thermal detector equipped with fixed

temperature release. When one or more

of the sprinkler heads located on the pilot

line fuses, or when a manual release

station is operated locally or remotely,

the Inbal Deluge Valve opens to allow

water to flow from all open sprinklers

and/or nozzles on the system.

While the valve operates, the deluge

system pressure is maintained at the

preset level within a narrow range. If the

downstream pressure changes slightly

the pilot control responds immediately to

modulate the Inbal Valve for the preset

pressure.

The use of the Inbal Pressure Control

Deluge Valve balances the distribution of

the water capacity available, throughout

the system and prevents a higher demand

from the areas which are of lower

altitude or are located closer to the

pressure source. Thus, the total system

demand is balanced and the excess flow

through the system with high pressure

water supplies is reduced to the desired

level. The adjustment of the valve's

delivery pressure can be easily modified

at the site.

Standard material Inbal Pressure

Control Deluge Valves are rated to 300

psi (21 bar) and are available in sizes 1"

(40 mm) to 12" (300 mm) with threaded,

flanged, grooved, or wafer ends.

The only moving part in the Inbal Valve,

when it operates, is the reinforced sleeve

which forms a drip tight seal with the

corrosion resistant core. It has a smooth

opening to prevent any water hammer in

the piping system .

The unique design of the Inbal Valve and

the pilot control, and variety of materials

and coatings, make the Inbal Pressure

Control Deluge Valve suitable for use

with brackish or sea water similar to

t hos e f ound i n chemi cal and

petrochemical facilities or in offshore

platforms.

Technical Data

Approvals

The basic Inbal Deluge Valve is FM

Approved to 300 psi (21 bar) in sizes 3",

4", 6", and 8" (80, 100, 150, and

200 mm). Inbal Valves are Lloyd's,

DNV, and ABS Type Approved in sizes

1" (40 mm) to 12" (300 mm) to a

working pressure of 300 psi (21 bar).

Model Numbers

I nlet End Outlet End Model No.

Threaded Threaded 711DG-04AR01

Threaded Grooved 716DG-04AR01

Flanged Flanged 733DG-04AR01

Flanged Grooved 736DG-04AR01

Grooved Grooved 766DG-04AR01

Wafer Wafer 799DG-04AR01

"DG" can be replaced with "D" or "DX" depends

on the Inbal Automatic Water Control Valve series

in use. See bulletins F02-01-01, F02-02-01, and

F02-03-01.

The above model numbers refer to fully trimmed

valves. For basic trim replace "04" with "14".

(See also bulletin F01-03-01 for control trim "24"

& "34"). For example: 733D-14AR01 is a flanged

ends deluge valve with basic, hydraulically

actuated, pressure control trim.

Mil Ltd.

F06-02-01-002

Optional

Cast Steel ;

Bronze ;

Nickel Aluminum Bronze ;

Stainless Steel AISI 316 ;

Super Austenitic Stainless Steel ;

Super Duplex Stainless Steel ;

Titanium.

Coating

Standard

Powder epoxy coated. Thickness: 0.004"

(0.1 mm) external and internal surfaces.

Optional

High built epoxy coated and polyure-

thane finish. Thickness: 0.01" (0.3 mm).

Halar coated. Thickness: 0.02"

(0.5 mm) .

Halar is a registered trade mark of Ausimont USA Inc.

Control Trim

The control trim includes Deluge Pilot

Valve, Pressure Reducing Pilot Valve,

Emergency Release Valve, Pressure

Gauges, Pressure Gauge Valves, fittings,

and tubing. On standard the control trim

is supplied preassembled in sections.

See the applicable Trim Chart for

complete components list.

Features

! Dual function control trim on a single

valve body saves the use of two

different control valves.

! No Movi ng Mechani cal Part s

(N.M.M.P.) construction ensures a long

life of dependable operation and

provides stable delivery pressure and a

gradual closure, in case of increasing

delivery pressure, to eliminate surges.

! Quick, yet soft opening performance -

eliminates water hammer and conse-

quent damages.

! Fast and easy reset by merely pulling a

knob.

! Supplied as standard preassembled in

sections - saves the self assembly cost.

! Can be installed vertically or

hori zont al l y.

! Compact design - minimum space for

valve and trim.

! Unique principle of operation prevents

false operation due to water surges.

! Pressure rating to 300 psi (21 bar) for

standard material valve.

! Balanced, single seat design pilot

control for very accurate performance-

not affected, even slightly, by inlet

pressure fluctuations.

! Long spring design pilot control for

sensitive setting and maintaining

precise delivery pressure.

! Easily adjusted to the desired system

pressure.

! Hydrodynamically designed Inbal

Valve with streamline flow path-

provides increased flow capacity.

! Wide range of sizes for an ideal system

design.

! Control trim made of high grade

materials as standard.

! Epoxy coating supplied as standard -

ensures excellent corrosion resistance.

! Variety of available materials - to

ensure corrosion-free service even

under severe conditions.

Operation

The Control Chamber of the Inbal

Automatic Water Control Valve is the

annular space between the Valve

Housing and the Sleeve. The valve is

held in a closed position as long as inlet

pressure is maintained in the Control

Chamber.

The wet pilot line, equipped with closed

sprinkler heads, is pressurized through

the valve trim and located over the

protected area. The wet pilot line serves

the dual purpose of thermal detection and

release system.

In the set position, water pressure is

applied to the Control Chamber of the

Inbal Deluge Valve and to the hydraulic

release system from the upstream of the

Water Supply Valve. Consequently, the

Inbal Deluge Valve stays closed.

The Inbal Deluge Valve opens when one

or more of the sprinkler heads installed

on the wet pilot line fuses and water

pressure is allowed to escape, or when a

hydraulic manual release opens.

