Professional Documents

Culture Documents

05 Wake Frequency Calculation - 09 DG 005 Rev 0

Uploaded by

vivek_enggOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 Wake Frequency Calculation - 09 DG 005 Rev 0

Uploaded by

vivek_enggCopyright:

Available Formats

16-QSP-05-3A

DESIGN GUIDE

FOR

WAKE FREQUENCY CALCULATION

FOR THERMOWELL

W

o

r

d

0 31.8.04 Issued for implementation LR DB AMG

Rev. Date Description Prpd. Chkd. Appd.

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 1 of 11

16-QSP-05-3A

CONTENTS

1.0 PURP!"

#.0 !$P"

3.0 LI!% & ABBR"'IA%I(!

4.0 PR$"DUR"

).0 "*AMPL" PRBL"M

+.0 LIMI%A%I(

,.0 APPLI$ABL" $D"! - !%A(DARD!

W

o

r

d

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 2 of 11

16-QSP-05-3A

1.0 PURPOSE

%.e purpose of t.is do/ument is to pro0ide 1uidelines and ena2le one to determine if a

t.ermo3ell sele/ted for ser0i/e is stron1 enou1. to 3it.stand spe/ifi/ appli/ation /onditions

su/. as pressure4 0elo/it5 and 0i2ration.

2.0 SCOPE

%.is do/ument s.all in/lude 2ut is not limited to t.e safe len1t. re6uirements of t.ermo3ell

into a mo0in1 fluid.

3.0 LIST OF ABBREVIATIONS:

API 7 AM"RI$A( P"%RL"UM I(!%I%U%"

A(!I 7 AM"RI$A( (A%I(AL !%A(DARD! I(!%I%U%"

A!M" 7 AM"RI$A( !$I"%8 & M"$9A(I$AL "(GI(""R!

I!A 7 %9" I(!%RUM"(%A%I(4 !8!%"M! A(D AU%MA%I(

!$I"%8

4.0 PROCEDURE:

%.e t.ermo3ell pro0ides prote/tion for temperature sensin1 element in pressure 0essels

and pipelines. %.e t.ermo3ells are pro0ided 3it. e:ternal t.reads or ot.er means for

lea; ti1.t pressure atta/.ment to t.e 0essels and pipelines. %.e temperature sensor 3.i/.

resides inside t.e t.ermo3ell measures t.e temperature of a mo0in1 fluid in a /onduit

3.ere t.e stream e:erts an appre/ia2le for/e. %.e t.ermo3ells are desi1ned to 3it.stand

0arious t5pes of loadin1. A t.ermo3ell permits /.e/;in1 and repla/in1 t.e temperature

sensin1 elements 3it.out drainin1 t.e 0essel or pipeline or s.utdo3n of pro/ess.

%.ermo3ell failures are /aused 25 for/es imposed 25 stati/ pressure4 stead5 state flo34 and

0i2ration. !eparate e0aluations of ea/. of t.e a2o0e effe/ts s.ould 2e made in order to

determine t.e limitin1 /ondition.

%.is desi1n pro/edure does not allo3 for effe/ts due to /orrosion or erosion.

%.ere are four /riti/al parameters to /onsider in t.ermo3ell desi1n<

i= Material $ompati2ilit5

ii= &lo37Indu/ed 'i2ration

iii= !tati/ Pressure

i0= !tead5 !tate Bendin1 !tress

W

o

r

d

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 3 of 11

16-QSP-05-3A

Material Compatibility:

%.e t.ermo3ell material /.osen for t.e installation s.all 2e 1o0erned mainl5 25 t.e

/orrosion /onditions of t.e 3ell en0ironment. %.e material used s.all 2e for1ed or 2arsto/;

and s.all /onform to t.e A!%M spe/ifi/ations of A(!I !tandard B31.1 or one of t.e !A or

!B spe/ifi/ations listed in se/tion 7 II of t.e A!M" Boiler and Pressure 'essel $ode.

!ome of t.e most /ommonl5 used materials suita2le for t.ermo3ells are<

A10) Gr. II4 $ar2on steel

A181 Gr. II4 $ar2on steel

A18# Gr. &##4 Lo3 allo5 >/.rome mol5= steel

A18# Gr. &3044 9i allo5 >stainless= steel

A18# Gr. &31+4 9i allo5 >stainless= steel

B1+4 $lass A or B4 (i/;el 7 /opper allo5 >monel=4 annealed

B1+ $lass A or B4 &ree 7 /uttin1 2rass rod

%.e natural fre6uen/5 of t.e t.ermo3ell is dependent on t.e sele/ted t.ermo3ell material.

