Professional Documents

Culture Documents

ARP1383

Uploaded by

chrisrae23Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ARP1383

Uploaded by

chrisrae23Copyright:

Available Formats

SAE Technical Standards Board Rules provide that: This report is published by SAE to advance the state of technical

and engineering sciences. The use of this report is entirely

voluntary, and its applicability and suitability for any particular use, including any patent infringement arising therefrom, is the sole responsibility of the user.

SAE reviews each technical report at least every five years at which time it may be reaffirmed, revised, or cancelled. SAE invites your written comments and suggestions.

Copyright 2003 Society of Automotive Engineers, Inc.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written permission of SAE.

TO PLACE A DOCUMENT ORDER: Tel: 877-606-7323 (inside USA and Canada)

Tel: 724-776-4970 (outside USA)

Fax: 724-776-0790

Email: custsvc@sae.org

SAE WEB ADDRESS: http://www.sae.org

AEROSPACE

RECOMMENDED

PRACTICE

ARP1383

REV.

B

Issued 1978-03

Revised 2003-02

Superseding ARP1383A

(R) Impulse Testing of Aerospace Hydraulic Actuators, Valves,

Pressure Containers, and Similar Fluid System Components

NOTICE

Some test procedures are potentially dangerous. SAE Technical Reports do not purport to address all

of the safety problems, if any, associated with their use. It is the responsibility of the user of an SAE

Technical Report to establish and employ appropriate safety practices. Tests should only be conducted

by individuals who have been properly trained in test procedure and who are aware of any hazards

which may be present. Appropriate safety and health procedures must be employed when conducting

any test.

1. SCOPE:

This SAE Aerospace Recommended Practice (ARP) establishes the minimum requirements and

procedures for impulse testing of aerospace hydraulic actuators, valves, pressure containers, and

similar fluid system components, for use in aerospace hydraulic systems; for exceptions, see

paragraph 9.1. This ARP also refers to standard impulse test equipment, which may be used in

conducting these impulse tests.

2. REFERENCES:

2.1 Applicable Documents:

The following publications form a part of this document to the extent specified herein. The latest

issue of SAE publications should apply. The applicable issue of other publications shall be the issue

in effect on the date of the purchase order. In the event of conflict between the text of this document

and references cited herein, the text of this document takes precedence. Nothing in this document,

however, supersedes applicable laws and regulations unless a specific exemption has been

obtained.

SAE ARP1383 Revision B

- 2 -

2.1.1 SAE Publications: Available from SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.

ARP603 Impulse Testing of Hydraulic Hose Assemblies, Tubing, Fittings

AIR1228 Standard Impulse Machine Equipment and Operation

AS4265 Impulse Testing of Hydraulic Tubing and Fittings, S-N Curve

AIR4298 Impulse Test Machine, Sine Wave, Equipment and Operation of

2.1.2 U.S. Government Publication: Available from DODSSP, Subscription Services Desk, Building 4D,

700 Robbins Avenue, Philadelphia, PA 19111-5094.

MIL-HDBK-5 Metallic Materials and Elements for Aerospace Vehicle Structures

2.1.3 NFPA Publication: Available from the National Fluid Power Association, 3333 N. Mayfair Road,

Milwaukee, WI 53222-3218.

NFPA/T2 .6.1 Fluid power components - Method for verifying the fatigue and establishing the burst

pressure ratings of pressure containing envelope of a metal fluid power component

2.2 Definitions:

2.2.1 Miners Rule: Palmgren-Miner cycle-ratio summation theory, also known as Miner's rule, may be

expressed as:

A method that may be used to approximate the cumulative fatigue damage at a point in a metallic

part from the repeated exposure to cycles of various stress levels. For given maximum and

minimum stress levels, the fatigue life in terms of the number of cycles is found from a S/N curve.

The damage fraction is the applied number of cycles divided by the fatigue life. The fractional

damage amounts for each stress level are added together to calculate the total fatigue damage.

Cumulative fatigue damage greater than or equal to 1 indicates that the part will fail.

2.2.2 Rate of Rise: The rate of rise is defined as the slope of the pressure-time curve in the straight

portion of the initial pressure increase portion between 10% of the total rise above back pressure

and 10% of the total rise below peak pressure.

2.2.3 Cycle: The time from minimum pressure to maximum pressure and back to minimum pressure

(see Figures 1, 2 and 3).

