Professional Documents

Culture Documents

Skid Lifting Lug Design

Uploaded by

mahhor82_6356438380 ratings0% found this document useful (0 votes)

1K views3 pageslug design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentlug design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views3 pagesSkid Lifting Lug Design

Uploaded by

mahhor82_635643838lug design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

1- Loading:

W = 1,700 kg Weight of component to be lifted

FS = 2 Impact factorof Safety

SWL = 35 ton shackle safe working Load

N = 1 No.s No. of Lugs

a = 90 deg. in Plane Force Angle

b = 0 deg. Out of Plane Force Angle

W

factored

= W X FS = 1700 X 2 = 3,400 kg

= 33.34 kN factored Load

T

s

= W / N = 1700 / 1 = 1,700

kg Max Tension on Padeye

= 16.671 kN

P = T

s

X FS = 16.671 X 2 = 33.34 kN < SWL OK

F

z

= P Sin (a) = 33.343

kN Vertical Force on Padeye

F

y

= P Sin (b) = 0.000

kN Out of Plan Force on Padeye

F

x

= P Cos (a) = 0.000

kN Horizontal Force on Padeye

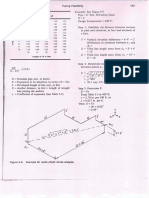

2- Dimensioning:

a- Skid Lug Sizing: Profle: W10X49

k = 70 mm Distance from lug hole to edge of beam

r

L

= 70 mm Lug radius

t

L

= 35 mm Lug thickness, tL

t

cp

= 12 mm Collar plate thickness, tcp

d = 62 mm Diameter of hole, d

h

L

= 193 mm Distance from lug hole to base, hL

w

L

= 253 mm Lug base width, wL

D

cp

= 100 mm Collar ring diameter, Dcp

H = ( 253 )/2 - 70 = 56.50

a- Shakle Sizing:

B = 57 mm Pin Dia, Dp

A = 83 mm Shackle Clearance

C = 197 mm Shackle Depth Clearance

c- Clearance between shackle & Lug :

59 mm

A = 83 mm

tLt < A OK

r

L

= 70 mm

C = 197 mm

rL < C OK

OK so Lug is Acceptable

d- Lug Hole Diameter Check:

- Max of : B X 1.05 = 57 X 1.05 = 59.85 mm

or B+3 = 57 + 3.00 = 60.00 mm

Max = 60.00 mm

- Also d< (B+6) Shall be Satisfied

57 + 6.00 = 63.00 mm

60.00 < 62 < 63.00

So d is: Acceptable

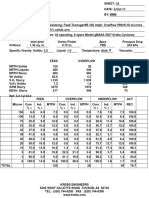

3- Lifting Lug Material & Properties:

ASTM A36

Fy = 248.21 MPa Yield Strength

f

by all

= 0.66 Fy = 163.82 MPa Allowable bending Stress in Plane

f

bz all

= 0.75 Fy = 186.16 MPa Allowable bending Stress out of Plane

f

t all

= 0.60 Fy = 148.93 MPa Allowable tensile Stress

f

br all

= 0.90 Fy = 223.39 MPa Allowable Bearing Stress

f

s all

= 0.40 Fy = 99.28 MPa Allowable Shear Stress

For Skid VESSEL

33.343 X Sin (90) =

33.343 X Sin (0) =

33.343 X Cos (90) =

tLT = tL+ 2 X tcp = 35 + 2 X12 =

Hence Dimensions are

Material Used :

H

4- Stress Check at Base of Lug:

a- Bending Stresses:

M

y

= in Plane Moment

= -6,425,120.95 N.mm

f

by

= in Plane Stress

= -17.21 MPa

f

by < f

by all

17.21 < 163.82 in Plane is: OK

M

z

= (F

y

X h

L

) Out of Plane Moment

= 0.00 N.mm

f

bz

= Out of Plane Stress

= 0.00 MPa

f

bz < f

bz all

0.00 < 186.16 out of Plane is: OK

b- Tensile Stresses:

f

t

=

= 0.00 MPa

f

t < f

t all

0.00 < 148.93 tensile is: OK

c- Combined Stresses:

