Professional Documents

Culture Documents

Energy Performance Assessment of Hvac Systems

Uploaded by

Tran Duc GiangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Performance Assessment of Hvac Systems

Uploaded by

Tran Duc GiangCopyright:

Available Formats

9.

ENERGY PERFORMANCE ASSESSMENT OF HVAC

SYSTEMS

9.1 Introduction

Air conditioning and refrigeration consume significant amount of energy in buildings and in

process industries. The energy consumed in air conditioning and refrigeration systems is

sensitive to load changes, seasonal variations, operation and maintenance, ambient conditions

etc. Hence the performance evaluation will have to take into account to the extent possible all

these factors.

9.2 Purpose of the Performance Test

The purpose of performance assessment is to verify the performance of a refrigeration system

by using field measurements. The test will measure net cooling capacity (tons of

refrigeration) and energy requirements, at the actual operating conditions. The objective of

the test is to estimate the energy consumption at actual load vis--vis design conditions.

9.3 Performance Terms and Definitions

Tons of refrigeration (TR): One ton of refrigeration is the amount of cooling obtained by

one ton of ice melting in one day: 3024 kCal/h, 12,000 Btu/h or 3.516 thermal kW.

Net Refrigerating Capacity. A quantity defined as the mass flow rate of the evaporator

water multiplied by the difference in enthalpy of water entering and leaving the cooler,

expressed in kCal/h, tons of Refrigeration.

kW/ton rating: Commonly referred to as efficiency, but actually power input to compressor

motor divided by tons of cooling produced, or kilowatts per ton (kW/ton). Lower kW/ton

indicates higher efficiency.

Coefficient of Performance (COP): Chiller efficiency measured in Btu output (cooling)

divided by Btu input (electric power).

Energy Efficiency Ratio (EER): Performance of smaller chillers and rooftop units is

frequently measured in EER rather than kW/ton. EER is calculated by dividing a chiller's

cooling capacity (in Btu/h) by its power input (in watts) at full-load conditions. The higher

the EER, the more efficient the unit.

9.4 Preparatory for Measurements

After establishing that steady-state conditions, three sets of data shall be taken, at a minimum

of five-minute intervals. To minimize the effects of transient conditions, test readings should

be taken as nearly simultaneously.

Bureau of Energy Efficiency 115

9. Energy Performance Assessment of HVAC Systems

9.5 Procedure

9.5.1 To determine the net refrigeration capacity

The test shall include a measurement of the net heat removed from the water as it passes

through the evaporator by determination of the following:

a. Water flow rate

b. Temperature difference between entering and leaving water

The heat removed from the chilled water is equal to the product of the chilled water flow rate,

the water temperature difference, and the specific heat of the water is defined as follows

The net refrigeration capacity in tons shall be obtained by the following equation:

3024

) ( C x m

(TR) Capacity ion refrigerat Net

p out in

t t x

=

Where m mass flow rate of chilled water, kg/hr

c

p

- Specific heat, kcal/kg

o

C

t

in

Chilled water temperature at evaporator inlet

o

C

t

out

- Chilled water temperature at evaporator outlet

o

C

The accurate temperature measurement is very vital in refrigeration and air conditioning and

least count should be at least one decimal.

Methods of measuring the flow

In the absence of an on-line flow meter the chilled water flow can be measured by the following

methods

In case where hot well and cold well are available, the flow can be measured from the

tank level dip or rise by switching off the secondary pump.

Non invasive method would require a well calibrated ultrasonic flow meter using

which the flow can be measured without disturbing the system

If the waterside pressure drops are close to the design values, it can be assumed that

the water flow of pump is same as the design rated flow.

9.5.2 Measurement of compressor power

The compressor power can be measured by a portable power analyser which would give

reading directly in kW.

