Professional Documents

Culture Documents

Application of Value Streem Mapping - Dr. Farzad Tahriri-Libre

Uploaded by

PankajatSIBMOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Value Streem Mapping - Dr. Farzad Tahriri-Libre

Uploaded by

PankajatSIBMCopyright:

Available Formats

230 Int. J. Industrial and Systems Engineering, Vol. 8, No.

2, 2011

Copyright 2011 Inderscience Enterprises Ltd.

Application of value stream mapping using

simulation to decrease production lead time:

a Malaysian manufacturing case

Alireza Esfandyari*

Technical Faculty,

Institute of Manufacturing Automation and Production Systems

(FAPS),

University of Erlangen-Nuremberg,

Egerlandstr. 7-9, Erlangen 91058, Germany

Fax: +49 9131 302528

E-mail: Esfandyari@faps.uni-erlangen.de

*Corresponding author

Mohd Rasid Osman and Napsiah Ismail

Faculty of Engineering,

Department of Mechanical and Manufacturing Engineering,

Universiti Putra Malaysia,

Selangor 43400 UPM, Malaysia

Fax: +60 3 8656 7122

E-mail: rasid@eng.upm.edu.my

E-mail: napsiah@eng.upm.edu.my

Farzad Tahriri

Faculty of Engineering,

Center for Product Design and Manufacturing (CPDM),

University of Malaya (UM),

Kuala Lumpur 50603, Malaysia

E-mail: Farzad_tahriri@Hotmail.com

Abstract: Lean concept has been applied across many companies which offer

value and eliminate wastes. Value stream map (VSM) as one of the

fundamental tools in lean concept outlines the material and information flows

for a product family to reduce wastes at discrete event production routine. In

this paper, the improvement of the production lead time using VSM as a

technique in a Malaysian supplier, with a job shop production system, is

investigated. The main contribution of this paper is reducing production lead

time when the Takt Time is much higher than the highest stations cycle time,

and reducing unplanned released orders. This paper evaluates the present

routing events using current state map and the future state is created answering

the eight standard questions. Then, a detailed simulation model was developed

to verify the result from future state map and answering the questions that are

unable to be addressed by VSM.

Application of value stream mapping 231

Keywords: VSM; value stream mapping; lean manufacturing system;

simulation.

Reference to this paper should be made as follows: Esfandyari, A.,

Osman, M.R., Ismail, N. and Tahriri, F. (2011) Application of value stream

mapping using simulation to decrease production lead time: a Malaysian

manufacturing case, Int. J. Industrial and Systems Engineering, Vol. 8, No. 2,

pp.230250.

Biographical notes: Alireza Esfandyari is a PhD Candidate in Production

Systems at the Institute of Manufacturing Automation and Production Systems

(FAPS), Erlangen-Nuremberg, Germany. He received his MSc in Industrial and

Systems Engineering from Universiti Putra Malaysia (UPM), Malaysia in 2008.

His professional and research experience spans over the areas of lean

manufacturing system, production logistics, value stream mapping (VSM) and

supply chain management (SCM).

Mohd Rasid Osman is a Lecturer in the Department of Mechanical and

Manufacturing Engineering at the Universiti Putra Malaysia. He has

professional qualifications from the Board of Engineers Malaysia. He received

his BSc in Mechanical Engineering from the University of Sussex in 1984, and

MSc in Engineering Production from Birmingham University. His research

interest is in the area of manufacturing system and manufacturing management.

Currently, he is seconded to the Malaysian Road Safety Research Institute as a

Research Officer. Currently, he is doing research on safety in road

transportation and quality improvement of driving schools.

Napsiah Ismail is an Associate Professor of Mechanical and Manufacturing

Engineering at the Universiti Putra Malaysia, Malaysia. She received her PhD

in Advanced Manufacturing Technology from the Universiti Teknologi

Malaysia, Malaysia in 2000, and MSc in Mechanical Engineering from the

University of Leeds, UK in 1988. She was appointed as a Head of the

Department, Department of Mechanical and Manufacturing Engineering from

2003 to 2008. Her research areas are intelligent manufacturing system,

automation and robotics, integration of cad and cam and feature-based

modelling.

Farzad Tahriri is a PhD Candidate in Industrial and System Engineering at the

University of Malaya (UM). He received his MSc in Industrial and System

Engineering in 2008 at the Universiti Putra Malaysia (UPM). His research

interests include robot optimisation and simulation, virtual reality, decision

making and optimisation model.

1 Introduction

In an increasingly competitive world, manufacturing firms are looking for a competitive

edge over their competition and for many manufacturing companies that edge its lean

manufacturing. Implementing the lean manufacturing concept is a difficult process that

requires effort and high understanding of its own philosophy. The basic ideas behind the

lean manufacturing system, which have been practiced for many years in Japan, is often

associated with benefits such as reduced inventory, reduced cycle time, increased quality,

increased flexibility and increased customer satisfaction (Alavi, 2003; Lee-Mortimer,

232 A. Esfandyari et al.

2006; Muthiah and Huang, 2006; Ross and Francis, 2003; Womack and Jones, 2003)

with a consecutive conclusion to eliminate waste. Given the dramatic productivity

increases and what the companies were able to do because of them, it is not hard to

understand why so many companies even in the non-production environment transit

to lean operation.

Lean concept has been investigated in operation sectors for leanness, and business-

oriented sectors for agility (Gore et al., 2009) in managerial- and worker-level stages.

General electric saw an improvement to 100% of on time deliveries (Murman, 2002). In

aerospace, Lockheed Martin obtained large savings on the F-16 project, including a 50%

reduction in floor space and a 6080% improvement in cycle time (Lewis et al., 2000).

All reported results are the consequent application of lean tools and techniques that entail

elimination of wastes and non-value-added activities in a production flow.

One of the most conventional lean tools that provide an insight on value-added

activities including information and material flow is value stream mapping (VSM).

Tremendous efforts have been made so far to examine the advantages of VSM in

healthcare centre (Snyder et al., 2005), equipment breakdown maintenance activities

(BMA) (Sawhney et al., 2009), complex scheduling of bill of materials (Braglia et al.,

2006), production system redesign (Serrano et al., 2008), elimination of excessive

inventory in supply chain (Seth et al., 2008), lead time and cycle time reduction (Seth and

Guptaj, 2005). Investigating the total time/lead time of manufacturing components in

the shop floor is one of the substantial ideas in VSM, beginning with arrival of raw

material to shipment of finished/semi-finished goods to customer. In this paper, VSM is

about elimination of wastes in information and material flow to reduce the production

lead time.

2 Literature review

Lean manufacturing associated with tools and techniques such as cellular manufacturing

(CM), one-piece flow, visual control, kaizen, kanban, production smoothing (Heijunka),

workplace organisation (5S), autonomation, poka-yoke, standardised work, total

productive maintenance (TPM) and VSM to reduce manufacturing waste. VSM is a big

picture that considers all lean tools in a lean transformation, and improves the whole flow

and not just optimising the pieces. These creations make steps to common language for

production process, thus facilitating more thoughtful decisions to improve the value

stream (McDonald et al., 2002). Beside VSM tool, there are other useful redesigning

tools such as process mapping (PM) tool, ICAM definition zero (IDEF0) method and

graphs with results and actions interrelated (GRAI) method (Lasa et al., 2008). However,

VSM was selected as an analysis tool because of its comprehensive inclusion of the entire

informational and material value stream.

Drastic results have been reported that VSM was used to reduce production lead time.

Brunt (2000) presented the reduction in production lead time from 47 and 65 days to 11.5

days, and the reduction of cycle time from 7,262 to 6,902 sec. In the book Learning to

See: Value Stream Mapping to Add Value and Eliminate Muda (Rother and Shook,

1999), two accomplishments in the steel fabrication industry were described. In the first

case at the State Straight Company, the lead time of producing for the steel clamp of

steering arm is decreased from 23.6 to 5 days. In the second case for TWI industries, a

steering arm producer, the lead time improved from 48 days to less than 11 days. Seth

Application of value stream mapping 233

and Guptaj (2005) reported reduction of 3.215 to 0.54 days for production lead time in a

motorcycle manufacturer. In a plastic components manufacturer for automotive, 4 days

reduction is reported from 26 days for production lead time (Lasa et al., 2008). In a diesel

traction-manufacturing firm in India, production lead time was reduced from 53.31 to

4.11 days (Singh and Sharma, 2009). Given the benefits from VSM, there are shortages

and uncertainties associated with this tool make it ambiguous. There is an agreement

between all researchers that the inherent static particular of this tool makes the result

doubtful, but it is still useful for Lean transition. In general, a complementary tool is

needed due to the deficiencies of VSM.