Either one of these operations releases

water from the Deluge Pilot Valve which

opens to release water from the Inbal

Valve Control Chamber. The flow

through the Pressure Reducing Pilot

Valve responds to changes in the

downstream pressure while controlling

the pressure at the Inbal Valve Control

Chamber. When the delivery pressure

decreases, the pilot valve and the Inbal

Valve open wider to increase the

pressure. When the delivery pressure

increases, the pilot valve and the Inbal

Valve close to throttle further the flow

Sizes

Threaded End:

1", 2", 2", & 3" (40, 50, 65,&80 mm).

Flanged and Grooved Ends:

1", 2", 2", 3", 4", 6", 8", 10", & 12"

(40, 50, 65, 80, 100, 150, 200, 250, &

300 mm).

Wafer End:

3", 4", 6"; 8",10", & 12" (80, 100, 150,

200, 250, & 300 mm).

End Standards

Threaded End:

NPT or BSPT.

Flanged End:

ANSI B16.5 class 150 & 300 ;

ISO 7005 - PN 10, 16 & 25 ;

BS 10 Table D & E ;

AS 2129 Table D & E ;

Jis B2212; 2213, & 2214.

Wafer End:

Fits most of the abov e standards.

Grooved End:

ANSI/AWWA C606-87.

Pressure Rating

Maximum working pressure*: 300 psi

(21 bar).

* Standard material valve.

Adjustment Range

Standard*

30 to 300 psi (2 to 21 bar).

* Marked red.

Temperature Range

Water: Max. +150F (+65C).

Installation Position

Vertical or horizontal.

Materials

Standard

Valve Housing:

Carbon Steel (SAE 1021).

Valve Ends and Wafer Flow Test & Drain

Ends:

Ductile Iron (ASTM A536-65 45 12).

Threaded, Flanged, and Grooved Flow

Test & Drain Ends:

Carbon Steel (SAE 1020).

Sleeve:

SMR5 Elastomer reinforced with poly-

ester and Kevlar.

Control Trim:

Brass Nickel Chrome plated, Stainless

Steel, and Galvanized Steel.

0

0

0

0

0

1 Inbal Automatic

Water Control Valve

2 Emergency Release Station

3 Automatic Drain Valve

4 Trim Shutoff Valve

5 Y-Strainer

0

0

6 Check Valve

7a Supply Pressure Gauge

7b System Pressure Gauge

9 Pressure Reducing

Pilot Valve

19 Restriction Orifice

_

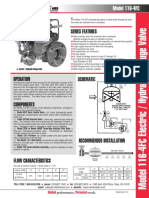

Schematic Control Diagram 700DG- 04AR01

OPEN

CLOSE EMERGENCY

MANUAL VALVE

2

6

9

26

4

19

5

6

35

25

7b

7a

To

Drain

To

Drain

To Alarm

Pressure

Switch

To

Drain

3

W

e

t P

ilo

t L

in

e

Inspector's

Test Valve

F06-02-01-003

25 Deluge Pilot Valve

26 Flow Control Unit

35 Alarm Test Valve

38a Flow Test Valve

38b Drain Valve

38a

To Drain

To System

To Drain

38b

1

To Water

Motor

Alarm

Water

Supply

Valve

and consequently the delivery pressure is

decreased. Thus, the outlet pressure is

maintained within a close limit. The

operation of the Inbal Deluge Valve will

flow water from any open sprinklers

and/or spray nozzles on the system while

activating the system's alarm devices.

Once the Deluge Pilot Valve operates, it

latches in an open position, preventing

the Inbal Pressure Control deluge Valve

from closing even if the open releasing

wet pilot line closes. The Inbal Valve

will close only when the Resetting

procedure is followed.

The Deluge Pilot Valve spring tension is

adjusted to open wide when the wet pilot

line operates and to be in a drip tight

closed position when the wet pilot line is

reset.

The Emergency Release Valve is used

for emergency actuation of the Inbal

Deluge Valve and for routine testing.

I nstallation

Refer to the Trim Chart applicable to the

specific Inbal Pressure Control Deluge

Valve model in use.

1.When the Inbal Deluge Valve is

delivered, carefully unpack and

visually check that there has been no

damage to the operating components,

piping, and fittings.

2.Always flush the pipelines before

installing the Inbal Valve.

3.Place the Inbal Valve in the piping at

the outlet of the Water Supply Valve.

Verify that the arrow on the valve

Housing matches the actual flow

direction. Determine which side the

system will be accessed from and

locate the Inbal Deluge Valve

accordingly.

4.Install the Inbal Deluge Valve in the

pipeline. Use gaskets, bolts, stud

bolts, bolt sleeves, and nuts as

required by the valve ends.

5.Complete the trim assembly by

connect i ng t he preassembl ed

sections, or assemble the trim if

ordered in loose component form.

Refer to the applicable Trim Chart

and Installation Guide

6.The water pressure supply to the

control trim must always be sourced

from the inlet of the Water Supply

Valve through a " pipe.

7.Connect the drain tube of the Deluge

Pilot Valve and all the other drain

tubes to the drainage system.

8.It is recommended to install an

0

0

0

0

0

0

0

0

inspector's test valve on the hydraulic

release system. The inspector's test

valve is a locked closed ball valve

with an outlet end orifice equivalent

to the smallest orifice of releasing

device provided on the system. The

inspector's test valve may be used to

verify adequate operation of the

deluge system when a releasing

device operates.