U =

= 0.11 < 1.00

OK

d- Shear Stresses:

f

sz

= in Plane Stress

= 3.77 MPa

f

sz < f

s all

3.77 < 99.28 In Shear is: OK

f

sy

= Out of Plane Stress

= 0.00 MPa

f

sy < f

s all

0.00 < 99.28 Out Shear is: OK

e- Von-Mises Stresses:

f

z

= f

t

+ f

by

= 0 + 17.21 = 17.21 MPa

f

y

= f

t

+ f

bz

= 0 + 0 = 0.00 MPa

f

xy

= f

sz

2

+ f

sy

2

Average Shear Stresses

= = 3.77 MPa

f

comb

=

=

=

f

comb all

= 0.66 Fy = 163.82 MPa

f

comb < f

comb all

15.37 < 163.82 So: OK

( 0 X 192.7 ) =

(F

x

X H)-(F

z

X h

L

)

( 0 X 56.5 ) - ( 33342.61 X 192.7 ) =

6 M

y

/ (t

L

X w

L

2

)

6 X -6425120.95 / ( 35 X 253 ^2 ) =

f

z

2

+ f

y

2

- (f

z

+ f

y

+3f

xy

2

)

6 M

y

/ (w

L

X t

L

2

)

6 X 0 / ( 253 X 35 ^2 ) =

F

x

/ (t

L

X w

L

)

0/ ( 35 X 253 ) =

(17.21 / 163.82) + (0 / 186.16) + (0 / 148.93)

So Combined Stressess are:

F

z

/ (t

L

X w

L

)

33342.61/ ( 35 X 253 ) =

F

y

/ (t

L

X w

L

)

0/ ( 35 X 253 ) =

3.77^2 + 0^2

17.21^2 + 0^2 - ( 17.21 + 0 + 3X[3.77]^2 )

15.37 MPa

5- Stress Check at Pin Hole:

a- Tensile Stresses:

P = 33,342.61 N

A

t

=

= [ 2 X ( 35 X (70 - 62/2) ) ] + 2 X [ 2 X ( 12 X ( (100/2) - 62/2 ) ) ]

= 3642.00 mm

2

f

t

= P/A

t

= 9.16 MPa

f

t < f

t all

9.16 < 148.93 Padeye T is: OK

b- Bearing Stresses:

A

br

=

= 57 X (35 + 2 X 12 ) t

cp

= 3363.00 mm

2

f

br

= P/A

br

= 9.91 MPa t

L

f

br < f

br all

9.91 < 223.39 Padeye Br is: OK

t

cp

B , Shackle Bolt Dia

c- Shear Stresses:

A

s

= A

t

& f

s

= f

t

f

s < f

s all

9.16 < 99.28 Padeye S is: OK

33342.61 / 3363 = Lug Thickness

Collar Plate Thickness

[ 2 X ( t

L

X (r

L

- d/2) ) ] + 2 X [ 2 X (t

cp

X ( (D

cp

/ 2) - d/2) ) ]

33342.61 / 3642 =

B X (t

L

+ 2t

cp

)

Collar Plate Thickness

A

t

A

t

You might also like

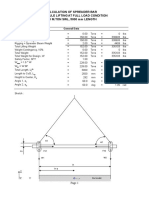

- Spreader Bar CalculationDocument2 pagesSpreader Bar Calculationmahhor82_63564383870% (10)

- Spreader Bar CalculationDocument2 pagesSpreader Bar Calculationmahhor82_63564383870% (10)

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationEm Mar100% (2)

- Lifting Lug DesignDocument6 pagesLifting Lug DesignmaniaxpdfNo ratings yet

- Wing Wall DesignDocument19 pagesWing Wall DesignMAGED MOHMMED AHMED QASEMNo ratings yet

- Lifting LugDocument8 pagesLifting LugAzwan ShahNo ratings yet

- Retaining Wall Design - 1Document23 pagesRetaining Wall Design - 1abhijithaval100% (3)

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- Lifting Lug Calculation ParametersDocument3 pagesLifting Lug Calculation Parametersdhirendarji83% (6)

- Design of Padeye CalcDocument3 pagesDesign of Padeye CalcBolarinwa89% (9)

- HTCC Room padeye calculations sheetDocument28 pagesHTCC Room padeye calculations sheetghoshamit4100% (5)

- Skid LiftDocument2 pagesSkid LiftAmi PutraNo ratings yet

- Calculation of Lifting ForcesDocument9 pagesCalculation of Lifting ForcesprantikduarahNo ratings yet

- Skid CalcDocument8 pagesSkid CalcRyan Fadhli50% (2)