Supporting VSM with statistics and fuzzy algebra (Braglia et al., 2009), detailed

mapping and simulation (Lian and Van Landeghem, 2007), are of enhancement

approaches that were examined. Simulation is an obvious tool, which is capable of

generating resource requirements and performance statistics yet remaining flexible to

specific organisational details. It can be used to handle uncertainty and create dynamic

views of inventory levels, lead-times and machine utilisation for different future state

maps (Abdulmalek and Rajgopal, 2007). Furthermore, following benefits are realised for

using simulation models:

1 For Greenfield:

a simulation as an initiation tool for the lean success (Harrell et al., 2004)

b simulation as a quantitative tool to assess risk of lean performance.

2 For Brownfield:

a simulation as a cost saving and training tool (Lian and Van Landeghem, 2007;

Van Landeghem and Debuf, 1997)

b simulation as an evaluative tool to assess the before and after scenarios in

details and illustrating the potential benefits to managers (Abdulmalek and

Rajgopal, 2007)

c simulation as a predicting tool to justify impact of transformation (Sullivan

et al., 2002)

d simulation as an evaluative tool to assess the impact of the key performance

metrics in a system and answering the questions that cannot be addressed using

the static nature of VSM (McDonald et al., 2002)

e simulation as a monitoring tool for continuous improvement performance.

In this paper, simulation tool was used as a quantitative tool in support of VSM tool to

verify the results from future state map, and answering the questions that are unable to be

addressed using static nature of VSM.

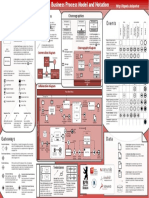

3 VSM

In their book Learning to See: Value Stream Mapping to Add Value and Eliminate Muda

(Rother and Shook, 1999) designed a roadmap to develop the VSM. The roadmap starts

with specifying a core product family. Then, the first design should be done using pencil

and paper to avoid limitations of graphical tools. The VSM is created using a set of

234 A. Esfandyari et al.

predefined icons (McDonald et al., 2002). A current state map for the specified value

stream was developed including a collection of informational and material data. Rother

and Shook (1999) identified eight questions that are answered to draw the future state

map in this paper. These questions are shown in Table 1.

This paper focuses on VSM tool to reduce production lead time for three

reasons. Firstly, associated techniques used to develop the future state of VSM inherently

consider the excess inventory for reduction. Since inventories are implied as the source

of other waste, it is important to level the inventory whereas other waste will be

reduced. Furthermore, inventory and production lead time are the two equivalent factors

which deduction of one factor affects another one to be reduced. Therefore, VSM has

appeared as the preferred way to identify all types of waste and reducing production lead

time for the studied case. Secondly, elements of production lead time are included to

order entry, material accumulation, machine setup, queue, processing, movements and all

activities in whole flow. VSM takes the whole flow viewpoint and addresses each process

and element to investigate for waste. Finally, in most previous research, VSM was

applied in less complex processes with serial steps. In this study, VSM address a job shop

serial production system with complexities such as high inconsistencies of stations

operation time and a flow line, that is, supported by outside suppliers. Furthermore,

available production time in current value flow is much more than production lead time

for a dedicated product family. Therefore, the urgent orders are accepted to be produced

for the rest of working time and these cause complexities to realise the actual production

lead time. In this paper, VSM is then used as an indexing tool to comprehend the

production lead time for a dedicated product family.

Table 1 Questions to create future state map

Future-state questions

1 What is the Takt Time?

2 Will production produce to a finished goods supermarket or directly to shipping?

3 Where can continuous flow be utilised?

4 Where should ABC use a pull system supermarket in the value stream?

5 Which single point in the production chain (the pacemaker process) should ABC

schedule?

6 How should ABC level the production mix at the pacemaker process?

7 What increment of work (the pitch) will be consistently released to the pacemaker

process?

8 What process improvement will be necessary?

Source: Rother and Shook (1999).

Application of value stream mapping 235

4 Profile of manufacturing firm

The application of production lead time reduction was investigated in a metal-based

fabrication industry with a job shop environment. This small- and medium-sized

company was incorporated in April 1996 and it is one of the suppliers for the Pernec

group of companies (the supplier of telecommunications equipment) in Malaysia. The

real company name referred to as ABC in this paper changed due to confidential issues.

ABC is equipped with various machines and equipments to ensure their production is

on target. This company produces several types of metal fabrications such as cash box,

cabin, back plate indoor and back plate outdoor for public phones. Presently,

Malaysian are using more cell phones, while public phone usage has decreased

significantly. This makes the market of back plate indoor product high competitive for

ABC. The bad order release processing has also made some complexities to distinguish a

precise calculation of production lead time of products. Faced with these challenges, the

ABC Company targeted to distinguish the production lead time for back plate products

and reduce it without incurring additional capital expenses.

However, the back plate product family needs to be identified. Back plate indoor and

back plate outdoor product pass through similar stations and differences are only related

to welded parts dimension and thickness of used steel sheets. So these two products are

identified as a product family. But, at the time of data collection for mapping the value

states, there was no purchasing order for back plates outdoor, so this paper concentrates

on the back plate indoor production flow.

5 Present work

In this section, mapping method using VSM is presented. The current state map is built

through observing the shop floor and analysing the collected data by the main author.

Departments were investigated to get detailed information of current state, while creating

the desired future state map were research and development (R&D), production,

purchasing and store departments.

5.1 VSM: current state map

To collect data for material and information flow, the production line was observed from

downstream to upstream. The goal of mapping the current state is to come up with real

events of informational and material flow of production. Figure 1 shows the VSM at the

ABC Company.

The back plate indoor is passing through three main departments of punching,

bending and welding to be produced. The back plates indoor are formed by assembling

11 parts, namely, the frame, back plate, bracket holder, nut, hinge support, bracket filler

hinge, bracket mounting, bracket filler lock, bracket lower lock and bracket cover lock.

The first four parts are manufactured using the Computer Numerical Control (CNC)

machine. Nuts and other parts which are assembled for brackets are purchased from

outside suppliers.

236 A. Esfandyari et al.

Figure 1 Current state map for back plate indoor at ABC Company (see online version

for colours)

Steel sheets are only ordered when demand is created, since there is no precise record of

raw material, warehouse shortage of steel sheets or semi-product occurs. After assessing

the steel sheets required for the ordered lot size, purchase orders are released to the

supplier company after benchmarking available companies about the minimum price.

Since available production time usually exceeds production lead time of ordered back

plates, urgent orders are accepted without considering ongoing production. This will

result in an unpredicted quantity of work-in-process (WIP) stocks in all workstations.

In the next department, back plates and frames are bended and pushed to the welding

station. In the welding department, parts are assembled. This department contains a set of

three electrodes welding and one gas welding equipment. Back plate indoor, frame and

back plates are welded by gas welding and the brackets are assembled using the electrode

welding.

The assembled back plates are then pushed for hard and soft grinding and final

checking. After preparation of ordered lot size, the back plates are carried by lorries to

the venture coating supplier and after two days, the coated back plates are sent back

to ABC for installing the silk screen plate on the top right of back plate indoor.

Each back plate indoor weighs 10 kg, in which over one pallet, 50 units can be

wrapped. The lorries at ABC are capable to carry one to three tons. On average four

pallets in a three-ton lorry are carried to Pernec or venture coating.

According to an order schedule from a customer during the past 104 days, 2,400 units

of back plate were delivered to Pernec. Hence, after deduction of holidays, 38 units of

product were produced per working day. The average daily output is significant for two

reasons. First, it can be used to determine quantity of WIP between the stations. So, all

quantity of WIP should be divided into 38 to calculate the worth of WIP between each

department. Second, Takt Time will be calculated according to average daily output.