Flow-induced Vibration:

?.en a t.ermo3ell is inserted into flo3in1 li6uid or 1as4 /ir/ular flo3 is /reated do3n

stream of t.e t.ermo3ell. %.is /ir/ular flo3 patterns are /alled 'on @arman >3a;e=

0orti/es. %.ese 0orti/es 2rea; a3a5 periodi/all54 ;no3n as 0orte: s.eddin1 and /ause a

re1ular /.an1e in t.e for/e on t.e t.ermo3ell4 3.i/. is proportional to t.e flo3 0elo/it5. If

t.e re1ular /.an1e4 or fre6uen/5 >3a;e fre6uen/5= is /lose to t.e natural fre6uen/5 of t.e

t.ermo3ell4 a resonan/e /ondition ma5 o//ur 3.ere a massi0e amounts of ener15 are

a2sor2ed 25 t.e t.ermo3ell4 resultin1 in 0er5 .i1. stresses and possi2le failures. "0en if t.e

t.ermo3ell does not fail4 t.e sensor /apsule inside t.e t.ermo3ell ma5 2e su2Ae/ted to

se0ere le0els of s.o/; and 0i2ration4 resultin1 in erroneous readin1s or total sensor failure.

%.e A!M" P%$ 1B.3 7 1B,4 re6uires t.at t.e ratio of 3a;e fre6uen/5 to natural fre6uen/5

of a t.ermo3ell 2e less t.an 0.8. In instan/es 3.ere t.e ratio is 1reater t.an 0.84 t.e user .as

t3o options<

1. De/rease t.e 3a;e fre6uen/5 25 redu/in1 t.e flo3 0elo/it5 or usin1 a lar1er

diameter t.ermo3ell4 or

#. In/rease t.e natural fre6uen/5 of t.e t.ermo3ell 25 usin1 a stron1er t.ermo3ell

/onfi1uration >a different t.ermo3ell t5pe or material4 or a s.orter len1t.

t.ermo3ell=.

W

o

r

d

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 4 of 11

16-QSP-05-3A

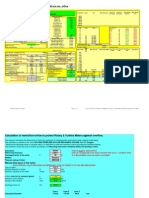

FIGURE 1

%.is /al/ulation is not re6uired 3.en t.e t.ermo3ell is inserted in fluid t.at is not mo0in1.

>for e1.4 temperature elements in 0essels=

%.e /riteria for an a//epta2le desi1n is<

r (f

w

/f

n

)

< 0.8 "6uation >1=

3.ere

r C &re6uen/5 ratio

f

3

C ?a;e &re6uen/54 /5/les per se/ond

f

n

C (atural &re6uen/5 of t.e 3ell at 3or;in1 temperature4 /5/les per se/ond

%.e 3a;e or !trou.al fre6uen/5 and natural fre6uen/5 is 1i0en 25<

F

w

2.64 ` (V/B) "6uation >#=

F

n

(K

f

/L

2

) ` ( ( e E/Y)) "6uation >3=

?.ere

' C &luid 0elo/it54 fps

W

o

r

d

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 5 of 11

16-QSP-05-3A

B C Diameter of t.ermo3ell at tip4 in/.es

L C Insertion len1t. of t.ermo3ell4 in/.es

" C Modulus of elasti/it5 of 3ell material at use temperature4 psi

8 C !pe/ifi/ 3ei1.t of 3ell material4 l2 per /u in.

@

f

C A /onstant o2tained from %a2le71

%.e ratio DrE s.all not e:/eed 0.84 and 3.en t.is /ondition is met4 t.e Ma1nifi/ation &a/tor4

t.e ratio of d5nami/ to stati/ amplitude4 is 1i0en 25<

F

m

r

2

/(1-r

2

) "6uation >4=

Static Pressure:

%.e ma:imum pressure t.at a t.ermo3ell /an 3it.stand for a 1i0en material at a 1i0en

temperature s.all 2e /omputed from t.e follo3in1<

P K

1

S "6uation >)=

?.ere

P C ma:imum Allo3a2le stati/ 1au1e pressure4 psi

! C Allo3a2le stress for material at operatin1 temperature as 1i0en in t.e A!M" Boiler

and Pressure 'essel or Pipin1 $ode4 psi

@

1

C A stress /onstant o2tained from %a2le73

Steady State Bending Stress:

?.en a t.ermo3ell is inserted into mo0in1 fluid it is su2Ae/ted to a stead5 state 2endin1

stress. &luid flo34 3.i/. is a fun/tion of flo3 0elo/it5 and densit54 /auses a for/e to 2e

e:erted on t.e t.ermo3ell. %.e lon1er t.e t.ermo3ell4 t.e .i1.er t.e stress.