2.2.4 Dwell time (Time at Pressure): The time for which the pressure exceeds the lower tolerance for

P(max).

2.2.5 P(max): The maximum supply cavity test pressure.

2.2.6 P(min): The minimum return pressure experienced in normal operation.

SAE ARP1383 Revision B

- 3 -

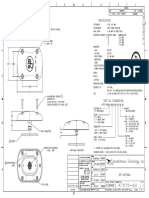

FIGURE 1 - Supply Cavity and Return Cavity Impulse Waveform

SAE ARP1383 Revision B

- 4 -

FIGURE 2 - Alternate Impulse Trace - Damped Wave

SAE ARP1383 Revision B

- 5 -

FIGURE 3 - Alternate Impulse Trace Sine Wave

2.2.7

2.2.8 P(oper): The nominal system design operating pressure.

2.2.9 PR: The nominal return line design pressure.

2.2.10 PR(max): The maximum return cavity test pressure.

P(Mean)

P(Max) P(Min)

2

------------------------------------------- =

SAE ARP1383 Revision B

- 6 -

3. REQUIREMENTS:

The pressure-impulse test is basically an accelerated fatigue test. This document defines the impulse

test procedures recommended for the hydraulic equipment listed in SCOPE.

The procedure is divided into two categories:

CATEGORY I: GENERICALLY DERIVED TEST REQUIREMENTS

CATEGORY II: SPECIFICALLY DERIVED TEST REQUIREMENTS

3.1 Category I: Generically Derived Test Requirements:

This category is applicable to generic aerospace hydraulic equipment impulse testing, with

recommended pressure levels and test cycle requirements being provided. The pressure and return

cavities of the component should be tested, as a minimum, to the number of pressure impulse cycles

defined below for the applicable aircraft classification.

3.1.1 Fixed Wing Aircraft:

(1) Flight control actuators/valves/components, P(max) = 1.5 x P(oper), 200,000 cycles

(2) Utility actuators/valves/components, P(max) = 1.5 x P(oper), 100,000 cycles

(3) Return ports/passages and components subjected to return pressure only, PR(max) = PR x

1.5, 100,000 cycles, with PR taken as 0.5 x P(oper)

3.1.2 Rotary Wing Aircraft:

(1) Primary flight control actuators: 1,000,000 cycles, P(max) = 1.5 x P(oper)

(2) Secondary flight control actuators: 1,000,000 cycles, P(max) = 1.5 x P(oper)

(3) Utility actuators: 300,000 cycles, P(max) = 1.5 x P(oper)

(4) Flight control system hydraulic components: 1,000,000 cycles, P(max) = 1.5 x P(oper)

(5) Utility system hydraulic components: 300,000 cycles, P(max) = 1.5 x P(oper)

(6) Return ports/passages and components subjected to return pressure only: 300,000 cycles,

PR(max) = 1.5 x PR with PR taken as 0.5 x P(oper)

(7) S-N curve generation. In addition to meeting the criteria specified in 1 through 6 above, a S-N

curve should be generated for critical components in the rotary-wing aircraft hydraulic system.

Unless otherwise specified, a minimum of six specimens should be utilized for testing. See

Appendix A for additional data on S-N curve generation and usage.

SAE ARP1383 Revision B

- 7 -

3.2 Category II: Specifically Derived Test Requirements:

Category II is applicable to all aircraft configurations (including helicopters), both military and

commercial, where the test requirements are derived from specifically related system values.

The number of test cycles are to produce equivalent fatigue damage, when the component is tested

at the design operating pressure, using the selected wave form (see Figures 1, 2 or 3), to the

damage the component is expected to receive during the lifetime of the applicable aircraft. The

determination of the number of test cycles must consider both mean and alternating stresses for in-

service, ground, and test operations of the aircraft during its expected life. The cycles at various

stress levels are combined by Miners Rule to determine the number of equivalent cycles at the

design operating pressure. Appendix B provides details of the method to be used to determine test

cycles by means of an example. Because in this example only one unit is tested during qualification,

it is necessary for additional cycles to be performed to verify reliability. (Example: to demonstrate

95% reliability with 95% confidence, it would be necessary to test four lifetimes of one unit). For

guidance on the testing of multiple samples, to obtain specific confidence levels, see NFPA/T2.6.1.

UNLESS OTHERWISE SPECIFIED, THE FOLLOWING GENERAL REQUIREMENTS ARE

APPLICABLE TO TEST CATEGORIES I AND II.