Application of value stream mapping 237

Table 2 Units per day at each department

Workstation

Available time per

shift (sec)

Cycle time

measured by

ABC (sec)

Cycle time

measured by

author (sec)

Units per

shift (Pcs)

Punching 22,680 240 248 91

Bending 28,800 480 430 67

Welding 1 (back plate and

frame assembly)

28,800 360 360 80

Welding 2 (bracket

assembly)

28,800 180 180 160

Welding 4 (hinges

assembly)

28,800 30 20 1,440

Welding 3 (bracket and back

plate assembly)

28,800 240 210 137

Grind 1 28,800 60 90 320

Grind 2 28,800 60 60 480

The welding department works in one shift, and the punching and bending machines are

working in two shifts (the second shift always will be engaged for other urgent product

families). Although there are ten working hours per shift, after subtracting break times,

8 hr is the available production time. Table 2 shows the capability of each department to

process the parts at an available production time per shift.

According to Table 2, the units per shift column reveals a great inconsistency with

what is currently produced at ABC compared to the 38 unit back plates which must be

produced per shift based on customer demand. So, it is identified as the average quantity

of excess inventory which is produced in a push system.

The WIP amount is considerable to distinguish the waste amount for non-value-added

time. A current state map shows the 15 days worth of WIP throughout the departments

compare with 1,398 sec of value-added time. It means that the worth of value-added time

is 0.33% of total lead time. This measure indicates affect of a problematic condition of

waste in the value stream of ABC.

5.2 VSM: future state map

Developing the future state map begins with targeting the areas in the current state map

for improvement. There are several issues which should be considered at ABC due to

great inconsistencies with what should truly be applied as a systematic flow line:

1 Undedicated production time to back plate product family (due to the excess of

available production time compared with required production time for satisfying

the demand).

2 Large inventory and WIP.

238 A. Esfandyari et al.

3 Huge differences between production lead time (15 days) and value-added time

(0.048 day).

4 The significant quantity of WIP in welding department due to unplanned release

order of parts in batch amount.

Although the goal of this paper is to concentrate on reduction of production lead time,

consequently the lead time and inventory are two equivalent factors. It means that

controlling inventory explicitly decrease the production lead time.

Developing the future state at ABC involves addressing the following eight questions

as shown in Table 1. The major difference between the current and future state is the

production control strategy, as seen by comparing the current state (Figure 1) with

the future state map (Figure 5).

Question 1: What is the Takt Time?

Takt Time is calculated through dividing 8 hrs available production time by 38 units of

the average daily demand. The result shows that at every 12.63 min one unit of back plate

needs to be completed. Hence, customer demand is met in every 12.63 min for each

product.

Question 2: Will production produce to a finished goods supermarket or directly to

shipping?

A supermarket is nothing more than a buffer area (space allocated for product storage)

for products that are ready to be shipped, located at the end of the production process

(Rother and shook, 1999).

Currently, ABC produces the back plate indoors and sends them to the shipping area

where they are stored and are ready to be carried to the Venture Coating. Since the

production strategy is based on the push system, all the back plates are kept for a long

time in warehouse before shipping. Two issues are highlighted while determining the

batch sizes at each lot size for back plates. Firstly, the weight that a lorry is able to

carry is limited. A three-ton lorry can carry 300 units with an estimated weight of 10 kg

for each back plate. Therefore, the nominal quantity that can be shipped at each freight is

300 units, but there is limited capacity for Venture Coating supplier to coat the back

plates. Secondly, the order delivery statistics indicate that the supplier response is up to

200 units per each release. In addition, 50 units of back plates can be wrapped in one

pallet. Therefore, four pallets contain of 200 units and this batch is selected as a fix lot

size for shipping.

ABC should design an area between the stations (which will be called supermarket)

and store the parts based on a kanban system. Although using a supermarket before

shipping to Venture Coating prevents extra inventory, using a FIFO technique at this area

will be beneficial due to two reasons. Firstly, there is no other variety at projected

product family in this study, so there is no need to classify the products in supermarket.

In addition, using FIFO helps to maintain flow of production. FIFO works as a channel in

which the welding department locates at the beginning and the Venture Coating supplier

is allocated at the end. If ABC follows the FIFO rule and pitch time (it will be discussed

in Question 7), the excess inventory created in push system will be nominal.

Application of value stream mapping 239

As discussed, the best delivery lot size for shipping is 200 units, so the FIFO channel

is capable to contain 200 units of back plates. Whenever this channel becomes full

product, the orders will not be released any more using kanban to the welding department

(in Question 5, it is answered why the order should be released to the welding

department).

After the coating process at outsourced supplier, ABC receives back the back plates

to install the silk screen plates and doing the finishing process. Finishing process at ABC

entails reworking, time and re-transport waste processes which should be revised for

elimination. in Question 8, it is proposed how to do the revision action.

Question 3: Where can continuous flow be utilised?

The operator-balanced chart in Figure 2 shows the current cycle time at each station for

the product being studied. This chart shows the gap between the Takt Time and the

average balance workload for each workstation. The main reason for such a big

difference is the excess of available production time for a dedicated product family. The

urgent order released usually fills the left working time, and this cause inaccuracy to

distinguish the actual production lead time for studies product family.

Figure 2 shows that ABC Company is potentially capable to produce back plates in

double quantity as they are producing. The potential capability of producing more on

demand products serves two possibilities according to Takt Time calculation. Firstly, it

increases the number of products which could be manufactured, and this decrease the

processing time per unit of product. Secondly, it decreases the Takt Time for the stations

highest cycle time. Then, all stations cycle time should be levelled under the Takt Time.

The second strategy enables the ABC Company to have shorter production lead time

when some other urgent orders can be produced after finishing back plate production.

Takt Time is always determined based on customer orders. In the case that calculated

Takt Time is much bigger than the highest stations cycle time, a virtual Takt Time can

be determined. Also, for the Takt Time is shown in Figure 2, and a virtual Takt Time is

determined in Figure 3.

According to the shown cycle times in Figure 2, it is revealed that it is necessary to

redistribute and level the work piece-load for each workstation. The main problem with

balancing the cycle times is because of the bending station which has the highest cycle

time and should be reduced. At this station, three parts of the frame, back plate and nut

are bent with a number of bending angles of 8, 8 and 2. Although the cycle time for

bending one angle takes 1 sec, but the setting of parts under the fixtures in order to

accurate bending takes 20 sec. The auxiliary setting devices help to easily achieve 15 sec

setting times. In addition, each nut averagely takes 50 sec to be released. If two nuts are

bent per each action of bending instead of one, the average lead time for production of

three nuts at this department will be reduced to 45 sec. To obtain the proposed reduction,

there needs to be more expert workers and auxiliary setting equipment. Eventually, the

cycle time at this department will be deducted from 430 to 285 sec.

240 A. Esfandyari et al.

Figure 2 Current operator-balanced chart

Figure 3 Future operator-balanced chart

The welding department can be improved using the cellular manufacturing (CM)

technique. CM layout will smooth the way for one-piece flow of an incomplete back

plate to the four workstations at a welding department (Figure 3). The cycle times at this

department should be kept alike to prevent excess inventories. In this flow, workers push

one semi-product to the next worker. The advantage of this type of layout keeps operators

in transition. It means that the workers can keep and set the pace of flow visually based

on the determined Takt Time.

Dividing the total cycle time at welding station by Takt Time (680/285) is equal with

(2.38) three labours. This value shows the number of workers needed to fulfil the job at

Application of value stream mapping 241

welding departments in a continuous flow. One worker assembles the frame, back plate

and nut at welding 1, the second worker assembles the brackets at welding 3 and the

brackets and frames will be assembled at welding 2. At the next stage of completion,

back plate indoors are sent to the hard and soft grinding. Grouping this process with

welding cell helps the continuous flow in addition of reducing the transportation and

excess inventory. Then each soft and rough grinding can be done by one worker

continuously. Although redistribution of workloads should be done homogeneously

between each worker, there are still inconsistencies between the cycle times. This can be

improved using Kaizen or time buffer.

In the proposed operator-balanced chart (Figure 3), the virtual Takt Time was

determined based on the stations highest cycle time which is grinding. The 90 sec

checking time at welding 1 should be eliminated in future state map. This activity is pure

waste and can be eliminated easily through implementation of TPM technique. The

workers at welding 2 should process welding the hinges in one piece flow. In addition, if

rough and soft grinding were assigned to one worker, accumulative cycle time would be

still less than virtual Takt Time.

The next area to plan for improvement is before shipping to a Venture Coating

supplier. It was described in Question 2, and how a FIFO technique optimises this area

for excess inventory prevention.

Question 4: Where should ABC use a pull system supermarket in the value stream?

A pull system supermarket is a technique to transit from discrete to continuous flow.