9.Connect the wet pilot line to the

Deluge Pilot Valve. Open the Trim

Shutoff Valve and allow water

pressure to build up in the trim, Inbal

Valve Control Chamber, and the pilot

line. Open the inspectors test valve

and verify that the Deluge Pilot Valve

opens fully. If the Deluge Pilot Valve

opens partially or remains closed,

tighten the adjusting screw until full

open position is obtained. Close the

inspectors test valve, reset the

Deluge Pilot Valve [see (7) in

Resetting], and verify that the Deluge

Pilot Valve is drip-tight closed. See

0

Graph (1) in bulletin F33-03-01 for

Deluge Pilot Valve adjustment range.

10.The downstream pressure adjustment

is recommended at a minimum flow

velocity of 1.5 ft/sec (0.5 m/sec).

When it is not feasible to flow the

system, close the system shutoff

valve and open the Drain Valve.

11.Operate the system to establish the

minimum flow. Check the System

Pressure Gauge reading. If adjust-

ment is required turn the Pressure

Reducing Pilot Valve adjusting screw

clockwise to increase or counter-

clockwise to decrease the pressure

setting.

12.Open the system shutoff valve and

close the Drain Valve.

13.Set the Inbal Pressure Control

Deluge Valve by following the

Resetting procedure.

14.Test the Inbal Deluge Valve, the trim

and the alarm according to the

Testing procedure.

March 2000 / F06-02-01

Deluge Valve, Pressure Control

Series700D/DG/DX - 04/14AR01

Resetting

The Inbal Pressure Control Deluge

Valve system must be reset and restored

to service as soon as possible after auto-

matic, emergency, or manual actuation.

1.Close the Water Supply Valve. The

water flow alarms are reset.

2.Close the Trim Shutoff Valve.

3.Open the Flow Test and Drain Valves,

allowing all the water to drain.

4.Inspect and replace any portion of the

detection system subjected to fire

conditions.

5.Inspect the trim and alarm Y-

Strainers. Clean if necessary.

6.Verify that the Emergency Release

Valve is in a closed position.

7.Open the Trim Shutoff Valve and

allow the water to fill up the pilot line.

Pull the reset knob of the Deluge Pilot

Valve and position the Resetting

Indicator. As soon as the pilot system

pressure exceeds the preset pressure,

the Resetting Indicator should fall

off, hanged by the Secured Chain. If

Deluge Pilot Valve adjustment is

required see (10) in Installation.

.Close the Flow Test Valve.

9.Fully open the Water Supply Valve.

Verify that there is no flow from the

Drain Valve downstream of the Inbal

Valve.

10.Close the Drain Valve.

Maintenance, I nspection, & Testing

It is recommended that periodic inspec-

tions and tests be conducted by qualified

personnel to ensure that the Inbal Pressure

Control Deluge Valve and related

equipment are in good operating condition.

The inspection and testing activities should

be done according to NFPA Standards,

the guidelines and regulations of the

authorities having jurisdiction, and the

following instructions. It is recommended

that the Pressure Control Deluge Valve be

tested, operated, cleaned, and inspected at

least on a routine basis.

0

0

0

0

0

0

0

0

0

8

Inspection

A weekly Inspection is recommended:

1. Verify that the Water Supply Valve is

sealed in full open position.

2. Verify that the required water pressure

is being applied to the Inbal Deluge

Valve inlet and trim.

3. Verify that the Trim Shutoff Valve,

Alarm Test Valve, Emergency Release

Valve, Pressure Gauge Valves, and

Drain Valve are in se t position.

4.Check the Supply and System

pressure gauge readings.

5. Visually inspect for broken or missing

parts, or other evidence of impaired

protection.

Strainer Cleaning

A quarterly Strainer Cleaning is

r e c o mme n d e d :

1. Close the Trim Shutoff Valve.

2. Remove the covers of the trim and

alarm Y- Strainers. Clean if necessary.

3. Open the Trim Shutoff Valve.

Alarm Testing

A quart erl y Al ar m Test i ng i s

r e c o mme n d e d :

1. Test the Water Motor Alarm or Alarm

Pressure Switch by opening the Alarm

Test Valve.

2. Water Motor Alarm should be audible.

Alarm Pressure Switch should

activate.

3. Close the Alarm Test Valve. All local

alarms stop sounding and pressure

switch is reset.

4. Verify that the supply piping to alarm

drains properly .

Deluge Trim Testing

A semi-annual Deluge Trim Testing is

recommended. Testing of the control

trim is conducted with no flow of water

to the system.

1. Open the Flow Test Valve to flush

away debris or foreign particles

which may have accumulated in the

Inbal Deluge Valve inlet.

2. Close the Flow Test Valve.

3. Close the Water Supply Valve installed

in the inlet of the Inbal Valve.

4.Open the inspector's test valve

installed on the hydraulic release

system. Water should be drained from

the deluge trim. If an adjustment of the

Deluge Pilot Valve is needed see (10)

in Installation and (7) in Resetting.

5.Reset the Valve by performing the

instructions in Resetting.

Trip Testing

An annual Trip Testing is recommended.

By performing the Trip Testing, water

will flow from all open sprinklers and/or

nozzles. Prevent damage by taking the

necessary precautions.

1.Trip the Inbal Valve to open by

opening the inspector's test valve.

The water in the Inbal Valve

Control Chamber is released to the

atmosphere. The Inbal Deluge Valve

will open and water will flow to the

system.

2.Check the Supply and System Pressure

Gauge readings. Verify that the

delivery pressure is as predetermined.

3.Record the actual flow rate and

upstream and downstream pressures.

4.Verify that all the alarms operate

properly.

5.Close the inspector's test valve.

6.Reset the valve by performing the

instructions in Resetting.

Removal

To remove the Inbal Deluge Valve:

1. Close all the pressure supplies:

a) Water Supply Valve.

b) Trim Shutoff Valve.

