Professional Documents

Culture Documents

Hypoxy Steelbond

Uploaded by

Mostafizur Rahman0 ratings0% found this document useful (0 votes)

53 views2 pagesHYPOXY STEELBOND is a two-component epoxy formulation highly filled with carefully selected pure steel Fillers, modified curing agents, and special high quality additives to provide maximum strength, durability, and ease of application. Will adhere to vertical surfaces and is easily machineable with standard metalworking tools and equipment. Hardens to a gray metallic mass and adheres soundly to almost every material except for polyethylene.

Original Description:

Original Title

HYPOXY_STEELBOND

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHYPOXY STEELBOND is a two-component epoxy formulation highly filled with carefully selected pure steel Fillers, modified curing agents, and special high quality additives to provide maximum strength, durability, and ease of application. Will adhere to vertical surfaces and is easily machineable with standard metalworking tools and equipment. Hardens to a gray metallic mass and adheres soundly to almost every material except for polyethylene.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

53 views2 pagesHypoxy Steelbond

Uploaded by

Mostafizur RahmanHYPOXY STEELBOND is a two-component epoxy formulation highly filled with carefully selected pure steel Fillers, modified curing agents, and special high quality additives to provide maximum strength, durability, and ease of application. Will adhere to vertical surfaces and is easily machineable with standard metalworking tools and equipment. Hardens to a gray metallic mass and adheres soundly to almost every material except for polyethylene.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

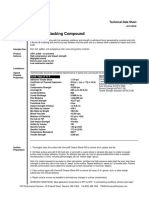

HYPOXY STEELBOND

STEEL REPAIR PUTTY

PRODUCT: H-100 1Lb (454 gms ) Pack.

DESCRIPTION: A two-component epoxy formulation highly filled with carefully selected pure steel

Fillers, modified curing agents, and special high quality additives to provide maximum strength,

durability, and ease of application. Will adhere to vertical surfaces and is easily machineable with

standard metalworking tools and equipment.ns to a gray metallic mass and adheres soundly to a

APPLICATIONS:

HYPOXY STEELBOND hardens to a gray metallic mass and

adheres soundly to almost every material except for

polyethylene.

A permanent, non-shrinking metallic filler for blow holes in

castings. Ideal for building up metal surfaces. Widely used for

fast, inexpensive, but accurate drill jigs and placement

fixtures.

HYPOXY STEELBOND is especially formulated for repairing

valves, pumps, castings, water jackets, radiators, Pipe, Tanks,

Engine Blocks etc.

HYPOXY STEELBOND is unaffected by water, oil and

gasoline and widely used by professional tradesman

worldwide.

HYPOXY STEELBOND cured deposit can be machined,

sanded, drilled and tapped which makes it a popular choice for

automotive, plumbing and HVAC repairs. It is also commonly

used as a reinforcement coat over HYPOXY STEELFAST

after attending the emergency oil / water / gas leakages

CHEMICAL RESISTANCE:

Hydrochloric Acid 10% -: Very Good

Hydrochloric Acid 50% -: Good

Sulfuric Acid 10% -: Very Good

Sulfuric Acid 50% -: Good

Water -: Very Good

Ammonia -: Very Good

Sodium Hydroxide 10%-: Very Good

Gasoline, Oil, Kerosene -:Very Good

Mineral Spirits -: Very Good

Toluene -: Good

Methanol -: Fair

MEK -: Fair

Propylene Glycol -: Very Good

PHYSICAL PROPERTIES:

Color -: Dark Grey

Pot Life 1 lb. @ 24C (75F) -: 45 minutes

Viscosity -: Non-sagging Paste

Mixed Viscosity -: 350,000 cps

Cure Shrinkage -: 0.0005 in/in

Temperature Resistance -: 250F (121C)

Hardness (Shore, ASTM D 1706) -: 85D

Cured Density -: 11.9 cu. in. per lb.

Coefficient of Thermal Expansion -: 65 X 10- 6 cm/cm/C

Compression Strength

(ASTM D 695) -: 8,100 psi (56 M Pa)

Tensile Strength

(ASTM D 638) -: 4,100 psi (28 M Pa)

Flexual Strength

(ASTM D 790 ) -: 6300 psi ( 43 M Pa )

Dielectric Strength -: 30 Volts / mil

SURFACE PREPRATION :

Surfaces must be clean, dry, and preferably roughened for maximum adhesion. Proper surface preparation is critical

to the long term performance of this product. The exact requirements for surface preparation vary with the severity of

the application, expected service life, and the initial substrate condition.