Whenever the productions show disconnect in flow, supermarkets connect the disparate

stream. The supermarkets at the future state map for ABC are placed between the

processes stations where inventory is created and should be controlled based on next

station demand.

Three places are considered to use supermarket. The first supermarket should be

placed before the CNC punching machine, where the daily needed sheets are stocked

here. Since the steel sheets supplier is not yet connected to the ABC via the pull system,

the received steel sheets should be stocked at the main warehouse. Then, daily demanded

sheets are pulled out to the manufacturing area using kanban. Currently, the parts are

punched in big batches for frames or back plates individually but the daily demand for

these parts is 38 units, and each steel sheet is punched for five frames, therefore there are

eight sheets needed per day for the frame. Consequently, another eight steel sheets

are needed to be punched for back plates (16 steel sheets for 38 back plates). Bracket

holders will be produced on the same sheet while frame punching is being finished.

According to the load-levelling technique, after punching each sheet for frames, the next

sheet will be punched for back plates. In this way, the supermarket before bending

machine would be full of parts needed at the next station. The ABC production controller

will tag a withdrawal kanban to the batch of steel sheets, brackets and hinges provided by

suppliers. Whenever this batch feeds into the production line, the tagged kanban will be

removed and dispatched to the production control. Consequently, the production control

records inventory stock and prevent a miss of steel sheets. Currently, the steel sheets are

provided two times per month, which could be reduced to weekly schedule.

The second suitable area for the supermarket is the punching department that

produces four main parts. The parts ready at the supermarket are tagged as a production

kanban. Whenever the bending machine operator pulls the next quantity of parts, he/she

removes the parts and sends the production kanban to the punching machine operator.

242 A. Esfandyari et al.

Then, the CNC machine operator finds out that which parts are on demand at the next

station. Then the operator can change the programming of CNC machine accordingly for

frame or back plate production.

The third place to put the supermarket is before the welding department. The welding

workstation needs to be provided of four main parts: the back plate, frame, bracket and

hinges. Then for each part, one supermarket is allocated. Hinges and brackets are

provided by the outside suppliers. Designing two supermarkets before the welding

department for these parts is necessary to prevent uncertain forecasting, parts missing and

disturbance caused by uncontrolled quantity of excess inventory. The daily delivery of

these parts makes an efficient use of space in addition to regulate the systematic flow in

one day, and another two supermarkets will be placed for a bended frame and back

plates.

Question 5: Which single point in the production chain (the pacemaker process) should

ABC schedule?

To stop over production at any workstation in the value stream, only one point in the

supplier to the customer value stream needs to be informed about the final production

output. This point is called the pacemaker process, because this point sets the pace of

production for all the upstream processes and connects the flow of downstream and

upstream flow. Usually, the pacemaker process has the most downstream continuous

flow in the value stream, so there should be no supermarket downstream of the

pacemaker process (Rother and Shook, 1999). For ABC, the welding cell operates

continuously and all supermarkets are located before this station. Then the welding-

assembly cell is selected as the pacemaker, and the preceding workstations pull out the

production information.

Question 6: How should ABC level the production mix at the pacemaker process?

The objective of this question is to distribute the production workload uniformly over the

production time of the pacemaker process. This will allow workstations to handle

balanced jobs and prevent creation of excess inventory and a long-lead time.

Considering that the CNC machine punches each steel sheet into batches of five

frames, back plates or nuts, the style of bending for all these parts is the same, and there

would not be any changeover time for this machine. The consecutive production levelling

at the pacemaker process would be five frames, five nuts and five back plates. The

kanban cards are placed in the Heijunka box based on this sequence. The Heijunka box is

located near the welding cell. The cycle of the kanban system will be commenced by

taking the first kanban card at welding 1. The pace of production at the welding cell is

controlled by a one-piece flow technique and no more cards will be released into the

system when the FIFO channel becomes full.

Question 7: What increment of work (the pitch) will be consistently released to the

pacemaker process?

The pitch is the basic time block of the production schedule for a product family. The

pitch is calculated by multiplying the Takt Time or its coefficient by the finished goods

transfer quantity (e.g. number of containers) at the pacemaker process (Rother and

Shook, 1999). Pitch in this case calculated accordingly is:

Pitch : 285sec(Takt time) 5unit (pack out) 1,425sec(23.75min 24min)

Application of value stream mapping 243

The CNC punching machine will punch each steel sheet into five pieces of frame or back

plates; it has the least quantity to be determined for pack out batch. At every pitch (each

24 min), one production kanban will be dispatched to the welding department. In each

turn, the orders are released in a paced speed and the finished products are stocked at the

FIFO channel, where the pace of production is maintained constant.

The number of kanban card are depend on the daily demand and transfer lot size, and

is shown in Table 3. Timing the release of the kanban cards needs a Heijunka box (load-

levelling box). The Heijunka box (Figure 4) has a column of kanban slots for each pitch

interval and a row of kanban slots for each product type. The kanban cards are placed in

the Heijunka box. The material handler picks a kanban at every pitch and delivers it to

welding 1. Then the worker at welding 1 pulls out the needed raw materials from the

bending department.

Daily demand is divided by the quantity per each transfer (38/5 8). The pitch will

be released eight times to the pacemaker process per working shift. The time interval

required for every manufacturing order is followed by removing one kanban from

Heijunka box and, calculated by dividing the available time in a work shift by the number

of pitches for a back plate indoor (192/8). It means that at each 24 min, one increment of

work will be released to the pacemaker process using one kanban card.

The following steps describe how the paced withdrawal and load-levelling box

will work:

1 Operator at welding 1 checks the Heijunka box and takes K

1

(first kanban card

at 8:30).

2 This signals the welding 1 worker to pull out the required parts from the

supermarket.

3 Currently, each kanban card identifies the production of five back plates indoor.

The workers at welding 1 pulls out the components of the first five units from

the supermarket and removes the attached kanban card, then sends it to

the bending operator.

4 In a similar manner, welding 3 removes the attached kanban card from the bracket

parts and sends them to the kanban post.

5 The station upstream process commences to pull out needed materials from the

preceding supermarkets.

6 When parts are removed from supermarkets, workstations start to refill them.

7 Repeat of all above steps for available time (currently, 3 hrs for 38 units of on

demanded back plate indoor in one day).

Table 3 Number of required kanban card

Product Daily demand Transfer lot size

Number of kanban

cards required

Back plate indoor 38 5 8

244 A. Esfandyari et al.

Figure 4 The Heijunka box (load-levelling box) (see online version for colours)

Questions 8: What process improvement will be necessary?

To comprehensively accomplish the future state for material and information flow, the

following actions should be carried out:

1 Delegating the program switching of CNC machine to operator.

2 Elimination of checking time at welding 1 that is a pure reworking waste.

3 Checking the production pace at the bending department, and whether operators

follow the specified job cycle time.

4 It is proposed that instead of receiving back the back plates, after the coating process,

the silk screens will be installed by two contracted worker at the Venture Coating.

After receiving the finished product, the products will be sent to the customer

directly.

The future state design for ABC is shown in Figure 5. The figure illustrates all

information and material flow, and proposed kaizen. It is considerable that the described

future state is planned for production of 38 units for proposed virtual Takt Time in 3 hrs

per working day. The increment production of 38 units in 3 hrs afford two alternatives:

firstly, dedicating complete working time per day to the back plate indoor production and

rerunning the process for the next 3 hr. Secondly, the urgent orders can be satisfied

within the rest of available time. These two alternatives each can be accomplished

appropriately.

Production lead time in the future state map indicates production of 200 units of back

plate indoor in less than nine days. It means that the worth of WIP throughout the ABC

workstation before sending the products to an outside supplier is less than seven days;

also, the 1,363 sec value-added time shows the trade-off value that customer would like

to pay for.

The result from VSM encourages managers to accomplish the future state; however,

it is still insufficient to overcome the resistance of social-technical belief. Furthermore,

the deficiencies due to complexity of production variety (Rother and Shock, 1999), time-

consuming facts (Hines et al., 1998), difficulties in implementation of techniques and

machines (Sullivan et al., 2002) and lack of considering the dynamic behaviour of the

production process (McDonald et al., 2002; Sullivan et al., 2002), cause the inevitable use

of a complementary tool with VSM. Also, predicting the situation of production lead time

elements are usually impossible with only a future state map, because with a static model

one cannot study how these elements affect one another.