If not, the ampere has to be measured by the available on-line ammeter or by using a tong

tester. The power can then be calculated by assuming a power factor of 0.9

Power (kW) = 3 x V x I x cos

Bureau of Energy Efficiency

116

9. Energy Performance Assessment of HVAC Systems

9.5.3 Performance calculations

The energy efficiency of a chiller is commonly expressed in one of the three following ratios:

1.Coefficient of performance

COP = kW refrigeration effect

kW input

2. Energy efficiency ratio

EER = Btu/h refrigeration effect

Watt input

3. Power per Ton

kW/Ton = kW input

Tons refrigeration effect

First calculate the kW/ton rating from the measured parameters.

a)

(TR) capacity ion refrigerat Net

kW power, compressor Measured

rating kW/ton =

Use this data to calculate other energy efficiency parameters with the following relations

COP =0.293 EER EER =3.413 COP

kW/Ton =12 / EER EER =12 / (kW/Ton)

kW/Ton =3.516 / COP COP =3.516 / (kW/Ton)

* Source : American Refrigeration Institute

b)

rating kW/ton

3.516

(COP) e performanc of t Coefficien =

c)

rating ton kW

EER Ratio Efficiency Energy

/

12

) ( =

9.5.4 Performance evaluation of air conditioning systems

For centralized air conditioning systems the air flow at the air handling unit (AHU) can be

measured with an anemometer. The dry bulb and wet bulb temperatures can be measured at

the AHU inlet and outlet. The data can be used along with a psychrometric chart (Figure 9.1)

to determine the enthalpy (heat content of air at the AHU inelt and outlet)

3024 18 . 4

) (

) (

x

h h x m

TR load Heat

out in

=

m mass flow rate of air, kg/hr

h

in

enthalpy of inlet air at AHU, kJ /kg

h

out

enthalpy of outlet air at AHU, kJ /kg

Bureau of Energy Efficiency

117

9. Energy Performance Assessment of HVAC Systems

Heat load can also be calculated theoretically by estimating the various heat loads, both

sensible and latent, in the air-conditioned room (refer standard air conditioning handbooks).

The difference between these two indicates the losses by way of leakages, unwanted loads,

heat ingress etc.

9.6 Measurements to be Recorded During the Test

All instruments, including gauges and thermometers shall be calibrated over the range of test

readings for the measurement of following parameters.

Evaporator

a. Temperature of water entering evaporator

b. Temperature of water leaving evaporator

c. Chilled water flow rates

d. Evaporator water pressure drop (inlet to outlet)

Compressor

e. Power input to compressor electrical power, kW

9.7 Example

In a brewery chilling system, ethylene glycol is used a secondary refrigerant. The designed

capacity is 40 TR. A test was conducted to find out the operating capacity and energy

performance ratios. The flow was measured by switching off the secondary pump and

measuring the tank level difference in hot well.

Measurements data:

Temperature of ethylene glycol entering evaporator =(-) 1

o

C

Temperature of ethylene glycol leaving evaporator =(-) 4

o

C

Ethylene glycol flow rates = 13200 kg/hr

Evaporator ethylene glycol pressure drop (inlet to outlet) = 0.7 kg/cm

2

Power input to compressor electrical power, kW = 39.5 kW

Specific heat capacity of ethylene glycol = 2.34 kCal/kg

o

C

Calculations

3024

) ( C x m

(TR) Capacity ion refrigerat Net

p out in

t t x

=

3024

)) 4 ( 1 ( 34 . 2 x 13200

(TR) Capacity ion refrigerat Net

=

x

= 30.65 TR

Bureau of Energy Efficiency

118

9. Energy Performance Assessment of HVAC Systems

(TR) capacity ion refrigerat Net

kW power, compressor Measured

rating kW/ton =

TR kW / 29 . 1

TR 30.65

kW 39.5

rating kW/ton = =

rating kW/ton

3.516

(COP) e performanc of t Coefficien =

= 3.516

1.29

= 2.73

rating ton kW

EER Ratio Efficiency Energy

/

12

) ( =

= 12

1.29

= 9.3

Bureau of Energy Efficiency

119

9. Energy Performance Assessment of HVAC Systems

Bureau of Energy Efficiency

120

Figure 9.1 Psychrometric Chart

9. Energy Performance Assessment of HVAC Systems

QUESTIONS

1) What is meant by a ton of refrigeration?