2.Open the Emergency Release Valve to

release the water pressure from the

Inbal Valve Control Chamber.

3.Open the Drain Valve to allow all the

water to drain.

4.Disconnect the union and remove the

trim from the valve.

5.Remove the Inbal Valve from the line

for inspection.

6.To reinstall, follow the Installation

procedure (use new gaskets for flanged

or wafer valve).

I nquiries/Orders

The Data Sheet For Inquiries/Orders

(bul l et i n F01-05-01) shoul d be

submitted.

Mil Ltd. 17 Moshe Beker Street, P.O.Box 15200, Rishon Lezion 75051, Israel. Tel: +972 3 966 4350, Fax: +972 3 966 4320, E-mail:inbalvl@attglobal.net

Model 799D

Mil Ltd.

Automatic Water Control Valve

Series 700D

F02-01-01

General Description

The Inbal Automatic Water Control

Valve series 700D is a pressure operated,

sleeve actuated, axial valve, designed

from basic concepts, with a built-in

actuator to function as control valve in

fire protection system. The Inbal series

700D is used as deluge, preaction, dry

pipe, remote control, pressure reducing,

pressure relief, pump control, water level

control, and other types of control

valves. The standard material Inbal

Valve is rated to 300 psi (21 bar) and

requires a minimum line pressure of 20

psi (1.5 bar) for operation. Upon removal

of the control pressure the Inbal Valve

opens instantaneously, yet very

smoothly, to prevent any water hammer

in the piping system. The Inbal 700D

performance and ease of resetting are not

affected by vertical or horizontal

installation.

The Inbal Automatic Water Control

Valve utilizes the unique N.M.M.P. (No

Moving Mechanical Parts) design. The

only moving part when the Inbal Valve

operates, is the reinforced sleeve which

forms a drip-tight seal with the corrosion

resistant core. The Inbal design also

prevents false operation due to transient

surges in water supply pressure. The

N.M.M.P. design and variety of mater-

ials and coatings make the Inbal Auto-

matic Water Control Valve ideally

suitable for use with brackish or sea

water similar to those found in chemical

and petrochemical facilities or in

offshore platforms. It can also be used as

a foam concentrate control valve in

foam/water systems.

The Inbal Automatic Water Control

Valve series 700D is available in sizes

1" (40 mm) to 12" (300 mm). The

valves have threaded, flanged, or wafer

inlet and outlet ends.

Technical Data

Approvals

The Inbal Automatic Water Control

Valve is FM approved to 300 psi (21 bar)

in sizes 3", 4", 6", and 8" (80, 100, 150,

and 200 mm). Consult the FM Approval

Guide for acceptable applications.

Inbal Deluge Valves have Lloyd's, DNV,

and ABS Type Approvals for all sizes and

most models.

Model Numbers

I nlet End Outlet End Model No.

Threaded Threaded 711D

Flanged Flanged 733D

Wafer Wafer 799D

Sizes

Threaded End:

1", 2", 2", & 3"(40, 50, 65, & 80mm).

Flanged End:

2", 2", 3", 4", 6", 8", 10", & 12" (50, 65,

80, 100, 150, 200, 250, & 300 mm).

Wafer End:

3", 4", 6", 8", 10", & 12" (80, 100, 150,

200, 250, & 300 mm).

End Standards

Threaded End:

NPT or BSPT.

Flanged End:

ANSI B16.5 class 150 & 300 ;

ISO 7005 - PN10, 16 & 25 ;*

BS 10 Table D & E ;**

AS 2129 Table D & E ;**

Jis B 2212, 2213, 2214 ;**

Wafer End:

Fits all above standards.**

* Compatible with DIN 2501 and BS 4504.

** Exclude:

BS 10 Table E 6" (150 mm);

AS 2129 Table E 6" (150 mm);

Jis B2212 regular flange in sizes 4", 8", &12"

(100, 200, & 300 mm).

Pressure Rating

Maximum working pressure*: 300 psi

(21 bar). Minimum Working Pressure:

20 psi (1.5 bar).

* Standard material valve.

F02-01-01-002

Full open operation

When pressure in the Control Chamber is

relieved to the atmosphere, the Inbal

Valve opens wide. The sleeve assembly

is safely enveloped by the housing.

Tight closing operation

When pressure from the valve inlet (or an

equivalent independent operating

pressure) is applied to the Control

Chamber, the Inbal Valve closes drip

tight. The fabric sleeve safely envelopes

the resilient sleeve giving full support.

Modulating action

A stable throttling position is obtained

when a quantity of pressurized fluid is

held in the Control Chamber. It is the

amount of fluid in the Control Chamber

that determines the position of the sleeve

assembly. The Control Chamber can be

alternately filled or exhausted to achieve

the desired operating condition.

Figure (1) Figure (2) Figure (3)

Temperature Range

o o

Water: Max. +150 F (+65 C).

Installation Position

Vertical or horizontal.

Materials

Standard

Valve Housing:

Carbon Steel (SAE 1021).

Valve Ends:

Ductile Iron (ASTM A536 65-45-12).

Sleeve:

SMR5 Elastomer reinforced with Poly-

ester and Kevlar.

Optional

Cast Steel ;

Bronze ;

Nickel Aluminium Bronze ;

Stainless Steel AISI 316 ;

Super Austenitic Stainless Steel ;

Super Duplex Stainless Steel ;

Titanium.

Coating

Standard

Powder epoxy coated. Thickness: 0.004"

(0.1 mm) external and internal surfaces.

Optional

High built epoxy coated and polyure-

thane finish. Thickness: 0.01" (0.3 mm).

Halar coated. Thickness: 0.02"

(0.5 mm).

Halar is a registered trade mark of Ausimont USA Inc.