Optimum preparation will provide a surface thoroughly cleaned of all contaminants and roughened to an angular

profile between 75-125 microns ( 3 to 5 mils ). This is normally achieved by initial cleaning, followed by abrasive

blasting to a cleanliness of white metal ( SA3 / SSPC-SP5) or Near White Metal (SA 2 SSPC SP 10 ) followed by

rinsing with an organic solvent which evaporates leaving no film residue. Grinding or machining to a rough surface

profile followed by rinsing with solvent is acceptable although a subsequent lowering in adhesion may result.

MIXING :

Add all of the hardener to all of the resin in the resin container. For smaller portions, dole out 1 part hardener to 3

parts resin by volume (1 to 9 parts by weight).

Mix thoroughly, making certain that all of the hardener comes in contact with all of the resin. While mixing be sure to

scrape the sides and bottom of the container.

Apply the mixed compound with putty knife, spatula, or similar tool. The tool may be moistened with water to provide a

smooth finish to the HY-POXY. Since HY-POXY will not adhere to polyethylene, a piece of that plastic can be

placed on the uncured HY-POXY and removed after the material cures to leave a very smooth finish.

COVERAGE:

1lb. (454g) STEELBOND kit covers approximately 47sq. inches (303sq.centimeters) at (6.35mm) thickness.

CURING TIME:

At 75F (24C) a (12.5mm) layer of HY-POXY STEELBOND putty will be hard in approximately 4 hours. FULL

cure times are as follows:

TEMPERATURE WORKING TIME FULL CURE TIME

60F (16C) 90 Minutes 32 Hours

75F (24C) 45 Minutes 16 Hours

90F (32C) 25 Minutes 8 Hours.

SAFETY :

Before using any product, review the appropriate Material Safety Data Sheet ( MSDS ). Follow standard confined

space entry and work procedures, if appropriate.

NON-WARRANTY:

We can accept no responsibility or liability for lack of results because the storage, handling, and application of the

compound is beyond our control.

PL CALL IN YOUR LOCAL AUTHORISED DEALER TO GET FULL ADVANTAGE OF PRODUCT TRAINING AND

KNOW HOW TO MAKE MORE USE OF HY POXY PRODUCTS

HY POXY SYSTEMS INC. USA Marketed & Serviced in Bangladesh by -:

Maintenance Chemical Agencies Ltd.

1005 East Nasirabad, CDA Avenue

Chittagong-4225, BANGLADESH

Tel: + 880-31-652294, 653197

Fax: + 880-31-655850 Cell: + 880-1713 100850

E-mail: mcalbd@gmail.com

mcal@colbd.net

You might also like

- Rapid Cure Steel Putty for RepairsDocument3 pagesRapid Cure Steel Putty for RepairsOo Pen DraNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthNo ratings yet

- Hy-Poxy Steel FastDocument2 pagesHy-Poxy Steel FastAqueel KhanNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Hind ERS 31 (LV)Document2 pagesHind ERS 31 (LV)Rajesh GiriNo ratings yet

- Titanium Putty HPDocument2 pagesTitanium Putty HPDivyanshu GuptaNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraNo ratings yet

- Description Packaging Product Data SheetDocument2 pagesDescription Packaging Product Data SheetRonald Fernandez ManubuluNo ratings yet

- Physical Properties: % of Initial Strength Environment °C 100 HR 500 HR 1000 HRDocument1 pagePhysical Properties: % of Initial Strength Environment °C 100 HR 500 HR 1000 HRAlberto GutierrezNo ratings yet

- Product Data Sheet SP-8888Document7 pagesProduct Data Sheet SP-8888pablo gonzalezNo ratings yet

- Loctite 594 1998Document5 pagesLoctite 594 1998Boss_enqNo ratings yet

- DEVCON® Fasmetal 10 HVAC Repair (Special F)Document2 pagesDEVCON® Fasmetal 10 HVAC Repair (Special F)mohamed hamedNo ratings yet

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Plastic Steel Putty (A) : Technical Data SheetDocument3 pagesPlastic Steel Putty (A) : Technical Data SheetsanjayNo ratings yet

- Cloverdale - (Data Sheet) Clovaprimer h20-0020Document3 pagesCloverdale - (Data Sheet) Clovaprimer h20-0020PubcrawlNo ratings yet

- 134 TDS Updated Feb 2016 78-8141-8528-2 Rev ADocument6 pages134 TDS Updated Feb 2016 78-8141-8528-2 Rev AUriel GarciaNo ratings yet

- Scotch KoteDocument4 pagesScotch KoteJavier Gomez ReyesNo ratings yet

- Ceilcote 6640 Ceilcrete+ds+engDocument4 pagesCeilcote 6640 Ceilcrete+ds+englivefreakNo ratings yet