%.is /al/ulation is not re6uired 3.en t.e t.ermo3ell is inserted in fluid t.at is not mo0in1.

It does not a//ount for 2endin1 stress due to t.ermo3ell 3ei1.t.

The maximum length that a thermowell can be made for given service is dependent

upon both vibratory and steady state stress. The necessity for keeping the frequency

ratio at 0.8 or less impose one limitation on maximum length. The other limitation is

one of steady state stress considerations, as given by the following equation<

L

max

(K

2

/V) ` w{v(S-K

3

P

0

)/(1+F

m

)}] "6uation >+=

?.ere

L

ma:

C Ma:imum 0alue of L for a 1i0en ser0i/e

0 C !pe/ifi/ 0olume of t.e fluid4 /u ft per l2

P

0

C !tati/ operatin1 1au1e pressure4 psi

&

m

C Ma1nifi/ation fa/tor

@

#

4 @

3

C !tress /onstants o2tained from %a2le73

' C &luid 0elo/it54 fps

! CAllo3a2le stress for material at operatin1 temperature as 1i0en in t.e A!M"

W

o

r

d

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 6 of 11

16-QSP-05-3A

Boiler and Pressure 'essel or Pipin1 $ode4 psi

NOTE

&or 0elo/ities of 300 fps or less4 tapered t.ermo3ells s.all 2e used. &or 0elo/ities in e:/ess

of 300 fps4 a fi:ed 2eam t5pe t.ermo3ell is re/ommended.

TABLE - 1: VALUES OF K

f

Well

Length

L, inches

Nominal Size of Sensing Element, inches

1/4 3/8 9/16 11/16 7/8

#71F# #.0+ #.4# #.B, 3.3# 3.84

471F# #.0, #.4) 3.01 3.3B 3.B+

,71F# #.08 #.4+ 3.0) 3.44 4.03

1071F# #.0B #.4, 3.0+ 3.4+ 4.0+

1+ #.0B #.4, 3.0, 3.4, 4.08

#4 #.0B #.4, 3.0, 3.48 4.0B

TABLE - 2 : WELL DIMENSIONS IN INCHES >R"&"R &IGUR" 1 &R

DIM"(!I(AL D"%AIL!=

Dimensions Nominal Size of Sensing Element, inches

1/4 3/8 9/16 11/16 7/8

A >minimum= 13F1+ 1)F1+ 171F8 171F4 17,F1+

B >minimum= )F8 3F4 1)F1+ 171F1+ 171F4

d >minimum= 0.#)4 0.3,B 0.)++ 0.+B1 0.8,B

d >ma:imum= 0.#+# 0.38, 0.),) 0.,00 0.888

TABLE - 3: VALUES OF STRESS CONSTANTS

Stress

constants

Nominal Size of Sensing Element, inches

1/4 3/8 9/16 11/16 7/8

@

1

0.41# 0.334 0.##3 0.#0# 0.1))