3.3 Test Conditions:

When this document is referenced in a design specification as part of the requirements, the following

additional requirements must be specified:

a. Number of test cycles (for Category I testing, see 3.1; for Category II testing, see 3.2)

b. Test pressures for all cavities

c. Operating temperature(s) (see 4.4)

d. Fluid (see 4.5)

e. Wave shape (figure number if other than Figure 1) (see 4.1)

f. Component/valve position (see 6.3.1)

g. Minimum return line pressure and return line design pressure (for Category I testing see 3.1; for

Category II testing see 3.2)

h. Number of actuator cycles extended and retracted and position, if applicable (see 6.3.2)

i. Cycling rate and tolerance (see 4.3)

j. Layering requirements (sequential test condition(s) groupings)

SAE ARP1383 Revision B

- 8 -

3.3 (Continued):

k. Pressure transients/surges (pressure and return if known) (see 4.1)

l. When a S-N curve is to be developed and if less than 6 specimens are permitted (see Section 7)

m. Any post fatigue performance tests that must be satisfactorily completed (see 8.1)

4. GENERAL TEST REQUIREMENTS:

4.1 Shape of the Impulse Cycle:

The limits shown in Figure 1 define the pressure-time cycle for both pressure and return cavities

when observed on an oscilloscope and instrumented per AIR1228. Alternative pressure-time cycles

for the pressure and return cavities are shown in Figures 2 and 3.

The dynamic impulse trace, produced by the test machine, should be in conformance with Figures 1,

2 or 3 as applicable, and the actual pressure-time curve should be confined to the area shown.

4.2 Rate of Rise:

The rate of rise should be in accordance with Figures 1, 2 and 3, and as defined in 2.2.2.

4.3 Cycling Rate:

4.3.1 A cycling rate of 1 Hz is recommended. Consideration should be given to other cycling rates when

pressures must penetrate between close fitting parts or restrictions and where hysteresis can affect

stresses. Cycling rates up to 5 Hz may be allowed for small components, with actual cycling rate

defined in the component specification.

4.3.2 See Figures 1 through 3 for suggested pressure waveforms. Verify that peak pressures are within

their specified tolerances. Note restrictions when using the Damped Wave Impulse Trace (Figure

2) (see 4.3.4).

4.3.3 For test cycling rates exceeding 1 Hz the stress level of at least one test sample should be verified

by analysis or by strain gauge.

4.3.4 The following additional verifications are recommended for impulse tests where the cyclic rate

exceeds 1Hz, or when employing a Damped Wave Impulse Trace (Figure 2).

a. Verify by strain gauge or analysis that the ratio of induced stress to pressure at the test cycling

rate is the same as during the static loading.

b. Verify that temperatures of the test component are within allowable limits.

SAE ARP1383 Revision B

- 9 -

4.4 Temperature:

The fluid temperature during testing should be maintained at the nominal component operating

temperature within +15 to 0 C (+27 to 0 F). The nominal component operating temperature should

be specified in the detail specification. Components which operate at more than one stabilized

temperature, such as during subsonic cruise and during supersonic flight, should be tested at each

temperature for approximately the same percentage of time predicted for operation during service as

defined in the detail specification.

4.5 Test Fluid:

The fluid used for the test should be the service fluid of the component undergoing test unless

specified otherwise.

5. TEST EQUIPMENT:

The test setup should produce repeatable pressure pulses within the limits defined in 4.1.

5.1 Accuracy:

The test equipment and instrumentation should be set up and maintained so that all data is accurate

within 4% of the maximum actual value unless otherwise specified. Temperature recording accuracy

should be maintained at 3 C (5 F).

5.2 Oscilloscope:

Where oscilloscopes are utilized to record the cycle shape, the sweep rate on the oscilloscope

should be adjusted so that the slope of the pressure rise takes advantage of the full size of the

screen. The trace and photos of the impulse cycle should be an accurate record of the impulse cycle

and show a grid or other means to permit accurate checking.

6. TEST PROCEDURE:

The method of testing is intended to determine the ability of hydraulic actuators, valves, and pressure

containers (for exceptions see 9.1) to withstand the hydraulic pressure-impulse cycling for qualification

testing.