Application of value stream mapping 245

Figure 5 Future state map for back plate indoor at ABC Company (see online version

for colours)

Simulation is a scheduler to generate production schedules and to improve the operational

effectiveness in factory floor. In addition, simulation satisfies the inherent shortage of

the VSM tool. It means that simulation is a useful tool to help with what if and short-

term tactical questions that cannot be answered using the VSM tool. These questions can

be answered by making quick changes or assessing the impacts on a simulated system.

This issue explicitly highlights the necessity of associating these two tools as a tool-set.

The following two questions will be answered in Section 6 as short-term tactical

questions.

1 How much impact a dynamic nature of simulation would have on calculating the

production lead time compare with the static methodology?

2 One-piece flow technique is proposed for the welding cell to fix the pace of

flow in future state map. Is this technique useful in this area if it is accomplished

correctly?

6 The simulation model

The simulation model for the proposed future state map was developed using system

modelling corporations Arena 7 package. This simulation model requires approximately

50 hrs of development time. There are two different views of this model. The first is a

facility view which describes the work cells and related resources that make up the

factory. The second is a product view which describes the flow of work through the

facility. Data-related facility view is collected through an over on location of stations and

machines. Also for product view, the product should be described as being produced,

along with the process plan that defines its flow through the factory. The collected data

includes: the quantity of demanded parts by the nest stations, the earliest start date, the

246 A. Esfandyari et al.

due date for completion of a job, the order times for each part by the next stations,

the initial quantity for each part in supermarkets, the cycle time for each operation, the

buying lead time for suppliers, the quantity and the arrival date for parts from outside

suppliers, production and reorder lot sizes for outside suppliers, numbers of worker, and

available working hours.

During the facility view data collection, some features such as setup times and

machine breakdowns are recognised insignificant. Several simplifications made in the

representation of the production line are the purpose of this paper. These features were

not considered in the simulation model: reworking on rejected units, employee breaks

and fluctuations in product demand (quantity). The developed model includes the area

where steel sheets are being prepared behind the CNC punching machine to the stage

which back plate indoor is released from the grinding station. The Venture Coating is

then an outside supplier used up two days. The output lead time from the simulated

model can be added to two days in order to realise the total lead time.

Verification is the process that makes certain that the simulation model follows the

real system (Law and Kelton, 2000). Since this model is rather small with one type of

product in the system, verification will check whether the product follows its sequence or

not. To see if the model represents the real system, the SIMAN code was examined.

Figure 6 illustrates a view of the simulation model representing the production flow.

The Arena model is based on the SIMAN language. Its modelling consists of

two system frames: the model frame and the experiment frame (Kelton et al., 2004).

To simulate the ABC Company, the steps that each back plate indoor parts go through

during the simulation run were traced. Then, a careful trace procedure was carried out by

following an entity and then once it is created until it is dispatched from the system.

The Step feature provided by Arena was used to control the accomplishment of the

model.

Based on the scheduled mapping of the future state map, the planned schedule

indicates production of 38 units of back plate indoor per day. Production of this demand

needs an accumulative production time of 200 min per shift. Therefore, the available

working hours are 200 min for the time pattern introduced to the model. Moreover, the

manufacturing orders and quantities for material arrival modules are provided for

the production of 38 units. The simulation model was run for a complete working shift

starting from 8:30 a.m. and ending at 12:10 a.m. Warm-up periods are useful for systems

that are continuous and do not have a distinct period in which statistics are desired for

that time. The simulation model in this case is scheduled for one shift that is a distinct

period. The supermarkets between the workstations are always full of parts to be

produced and then at the start of the next day workers immediately can pull out the

needed parts from their previous stations. Therefore, a warm up period and transient time

is not required. About 100 replications are used to run the model. The reason for this is

the fact that half wide for the 95% confidence interval of produced back plate indoor

turns out to be 34. To produce the 34 units of product, the half wide would be 0.19. This

value indicates that the absolute error would be 0.55%, which is small enough in order to

verify 34 units of back plate indoor in a day shift.

Figure 7 shows how the units of final product increased across a three hours and

thirty minutes period. The steps in this plot verify the production of one unit of back plate

indoor and the yellow area shows the break time that starts from 10 a.m. and ends at

10:15 a.m.

Application of value stream mapping 247

The simulated model at ABC indicates the production in one working day. The

schedules and manufacturing orders are planned as one-day production and cannot be

extended for more than a one-day replication. To realise the production for more than one

day, 34 units of products should be multiplied to the number of required days. There are

two reasons in doing so. Firstly, the manufacturing order module cannot be accessed for

more than the current schedule because the software is used as a student edition.

Secondly, the production scheduling is accomplished for a one-day period. For the

following days, the scheduling process was repeated, and an extension of planning for

more than one day does not affect the final answer.

In the future state model, it was revealed that 34 units of product will be produced in

a day. It means that in order to ship 200 units of back plate indoor to the Venture Coating

supplier, it takes 5.8 days (6 days). It was also shown that coating the 200 units at this

outside supplier takes two working days. The total lead time for 200 units of back plate

indoor is eight days. The simulation shows the 47% reduction in production lead time and

inventory reduction could be obtained if lean tools and techniques are implemented.

Figure 6 Arena model screen shot (see online version for colours)

Figure 7 Increment of back plate indoor per shift (see online version for colours)

248 A. Esfandyari et al.

The results from the future state of VSM (less than nine days) and simulation (eight days)

indicate less than one day difference. This differentiation is not significant and the future

state simulation verifies the result from the future state map. After the simulation was

developed, the specific questions noted earlier that could not be answered

straightforwardly using VSM are discussed below:

1 How much would be the impact of dynamic nature of simulation for value-added

time compare with the static methodology?

The future state map indicates value-added time of 1,363 sec for 38 units of product. The

factory analysis for simulation shows the value-added time of 1,225 sec for production of

34 units. Using a balanced equation, it shows the value-added time of 1,369 units for

38 units in a dynamic methodology. Thereafter, it can be perceived that the value-added

time for a dynamic nature shows the 0.45% reduction compared with static nature.

2 One-piece flow technique is proposed for welding cell to fix the pace of flow in future

state map. Is this technique useful in this area if it is accomplished correctly?

In factory analysis data sheets for simulation, the average total accumulative time for

weldings 13 are 5.35, 3.98 and 4.6 hrs, respectively. These measurements show the total

operation time that each worker spent to process the parts for the complete working shift.

To prevent WIP and fixing the pace of one-piece flow, these measures should be

balanced. The flow can be improved using a time buffer technique for welding 2 and

reducing operation cycle time at welding 1.

7 Conclusion

The VSM provides structured continuous improvement and it can be used in discrete

production flow. ABC has different problems such as high inconsistency of operation

cycle time for stations and ambiguity of production lead time. VSM is, therefore, a

valuable tool for production lead time investigation. The result from VSM was verified

using simulation. Although there is a consensus for using VSM and simulation as a tool

set, the questions answered using simulation demonstrate the necessity of associating

these two tools. For the main contribution, 47% production lead time reduction deduced.

Furthermore, following benefits of utilising simulation as a complementary tool for VSM

is indisputable: the power of imitate visualising investigates the interaction of production

flow elements, cost and time saving, and it is an instant alter attempt for trial and error for

different scenarios. In addition, setting up the developed model for different scenarios

provide a valuable tool for managers in terms of training for employees and customer,

reliability issues for lean transition, and evidence the practicability of lean operation at

ABC are of managerial implication for associating simulation modelling with VSM.

Several areas can be extended for future research. First, the current work can be

extended for other product families at ABC and how implementation of Lean Concept for

several product families can be synchronised. Another area for future research is to

investigate elimination of wastes at a managerial-level stage. At a managerial-level stage,

behaviours may cause problems that appear as a waste at shop floor. Developing a root-

cause analysis associated with the VSM tool gives more clear understanding to plan the

future state. Strategic behaviours in managerial-level could be evaluated in different

scenarios through simulation.

Application of value stream mapping 249

Acknowledgements

The authors would like to thank Ir. Rasid Osman for his valuable advice in this research

work and the referees for their suggestions and useful comments that made it possible to

greatly improve the structure and the quality of this paper.

References

Abdulmalek, F.A. and Rajgopal, J. (2007) Analyzing the benefits of lean manufacturing and value

stream mapping via simulation: a process sector case study, Int. J. Economics, Vol. 107,

No. 1, pp.223236.