@

#

3,.) 4#.3 4+.8 48., )0.1

@

3

0.11+ 0.#0) 0.38B 0.)48 0.8+4

TABLE - 4: MODULUS OF ELASTICITY, PSI x 10

6

W

o

r

d

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 7 of 11

16-QSP-05-3A

Modulus of "lasti/it5 >"= !pe/ifi/

?ei1.t in

P!I >8= Material %emperature in &

#00 300 400 )00 +00 ,00 800 B00 1000 1100 1#00 1300 1400 1)00 1+00 1800

!!30#

#,.B #,.3 #+., #+.0 #).4 #4.8 #4.# #3.+ #3.0 ##.3 #1.8 #1.# #0.+ #0.0

0.#B

!!304

#,.B #,.1 #+.+ #+.0 #).+ #4., #4.1 #3.# ##.) #1.8 #1.1 #0.4 1B.4 18.1

0.#B

!!30B

#3.1 ##.+ #1.8 #1.# 1B.8 1B.#

0.#B

!!310

#8.# #,.) #+.8 #+.# #).) #4.B #4.# #3.+ #3.0 ##.4 #1.8 #1.# 1B.8 1B.#

0.#B

!!31+

#8.1 #,.) #+.B #+.3 #).+ #4.B #4.# #3.) ##.8 ##.# #1.) #0.8 #0.0 1B.1

0.#B

!!3#1

#8.0 #,.3 #+.) #).8 #).3 #4.) #4.# #3.# ##.) #1.B #1.# #0.4 1B., 1B.1

0.#B

!!34,

#8.# #,.) #+.8 #+.1 #).4 #4.8 #4.1 #3.1 ##.8 ##.0 #1.4 #0., #0.0 1B.4 18.,

0.#B

Allo5 400

#+.8 #,.4 #).+ #4.8 #3., ##.+ #1.3 18.3

0.31B

Allo5 +00

31.0 #B.) #8.0 #+.8 ##.) #4.0 ##.) #1.0

0.304

A10)

#B.) #B.0 #8.3 #+., #).4 #3.8

0.#83

Alum

1100

10.0

0.0B8

(i #00

#B.1 #8.3 #,.4 #+.4 #).#

0.3#1

(i 410

#B.0 #8.3 #,., #,.0 #+.0 #4.8 #3.1 #1.4 1B.,

0.#8

(i 44+

#B.0

0.#,

$opper

14.0

0.3#3

Brass

B.0

0.304

In/ 800

#8.0 #+.+ #4.4 ##.3 #1.1 #0.0 18.,

0.#B

9ast B

30.0 #B., #,.B #+.B #+.0 #4., #3.3 #1.+

0.334

TABLE - 5: ALLOWABLE STRESS VALUES

Allowable Stress Values, PSI (S)

Material

Temperature in F

0 300 500 700 900 1100 1300

!!30# 11#)0.0 11000.0 10#)0.0 B000.0 ,,)0.0 +)00.0

!!304 18,)0.0 13,)0.0 11400.0 10)00.0 10000.0 8#)0.0 3400.0

!!310 18,)0.0 13,)0.0 1))00.0 1)100.0 11+)0.0 8)00.0 3)00.0

!!31+ 18,)0.0 14+00.0 1#+00.0 11300.0 10300.0 B4)0.0 4000.0

!!3#1 18,)0.0 1)300.0 13)00.0 1##00.0 11300.0 B100.0 ##00.0

!!34, 18,)0.0 1)300.0 13)00.0 1##00.0 11300.0 B100.0 ##00.0

Allo5 400 1++00.0 13+00.0 13100.0 13100.0 8000.0

Allo5 +00 #0000.0 18800.0 18)00.0 18)00.0 1+000.0 3000.0

Alum

1100

#3)0.0 18)0.0

W

o

r

d

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 8 of 11

16-QSP-05-3A

Alum +0+17% +000.0 )000.0

(i/;el 10000.0 10000.0 B)00.0

Brass 10000.0 10000.0

In/ 800 1)+00.0 1#100.0 10400.0 B+00.0 B100.0 8800.0 41)0.0

9ast B #)000.0 #4,)0.0 #14)0.0

9ast : #)3)0.0 188)0.0 1+000.0 1))00.0 1))00.0 1))00.0 B)00.0

5.0 EXAMPLE PROBLEM:

Assume t.at it .as 2een determined on t.e 2asis of t.ermometr5 /onsideration t.at a 4

1

F

#

in/.

3ell is re6uired to a//ommodate a BF1+ in/. sensin1 element to measure t.e temperature of

super.eated steam at #400 psi14 10)0

0

&4 flo3in1 at a 0elo/it5 of 300 fps. If t.e 3ell material

is to 2e %5pe 3#1 stainless steel4 3ill t.e 3ell 2e safeG

SOLUTION:

Let us /onsider t.e ne/essar5 data and 0alues of different /onstants from t.e 0arious ta2les.

' C 300 fps

B C 1)F1+ >&rom %a2le 7 #=

@

f

C 3.01 >&rom %a2le 7 1=

L C 4.) in/.

" C #8 * 10

+

psi >&rom %a2le 7 4=

8 C 0.#B l2 per /u in/. >&rom %a2le 7 4=

@

1

C 0.##3 >&rom %a2le 7 3=

! C 134100 psi >&rom %a2le 7 )=

@

#

C 4+.8 >&rom %a2le 7 3=

0 C 0.33)3 /u ft per l2 >&rom 1B+, 7 A!M" !team %a2les=

@

3

C 0.38B >&rom %a2le 7 3=

P

0

C #400 psi1

%.erefeore4 su2stitutin1 t.e 0alues in t.e a2o0e e6uations4 t.e follo3in1 results are o2tained<

f

w

C #.+4 * >300F>1)F1+== C 845 cps >&rom e6uation 7 #=

f

n

C >3.01F>4.)=

#

= * >w >#8*10

+

= F 0.#B= C 14+1 >&rom e6uation 7 3=

%.e 0alue of f

n

is at temperature of ,0

0

&.