SAE ARP1383 Revision B

- 10 -

6.1 Selection of Specimen:

The test specimen should meet the following criteria:

a. The unit should be a production unit or representative of production. Conservative substitutions,

adequately substantiated by the equipment manufacturer are acceptable. Material Review Board

(Group that provides dispositions/corrective actions for discrepancies occurring in the

manufacturing process) actions should be documented and reviewed for effect on test validity.

b. The unit should not have been previously subjected to loads exceeding the limit load or

pressures exceeding proof pressure, unless such application of load or pressure is a normal step

in the production process. Any yielding, however microscopic, in stress concentration areas may

result in unrealistic fatigue life.

c. The unit should not have been previously subjected to vibration tests or other fatigue type tests.

The life capability used up in such tests may result in unrealistic low pressure-impulse fatigue life.

6.2 Preparation of Specimen:

Prior to pressure-impulse testing, the unit should be disassembled and thoroughly examined for

cracks or structural failure or flaws in accordance with production requirements, such as, visually and

by use of fluorescent-penetrant, ultrasonic or magnetic-particle inspection. The inspection of test

specimen for flaws prior to testing shall not include any inspections not required for production units.

It should then be reassembled with new seals, proof pressure tested, and given a baseline functional

test including measurement of internal and external leakage prior to pressure-impulse testing. This

requirement may be waived if the unit is inspected prior to assembly and impulse testing is the first

qualification type test imposed on the test specimen.

The production acceptance test may be used to satisfy requirements for initial baseline test

requirements pertinent to impulse testing and may eliminate non-pertinent tests such as frequency

response, insulation resistance, no-load velocity, etc.

NOTE: A component should not be subjected to a proof pressure test prior to the pressure impulse

test if it does not have a proof test as part of its ATP (Acceptance Test Procedure).

6.3 Test Setup:

All entrapped air should be bled as well as possible from the test component and test circuit. All

drains and low-pressure ports that are not part of the area under test should be allowed to drain

freely and kept at atmospheric pressure. Metal shot or loosely fitting metal pieces may be placed in

the test unit if desired to minimize fluid volume. Measurement of the pressure cycle shall be made as

close to the test specimen as is practical.

SAE ARP1383 Revision B

- 11 -

6.3.1 Valve Positions: Variable-position valves, such as directional-control valves and servovalves,

should be tested at their various positions so that each port and chamber is appropriately stressed.

The total number of pressure-impulse cycles should be apportioned and applied at each position in

approximately the same percentage expected in service. Simplifying tests should not result in

undertesting any area. However, no chamber should see less than the number of cycles

appropriate to the procedure selected.

6.3.2 Actuator Piston Positions: Actuating cylinders should be tested so that the pressure application

should reflect conditions of operation. For example, if both sides of a piston are pressurized

simultaneously during operation, then the test conditions should reflect this condition. In addition,

actuating cylinders should be tested so that all elements exposed to fluid pressure are

appropriately stressed. Unless otherwise specified in the detail procurement specification,

actuators should be tested with the piston rod restrained in mid-position and the maximum number

of cycles should then be applied in the retract pressurized direction. The required number of

impulse cycles should then be repeated with pressure applied to the extend direction. Pressure

should not be applied simultaneously to extend and retract directions. Servoactuators should see

the full impulse range P(max) to PR during impulse testing.

6.3.3 Inlet Check Valves: For impulse testing of pressure vessels containing inlet check valves, the inlet

check valve should be removed to obtain full pressure excursions for all valve components during

testing.

6.3.4 Dual Pressure Systems: Components which operate at more than one pressure level, such as in

dual pressure level systems, should be tested at each pressure level. The percentage of the total

impulse test cycles, which are run at the higher pressure, should be equivalent to twice the

percentage of the operating time at that (higher) pressure, predicted in service. For Category 1

testing, the apportioning (percentage) of the cycles to be run at the higher pressure should be

defined in the detail specification.

6.4 Impulse Test:

The impulse test should be conducted as required under Section 3 and the detail specification.

Where applicable (i.e., Category II), the impulse test should be conducted in cyclical layers with each

layer including no more than the total number of pressure-impulse cycles expected during the

components service life. If testing is done at more than one fluid temperature or test position, those

variables should be interspersed within each layer in the same proportions expected in service.

After completion of each test layer, the external surfaces of the component should be visually

examined for cracks, leaks, or other evidence of structural failure. Then, before proceeding with the

next test layer, the baseline performance should be rerun and the results, including internal and

external leakage, recorded. Elastomeric, plastic, or other nonstructural wear sensitive components

may be replaced prior to proceeding to the next test layer.