Features

! The Inbal Valve, designed for control

valve service from basic concepts,

utilizes a built-in sleeve actuator.

! No Movi ng Mechani cal Part s

(N.M.M.P.) construction ensures a long

life of dependable operation, reducing

the cost of maintenance.

! The N. M. M. P. Design assures

frictionless operation. No sticking after

staying for prolonged periods in a

closed position. Suitable for brackish

and sea water.

! Quick, yet soft opening performance -

eliminates water hammer and conse-

quent damage.

! The line pressure or an equivalent

independent operating pressure, is

sufficient to close the Inbal Valve

tightly.

! Soft closure performance due to

inherent characteristics of the Inbal

Valve. Utilizes no spring to ensure

surge-free closing.

! Pressure rating of 300 psi (21 bar) for

standard materials valve due to rigid

construction.

! Suitable for vertical or horizontal

installation with no effect on Inbal

Valve performance.

! Lightweight - easy to be installed and

maintained.

! Available with threaded, flanged, and

wafer ends to various standards.

! Unique principle of operation prevents

false operations due to water surges.

! Wide range of sizes for an ideal system

design.

! Compact design - minimum space for

valve and trim. Enable installation in

confined spaces.

! Epoxy coating supplied as standard-

ensures excellent corrosion resistance.

! Variety of available materials - to

ensure corrosion-free service even

under severe conditions.

! Compatible with electric, pneumatic,

and/or hydraulic release.

! Excellent regulating performance in a

wide range of flows and line pressures.

! Wide selection of pilot valves,

actuators, and accessories to design the

ideal control valve for the purpose.

! A single Inbal Automatic Water

Control Valve can perform multi-

function controls.

! Every single valve is hydraulically

tested in real flow and pressure

conditions.

! Innovative design with a long record of

proven performance.

Operation

The Control Chamber of the Inbal

Automatic Water Control Valve is the

annular space between the valve

Housing and the Sleeve. The valve is

held in a closed position as long as inlet

pressure is maintained in the Control

Chamber.

In the set position, the water pressure is

transmitted from the upstream through

the valve trim to the Control Chamber,

and the Inbal Valve stays closed.

Actuation of the valve by a manual,

hydraulic, pneumatic, or electric release

system allows venting of the pressure in

the Inbal Valve Control Chamber, and

the valve opens wide, permitting a flow

of water to the piping system. When a

pressure or flow control is added, the

Control Chamber is monitored to

modulate a preset delivery pressure,

maximum inlet pressure, or flow rate.

The principle of operation is illustrated

in Figures (1) through (3). The nominal

pressure losses are shown in Graph (1).

I nstallation

Refer to the Trim Chart applicable to the

specific Inbal Valve model in use.

1. When the Inbal Valve is delivered,

carefully unpack and visually check

that there has been no damage to the

operating components, piping, and

fittings.

2. The Inbal Valve must be installed in

an area not subject to freezing

conditions.

3. Always flush the pipelines before

installing the valve.

4. Place the Inbal Valve in the piping in

the outlet of the Water Supply Valve.

Verify that the arrow on the valve

housing matches the actual flow

direction. The Inbal Valve may be

installed in any position. Determine

which side the valve will be accessed

from and locate all the components

accordingly.

5. Install the Inbal Valve in the piping

system. Refer also to the applicable

Installation Guide.

Threaded End Valve - connect the

female threaded ends of the Inbal

Valve to the male threads of the

piping. Use the pipe joint compound

sparingly on the male threads only.

Flanged End Valve - connect with

bolts and nuts, the valve flanges to

the existing flanges in the piping

system, using gaskets in between.

Complete bolting with uniform

tightening.

0

0

0

0

0

Wafer End Valve - Install the Inbal

Valve between the piping flanges.

Place gaskets between the valve ends

and the pipe flanges. Insert four of

o

the stud bolts, 90 apart around the

valve, through the bolt sleeves and

the pipe's flanges, and tighten with

nuts. Complete bolting with uniform

tightening.

6. Complete the trim assembly by

connect i ng t he preassembl ed

sections, or assemble the trim if

ordered in loose component form.

Refer to the applicable Trim Chart

and Installation Guide.

7. The pressure supply to the trim must

always be sourced from either inlet

of Water Supply Valve or Inbal

Valve upstream, through a " pipe.

8. Exhaust tube must be free of any back

pressure. Provide an air gap between

the exhaust tube and drain facility.

9. Set the Inbal Valve by following the

applicable Resetting procedure.

10. Test the Inbal Valve, the trim, and

alarms according to the applicable

Testing procedure.

Resetting

The Inbal Automatic Water Control

Valve system must be reset and restored

to service as soon as possible after

automatic, emergency, or manual

actuation. Refer to the relevant bulletin

for detailed procedure.

0

0

0

0

F02-01-01-003

Core

Sleeve Assembly

Housing

End

Mil Ltd. 17 Moshe Beker Street, P.O.Box 15200, Rishon Lezion 75051, Israel. Tel: +972 3 966 4350, Fax: +972 3 966 4320, E-mail:inbalvl@attglobal.net

March 2000 / F02-01-01

Automatic Water Control Valve

Series 700D

FlowChart

Graph (1)

Flow Rate

4 5 6 7 10 20 30 40 50 75 100 200 300 500 1000 150 2000 3000

2 3 4 5 10 15 20 30 40 50 100 150 200 300

500

700

20 30 40 50 100 200 1000

2000 3000

5000 10000

300 500

6" 4" 3" 2" 1 12"

300

10"

250

8"

200 150 100 80 50 40

inch

mm

l/s

gpm

3

m /h

bar

0.1 0.98

0.2

0.3

0.4

0.5

3

1

0.1

0.01

0.02

0.03

0.04

0.05

1.5

2

2

3

4

5

10

10

15

20

30

40

50

100

5

4

0.15

0.2

0.3

0.4

0.5

1

psi

0.14

0.3

0.4

0.2

0.5

1

KPa m H O

2

Inbal Valve Size

H

e

a

d

L

o

s

s

15

10

3

1.5

2

5

4

ValveSize FlowFactor

mm inch Kv Cv

40 1'' 60 70

50 2'' 90 105

80 3'' 140 162

100 4'' 330 383

150 6'' 610 708

200 8'' 1150 1334

250 10'' 1630 1891

300 12'' 2365 2743

Flow Factor

Q = Flow rate in

3

m / h.