%.erefore t.e a/tual 0alue of fn is<

f

n

C 0.B18 * 14+1 C 1341 cps

3.ere 0.B18 is t.e /orre/tion fa/tor

r 845 / 1341 0.63 >&rom e6uation 7 1=

W

o

r

d

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 9 of 11

16-QSP-05-3A

!in/e r H 0.8 t.e 0alue is satisfa/tor5.

F

m

C >0.+3=

#

F >17 >0.+3=

#

= C 0.658 >&rom e6uation 7 4=

P C 0.##3 * 134100 C 2921 psig >&rom e6uation 7 )=

%.e /al/ulated 0alue of t.e ma:imum allo3a2le stati/ pressure is 1reater t.an t.e re6uired

0alue4 3.i/. is satisfa/tor5.

L

max

C >4+.8F300= * > w >>0.33)3 * >13100 7 >0.38B * #400===F >1 I 0.+)8==

C 7.7 inch >&rom e6uation 7 +=

%.is 0alue of L

ma:

is 1reater t.an t.e re6uired 4

1

F

#

in/. t.ermo3ell. 9en/e t.is /ondition is

fulfilled.

Conclusion:

All t.e re6uirements for fre6uen/5 and stress .a0e 2een met4 t.erefore t.e t.ermo3ell 3it.

all t.e a2o0e spe/ifi/ations is satisfa/tor5 in all respe/t for t.e intended ser0i/e.

6.0 LIMITATION:

!iJin1 limitation e:ist 3.en t.e diameter of t.e %ip is in/reased to t.e ma:imum and t.e

len1t. of t.e t.ermo3ell is redu/ed to 1F3

rd

of pipe ID. Redu/in1 len1t. 2elo3 t.is 0alue

3ill not allo3 .eat transfer distri2ution properl5. %o retain t.e len1t. to t.e minimum of t.e

1F3

rd

of t.e pipe ID and also retain t.e tip diameter 3it.in t.e limits t3o alternati0es e:ist.

i= Installation of /ollar<

A /ollar .as to 2e 3elded around t.e t.ermo3ell in a trian1ular s.ape 3it. a

/ur0ature around t.e ed1e of t.e trian1le. %.is 3ill ena2le for eas5 installation

into t.e pipe noJJle 3it.out /reatin1 an5 2lurs. B5 /reatin1 t.e /ollar4 t.e len1t.

is automati/all5 redu/ed sin/e no3 t.e len1t. is measured from t.e /ollar point

to 1F3

rd

of t.e pipe ID to t.ermo3ell tip and t.ere25 ratio DrE ma5 2e a/.ie0ed

3it.in t.e limits. $ollar desi1n is prefer met.od in t.e steel pipe as t.e 0elo/ities

in t.ese pipes rea/. to t.e ma:imum limit.

ii= %.ermo3ell lo/ation<

!e/ond alternati0e met.od is to install t.e t.ermo3ell from t.e 2ottom of t.e

pipe or t.e du/t. B5 t.is met.od in t.e li6uid ser0i/es or in t3o p.ase ser0i/e t.e

t.ermo3ell 3ill 2e totall5 in /onta/t 3it. t.e flo3in1 p.ase t.ere25 esta2lis.in1

a proper .eat transfer 3it. t.e t.ermo3ell. But t.is pra/ti/e is not re/ommended

as t.ere s.all 2e lots of pro2lems from t.e maintainan/e point of 0ie3 and also it

is not safe in /ase t.e fluid in t.e pipe is of /orrosi0e nature.

W

o

r

d

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 10 of 11

16-QSP-05-3A

7.0 APPLICABLE CODES & STANDARDS:

I. A!M" F A(!I P%$ 1B.37Latest "dition

II. A!M" !e/tion 'III Di0ision I4 !e/tion II7D

III. A!M" F A(!I B1+.)4 Pipe &lan1e and &lan1ed &ittin1s

I'. Mar;s !tandard 9and2oo; for Me/.ani/al "n1ineers.

W

o

r

d

DESIGN GUIDE FOR

WAKE FREQUENCY

CALCULATION FOR

THERMOWELL

Std. / Doc. Number Rev.