- SynoliteDocument3 pagesSynoliteAlptekinNo ratings yet

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDocument3 pagesPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerNo ratings yet

- Sikafloor®-161: Product Data SheetDocument5 pagesSikafloor®-161: Product Data SheetashayshaNo ratings yet

- Carbomastic 15 PDS 2013Document2 pagesCarbomastic 15 PDS 20134508366279No ratings yet

- Product Description: Epoxy Coating System, 100% SolidsDocument4 pagesProduct Description: Epoxy Coating System, 100% SolidsKatherine GonzalesNo ratings yet

- Hysa9460 enDocument3 pagesHysa9460 enengpontelliNo ratings yet

- Plastic Steel Putty - Materijal Za IspunuDocument2 pagesPlastic Steel Putty - Materijal Za Ispunudavorp1402No ratings yet

- TDS Loctite 3355 PDFDocument3 pagesTDS Loctite 3355 PDFffincher4203No ratings yet

- Sealbond 218 P Pressure Injection EpoxyDocument1 pageSealbond 218 P Pressure Injection EpoxyLeoven Jef Suzara Lorin0% (1)

- Floor Patch Fast CureDocument2 pagesFloor Patch Fast CureStevenFerrelNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- 3M2216Document8 pages3M2216pat_kunal1601No ratings yet

- Liquid Epoxy Coating (3M)Document5 pagesLiquid Epoxy Coating (3M)Thamaraikani ManiNo ratings yet

- Izel Kimya Urun Katalog en - 20082022140320 2 - 17112023164927 2Document46 pagesIzel Kimya Urun Katalog en - 20082022140320 2 - 17112023164927 2Onur DNo ratings yet

- Ceilcote 6650 Ceilcrete+ds+engDocument4 pagesCeilcote 6650 Ceilcrete+ds+engMohamed NouzerNo ratings yet

- 323 Data Sheet and Application GuideDocument4 pages323 Data Sheet and Application Guidejast111No ratings yet

- DutchBoy_Epoxy_enamel_9200Document4 pagesDutchBoy_Epoxy_enamel_9200Abdel Razak Al AsmarNo ratings yet

- Polyclad 975 H PDSDocument2 pagesPolyclad 975 H PDSLinnie McleodNo ratings yet

- Gun Grade NEWDocument2 pagesGun Grade NEWSunny SinghNo ratings yet

- Nukote XT Plus TdsDocument4 pagesNukote XT Plus TdsAnsar AliNo ratings yet

- Armorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsDocument4 pagesArmorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsOswaldo SantoyoNo ratings yet

- Ficha Icat LS-2001 BasecoatDocument3 pagesFicha Icat LS-2001 BasecoatOAM INGENIERIA SASNo ratings yet

- Loctite 222MS™: Technical Data SheetDocument4 pagesLoctite 222MS™: Technical Data SheetbabshuagNo ratings yet

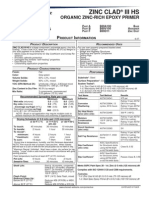

- Zinc Clad IIIDocument4 pagesZinc Clad IIIScott Van PeltNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- High Solids Epoxy Zinc Rich Primer for Corrosion ProtectionDocument2 pagesHigh Solids Epoxy Zinc Rich Primer for Corrosion ProtectionmuthukumarNo ratings yet

- SP-9888® Tank Lining: Selection & Specification DataDocument4 pagesSP-9888® Tank Lining: Selection & Specification DataSatees KrishnanNo ratings yet

- Tds Supermend Epoxy EnglishDocument4 pagesTds Supermend Epoxy EnglishNiklas LuwamNo ratings yet

- 3651 TDS - eDocument3 pages3651 TDS - eDavidNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Araldite LY556 - Aradur 917 - Accelarator DY 070 - TDSDocument6 pagesAraldite LY556 - Aradur 917 - Accelarator DY 070 - TDSjbd170352No ratings yet

- Plastic Steel 5 Minute PuttyDocument3 pagesPlastic Steel 5 Minute PuttyDivyanshu GuptaNo ratings yet

- AS5272Document2 pagesAS5272Hoeruman oenNo ratings yet

- Zinc Anode 304 Protects Steel Against CorrosionDocument2 pagesZinc Anode 304 Protects Steel Against CorrosionIsaac SamuelNo ratings yet

- Ceilcote 380 PrimerDocument4 pagesCeilcote 380 Primeryoonchankim0911No ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Ceramics for Environmental SystemsFrom EverandCeramics for Environmental SystemsLianzhou WangNo ratings yet

- Dsi Suspa Systems Eta 07 0186 Suspa Wire Ex enDocument48 pagesDsi Suspa Systems Eta 07 0186 Suspa Wire Ex enAnonymous TxhyGfNo ratings yet