SAE ARP1383 Revision B

- 12 -

6.4 (Continued):

If seals or gaskets are replaced during testing, it is recommended that the torque required to remove

any fasteners be recorded and that on reinstallation, these fasteners be torqued to the same value

as determined during removal. Thus if the prestress has been reduced during the cycles previously

conducted, the test is resumed at conditions similar to those conditions before seal replacement was

necessary.

7. S-N CURVE:

If specified (see 3.3[l]), a S-N curve should be generated for critical components. Unless otherwise

specified, a minimum of six specimens should be utilized for testing. See Appendix A for additional

data on S-N curve generation and usage.

8. POST TEST REQUIREMENTS:

8.1 Performance After Test:

The component should conform to the post impulse test performance requirements specified after

completion of the impulse cycling (see 3.3[m]). Depending upon the test procedure used,

performance testing may or may not be required.

8.2 Component Verification:

Upon completion of post test performance tests specified, the unit should be disassembled and

inspected for cracks or structural failure. The presence of detectable cracks constitutes failure unless

otherwise determined by the procuring activity. If a post test performance test is required and any

performance characteristic fails to meet the requirements specified in the detail specification, the unit

should be reassembled with new seals, proof tested, and re-subjected to the post test performance

requirements (see 8.1) to determine the reason for deteriorated performance.

8.3 Approval:

Designs are considered acceptable if no cracks or other structural damage occur during or as a

result of the impulse test. Alternatively, in less critical circumstances where some degree of

performance degradation is considered acceptable, the detail specification should specify the

associated allowable conditions, such as, maximum acceptable crack size, inspection methods and

procedures to be employed (example: Visual; with degree of magnification, Penetrant, and/or

Magnetic Particle Inspections), and the resulting minimum acceptable performance requirements. If

unacceptable performance degradation is found following the first layer of a multilayer test, the test

should be interrupted until corrective redesign or part replacement is implemented.

SAE ARP1383 Revision B

- 13 -

9. NOTES:

This section does not contain mandatory requirements and is for information only.

9.1 Intended Use:

This document, as indicated by the Scope (Section 1) is intended for use as a standard for impulse

test requirements and procedures for qualification and evaluation testing of the hydraulic system

components indicated. This document does not apply to the impulse testing of the following hydraulic

components; where known the applicable impulse test document is noted.

9.2 Key Words:

Test, cycling rate, wave form, fatigue test

9.3 The change bar ( l ) located in the left margin is for the convenience of the user in locating areas

where technical revisions, not editorial changes, have been made to the previous issue of this

document. An (R) symbol to the left of the document title indicates a complete revision of the

document.

PREPARED UNDER THE JURISDICTION OF

SAE COMMITTEE A-6, AEROSPACE FLUID POWER, ACTUATION,

AND CONTROL TECHNOLOGIES

TABLE 1

Components Refer to

Hydraulic Accumulators

Hydraulic Pump and Motor Rotating Elements AS7997 & AS19692

Hydraulic Hose Assemblies, Tubing, and Fittings ARP603 & AS4265

SAE ARP1383 Revision B

- 14 -

APPENDIX A

S-N CURVE GENERATION

A.1 SCOPE:

This appendix specifies the procedure to be used in preparation of S-N curves as required by 3.1.2

(7) Category I, and where required in detail specifications (see Section 7).

A.2 APPLICABLE DOCUMENTS:

This section in not applicable to this appendix.

A.3 REQUIREMENTS:

A.3.1 Upon completion of test, plot the test point(s) as an S-N plot. Designate point(s) as either a run-out

(no test failure for the number of cycles tested) or failure point (see legend, Figure A1).

A.3.2 Draw the appropriate curve through the point(s) using the equivalent data point routine. Mean

endurance limit is acceptable for a mix of fractures and run-outs. For run-outs the highest run-out

may be used to establish the mean S-N curve (Figure A1). The low cycle reduction allows for

increased scatter factor at low number of cycles.

A.3.3 Construct a working curve based on the number of samples tested. (The smaller the number of test

specimens the greater the reduction in allowables in the mean S-N curve). The working curve

using the three sigma scatter factor is appropriate (Figures A1, A2, and A3).