- Design Structural Steel Design and Construction PDFDocument59 pagesDesign Structural Steel Design and Construction PDFdkaviti100% (2)

- Twenty Five Ton Padeye - SpreadsheetDocument4 pagesTwenty Five Ton Padeye - Spreadsheetoluomo1No ratings yet

- Lug Design (XLS)Document4 pagesLug Design (XLS)Bhartendu Patni100% (1)

- LIFTING LUG Weld Check KGDocument4 pagesLIFTING LUG Weld Check KGjoerijiNo ratings yet

- R C C +Retaning+WallDocument24 pagesR C C +Retaning+Walladeewijaya32100% (1)

- Design of FootingDocument31 pagesDesign of FootingAbhinav100% (1)

- Calculation LugDocument20 pagesCalculation LugKartika ZuhraNo ratings yet

- Abus CranesDocument12 pagesAbus Cranesmahhor82_635643838No ratings yet

- Mathcad - 13-Column DesignDocument34 pagesMathcad - 13-Column DesignShivakumar Patil50% (2)

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument26 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraNo ratings yet

- Lift Analysis: R L T LDocument27 pagesLift Analysis: R L T Lgarateta100% (5)

- Stair DesignDocument6 pagesStair DesignBathrudeen IshakNo ratings yet

- Pveng: Pressure Vessel Engineering LTDDocument5 pagesPveng: Pressure Vessel Engineering LTDBruno TrujilloNo ratings yet

- Lifting LugDocument7 pagesLifting LugSajal KulshresthaNo ratings yet

- Lift Lug SpreadsheetDocument2 pagesLift Lug Spreadsheetpgarrett775814233100% (1)

- Saddle AnalysisDocument17 pagesSaddle AnalysisPEJU0007No ratings yet

- Interaction DiagramDocument15 pagesInteraction DiagramjungzkiNo ratings yet

- PT TECHNICs SPREADER BEAM CALCULATION TITLEDocument5 pagesPT TECHNICs SPREADER BEAM CALCULATION TITLEmramico100% (1)

- Cantilever 1111Document36 pagesCantilever 1111Gaurav GhaiNo ratings yet

- Structural Bolting GuideDocument14 pagesStructural Bolting GuideLintang Jarai0% (1)

- Structural Bolting GuideDocument14 pagesStructural Bolting GuideLintang Jarai0% (1)

- Design of Pad Eye Using Check PlatesDocument3 pagesDesign of Pad Eye Using Check Plateshyoung65No ratings yet

- Anchor Chair Design CheckDocument5 pagesAnchor Chair Design CheckHomer SilvaNo ratings yet

- Lifting Lug - Skid - 2018.07.16Document4 pagesLifting Lug - Skid - 2018.07.16RaghNo ratings yet

- Spreader Bar3 - L.9 M-CertificationDocument10 pagesSpreader Bar3 - L.9 M-CertificationsiagiandobahNo ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program Descriptionnamasral100% (3)

- Pipe Line Flexibility Manual CalculationDocument20 pagesPipe Line Flexibility Manual CalculationKagira Drawing Soltuion100% (3)

- Calculation of lift lug on spreader barDocument8 pagesCalculation of lift lug on spreader barrustamriyadiNo ratings yet

- Bottom Trunnion (-) 45m - With Shear Plate Extension (0 Deg)Document10 pagesBottom Trunnion (-) 45m - With Shear Plate Extension (0 Deg)nallay1705No ratings yet

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- Wind Analysis of Cable-Stayed BridgesDocument14 pagesWind Analysis of Cable-Stayed BridgesrohanborgesNo ratings yet

- Manhole Davit ArmDocument1 pageManhole Davit ArmgaratetaNo ratings yet

- Cover Plate CalculationDocument1 pageCover Plate CalculationSachin5586No ratings yet

- WRC-107 Lifting Trunnions - Horz. LiftDocument5 pagesWRC-107 Lifting Trunnions - Horz. LiftManoj MulikNo ratings yet

- (B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationDocument7 pages(B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationArt G. Enzi100% (1)

- ASME Vessel AnalysisDocument17 pagesASME Vessel AnalysiscutefrenzyNo ratings yet

- Lifting Trunnion AnalysisDocument1 pageLifting Trunnion Analysisprajwal86No ratings yet

- Chevron Bracing Details - SteelwiseDocument4 pagesChevron Bracing Details - SteelwiseEugene Afable100% (1)