Alavi, S. (2003) Leaning the right way, Manufacturing Engineer, Vol. 82, No. 3, pp.3235.

Braglia, M., Carmignani, G. and Zammori, F. (2006) A new value stream mapping approach for

complex production systems, Int. J. Production Research, Vol. 44, Nos. 1819,

pp.39293952.

Braglia, M., Frosolini, M. and Zammori, F. (2009) Uncertainty in value stream mapping analysis,

Int. J. Logistics: Research and Applications, Vol. 12, No. 6, pp.435453.

Brunt, D. (2000) From current state to future state: mapping the steel to component supply chain,

Int. J. Logistics: Research and Applications, Vol. 3, No. 3, pp.259271.

Gore, A., Haapasalo, H. and Tahtinen, T. (2009) Agile manufacturing enablers for Finnish steel

products network, Int. J. Industrial and Systems Engineering, Vol. 4, No. 3, pp.255269.

Harrell, C.R., Ghosh, B.K. and Bowden, R.O. (2004) Simulation using Promodel (3rd ed.).

New York, NY: McGraw-Hill.

Hines, P., Rich, N. and Esain, A. (1998) Creating a lean supplier network: a distribution case,

European Journal of Purchasing and Supply Management, Vol. 4, pp.235246.

Kelton, W.D., Sadowski, R.P. and Sturrock, D.T. (2004) Simulation with Arena. New York:

McGraw-Hill Higher Education.

Lasa, I.S., Laburu, C.O. and Vila, R.C. (2008) An evaluation of the value stream mapping tool,

Business Process Management Journal, Vol. 14, No. 1, pp.3952.

Law, A.M. and Kelton, W.D. (2000) Simulation Modelling and Analysis. New York: McGraw-Hill

Higher Education.

Lee-Mortimer, A. (2006) A lean route to manufacturing survival, Assembly Automation, Vol. 26,

No. 4, pp.265272.

Lewis, P., Norris, G. and Warwick, G. (2000) Manufacturing technology: building to win, Flight

International, 2531 July.

Lian, Y-H. and Van Landeghem, H. (2007) Analysing the effects of lean manufacturing using a

value stream mapping-based simulation generator, Int. J. Production Research, Vol. 45,

No. 13, pp.30373058.

McDonald, T., Van Aken, E.M. and Rentes, A.F. (2002) Utilizing simulation to enhance value

stream mapping: a manufacturing case application, Int. J. Logistics: Research and

Applications, Vol. 5, No. 2, pp.213232.

Murman, E. (2002) Lean Enterprise Value. New York: Palgrave Publishers Ltd.

Muthiah, K.M.N. and Huang, S.H. (2006) A review of literature on manufacturing systems

productivity measurement and improvement, Int. J. Industrial and Systems Engineering,

Vol. 1, No. 4, pp.461484.

Ross, A. and Francis, D. (2003) Lean is not enough, IEE Manufacturing Engineer, Vol. 82, No. 4,

pp.1417.

Rother, M. and Shook, J. (1999) Learning to See: Value Stream Mapping to Add Value and

Eliminate Muda (1/2 ed.). Brookline, MA: The Lean Enterprise Institute, Inc.

250 A. Esfandyari et al.

Sawhney, R., Kannan, S. and Li, X. (2009) Developing a value stream map to evaluate breakdown

maintenance operations, Int. J. Industrial and Systems Engineering, Vol. 4, No. 3,

pp.229240.

Serrano, I., Ochoa, C. and De Castro, D. (2008) Evaluation of value stream mapping in

manufacturing system redesign, Int. J. Production Research, Vol. 46, No. 16, pp.44094430.

Seth, D. and Guptaj, V. (2005) Application of value stream mapping for lean operations and cycle

time reduction: an Indian case study, Production Planning and Control, Vol. 16, No. 1,

pp.4459.

Seth, D., Seth, N. and Goel, D. (2008) Application of value stream mapping (VSM) for

minimization of wastes in the processing side of supply chain of cottonseed oil industry in

Indian context, Journal of Manufacturing Technology Management, Vol. 19, No. 4,

pp.529550.

Singh, B. and Sharma, S.K. (2009) Value stream mapping as a versatile tool for lean

implementation: an Indian case study of a manufacturing firm, Measuring Business

Excellence Journal, Vol. 13, No. 3, pp.5868.

Snyder, K.D., Paulson, P. and McGrath, P. (2005) Improving processes in a small health-care

network. A value-mapping case study, Business Process Management Journal, Vol. 11,

No. 1, pp.8799.

Sullivan, W.G., McDonald, T.N. and Van Aken, E.M. (2002) Equipment replacement decisions

and lean manufacturing, Robotics and Computer Integrated Manufacturing, Vol. 18, No. 3,

pp.255265.

Van Landeghem, H. and Debuf, M. (1997) Supply chain characterization through Monte Carlo

simulation, Proceedings of the Production Economics Conference, Goteborg, p.7.

Womack, J.P. and Jones, D.T. (2003) Lean Thinking Banish Waste and Create Wealth in Your

Corporation. New York, NY, USA: Free Press.

You might also like

- Productivity and Quality Improvement Through Value Stream Mapping: A Case Study of Indian Automotive IndustryDocument19 pagesProductivity and Quality Improvement Through Value Stream Mapping: A Case Study of Indian Automotive IndustryAnand DharunNo ratings yet

- Kanban and Value Stream Mapping Analysis in Lean Manufacturing Philosophy Via Simulation A Plastic Fabrication (Case Study)Document24 pagesKanban and Value Stream Mapping Analysis in Lean Manufacturing Philosophy Via Simulation A Plastic Fabrication (Case Study)thapanon khuisangeamNo ratings yet

- TeapothakkindaDocument19 pagesTeapothakkindaNecdet Oğuz YANARNo ratings yet

- The Effectiveness of A Vehicle Manufacturing Line Using Probabilistic Process TimingDocument24 pagesThe Effectiveness of A Vehicle Manufacturing Line Using Probabilistic Process TimingIJRASETPublicationsNo ratings yet

- Modelling of An Additive 3D-Printing Process Based On Design of Experiments MethodologyDocument24 pagesModelling of An Additive 3D-Printing Process Based On Design of Experiments MethodologyAli SarfrazNo ratings yet

- Potential of Lean Tools of Value Stream Mapping in ManufacturingDocument11 pagesPotential of Lean Tools of Value Stream Mapping in ManufacturingVictor MalulekaNo ratings yet

- Lead Time Reduction Through Lean Technique in An Engine Assembly LineDocument7 pagesLead Time Reduction Through Lean Technique in An Engine Assembly LineVarun KumarNo ratings yet

- 0 - Improving Productivity in A Mechanical Industry Using IndustrialDocument9 pages0 - Improving Productivity in A Mechanical Industry Using IndustrialAhmed AbdelhamidNo ratings yet

- AnalisBasedSimulation PDFDocument5 pagesAnalisBasedSimulation PDFRieska foni YuniarNo ratings yet

- Application of Value Stream Mapping For ReductionDocument10 pagesApplication of Value Stream Mapping For ReductionFrank CordovaNo ratings yet

- Facility and Process Layout Analysis of An SME Using Simulation: A Case Study of A Manufacturing CompanyDocument11 pagesFacility and Process Layout Analysis of An SME Using Simulation: A Case Study of A Manufacturing CompanyJon GatesNo ratings yet

- Research Papers On Advanced Manufacturing TechnologyDocument4 pagesResearch Papers On Advanced Manufacturing Technologygz8y0espNo ratings yet

- PHD Synopsis - Nilesh Pancholi - 129990919010 - 339919Document22 pagesPHD Synopsis - Nilesh Pancholi - 129990919010 - 339919Ibrahim RahimNo ratings yet

- Cycle Time Reduction in Deck Roller Assembly ProductionDocument10 pagesCycle Time Reduction in Deck Roller Assembly ProductionTeshome DengisoNo ratings yet

- Artigo Comparação 3Document16 pagesArtigo Comparação 3Jullyane FigueiredoNo ratings yet

- Management Science LettersDocument12 pagesManagement Science LettersRaka R RamadhianNo ratings yet

- Kumar 2020Document11 pagesKumar 2020Tania CanchanyaNo ratings yet

- Case Study On Identification and EliminaDocument13 pagesCase Study On Identification and Eliminastuart littleNo ratings yet