Kv = Flow factor.

Use Table (1)

Q

Kv

( )

2

P =

P = Head loss

in bar.

Table (1)

Table (2)

Valve Size Displacement

U.S.

mm inch liter gallon

40 1" 0.3 0.08

50 2" 0.3 0.08

80 3" 0.3 0.08

100 4" 0.5 0.13

150 6" 1.7 0.45

200 8" 3.5 0.92

250 10" 8.1 2.1

300 12" 12.7 3.4

Control Chamber Displacement

To define the head loss through an Inbal

valve at a specific flow rate use the

following equation (for water only):

The Flow Factor Cv (Kv) is defined as

3

the flow rate in gpm (m/h) of liquid at

0 0

68 F (20 c), flowing at 1 psi (1bar) head

loss.

Q = Flow rate in

gpm.

Cv = Flow factor.

Q

Cv

( )

2

P =

P = Head loss

in psi.

Trim Testing and/or Control Testing, as

well as a Quarterly Testing as listed in the

applicable data sheet of the specific

application in which the Inbal Auto-

matic Water Control Valve participates.

An Annual Testing shall include Trip

Testing, Semi-Annual Testing, and

Quarterly Testing as listed in the appli-

cable data sheet of the specific appli-

cation in which the Inbal Automatic

Water Control Valve participates.

Removal

To remove the Inbal Valve:

1.Close all the pressure supply valves:

a) Water Supply Valve

b) Trim Shutoff Valve.

2.Open the Emergency Release Valve to

release the water pressure from the

Inbal Valve Control Chamber.

3.Open the drain valves to allow all the

water to drain.

4.Remove the trim from the Inbal Valve.

5.Remove the Inbal Valve from the line

for inspection.

6.To reinstall, follow the Installation

procedure section (use new gaskets for

flanged or wafer valve).

I nquiries/Orders

The Data Sheet For Inquiries/Orders

(bul l et i n F01-05-01) shoul d be

submitted.

Maintenance, I nspection,& Testing

It is recommended that periodic

inspections and tests be conducted by

qualified personnel to ensure that the

Inbal Automatic Water Control Valve

and related equipment are in good

operating condition. The inspection and

testing activities should be done

according to NFPA Standards, the

guidelines and regulations of the

authorities having jurisdiction, and the

following instructions. It is recom-

mended that the Inbal Valve be tested,

operated, cleaned, and inspected on a

routine basis.

A Weekly Visual Inspection shall include

Water Supply Valve position, free

pressure access, and major trim compo-

nents as listed in the applicable data sheet

of the specific application in which the

Inbal Automatic Water Control Valve

participates.

A Quarterly Testing shall include Alarm

Testing, Strainer Cleaning, and major

components testing as listed in the

applicable data sheet of the specific

application in which the Inbal Auto-

matic Water Control Valve participates.

A Semi-Annual Testing shall include

Model 711D

Model 733D

Model 799D

* Refer to Standard Material Valve.

"

L

A

"

(TYPx2)

* Refer to Standard Material Valve.

** Refer to flange standard ANSI B16 150.

* Refer to Standard Materia l Valve.

SIZE A L Weight*

1 "

40 mm

2"

50 mm

2 "

65 mm

3"

80 mm

93

93

93

93

195

195

195

8"

203

18

8

lbs

kg

8 kg

lbs 18

8 kg

lbs 18

7.5

16.5

kg

lbs

5

3 " 8 /

5

3 " 8 /

5

3 " 8 /

5

3 " 8 /

5

7 " 8 /

5

7 " 8 /

5

7 " 8 /

300 mm

12"

200 mm

250 mm

10"

8"

150 mm

483

19"

447

308 343

16"

406 363

13 "

279 246

3"

6"

100 mm

80 mm

4"

SIZE

7 "

9 "

7 " 9"

11"

229 190

191 161

D** L

171 178 65 mm

50 mm

2 "

2"

7" 6 "

114

250

52

88

193

114

32

29

70

17

13

37

Weight*

13

29

12

26

lbs

kg

kg

lbs

kg

lbs

kg

lbs

kg

lbs

kg

lbs

kg

kg

lbs

lbs 6 "

165

6 "

171

5

17 " 8 /

3

14 " 8 /

3

6 " 8 /

1

12 " 8 /

Weight*

150 mm

200 mm

8"

100 mm

6"

3"

80 mm

4"

SIZE D L

kg

lbs

kg

lbs

kg

lbs

kg

lbs

300 mm

250 mm

12"

10"

kg

lbs

kg

lbs

130

160

6 "

218

273

10 "

324

12 "

381

157

6 "

186

238

302

350

13 "

443

17 "

6

13

9

20

21

46

35.5

78

53.5

117

81

178

5

8 " 8 /

3

7 " 8 /

3

9 " 8 /

7

11 " 8 /

1

5 " 8 /

L

"

D

"

(TYPx2)

"

L

D

"

(TYPx2)

15"