A.3.4 When one specimen is tested, whether a significant run-out or fracture, a 50% reduction in the

mean endurance (one-half of the mean curve pressure values at any given number of cycles) shall

be used unless otherwise specified by the procuring agency (Figure A4). This procedure may be

used to establish interim life of the component.

A.3.5 The working S-N curve shall be used to calculate the component life or replacement time.

SAE ARP1383 Revision B

- 15 -

FIGURE A1 - S-N Curves

FIGURE A2 - S-N Curves

SAE ARP1383 Revision B

- 16 -

FIGURE A3 - S-N Curves

FIGURE A4 - S-N Curves

SAE ARP1383 Revision B

- 17 -

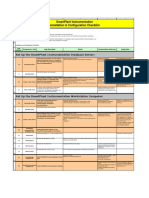

APPENDIX B

DETERMINATION OF TEST CYCLE REQUIREMENTS USING CATEGORY II

B.1 SCOPE:

This appendix presents an example to show how the number of test cycles applicable to 3.2

Category II can be determined for an application.

B.1.1 To use Category II of this document it is necessary to define the unique characteristics of the

fatigue cycles to be encountered during the life of each individual component to be evaluated and

determine the number of equivalent cycles at test pressure limits. The following example uses an

aileron actuator for a commercial airplane to illustrate the method recommended. This component,

used as an example, has two details that may be sensitive to fatigue and the analysis includes

many of the aspects typifying duty cycle definition. The actuator manifold and cylinder barrel are

pressure vessels for which the duty cycle is defined by pressure limits between zero and operating

pressure. The piston rod and rod end experience reversing loads during actual service. The piston

rod assembly may be tested concurrently with the cylinder by applying impulse pressure

alternately to opposing ends of the piston. Table B1 shows a summary of the determination of the

test cycle requirements for this actuator. The following text describes the procedure for defining

test cycles and applies it to the example.

B.2 APPLICABLE DOCUMENTS:

B.2.1 U.S. Government Publications:

Available from DODSSP, Subscription Services Desk, Building 4D, 700 Robbins Avenue,

Philadelphia, PA 19111-5094.

MIL-HDBK-5 Metallic Materials and Elements for Aerospace Vehicle Structures

SAE ARP1383 Revision B

- 18 -

T

A

B

L

E

B

1

-

D

e

t

e

r

m

i

n

a

t

i

o

n

o

f

F

a

t

i

g

u

e

T

e

s

t

C

y

c

l

e

s

T

y

p

i

c

a

l

A

i

l

e

r

o

n

A

c

t

u

a

t

o

r

,

6

2

,

0

0

0

F

l

i

g

h

t

s

-

1

L

i

f

e

(

R

e

f

e

r

e

n

c

e

s

t

o

p

r

o

c

e

d

u

r

e

s

t

e

p

s

i

n

t

e

x

t

a

r

e

i

n

d

i

c

a

t

e

d

b

y

<

x

>

)

<

1

>

F

l

i

g

h

t

S

e

g

m

e

n

t

<

1

>

F

l

i

g

h

t

S

e

g

m

e

n

t

~

/

f

l

t

n

/

f

l

t

<

1

>

F

l

i

g

h

t

S

e

g

m

e

n

t

n

c

y

c

l

e

s

o

n

e

l

i

f

e

M

a

n

i

f

o

l

d

D

e

t

a

i

l

m

i

n

p

r

e

s

s

p

s

i

M

a

n

i

f

o

l

d

D

e

t

a

i

l

m

a

x

p

r

e

s

s

p

s

i

M

a

n

i

f

o

l

d

D

e

t

a

i

l

m

i

n

s

t

r

e

s

s

k

s

i

M

a

n

i

f

o

l

d

D

e

t

a

i

l

m

a

x

s

t

r

e

s

s

k

s

i

M

a

n

i

f

o

l

d

D

e

t

a

i

l

(

N

)

M

a

n

i

f

o

l

d

D

e

t

a

i

l

(

n

/

N

)

R

o

d

E

n

d

T

h

r

e

a

d

D

e

t

a

i

l

m

i

n

p

r

e

s

s

p

s

i

R

o

d

E

n

d

T

h

r

e

a

d

D

e

t

a

i

l

m

a

x

p

r

e

s

s

p

s

i

R

o

d

E

n

d

T

h

r

e

a

d

D

e

t

a

i

l

m

i

n

S

t

r

e

s

s

k

s

i

R

o

d

E

n

d

T

h

r

e

a

d

D

e

t

a

i

l

m

a

x

S

t

r

e

s

s

k

s

i

R

o

d

E

n

d

T

h

r

e

a

d

D

e

t

a

i

l

(

N

)