2) Define the terms net refrigeration capacity, COP, energy efficiency ratio.

3) What is the relation between COP and kW/ton of refrigeration?

4) How would you calculate the heat load for a room to be air-conditioned?

5) If the power consumed by a refrigerating unit / ton of refrigeration is 2 kW then

find energy efficiency ratio?

REFERENCES

1. Refrigeration and Air Conditioning by Richard C.J ordan & Gayle B.Priester

Prentice Hall of India pvt.ltd.

2. Modern Air Conditioning Practice by Norman C.Harris McGraw-Hill International

Edition.

Bureau of Energy Efficiency

121

You might also like

- 4 CH 9Document7 pages4 CH 9Tusshar KNo ratings yet

- 4 CH 9Document7 pages4 CH 9Arul SankaranNo ratings yet

- COP Calculation of An HVAC SystemDocument7 pagesCOP Calculation of An HVAC SystemAbhishek PangeNo ratings yet

- Energy Performance Assessment of Hvac SystemsDocument4 pagesEnergy Performance Assessment of Hvac SystemsBudihardjo Sarwo SastrosudiroNo ratings yet

- 4.9 HVAC SystemDocument5 pages4.9 HVAC Systembsunanda01No ratings yet

- HVACDocument17 pagesHVACashwini_kumar1984No ratings yet

- Me Lab 8Document7 pagesMe Lab 8BensoyNo ratings yet

- Energy Performance Assessment of Hvac SystemsDocument4 pagesEnergy Performance Assessment of Hvac SystemsKhaled SolimanNo ratings yet

- ME2121-2 Lab ReportDocument14 pagesME2121-2 Lab ReportZu Jian LeeNo ratings yet

- CAUNK9EB Performance Improvement of The Combined Cycle Power Plant by Intake Air Cooling Using ADocument11 pagesCAUNK9EB Performance Improvement of The Combined Cycle Power Plant by Intake Air Cooling Using APeerasak ArunNo ratings yet

- Evaporative Cooling Technical Handbook - MuntersDocument20 pagesEvaporative Cooling Technical Handbook - MuntersradiopascalgeNo ratings yet

- Dougs Thermo 2a Complete Course Work Report FinalDocument23 pagesDougs Thermo 2a Complete Course Work Report Finaldoug2710No ratings yet

- Lab Manual - To Study Refrigeration Cycle, Determine of Coefficient of Performance of Cycle & Determine of Tonnage Capacity of Refrigeration UnitDocument4 pagesLab Manual - To Study Refrigeration Cycle, Determine of Coefficient of Performance of Cycle & Determine of Tonnage Capacity of Refrigeration UnitManikanta BoyinaNo ratings yet

- UtilityDocument8 pagesUtilityAmit JainNo ratings yet

- The Energetic and Exergic Performance of Gas Turbine Cogeneration SystemDocument6 pagesThe Energetic and Exergic Performance of Gas Turbine Cogeneration SystemAneta HaziNo ratings yet

- Problem Chapter 9Document48 pagesProblem Chapter 9Syahid ZamaniNo ratings yet

- Efficiencyt of RacDocument8 pagesEfficiencyt of RacAftab AlamNo ratings yet

- 3.4 HvacDocument8 pages3.4 HvacShehryar01No ratings yet

- Effect of Cooling Water Loop On The Thermal Performance of Air Conditioning SystemDocument14 pagesEffect of Cooling Water Loop On The Thermal Performance of Air Conditioning SystemTricia BiluganNo ratings yet

- Determine Specific Air Capacity Using Air Conditioning UnitDocument13 pagesDetermine Specific Air Capacity Using Air Conditioning UnitTan Xing YanNo ratings yet