Series 700D

Overall Dimensions & Weights

March 2000 / F02-01-01-005

Mil Ltd. 17 Moshe Beker Street, P.O.Box 15200, Rishon Lezion 75051, Israel. Tel: +972 3 966 4350, Fax: +972 3 966 4320, E-mail:inbalvl@attglobal.net

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- 1000 Solved Problems in Fluid K Subram 20347920Document2 pages1000 Solved Problems in Fluid K Subram 20347920RhiscptreohLtusocan39% (23)

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity Calculation@sssNo ratings yet

- Study of An FSAE UndertrayDocument57 pagesStudy of An FSAE UndertrayDaniel MendonçaNo ratings yet

- BE-WI-248-01-F19 Datasheet Breather ValveDocument3 pagesBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNo ratings yet

- Inbal - Deluge Valve Pressure Control 03 - 13 CR01Document4 pagesInbal - Deluge Valve Pressure Control 03 - 13 CR01gustavosalvatoNo ratings yet

- Inbal - Deluge Valve Pressure Control 03-13 CR01Document4 pagesInbal - Deluge Valve Pressure Control 03-13 CR01pvalverdea2014No ratings yet

- ValvesDocument44 pagesValvesأحمد محمد قدريNo ratings yet

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCONo ratings yet

- 04BR05Document6 pages04BR05martiguada1No ratings yet

- 10 ValvesDocument23 pages10 ValvesPower PlantNo ratings yet

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2No ratings yet

- Bermad: Pressure Reducing and Sustaining ValveDocument4 pagesBermad: Pressure Reducing and Sustaining ValvePerlita M. A SebastianNo ratings yet

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1No ratings yet

- PLL 2144Document80 pagesPLL 2144Amit TandelNo ratings yet

- Dow Control Valves DataDocument16 pagesDow Control Valves DatasaravanaNo ratings yet

- Dow Control Valves DataDocument16 pagesDow Control Valves DatasaravanaNo ratings yet

- Dow Control Valves DataDocument16 pagesDow Control Valves Dataerlangga cahyauutamaNo ratings yet

- DAN-EX Brochure WebDocument12 pagesDAN-EX Brochure Webzakkyf6455No ratings yet

- PRS 09i EX PDFDocument5 pagesPRS 09i EX PDFengp3077No ratings yet

- Reliable Deluge Valve Model DDXDocument8 pagesReliable Deluge Valve Model DDXmanbkk100% (1)

- Digital Control ValveDocument8 pagesDigital Control Valvecnrk777100% (1)

- Hydraulic Concentrate Control ValveDocument2 pagesHydraulic Concentrate Control ValveNandani MangaleeNo ratings yet

- Automatic Recirculation Valve BrochureDocument12 pagesAutomatic Recirculation Valve BrochureYuvaraj NithyanandamNo ratings yet

- 4 Water FloodDocument6 pages4 Water FloodEduardoWire100% (1)

- Tyco Alarm ValveDocument22 pagesTyco Alarm ValveMohammed BaquarNo ratings yet

- Cla-Val, Relief VanaDocument2 pagesCla-Val, Relief Vanadeyson galeanoNo ratings yet

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- 14 400E 6DC Final Valvula BermadDocument4 pages14 400E 6DC Final Valvula Bermadmax_powerNo ratings yet

- Yarway Valve DesignDocument12 pagesYarway Valve DesignwaqashabibNo ratings yet

- 08-Conv Valves Product InfoDocument18 pages08-Conv Valves Product Infoakrk777No ratings yet

- 50B4KGDocument2 pages50B4KGonin007No ratings yet

- On - Off ValveDocument5 pagesOn - Off Valvekresimir.mikoc9765No ratings yet

- SRC Alpha Version1 PDFDocument26 pagesSRC Alpha Version1 PDFRajat JainNo ratings yet

- Mankenberg Float ValvesDocument28 pagesMankenberg Float ValvescartarNo ratings yet

- Pressure Seal Valves-GateDocument24 pagesPressure Seal Valves-GateHieu NguyenNo ratings yet

- HD 102 Alarm Valve Model ADocument9 pagesHD 102 Alarm Valve Model AjabbanNo ratings yet

- Safety Shutdown Valve SSV Control System BrochureDocument12 pagesSafety Shutdown Valve SSV Control System BrochureWellington Barbalho100% (1)

- Fire HydrantDocument6 pagesFire HydrantdileepsiddiNo ratings yet

- Spring Loaded ValvesDocument10 pagesSpring Loaded ValvesKarl NakouziNo ratings yet

- Autoclave Engineers - Valves Fittings and Tubing - Condensed CatalogDocument16 pagesAutoclave Engineers - Valves Fittings and Tubing - Condensed Catalogchristophedepaepe100% (1)

- WW 770-UDocument4 pagesWW 770-UAhmad NasserNo ratings yet

- 19 102be PDFDocument6 pages19 102be PDFSani PoulouNo ratings yet

- Large Size Quarter Turn Control Valves Can Improve Safety in PipelinesDocument19 pagesLarge Size Quarter Turn Control Valves Can Improve Safety in PipelinesgpuzoneNo ratings yet

- Pressure Releif ValveDocument24 pagesPressure Releif Valvemtalha_loveNo ratings yet

- Direct Acting Excess Pressure ValvesDocument8 pagesDirect Acting Excess Pressure ValvescartarNo ratings yet

- Hoja de Datos - 116-4FCDocument2 pagesHoja de Datos - 116-4FCHenry Garavito RamirezNo ratings yet

- Pressure Independent Control ValveDocument16 pagesPressure Independent Control ValverakamechNo ratings yet

- Balem 531-S (Cooling Tower) PDFDocument2 pagesBalem 531-S (Cooling Tower) PDFanon_210074734No ratings yet