R

o

d

E

n

d

T

h

r

e

a

d

D

e

t

a

i

l

(

n

/

N

)

R

o

d

E

n

d

T

h

r

e

a

d

D

e

t

a

i

l

<

1

>

<

1

>

<

3

>

<

3

>

<

4

>

<

5

>

<

1

>

<

1

>

<

3

>

<

3

>

<

4

>

<

5

>

C

o

n

t

r

o

l

s

C

h

e

c

k

2

1

.

2

5

x

1

0

5

7

5

0

2

2

5

0

1

2

.

5

3

7

.

5

5

x

1

0

4

2

.

5

-

1

5

0

0

1

5

0

0

-

4

0

.

0

4

0

.

0

4

x

1

0

4

3

.

1

2

5

C

r

u

i

s

e

4

3

5

2

.

7

x

1

0

7

1

9

8

0

2

0

5

0

3

3

.

0

3

4

.

3

0

9

6

0

1

1

1

0

2

5

.

6

2

9

.

6

0

R

o

l

l

M

a

n

e

u

v

e

r

4

0

2

.

5

1

0

6

2

1

6

0

2

5

9

5

3

6

.

0

4

3

.

3

5

x

1

0

8

0

.

0

0

5

1

3

2

0

2

1

9

0

3

5

.

2

5

8

.

4

0

O

n

-

O

f

f

1

6

.

2

x

1

0

4

0

1

5

0

0

0

2

5

.

0

3

x

1

0

5

0

.

2

1

-

-

-

-

-

-

-

-

-

-

-

-

G

-

A

-

G

C

y

c

l

e

<

2

>

1

6

.

2

x

1

0

4

0

2

5

9

5

0

4

3

.

3

1

x

1

0

4

6

.

2

-

1

5

0

0

2

1

9

0

-

4

0

.

0

5

8

.

4

2

x

1

0

4

3

.

1

(

n

/

N

)

<

5

>

8

.

9

1

5

6

.

2

2

5

n

/

N

T

e

s

t

P

r

e

s

s

<

6

>

-

1

5

0

0

1

5

0

0

-

4

0

.

0

4

0

.

0

4

x

1

0

4

3

.

1

2

5

n

T

e

s

t

<

7

>

2

.

4

9

x

1

0

5

SAE ARP1383 Revision B

- 19 -

B.3 REQUIREMENTS:

B.3.1 Step 1, Determine Manufacturers Design Requirements:

Obtain from the aircraft manufacturer a definition of the load cycles (in terms of the fluctuations of

hydraulic pressure) that the component experiences during normal operation, the number of times

each load cycle is repeated during one flight, and the number of flights in the aircraft lifetime. For

components that experience reversing loads, this requires definition of pressures on either side of

the piston.

B.3.2 Step 2, Determine the Ground-Air-Ground Pressure Cycle:

Determine the maximum peak-to-peak pressure variation that occurs during one flight using the

data from Step 1.

TABLE B2 - Aircraft Manufacturers Data for the Example Chosen

Duty Conditions Manifold/Cylinder Detail Rod/Rod End Detail

One life = 62,000 flights 7075-T6 Aluminum AISI 4340, H.T. to 200 ksi

3000 psig design pressure K

t

= 3 in control pressure K

t

= 3 in threads

Flight segments pressure fluctuations pressure fluctuations

- controls check approx 2/flt 750/2250 psi -1500/1500 psi

- cruise

1

approx 435/flt 1980/2050 psi 960/1100 psi

- roll

1

approx 40/flt 2160/2595 psi 320/2190 psi

- on/off approx 1/flt 0/1500 psi -

NOTE: Large load offset from neutral during flight cycles.

TABLE B3 - G-A-G Cycle for the Example Chosen

Pressure Range Component Element

0 to 2595 psig Manifold

-1500 to 2190 psig Rod End

SAE ARP1383 Revision B

- 20 -

B.3.3 Step 3, Determine the Stress Cycle:

Select a stress/pressure ratio consistent with the materials and type of construction used in the

component. Refer to the notes at the conclusion of this appendix for suggestions related to making

this selection.