- Fluid Mechanics Cengel (Solutions Manual) Chap11-001Document21 pagesFluid Mechanics Cengel (Solutions Manual) Chap11-001NURUL SYUHADA BT ISMAIL HAJAR100% (3)

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Solution Manual For An Introduction To Mechanical Engineering 3rd Edition by WickertDocument38 pagesSolution Manual For An Introduction To Mechanical Engineering 3rd Edition by WickertScottWyattognje100% (42)

- 2 0 Insert Plate Calculations Type 14 PDFDocument4 pages2 0 Insert Plate Calculations Type 14 PDFKho C AhlNo ratings yet

- Skid DesignDocument138 pagesSkid Designbureqq100% (2)

- Steel Section Capacities BS 5950 SpreadsheetDocument362 pagesSteel Section Capacities BS 5950 Spreadsheetihpeter100% (1)

- 32 Samss 005Document34 pages32 Samss 005jagp_24No ratings yet

- Abus Jib CranesDocument26 pagesAbus Jib CranestintucinbNo ratings yet

- Base Plate CalculationDocument7 pagesBase Plate CalculationLcm TnlNo ratings yet

- Lifting LugsDocument2 pagesLifting LugsAdi Cahyoko82% (11)

- Lifting LugDocument5 pagesLifting LugFarid Tata100% (1)

- Pipe and Pipe Rack InteractionDocument6 pagesPipe and Pipe Rack InteractionapirakqNo ratings yet

- Geothermal Pipe Line DesignDocument15 pagesGeothermal Pipe Line DesignjohnjuantamadNo ratings yet

- ENDPLMC9.xlsDocument4 pagesENDPLMC9.xlsmahhor82_635643838No ratings yet

- ASME SpreaderBar DWGDocument1 pageASME SpreaderBar DWGInspetor SoldagemNo ratings yet

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocument1 page2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNo ratings yet

- Skid BeamDocument2 pagesSkid BeamYuni Ari WibowoNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- Solutions To Test 07Document29 pagesSolutions To Test 07Princess Gupo TañasNo ratings yet

- Column SpliceDocument6 pagesColumn SplicedudoodooNo ratings yet

- Example, Chap. 1&2Document46 pagesExample, Chap. 1&2Solomon AlemuNo ratings yet

- ProblemsDocument5 pagesProblemsJustine Roy PunzalanNo ratings yet

- Calculation of The Moment Resistance of Z - and C-Shaped Cold-Formed Sections According To Eurocode 3Document18 pagesCalculation of The Moment Resistance of Z - and C-Shaped Cold-Formed Sections According To Eurocode 3Liviu Ion100% (1)

- Priinciple StressDocument19 pagesPriinciple StressAshna WaseemNo ratings yet

- Mecanismos SolucionarioDocument16 pagesMecanismos SolucionarioSebastian L MillanNo ratings yet

- Recitation 5ADocument14 pagesRecitation 5AShaminda AmbaheraNo ratings yet

- Kgoc CV TC 202 Rev B 10 02 LastDocument1 pageKgoc CV TC 202 Rev B 10 02 Lastmahhor82_635643838No ratings yet

- Interaction Diagrams: N F Fa FaDocument7 pagesInteraction Diagrams: N F Fa FaSyeda Sana NaqiNo ratings yet

- Crane Beam Reactions (Rev. 1)Document3 pagesCrane Beam Reactions (Rev. 1)mahhor82_635643838No ratings yet

- Conn ModelDocument1 pageConn Modelmahhor82_635643838No ratings yet

- SPANCO FR WJ Instmaint Manual 103 0012Document16 pagesSPANCO FR WJ Instmaint Manual 103 0012mahhor82_635643838No ratings yet

- Autopipe New User Tips 9aDocument51 pagesAutopipe New User Tips 9aLuisRiosQNo ratings yet

- BB S W12X26Document4 pagesBB S W12X26mahhor82_635643838No ratings yet

- 110730Document20 pages110730Hebert CcahuanaNo ratings yet

- Pipes Tables & WeightsDocument1 pagePipes Tables & Weightsmahhor82_635643838No ratings yet

- Bolt TableDocument1 pageBolt TableErebert C. CaracasNo ratings yet

- GohKerShin AA070057d11tttDocument123 pagesGohKerShin AA070057d11tttChrisYapNo ratings yet

- Design of lifting lug for PPSV-205903-C-000 sheetDocument1 pageDesign of lifting lug for PPSV-205903-C-000 sheetmahhor82_635643838No ratings yet