- Development of Chilled Water Turbine Inlet Air Cooling Model For Enhancement of Turbine PerformanceDocument8 pagesDevelopment of Chilled Water Turbine Inlet Air Cooling Model For Enhancement of Turbine PerformanceAklilu BahetaNo ratings yet

- CQM TaikooDocument20 pagesCQM TaikooKCFUNGNo ratings yet

- 2-2 Te-2 GTDocument10 pages2-2 Te-2 GTVamsi KrishnaNo ratings yet

- Pressure Ake Int Absolute Stage Last of Pressure e Arg Disch AbsoluteDocument8 pagesPressure Ake Int Absolute Stage Last of Pressure e Arg Disch Absolutemasih tadayonNo ratings yet

- Air Conditioning Lab Final1Document20 pagesAir Conditioning Lab Final1haziqNo ratings yet

- PressorsDocument8 pagesPressorsManoj MisraNo ratings yet

- Increasing Efficiency of Air Conditioning Systems in High Building by Chiller System Load OptimizationDocument7 pagesIncreasing Efficiency of Air Conditioning Systems in High Building by Chiller System Load OptimizationAklilu BahetaNo ratings yet

- ASHRAE Journal SaveChillerPlantEnergyWithGuideline22 2008 - Feb 2010Document4 pagesASHRAE Journal SaveChillerPlantEnergyWithGuideline22 2008 - Feb 2010WahidHamed100% (3)

- COP of Vapor Compression Refrigeration SystemDocument4 pagesCOP of Vapor Compression Refrigeration SystemJowesh Avisheik Goundar50% (4)

- VRF Chiller Data TreatmentDocument5 pagesVRF Chiller Data TreatmentHadiNo ratings yet

- Cooling Load ConvertingDocument3 pagesCooling Load ConvertingAgus Cahyono100% (1)

- The Coefficient of Performance of An Ideal Air Conditioner: Short CommunicationDocument3 pagesThe Coefficient of Performance of An Ideal Air Conditioner: Short CommunicationShantanu SarkarNo ratings yet

- Lecture #03 - Introduction To Refrigeration CyclesDocument15 pagesLecture #03 - Introduction To Refrigeration Cyclesyosri8586No ratings yet

- Me2121-2 Performance Evaluation of Air-Conditioners (E1-03-01)Document11 pagesMe2121-2 Performance Evaluation of Air-Conditioners (E1-03-01)hybri8No ratings yet

- T2. Air Conditioning StudyDocument8 pagesT2. Air Conditioning StudyHaha WoNgNo ratings yet

- Chiller Efficiency ConversionDocument3 pagesChiller Efficiency Conversionsujan1980No ratings yet

- Catalan - Lbyme4a - Ee3 - Design of Experiment - Written ReportDocument5 pagesCatalan - Lbyme4a - Ee3 - Design of Experiment - Written Reportcatalan153709No ratings yet

- Cooling Load CalculationsDocument6 pagesCooling Load CalculationssamuelNo ratings yet

- Prediction of Thermal Performance of Cooling Tower of A Chiller Plant Using Machine LearningDocument8 pagesPrediction of Thermal Performance of Cooling Tower of A Chiller Plant Using Machine LearningHammad PervezNo ratings yet

- Slides Lec 9 HVAC and Refrigeration System PDFDocument28 pagesSlides Lec 9 HVAC and Refrigeration System PDFAhmed JavedNo ratings yet

- Project REMENA-2022Document16 pagesProject REMENA-2022ismail ghourabiNo ratings yet

- Cooling TowersDocument9 pagesCooling TowersTapan KumarNo ratings yet

- Refrigeration & Air ConditioningDocument35 pagesRefrigeration & Air ConditioninglanikhilNo ratings yet

- Condenser and Circulating Water SystemDocument26 pagesCondenser and Circulating Water SystemKhairun NisaNo ratings yet