- Control Valve PresentDocument120 pagesControl Valve PresentShoeb Ali KhanNo ratings yet

- Cat Acvbr9000Document16 pagesCat Acvbr9000gazwang478No ratings yet

- Electrohydraulic: Solenoid ValvesDocument16 pagesElectrohydraulic: Solenoid ValvesluisbottonNo ratings yet

- F 9197 FoamconcvalvehydrDocument2 pagesF 9197 FoamconcvalvehydrCkaal74No ratings yet

- Pressure Vacuum BleedersDocument4 pagesPressure Vacuum BleedersGustavo AlcaNo ratings yet

- Bermad IrrigationDocument48 pagesBermad Irrigationemongclooney11No ratings yet

- Sostenedora Presion BERMADDocument6 pagesSostenedora Presion BERMADguzman_10No ratings yet

- CROWN Esd Brochure Usa 3 2Document4 pagesCROWN Esd Brochure Usa 3 2Ahmed Ayman Yassin100% (1)

- Introduction To ValvesDocument11 pagesIntroduction To ValvesElton SitumeangNo ratings yet

- Turbine Bypass ValveDocument12 pagesTurbine Bypass ValveRam MohanNo ratings yet

- Valvula YarwayDocument12 pagesValvula YarwayRobert VillavicencioNo ratings yet

- Pressure Reducing Valve PDFDocument3 pagesPressure Reducing Valve PDFneversigNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- An Assessment of The Usefulness of Water Tunnels For Aerodynamic InvestigationsDocument49 pagesAn Assessment of The Usefulness of Water Tunnels For Aerodynamic InvestigationsEddy WibowoNo ratings yet

- Pumping Stations Design Lecture 2 PDFDocument25 pagesPumping Stations Design Lecture 2 PDFabuzaidcoNo ratings yet

- J3BGDF02BR030 07 02Document1 pageJ3BGDF02BR030 07 02Nauman TahirNo ratings yet

- Pump Selection According "Warman Slurry Pumping Handbook"Document12 pagesPump Selection According "Warman Slurry Pumping Handbook"yoel cueva arquinigoNo ratings yet

- Opening Area Calculation: PT Menara Alfa SemestaDocument1 pageOpening Area Calculation: PT Menara Alfa SemestaCak NhassNo ratings yet

- Diagrama Hidraulico Motoniveladora 140k Serie Szl00001upDocument33 pagesDiagrama Hidraulico Motoniveladora 140k Serie Szl00001upRoke LlamocaNo ratings yet

- 6-44-0002-Rev 2Document53 pages6-44-0002-Rev 2Vineet Singh100% (2)

- Louvered Grille Performance DataDocument7 pagesLouvered Grille Performance DataCarlos Valle TurciosNo ratings yet

- Hydraulic Twin Peaks Model Tests: Pumping Plant: U.S. Department of The InteriorDocument25 pagesHydraulic Twin Peaks Model Tests: Pumping Plant: U.S. Department of The InteriorJerry PellerNo ratings yet

- CH7 1Document25 pagesCH7 1Nikola TrnavacNo ratings yet

- Fluid Mechanics Lab: Department of Chemical Engineering University of Engineering & Technology, LahoreDocument13 pagesFluid Mechanics Lab: Department of Chemical Engineering University of Engineering & Technology, LahoreLim Andrew0% (1)

- CFD18 Homework 2Document1 pageCFD18 Homework 2Nitin TyagiNo ratings yet

- TurbimachinesDocument2 pagesTurbimachinesArun BeniwalNo ratings yet

- Main Features: 2 & 3-Way - Double Union - Ball Valve DN15 (1/2") To DN50 (2") - PPGF, PVDFDocument20 pagesMain Features: 2 & 3-Way - Double Union - Ball Valve DN15 (1/2") To DN50 (2") - PPGF, PVDFsteve cookNo ratings yet

- SS Stub End Thickness CalculationDocument1 pageSS Stub End Thickness CalculationSrinivas KadivetiNo ratings yet

- Wind Tunnel Blockage CorrectionsDocument136 pagesWind Tunnel Blockage CorrectionsYoun Seok ChoiNo ratings yet

- Sheet - 01 - FluidDocument66 pagesSheet - 01 - FluidMayank kr. jhaNo ratings yet

- Behavior of A Pneumatic Pressure Regulator Valve Under Leakage CircumstancesDocument7 pagesBehavior of A Pneumatic Pressure Regulator Valve Under Leakage CircumstancesbadaboyNo ratings yet

- Fluid Mechanics & Machines IES2009 GATE2009Document451 pagesFluid Mechanics & Machines IES2009 GATE2009paragmishra1986No ratings yet

- Tip Loss Corrections For Wind Turbine Computations - Shen PDFDocument19 pagesTip Loss Corrections For Wind Turbine Computations - Shen PDFJose Da SilvaNo ratings yet

- Load Cases For Stress Analysis of A Critical Piping System Using Caesar II PDFDocument6 pagesLoad Cases For Stress Analysis of A Critical Piping System Using Caesar II PDFmaxalfre100% (1)

- Ecuación de Hazen-Williams (Caída de Presión)Document6 pagesEcuación de Hazen-Williams (Caída de Presión)Estuardo Javier Gan RodríguezNo ratings yet

- Cycling Drag ForceDocument22 pagesCycling Drag Forcebertan dağıstanlıNo ratings yet

- JEE MODULE 3 PHY Waves and Mechanical Properties of Solids and FluidsDocument168 pagesJEE MODULE 3 PHY Waves and Mechanical Properties of Solids and FluidsHrittik Das100% (1)

- Pump Basics PDFDocument43 pagesPump Basics PDFtsrinivasan5083No ratings yet