- Installation - Operation - Maintenance - Instructions - 30 HXC PDFDocument36 pagesInstallation - Operation - Maintenance - Instructions - 30 HXC PDFNurmansyah Dwi Cahyono100% (3)

- Reaction Paper The Flight From ConversationDocument4 pagesReaction Paper The Flight From ConversationJoe NasalitaNo ratings yet

- Axial Piston Pump Variable Displacement Bosch Rexroth A4VSO-1421347275Document60 pagesAxial Piston Pump Variable Displacement Bosch Rexroth A4VSO-1421347275LIVIANo ratings yet

- Service Accessories: CatalogDocument32 pagesService Accessories: CatalogdummaNo ratings yet

- Converting Urban Waste To EnergyDocument11 pagesConverting Urban Waste To EnergyDéépákNo ratings yet

- Videojet 3140: Laser Marking SystemDocument2 pagesVideojet 3140: Laser Marking SystemSudiptoNo ratings yet

- Jumeirah Group Future IssuesDocument3 pagesJumeirah Group Future Issueshaelstone100% (1)

- Parts List CMX1402Document36 pagesParts List CMX1402Jayden BarnesNo ratings yet

- SAP-Press - Abap Development For Sap HanaDocument30 pagesSAP-Press - Abap Development For Sap HananicocastanioNo ratings yet

- Blackberry Enterprise Server For Microsoft Exchange: Troubleshooting GuideDocument48 pagesBlackberry Enterprise Server For Microsoft Exchange: Troubleshooting GuideKhaled AjouzNo ratings yet

- Model Manajemen Rantai Pasok Industri Perikanan Tangkap Berkelanjutan Di Propinsi MalukuDocument12 pagesModel Manajemen Rantai Pasok Industri Perikanan Tangkap Berkelanjutan Di Propinsi MalukuEmanuellaNo ratings yet

- MDN 1508DSDocument108 pagesMDN 1508DSdocazanNo ratings yet

- Export Promotion Councils - Final UpdatedDocument14 pagesExport Promotion Councils - Final UpdatedUtkarsh SaxenaNo ratings yet

- June 2014 Draft for Public ReviewDocument59 pagesJune 2014 Draft for Public ReviewRomel Vargas Sánchez0% (1)

- Corporate Bridge Internship ProposalDocument5 pagesCorporate Bridge Internship ProposalHBhatlaNo ratings yet

- WWW - Unitoperation Heat1Document12 pagesWWW - Unitoperation Heat1mahendra shakyaNo ratings yet

- Energy Equity Epic (Sengkang) Pty., Ltd. Central Gas Processing Plant Kampung Baru FieldDocument2 pagesEnergy Equity Epic (Sengkang) Pty., Ltd. Central Gas Processing Plant Kampung Baru FieldAsbar AmriNo ratings yet

- PowerOn Fusion PDFDocument16 pagesPowerOn Fusion PDFJagan VanamaNo ratings yet

- AIR Intelligence Manual 33 308100 004 RemoteDocument88 pagesAIR Intelligence Manual 33 308100 004 RemoteLeChancheNo ratings yet

- BOE-025 Consejo de EstadoDocument1 pageBOE-025 Consejo de Estado15mls23No ratings yet

- Bringing Industrial Automation Environment Into Classroom: A Didactic Three-Tank and Heat Exchanger ModuleDocument5 pagesBringing Industrial Automation Environment Into Classroom: A Didactic Three-Tank and Heat Exchanger Modulenicacio_89507470No ratings yet

- VAHAN SERVICE - User ManualDocument30 pagesVAHAN SERVICE - User ManualGURBACHAN SINGH ChouhanNo ratings yet

- BS Basics Boundary Scan PDFDocument2 pagesBS Basics Boundary Scan PDFShankar ArunmozhiNo ratings yet

- AcrSavoniacJ ZDocument454 pagesAcrSavoniacJ ZЕвгенияNo ratings yet

- Gas Range: Defsgg 24 SsDocument20 pagesGas Range: Defsgg 24 Ssfaker fake fakersonNo ratings yet

- ASTM 210cDocument1 pageASTM 210cDodi SuhendraNo ratings yet

- Learjet 45 Pilot Traning Manual Volumen 2Document539 pagesLearjet 45 Pilot Traning Manual Volumen 2Agustin Bernales88% (8)

- LTE UMTS GSM Network OptimizationDocument44 pagesLTE UMTS GSM Network OptimizationAvi Shetty100% (1)

- Aztech+700WR-3G User ManualDocument57 pagesAztech+700WR-3G User Manualkero_the_hero67% (3)