09-DG-005 0

Sheet 11 of 11

You might also like

- Metallographic Preparation of Cast Iron: Application NotesDocument6 pagesMetallographic Preparation of Cast Iron: Application NotesmarianaNo ratings yet

- Thermo S Workshop Manual PDFDocument75 pagesThermo S Workshop Manual PDFmuki461100% (1)

- Contents DrugDocument6 pagesContents Drugwestcoastaromatics0% (1)

- Sizing OrificeDocument19 pagesSizing OrificeEslamSheblNo ratings yet

- Blowdown Calculation Final Rev B1 PDFDocument23 pagesBlowdown Calculation Final Rev B1 PDFAwwalin Bocah Ilang100% (1)

- Steam Pressure DropDocument8 pagesSteam Pressure DropDavid Muñoz CastroNo ratings yet

- GraduateTraining InstrumentationDocument29 pagesGraduateTraining InstrumentationIslam SolimanNo ratings yet

- Heat Exchanger Sizing AC-6050 #1Document2 pagesHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleNo ratings yet

- Fatigue AssessmentDocument9 pagesFatigue AssessmentvsvineeshNo ratings yet

- Orifice Calc: LiquidDocument1 pageOrifice Calc: LiquidJames R. Lawrence Sr.100% (2)

- 14-A Fluid Flow GeneralDocument26 pages14-A Fluid Flow GeneralSuara84No ratings yet

- PSV 0764 CD Vent KO Drum Liquid Pump - L03Document3 pagesPSV 0764 CD Vent KO Drum Liquid Pump - L03Ebby OnyekweNo ratings yet

- Heat LossDocument36 pagesHeat LossHgagselim SelimNo ratings yet

- Heat Loss Insulated PipeDocument3 pagesHeat Loss Insulated PipeKatie BensonNo ratings yet

- Temperature Effects For High-Velocity Gas FlowDocument5 pagesTemperature Effects For High-Velocity Gas FlowkronafNo ratings yet

- ASME - Wake Frequency CalculationDocument7 pagesASME - Wake Frequency CalculationpsaayoNo ratings yet

- Flange Leakage Check Calculation - Updated On 27-09-2009Document24 pagesFlange Leakage Check Calculation - Updated On 27-09-2009SamNo ratings yet

- PSV Report BlockedDocument5 pagesPSV Report BlockedElias EliasNo ratings yet

- Blowdown OrificeDocument2 pagesBlowdown OrificeOmprakaash MokideNo ratings yet

- Press "CTRL+M" To Calculate C: Calculation of Theoretical Orifice Flow and C For Sharp Edged OrificeDocument14 pagesPress "CTRL+M" To Calculate C: Calculation of Theoretical Orifice Flow and C For Sharp Edged Orificehardik033No ratings yet

- ASME Ver1 4 (Beta)Document2 pagesASME Ver1 4 (Beta)arunradNo ratings yet

- Ognition PSV Sizing Calculation SpreadsheetDocument2 pagesOgnition PSV Sizing Calculation Spreadsheetrisqi ilham zulfahmiNo ratings yet

- Jet Mixing CalculationDocument3 pagesJet Mixing CalculationRachel FloresNo ratings yet

- APITECH 03 DecryptedDocument23 pagesAPITECH 03 Decryptedjokerveloz100% (2)

- 2 Phase Flow Pressure Drop Calc Suresh1Document853 pages2 Phase Flow Pressure Drop Calc Suresh1Phani Raj M100% (1)

- Meter Selection Rev 031Document5 pagesMeter Selection Rev 031andrew_c_potocki902No ratings yet

- Control Valve CalcDocument7 pagesControl Valve Calcartneves100% (1)

- White Paper On Liquid Hydrocarbon Drop Out in Natural Gas InfrastructureDocument30 pagesWhite Paper On Liquid Hydrocarbon Drop Out in Natural Gas InfrastructureHans MuellerNo ratings yet

- Datasheet For Restriction OrificeDocument1 pageDatasheet For Restriction OrificeRajesh Rajesh67% (3)

- A 02Document30 pagesA 02senioor2004No ratings yet

- Nitrogen Purging PDFDocument17 pagesNitrogen Purging PDFgshdavid100% (2)

- Orifice Plate Sizing CalculatorDocument11 pagesOrifice Plate Sizing Calculatormyself_riteshNo ratings yet

- Process Design: Norsok StandardDocument27 pagesProcess Design: Norsok StandardJason ThomasNo ratings yet

- Restriction Orifice Final CalculationDocument1 pageRestriction Orifice Final CalculationJasperTanNo ratings yet