- Advanced Refrigeration Technology: o o P oDocument6 pagesAdvanced Refrigeration Technology: o o P oDhruvakumar Mallappa0% (2)

- Application of Thermodynamics and Heat Transfer Theories To Analyze Performance Degradation of Air Cooled Condenser (ACC) at Gelugor Power StationDocument4 pagesApplication of Thermodynamics and Heat Transfer Theories To Analyze Performance Degradation of Air Cooled Condenser (ACC) at Gelugor Power StationRudy P. JongNo ratings yet

- RAC Lab VIISem-3-6Document4 pagesRAC Lab VIISem-3-6hoddiploma.meNo ratings yet

- Screenshot 2023-01-11 at 8.11.58 PMDocument15 pagesScreenshot 2023-01-11 at 8.11.58 PMAbdla DoskiNo ratings yet

- Assgmnt Thermal MEC551Document9 pagesAssgmnt Thermal MEC551khazwanNo ratings yet

- AT Question BankDocument3 pagesAT Question BankShubham Vijay JadhavNo ratings yet

- RAC - ME 3rd YearDocument2 pagesRAC - ME 3rd YearVinod yadavNo ratings yet

- National Institute of Technology, Rourkela Heat Transfer and Refrigeration Laboratory: Me471Document8 pagesNational Institute of Technology, Rourkela Heat Transfer and Refrigeration Laboratory: Me471AllenJohnAlexNo ratings yet

- Refrigeracion y Bombas de CalorDocument58 pagesRefrigeracion y Bombas de CalorAnonymous GOKse1EaPNo ratings yet

- Compressors Version 3Document4 pagesCompressors Version 3elpidiozr8229No ratings yet

- Handbook of Energy Data and Calculations: Including Directory of Products and ServicesFrom EverandHandbook of Energy Data and Calculations: Including Directory of Products and ServicesNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- 903 904cDocument2 pages903 904cTran Duc GiangNo ratings yet

- Omron My Series: General Purpose Miniature Power Relays: All Prices in UsdDocument1 pageOmron My Series: General Purpose Miniature Power Relays: All Prices in UsdTran Duc GiangNo ratings yet

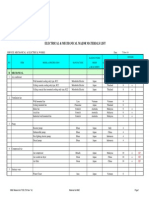

- Cover - M&E Material List TOEI (7th Nov' 14)Document2 pagesCover - M&E Material List TOEI (7th Nov' 14)Tran Duc GiangNo ratings yet

- Calculating Pump PressureDocument1 pageCalculating Pump PressureTran Duc GiangNo ratings yet

- Air Duct CalculatorDocument1 pageAir Duct Calculatoraravoof84No ratings yet

- T6360 Product SpecificationDocument4 pagesT6360 Product SpecificationTran Duc GiangNo ratings yet

- Pressure Loss CalculationDocument1 pagePressure Loss CalculationTran Duc GiangNo ratings yet

- MANUAL NEC National Electrical Code Style ManualDocument3 pagesMANUAL NEC National Electrical Code Style ManualTran Duc GiangNo ratings yet

- Dependence of Earth's Thermal Radiation On Five Most Abundant Greenhouse GasesDocument38 pagesDependence of Earth's Thermal Radiation On Five Most Abundant Greenhouse GasesMaycon Rogers Ribeiro AlvesNo ratings yet

- Spontaneous Infiltration of Non-Cylindrical Porosity: Close-Packed SpheresDocument5 pagesSpontaneous Infiltration of Non-Cylindrical Porosity: Close-Packed SpheresRoland EndrészNo ratings yet

- 304 Circuite ElectroniceDocument4 pages304 Circuite ElectronicesambadeeNo ratings yet

- Analysis of Pipe NetworksDocument14 pagesAnalysis of Pipe NetworksAhmad Sana100% (2)