- Application of Value Stream Mapping For Reduction of Cycle Time in A Machining Process PDFDocument10 pagesApplication of Value Stream Mapping For Reduction of Cycle Time in A Machining Process PDFGerardo MartinNo ratings yet

- Vitual PistonDocument31 pagesVitual PistonrenatoeliegeNo ratings yet

- A Comparative Study of Multi-Criteria Decision-Making Approaches For Prioritising The Manufacturing SystemsDocument24 pagesA Comparative Study of Multi-Criteria Decision-Making Approaches For Prioritising The Manufacturing SystemsBung RifandiNo ratings yet

- Abdulmalek, Rajgopal - 2007 - Analyzing The Benefits of Lean Manufacturing and Value Stream Mapping Via Simulation A Process Sector CaseDocument14 pagesAbdulmalek, Rajgopal - 2007 - Analyzing The Benefits of Lean Manufacturing and Value Stream Mapping Via Simulation A Process Sector CaseDragan DragičevićNo ratings yet

- Design For Quality in Agile Manufacturing Environment Through Modified Orthogonal Array-Based ExperimentationDocument22 pagesDesign For Quality in Agile Manufacturing Environment Through Modified Orthogonal Array-Based ExperimentationRasgullah PhaniNo ratings yet

- Mattress Production LineDocument12 pagesMattress Production LineUbaid Ur Rehman100% (1)

- Maximising Return On Investment (ROI) For Pharmaceutical ProductionDocument16 pagesMaximising Return On Investment (ROI) For Pharmaceutical ProductionViet Bui DucNo ratings yet

- Lean Manufacturing Concept: The Main Factor in Improving Manufacturing Performance - A Case StudyDocument12 pagesLean Manufacturing Concept: The Main Factor in Improving Manufacturing Performance - A Case StudyAbeeha NasirNo ratings yet

- .MP 1Document19 pages.MP 1Hanis Adibah AzizNo ratings yet

- Adaptation of The Value Stream Mapping Approach To The Design of Lean Engineer-To-Order Production SystemsDocument18 pagesAdaptation of The Value Stream Mapping Approach To The Design of Lean Engineer-To-Order Production SystemsLuis AlbertoNo ratings yet

- Total Productive Maintenance Implementation Procedures in Manufacturing Organizations Using Axiomatic Design PrinciplesDocument7 pagesTotal Productive Maintenance Implementation Procedures in Manufacturing Organizations Using Axiomatic Design PrinciplesSam ChristoberNo ratings yet

- Production Model Based On Total Productive Maintenance and Systematic Layout Planning To Increase Productivity in The Metalworking IndustryDocument5 pagesProduction Model Based On Total Productive Maintenance and Systematic Layout Planning To Increase Productivity in The Metalworking IndustrySolci AbantoNo ratings yet

- ArticuloDocument11 pagesArticuloTaniaNo ratings yet

- Use of 6-Sigma in Improvement of Manufacturing CompanyDocument6 pagesUse of 6-Sigma in Improvement of Manufacturing CompanyTran Minh TriNo ratings yet

- Implementation of Lean Six Sigma For Production Process Optimization in A Paper Production CompanyDocument20 pagesImplementation of Lean Six Sigma For Production Process Optimization in A Paper Production CompanyLuis MontoyaNo ratings yet

- Manufacturing System Design Based On Axiomatic Design: Case of Assembly LineDocument29 pagesManufacturing System Design Based On Axiomatic Design: Case of Assembly LineRieska foni YuniarNo ratings yet

- Implementation of Total Productive MaintDocument12 pagesImplementation of Total Productive MaintEregamani DinamaniNo ratings yet

- Implementation of Total Productive Maintenance Lean Tool To Reduce Lead Time-A Case StudyDocument12 pagesImplementation of Total Productive Maintenance Lean Tool To Reduce Lead Time-A Case StudyEregamani DinamaniNo ratings yet

- Process Improvement and Layout ForgingDocument9 pagesProcess Improvement and Layout ForgingManibalanNo ratings yet

- 2 PDFDocument13 pages2 PDFRegine Erika LaydiaNo ratings yet

- Accepted Manuscript: 10.1016/j.omega.2017.08.008Document23 pagesAccepted Manuscript: 10.1016/j.omega.2017.08.008Avinash KumarNo ratings yet

- Jurnal Internasional 3 PDFDocument8 pagesJurnal Internasional 3 PDFaziz abdulNo ratings yet

- Ijet 26753Document7 pagesIjet 26753kevin21790No ratings yet

- Improving Productivity of A Machine Workshop Through Facilities PlanningDocument6 pagesImproving Productivity of A Machine Workshop Through Facilities PlanningSISI GELAPNo ratings yet

- Android Application For Analysis of Productivity of Precision Machine ShopDocument7 pagesAndroid Application For Analysis of Productivity of Precision Machine ShopIJRASETPublicationsNo ratings yet

- Karan Das Main Bce Project123Document29 pagesKaran Das Main Bce Project123snehaNo ratings yet

- Balancing The Production Line by The Simulation and Statistics Techniques: A Case StudyDocument10 pagesBalancing The Production Line by The Simulation and Statistics Techniques: A Case StudyDonald Robert ManikNo ratings yet

- 1 s2.0 S266691292200006X MainDocument12 pages1 s2.0 S266691292200006X MainDiego YauriNo ratings yet

- Critical Study On Vital Factors Influencing Productivity ImprovementDocument8 pagesCritical Study On Vital Factors Influencing Productivity ImprovementIJRASETPublicationsNo ratings yet

- 3047 11934 1 PBDocument11 pages3047 11934 1 PBNaygerOrtizSolorzanoNo ratings yet

- Additive Manufacturing A Framework For ImplementationDocument8 pagesAdditive Manufacturing A Framework For Implementationnicero555No ratings yet

- SmedDocument4 pagesSmedYurdun OrbakNo ratings yet

- Analyzing The Benefits of Lean Manufacturing and Value Stream Mapping Via Simulation A Process Sector Case StudyDocument14 pagesAnalyzing The Benefits of Lean Manufacturing and Value Stream Mapping Via Simulation A Process Sector Case StudyJamesNo ratings yet

- 508 5408 2 PB PDFDocument17 pages508 5408 2 PB PDFTeknik IndustriNo ratings yet

- Waste Reduction in Production Processes Through Simulation and VSMDocument14 pagesWaste Reduction in Production Processes Through Simulation and VSMLuis Alejandro Cuervo GalvisNo ratings yet

- Journal of King Saud University - Engineering Sciences: Original ArticleDocument11 pagesJournal of King Saud University - Engineering Sciences: Original ArticleaodyNo ratings yet

- Extended Model For SMED Application Through GoodDocument9 pagesExtended Model For SMED Application Through GoodIrshad Ali100% (1)

- Balancing Mixed Ergonomics - Model Assembly Line To Reduce Work Overload in A Multi-Level Production SystemDocument9 pagesBalancing Mixed Ergonomics - Model Assembly Line To Reduce Work Overload in A Multi-Level Production SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Application of Lean Manufacturing Using VSM in Auto Parts Manufacturing UnitDocument13 pagesApplication of Lean Manufacturing Using VSM in Auto Parts Manufacturing UnitSaravananNo ratings yet

- The Impact of Lean Implementation On Operational Performance - A Study of Composite Manufacturing Companies in MalaysiaDocument16 pagesThe Impact of Lean Implementation On Operational Performance - A Study of Composite Manufacturing Companies in MalaysiaJim Juan OsmanNo ratings yet

- The Management of Additive Manufacturing: Enhancing Business ValueFrom EverandThe Management of Additive Manufacturing: Enhancing Business ValueNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Problem To SolutionDocument7 pagesProblem To SolutionPankajatSIBMNo ratings yet

- Bpmn2 0 Poster enDocument1 pageBpmn2 0 Poster enTubora100% (1)

- Animated Charts Collection: Your LogoDocument32 pagesAnimated Charts Collection: Your LogoPankajatSIBMNo ratings yet

- FF0246 01 Creative Business Slides Powerpoint TemplateDocument10 pagesFF0246 01 Creative Business Slides Powerpoint TemplateMuhammad Shoaib Asad KhalidNo ratings yet

- FF0189 01 Free 4 Step Horizontal Diagram 16x9Document7 pagesFF0189 01 Free 4 Step Horizontal Diagram 16x9scotchkarmaNo ratings yet