- Heisco Bolts HDGDocument2 pagesHeisco Bolts HDGmahhor82_635643838No ratings yet

- Connection Types: Simple (Shear) ConnectionsDocument5 pagesConnection Types: Simple (Shear) Connectionsmahhor82_635643838No ratings yet

- Pipes Tables & WeightsDocument1 pagePipes Tables & Weightsmahhor82_635643838No ratings yet

- C StructDesign Bendapudi Feb10Document3 pagesC StructDesign Bendapudi Feb10samvendanNo ratings yet

- Chul Park Calculation of Real-Gas Effects On Airfoil Aerodynamic CharacteristicsDocument3 pagesChul Park Calculation of Real-Gas Effects On Airfoil Aerodynamic CharacteristicslazharNo ratings yet

- Erdenet Concentrate Desliming - Alternate gMAX4 Simulation PDFDocument1 pageErdenet Concentrate Desliming - Alternate gMAX4 Simulation PDFolziitulga batboldNo ratings yet

- Piezoelectric Transducer: Submitted To Submitted by Ketan Tarkas Priyesh SirDocument7 pagesPiezoelectric Transducer: Submitted To Submitted by Ketan Tarkas Priyesh SirKetan TarkasNo ratings yet

- 機工實驗II Unit3^04 結報Document8 pages機工實驗II Unit3^04 結報Alton S H ChenNo ratings yet

- Buried Pipes in OLGADocument5 pagesBuried Pipes in OLGAmotalebyNo ratings yet

- SFD & BMDDocument12 pagesSFD & BMDgramopadhy18No ratings yet

- BMSE D 22 02382 ReviewerDocument28 pagesBMSE D 22 02382 ReviewerHEMANTH KUMAR CNo ratings yet

- Elastic Hysteresis LoopsDocument6 pagesElastic Hysteresis LoopsDev SoniNo ratings yet

- Activity 1 - Scalar Vs Vector Quantity: Physical ScienceDocument5 pagesActivity 1 - Scalar Vs Vector Quantity: Physical ScienceJhulz Evan P. Redosendo100% (2)

- Geodesy Flashcards - QuizletDocument11 pagesGeodesy Flashcards - QuizletTJ CabatinganNo ratings yet

- 2023 Unit 1 Lesson 1Document21 pages2023 Unit 1 Lesson 1Mr. CNo ratings yet

- Factors Affecting Diffusion of Solids in LiquidsDocument4 pagesFactors Affecting Diffusion of Solids in LiquidssamyukthaNo ratings yet

- BDA30203 Lecture#2Document14 pagesBDA30203 Lecture#2Churreya Chai LomNo ratings yet

- Satellite Communication Question BankDocument2 pagesSatellite Communication Question BankjubairNo ratings yet

- FHSC1014 - 202210 - LAB ASSESSMENT - Practical 7Document4 pagesFHSC1014 - 202210 - LAB ASSESSMENT - Practical 7Chong Wai LeongNo ratings yet

- 1974 - Impedance Functions For A Rigid Foundation On A Layered MediumDocument14 pages1974 - Impedance Functions For A Rigid Foundation On A Layered MediumdisotiriNo ratings yet

- DESIGNDocument15 pagesDESIGNMadhav PurohitNo ratings yet

- 4 Magnetic Field Due To A Current-Carrying Wire, Biot-Savart Law APCDocument24 pages4 Magnetic Field Due To A Current-Carrying Wire, Biot-Savart Law APCSayyad DawarNo ratings yet

- Heat Conduction Equation: Yoav PelesDocument36 pagesHeat Conduction Equation: Yoav Pelesmrm3zaNo ratings yet

- What Is Moment of Resistance in Case of A StructureDocument33 pagesWhat Is Moment of Resistance in Case of A StructureHiren DesaiNo ratings yet

- Investigating The Parameters of Circular OrbitsDocument4 pagesInvestigating The Parameters of Circular OrbitsPepe HandsNo ratings yet

- Machine Time Jarry enDocument19 pagesMachine Time Jarry enmariaNo ratings yet

- Tipos y Propiedades Del PapelDocument59 pagesTipos y Propiedades Del PapelMiguel MontielNo ratings yet

- Expt. 9 Natural ConvectionDocument5 pagesExpt. 9 Natural ConvectionPradeep DiwakarNo ratings yet