- CT LastDocument3 pagesCT LastJerick JusayNo ratings yet

- Modelling of Combined Vacuum and Surcharge PreloadDocument6 pagesModelling of Combined Vacuum and Surcharge PreloadAdriel ElezarNo ratings yet

- Chemical and Construction Input Industry Development Institute /C.C.I.I.D.IDocument5 pagesChemical and Construction Input Industry Development Institute /C.C.I.I.D.IEyob HaylemariamNo ratings yet

- Casting Process and Different Types of CastingsDocument31 pagesCasting Process and Different Types of CastingsTejas KumarNo ratings yet

- Sec-Butyl Alcohol Sec-Butyl Acetate N, N-Dimethyl FormamideDocument22 pagesSec-Butyl Alcohol Sec-Butyl Acetate N, N-Dimethyl FormamideCorona MarcUsNo ratings yet

- Gearbox MaintenanceDocument14 pagesGearbox MaintenancemahdiNo ratings yet

- 01-07-Wave Making ResistanceDocument47 pages01-07-Wave Making Resistancerahmahmed200kNo ratings yet

- Design of Automotive DifferentialDocument8 pagesDesign of Automotive DifferentialDeepak ChachraNo ratings yet

- 2015 Nasa Technology Roadmaps Ta 14 Thermal Management FinalDocument97 pages2015 Nasa Technology Roadmaps Ta 14 Thermal Management FinaloxotosNo ratings yet

- Velagapudi Ramakrishna Siddhartha Engineering College::VijayawadaDocument2 pagesVelagapudi Ramakrishna Siddhartha Engineering College::VijayawadaVenkateshNo ratings yet

- STM and ApplicationsDocument40 pagesSTM and ApplicationsMerve Ayvaz KöroğluNo ratings yet

- CH 1 Solid State SsnotesDocument29 pagesCH 1 Solid State SsnotesAnonymous 8VJhV1eI2yNo ratings yet

- Instruction Manual: DS-2000 Series Reflecting and Refracting TelescopesDocument44 pagesInstruction Manual: DS-2000 Series Reflecting and Refracting TelescopesBrandon BohannonNo ratings yet

- 10 139 Apostolopoulos-DimitrovDocument7 pages10 139 Apostolopoulos-Dimitrovsklong138No ratings yet

- Weather - DK Explore Nature With Fun Facts and Activities PDFDocument61 pagesWeather - DK Explore Nature With Fun Facts and Activities PDFLilet Caringal100% (2)

- R0-Sliding Gate, Fence, LadderDocument90 pagesR0-Sliding Gate, Fence, LadderMariam MousaNo ratings yet

- 2016-Exhaust Valve Analysis PDFDocument14 pages2016-Exhaust Valve Analysis PDFAniq Syazwan IINo ratings yet

- Common Ion Effect and Buffer SolutionDocument23 pagesCommon Ion Effect and Buffer Solutionribots2002100% (1)

- Design of Column Base PlatesDocument1 pageDesign of Column Base PlatesMelchizedek EllNo ratings yet

- Low Pressure Drop HVAC Design For LaboratoriesDocument9 pagesLow Pressure Drop HVAC Design For LaboratoriesankNo ratings yet

- Acoustics2 KKDocument8 pagesAcoustics2 KKAanchal BhartiyaNo ratings yet

- Mock XM CPC Science Paper 1Document17 pagesMock XM CPC Science Paper 1nurNo ratings yet

- Gauss Law Lab ExampleDocument6 pagesGauss Law Lab ExampleAnthony MajinianNo ratings yet

- Piezo Low FrequencyDocument21 pagesPiezo Low Frequencygastelum fernandezNo ratings yet

- Heat Ad Mass Transfer in A Cooling Tower With Special Attention To The Tower Characteristic RatioDocument5 pagesHeat Ad Mass Transfer in A Cooling Tower With Special Attention To The Tower Characteristic RatioAathithyayanSoundararajanNo ratings yet

- EM Paper 1Document1,156 pagesEM Paper 1sCience 123No ratings yet