- 10a - Pressure Relief SystemsDocument3 pages10a - Pressure Relief SystemsIslam SolimanNo ratings yet

- 761-V-103 (Vessel With Demister), PDFDocument1 page761-V-103 (Vessel With Demister), PDFAlvin SmithNo ratings yet

- SAD Steam Atomising Desuperheater-Installation Maintenance ManualDocument20 pagesSAD Steam Atomising Desuperheater-Installation Maintenance ManualparykoochakNo ratings yet

- Control Valve Hydraulics-GasDocument6 pagesControl Valve Hydraulics-GasganeshdhageNo ratings yet

- Input From Simulation Result From Table or Chart AssumptionDocument31 pagesInput From Simulation Result From Table or Chart AssumptionMohamed Mamdouh AbdelHameed100% (1)

- Control Valve Sizing - Steam or Vapor Rev 2Document2 pagesControl Valve Sizing - Steam or Vapor Rev 2dilip matalNo ratings yet

- 6b - Tower DesignDocument25 pages6b - Tower DesignIslam SolimanNo ratings yet

- Datasheet For RTD and ThermowellDocument1 pageDatasheet For RTD and ThermowellJeshinNo ratings yet

- Instrument Process Datasheet (IPDS)Document3 pagesInstrument Process Datasheet (IPDS)Vraja KisoriNo ratings yet

- 4 - HX PresentationDRAFT 3Document14 pages4 - HX PresentationDRAFT 3Islam SolimanNo ratings yet

- Flash TanksDocument8 pagesFlash TanksOwen HizriawanNo ratings yet

- V.W.I - 3.0 Theory & PracticalDocument131 pagesV.W.I - 3.0 Theory & Practicalrajesh100% (3)

- Design of Packed Bed Reactor Catalyst Based On Shape Size PDFDocument14 pagesDesign of Packed Bed Reactor Catalyst Based On Shape Size PDFArbaz AKNo ratings yet

- P & I Design LTD: Emergency Relief System (Ers) Sizing Software Methods & PracticeDocument29 pagesP & I Design LTD: Emergency Relief System (Ers) Sizing Software Methods & PracticeATUL SONAWANENo ratings yet

- Manifold PDFDocument32 pagesManifold PDFvivek_enggNo ratings yet

- Control Valve SizingDocument21 pagesControl Valve Sizingatif010No ratings yet

- 40863-001 Calc - Inline Heater PDFDocument3 pages40863-001 Calc - Inline Heater PDFomar equihuaNo ratings yet

- Sizing and Rating BLOWDOWN - ExerciseDocument19 pagesSizing and Rating BLOWDOWN - Exercisepolaris44No ratings yet

- 9 - Process Data InstrumentationDocument7 pages9 - Process Data InstrumentationIslam SolimanNo ratings yet

- Is 600 MM Sufficient To Keep BDV FunctionalDocument0 pagesIs 600 MM Sufficient To Keep BDV Functionalsachin2010No ratings yet

- Petrochemical Processes - 2010Document325 pagesPetrochemical Processes - 2010ERICK MENDEZ100% (1)

- Wake Freequency CalculationDocument5 pagesWake Freequency CalculationManoranjan Kumar ChoudharyNo ratings yet

- Liquid Line SizingDocument8 pagesLiquid Line Sizingsamuad59No ratings yet

- Korf Tutorial PDFDocument17 pagesKorf Tutorial PDFAadi Khan100% (1)

- Aashto T0048 PDFDocument4 pagesAashto T0048 PDFram6265790No ratings yet

- ASTM Equilibrio (Termodinámica)Document31 pagesASTM Equilibrio (Termodinámica)Ryan BeckerNo ratings yet

- FE3003 Ramsey Reset TestDocument4 pagesFE3003 Ramsey Reset TestPrshprshNo ratings yet

- Stage 3 Shutdown Start Up LogDocument21 pagesStage 3 Shutdown Start Up LogVIBHAVNo ratings yet

- Thermal BowingDocument8 pagesThermal BowingA. VenugopalNo ratings yet

- Station: NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 1 of 14Document16 pagesStation: NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 1 of 14sprotkarNo ratings yet

- Article PCC 2-2.X - XX Pressure and Tightness Testing of Piping and EquipmentDocument18 pagesArticle PCC 2-2.X - XX Pressure and Tightness Testing of Piping and EquipmentThamaraikani ManiNo ratings yet

- Monorail Electric HoistsDocument5 pagesMonorail Electric Hoistsvuong0% (1)