- Cheap Air Tickets Online, International Flights To India, Cheap International Flight Deals - SpiceJet AirlinesDocument1 pageCheap Air Tickets Online, International Flights To India, Cheap International Flight Deals - SpiceJet AirlinesPankajatSIBMNo ratings yet

- HealthifyMe T&C 28092022 CleanDocument8 pagesHealthifyMe T&C 28092022 CleanPankajatSIBMNo ratings yet

- Animated Charts Collection: Your LogoDocument32 pagesAnimated Charts Collection: Your LogoPankajatSIBMNo ratings yet

- VRF PDFDocument21 pagesVRF PDFPankajatSIBMNo ratings yet

- Kratika Sharma ResumeDocument2 pagesKratika Sharma ResumePankajatSIBMNo ratings yet

- Emerging Trends in Automated Wealth Management Advice Codex2629 PDFDocument20 pagesEmerging Trends in Automated Wealth Management Advice Codex2629 PDFPankajatSIBMNo ratings yet

- FNAL Capacity Management Policy Process ProceduresDocument36 pagesFNAL Capacity Management Policy Process ProceduresPankajatSIBMNo ratings yet

- Wealth Managment Trends 2018Document28 pagesWealth Managment Trends 2018Juliana LombanaNo ratings yet

- IP Address Management (IPAM) Best Practices PDFDocument20 pagesIP Address Management (IPAM) Best Practices PDFPankajatSIBMNo ratings yet

- Articlesonline Exclusive Kaizen Blitz Ready Fire AimDocument6 pagesArticlesonline Exclusive Kaizen Blitz Ready Fire AimPankajatSIBMNo ratings yet

- IP Address Management (IPAM) Best Practices PDFDocument20 pagesIP Address Management (IPAM) Best Practices PDFPankajatSIBMNo ratings yet

- RP, Avg, TSD, TW Answer KeyDocument2 pagesRP, Avg, TSD, TW Answer KeyPankajatSIBMNo ratings yet

- Paper2 V4 I2 PDFDocument7 pagesPaper2 V4 I2 PDFPankajatSIBMNo ratings yet

- Kaizen Blitz: An Introduction and Some Words of CautionDocument3 pagesKaizen Blitz: An Introduction and Some Words of Cautionpjanssen2306No ratings yet

- Case Interview Marathon Workshop: Overhead Slides v1.0Document30 pagesCase Interview Marathon Workshop: Overhead Slides v1.0Anonymous 8ooQmMoNs1No ratings yet

- Lean in A Lean EconomyDocument40 pagesLean in A Lean EconomyPankajatSIBMNo ratings yet

- Digital Inspection ToolsDocument13 pagesDigital Inspection ToolsPankajatSIBMNo ratings yet

- CSS Capabilities OverviewDocument24 pagesCSS Capabilities OverviewPankajatSIBMNo ratings yet

- Sustaining The Change Efforts: Inspection DepartmentDocument2 pagesSustaining The Change Efforts: Inspection DepartmentPankajatSIBMNo ratings yet

- Meqaps 19Document9 pagesMeqaps 19PankajatSIBMNo ratings yet

- Corporate Profile Schneider ElectricDocument6 pagesCorporate Profile Schneider ElectricPankajatSIBMNo ratings yet

- Recruitment & Selection at Tata Teleservices (Tata Docomo)Document11 pagesRecruitment & Selection at Tata Teleservices (Tata Docomo)PankajatSIBMNo ratings yet

- CFA AgentDocument3 pagesCFA AgentPankajatSIBMNo ratings yet

- Rims Business School PlacementsDocument4 pagesRims Business School PlacementsPankajatSIBMNo ratings yet

- Sample Project CharterDocument1 pageSample Project CharterPankajatSIBMNo ratings yet

- Introduction To Modeling For BiosciencesDocument329 pagesIntroduction To Modeling For BiosciencesCharles Moreno100% (1)

- Ecmo Terapy PDFDocument379 pagesEcmo Terapy PDFsarwansyahNo ratings yet

- Simulation & Its ApplicationsDocument19 pagesSimulation & Its ApplicationsAbhijeet SinghNo ratings yet

- Section 1 Cookery NC Ii Qualification: TRS311203 Perform Computer OperationsDocument17 pagesSection 1 Cookery NC Ii Qualification: TRS311203 Perform Computer OperationsYuriiNo ratings yet

- Modeling Digital Systems: © Sudhakar Yalamanchili, Georgia Institute of Technology, 2006Document19 pagesModeling Digital Systems: © Sudhakar Yalamanchili, Georgia Institute of Technology, 2006mahendra singhNo ratings yet

- Cyber Defense: Mathematical Modeling and Simulation: Dinesh Kumar SainiDocument14 pagesCyber Defense: Mathematical Modeling and Simulation: Dinesh Kumar SainiCaessar LogicNo ratings yet

- Iot Acceleration Lab Action Plan WWW - Iotlab.JpDocument19 pagesIot Acceleration Lab Action Plan WWW - Iotlab.JpsreeshpsNo ratings yet

- GQMP 7001 StabilityDocument20 pagesGQMP 7001 StabilitySakib ChowdhuryNo ratings yet

- Globes Manual 3.0.8Document182 pagesGlobes Manual 3.0.8John Vỏ MedinaNo ratings yet

- Document Upcast 2019-2020Document14 pagesDocument Upcast 2019-2020Linh HungNo ratings yet

- TU Package Options2Document1 pageTU Package Options2rstephenrajNo ratings yet

- ToLiss AirbusA319 V1.3.3 SimulationManualDocument50 pagesToLiss AirbusA319 V1.3.3 SimulationManualLORISNo ratings yet

- Compositional Reservoir Simulation: A ReviewDocument47 pagesCompositional Reservoir Simulation: A Reviewhossein.rezaie.mashhadNo ratings yet

- American Journal of Engineering Research (AJER)Document7 pagesAmerican Journal of Engineering Research (AJER)Jose MagalNo ratings yet

- Jacal AdlDocument1 pageJacal AdlJUAN SEBASTIAN GONZALEZ FORERONo ratings yet

- FSCD-Data Processing in Mass RunsDocument6 pagesFSCD-Data Processing in Mass RunsHoNo ratings yet

- MOSS Deadlock SimulatorDocument8 pagesMOSS Deadlock SimulatorbishnoishivuNo ratings yet

- Lyceum-Northwestern University Tapuac District, Dagupan City College of Business EducationDocument5 pagesLyceum-Northwestern University Tapuac District, Dagupan City College of Business EducationjolinaNo ratings yet

- So SPrimerDocument8 pagesSo SPrimerBob ParroNo ratings yet

- Group Assignment (Group 6) - SEMM 1921-80 - A22EM4023Document6 pagesGroup Assignment (Group 6) - SEMM 1921-80 - A22EM4023Roshan Jawad ZafirNo ratings yet

- CBC HEO (Backhoe Loader) NC IIDocument55 pagesCBC HEO (Backhoe Loader) NC IIJohn JamesNo ratings yet

- Brochure Cae Sim ProductsDocument12 pagesBrochure Cae Sim Productsdpineda_328No ratings yet

- Introduction To Monte Carlo Simulation - Excel - OfficeDocument6 pagesIntroduction To Monte Carlo Simulation - Excel - OfficeKush DewanganNo ratings yet

- ABM9 Buss. Interprise Simulation Prelim ModuleDocument5 pagesABM9 Buss. Interprise Simulation Prelim Modulemelindapido55No ratings yet

- Enhancing Safety and Minimizing Corrosion in Refineries Through Process Intelligence ToolsDocument20 pagesEnhancing Safety and Minimizing Corrosion in Refineries Through Process Intelligence Toolspapaya123No ratings yet

- 3 - Chap 3 - General PrinciplesDocument11 pages3 - Chap 3 - General PrinciplesLinh LilinNo ratings yet

- MSC - Adams Release Guide: Release - Book Page 1 Friday, August 5, 2005 11:53 AMDocument86 pagesMSC - Adams Release Guide: Release - Book Page 1 Friday, August 5, 2005 11:53 AMRuben Carballo Villazala0% (2)

- Simulation: Definition, Motivation: Simulation: To Construct and Test A ComputerDocument23 pagesSimulation: Definition, Motivation: Simulation: To Construct and Test A ComputerNaty MatNo ratings yet

- Marcet Boiler HE169Document4 pagesMarcet Boiler HE169HoongNo ratings yet