- The Pharmaceutical Industry... Interviewing For and Getting That JobDocument35 pagesThe Pharmaceutical Industry... Interviewing For and Getting That Jobvivek_enggNo ratings yet

- Wika 23x 54 Data SheetDocument2 pagesWika 23x 54 Data Sheetvivek_enggNo ratings yet

- Catalog P 8-9-A PDFDocument2 pagesCatalog P 8-9-A PDFvivek_enggNo ratings yet

- Methods of Protection - Intrinsic Safety ExiaDocument1 pageMethods of Protection - Intrinsic Safety Exiavivek_enggNo ratings yet

- PropeneDocument2 pagesPropenemow007100% (1)

- Viscoelastic and Rheological Properties of Syndiotactic 1,2-PolybutadieneDocument4 pagesViscoelastic and Rheological Properties of Syndiotactic 1,2-PolybutadieneAmit Kumar SenNo ratings yet

- Multi-Scale Control of Bunsen Section in Iodine-Sulphur Thermochemical Cycle ProcessDocument16 pagesMulti-Scale Control of Bunsen Section in Iodine-Sulphur Thermochemical Cycle ProcessPorkkodi SugumaranNo ratings yet

- Mineral Water Plant Gayatri DeviDocument24 pagesMineral Water Plant Gayatri DeviRishabh GuptaNo ratings yet

- Radiochemical Stability of Radiopharmaceutical Preparations: IsbnDocument6 pagesRadiochemical Stability of Radiopharmaceutical Preparations: IsbnIin Tirta SunartaNo ratings yet

- Rousselot 160 LB 8 (Pharma)Document2 pagesRousselot 160 LB 8 (Pharma)maha guettariNo ratings yet

- Furance LiningDocument8 pagesFurance LiningAnonymous RQSthBXACfNo ratings yet

- 12 Plate Type Heat ExchangerDocument3 pages12 Plate Type Heat ExchangerBharat ThakorNo ratings yet

- Summative Test in Science 6 Q1 W1-5Document1 pageSummative Test in Science 6 Q1 W1-5RHEA MARIE REYESNo ratings yet

- MDB3033 - Heat TransfersDocument8 pagesMDB3033 - Heat TransfersKamarul Aiman ShariffuddinNo ratings yet

- Is 432 2 1982 PDFDocument14 pagesIs 432 2 1982 PDFAnil Daniel HansNo ratings yet

- MSDS H2oDocument5 pagesMSDS H2oWilanda Tama50% (2)

- Core Material For AircraftDocument34 pagesCore Material For AircraftWarrior TempurNo ratings yet

- Physical Properties:-: Cacl CH Oh Cacl CH Oh MGCL Choh MgclchohDocument8 pagesPhysical Properties:-: Cacl CH Oh Cacl CH Oh MGCL Choh MgclchohA BeheraNo ratings yet

- Problema 12-10 TreybalDocument1 pageProblema 12-10 TreybalMiguel Angel Lugo CarvajalNo ratings yet

- Synthesis of Biodegradable Polymers From Renewable ResourcesDocument16 pagesSynthesis of Biodegradable Polymers From Renewable Resourcesnicholas zxcNo ratings yet

- Unit 14 Structure Elucidation by Integrated Spectroscopic MethodsDocument25 pagesUnit 14 Structure Elucidation by Integrated Spectroscopic Methodscbnnoon222No ratings yet

- Feasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofDocument9 pagesFeasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofUsman MadubunNo ratings yet

- Geolite Modifier 210Document4 pagesGeolite Modifier 210Izziddeen AhmedNo ratings yet

- Simulation Investment CastingDocument19 pagesSimulation Investment CastingtwanNo ratings yet

- Lab2 (Raw Assay)Document18 pagesLab2 (Raw Assay)Lana RaedNo ratings yet

- G7 SoilDocument43 pagesG7 SoilJamika ReyesNo ratings yet

- Solutions - AIATS Medical-2020 (XII Studying) - Test-5 - (Code-A & B) - 22-12-2019 PDFDocument30 pagesSolutions - AIATS Medical-2020 (XII Studying) - Test-5 - (Code-A & B) - 22-12-2019 PDFShashank KashyapNo ratings yet

- Chapter 12 Intermolecular Forces: Liquids, Solids, and Phase ChangesDocument24 pagesChapter 12 Intermolecular Forces: Liquids, Solids, and Phase ChangesGregNo ratings yet

- SterilizationDocument53 pagesSterilizationInam AliNo ratings yet