Apply the ratio K to the pressures from Steps 1 and 2 and to define the stress cycle for each flight

segment.

B.3.4 Step 4, Determine the Life Cycle Expectancy:

Identify a curve in MIL-HDBK-5C that most closely relates to the material and condition being

analyzed. See Figures B1 and B2 related to example chosen. Determine from the intersection of

lines representing minimum stress and maximum stress, using the results for each segment in

Step 3, the life cycle expectancy (N) in cycles for each segment.

TABLE B4 - Stress/Pressure Ratio for the Example Chosen

Component Element Stress Pressure K Factor

Manifold 50,000 psi 3000 psi 16.7

Rod End 80,000 psi 3000 psi 26.7

TABLE B5 - Stress Cycle for the Example Chosen

Flight

Segment

Manifold

Pressure

(psi)

min

Manifold

Pressure

(psi)

max

Manifold

K

Manifold

Stress

(ksi)

min

Manifold

Stress

(ksi)

max

Rod End

Pressure

(psi)

min

Rod End

Pressure

(psi)

max

Rod End

K

Rod End

Stress

(ksi)

min

Rod End

Stress

(ksi)

max

Controls Chk. 750 2250 16.7 12.5 37.5 -1500 1500 26.7 -40.0 40.0

NOTE: See Table B1 for data on remainder of flight segments.

SAE ARP1383 Revision B

- 21 -

FIGURE B1 - Example - Typical Constant Life Diagram, 7075T6 Aluminum Alloy

Data from MIL-HDBK-5C Figure 3.7.3.1.8(D) Detail Omitted for

Clarification of Example

TABLE B6 - Life Cycle Expectancy for the Example Chosen

Flight Segment

Manifold

Stress

(ksi)

min

Manifold

Stress

(ksi)

max

Manifold

MIL-HDBK-5C

Manifold

N

Rod End

Stress

(ksi)

min

Rod End

Stress

(ksi)

max

Rod End

MIL-HDBK-5C

Rod End

N

Controls Chk. 12.5 37.5 Figure B1

5 x 10

4

-40.0 40.0 Figure B2

4 x 10

4

SAE ARP1383 Revision B

- 22 -

FIGURE B2 - Example - Typical Constant Life Diagram, AISI 4340 Notched Bar Data

from MIL-HDBK-5C Figure 2.3.1.1.8(C) Detail Omitted for

Clarification of Example

B.3.5 Step 5, Calculate n/N and n/N:

Use the data from Steps 1 and 4, where n = cycles in one operational life and N = stress life cycle

expectancy for each flight segment. Calculate the arithmetic sum of the segment results.

TABLE B7 - n/N, n/N for Example Chosen

Flight Segment Control Check Cruise Roll On-Off G-A-G

n 1.25 x 10

5

2.7 x 10

5

2.5 x 10

6

6.2 x 10

4

6.2 x 10

4

N/A

Manifold N 5 x 10

4

5 x 10

8

3 x 10

5

1 x 10

4

N/A

Manifold n/N 2.5 0 0.005 0.21 6.2 8.915

Rod End N 4 x 10

4

-- 2 x 10

4

N/A

Rod End n/N 3.125 0 0 -- 3.1 6.225

SAE ARP1383 Revision B

- 23 -

B.3.6 Step 6, Calculate n/N for Test Pressure:

The pressure fluctuations used in conducting the test per Category II should be the best

representation of the service expected in the component using only one set of minimum/maximum

pressures. For most components this is the design operating pressure (0 to 3000 psi for a 3000 psi

system). However, if the operational cycle has reversing loads, the test should be conducted with

reversing loads.

B.3.6.1 n/N for Test of the Example Chosen: Inspection of Table B1 shows the rod end is subjected to

reversing cycles. The controls check segment was selected as the test condition although the

G-A-G segment could serve the same purpose. Using the controls check for the rod end N = 4 x

10

4

. The pressure application during testing is to alternate 1500 psi impulses to the head end

and rod end of the cylinder with the actuator mounts restrained to hold the piston at near mid

position.

B.3.7 Step 7, Calculate n for Testing:

Perform the following calculation:

(Eq. B1)

where:

ref = the data form the segment used in Step 6 to define the test conditions.

B.3.7.1 n for Test of the Example Chosen:

(Eq. B2)

B.4 NOTES:

The method of analysis for calculation of equivalent cycles has several differences from conventional

fatigue analysis.

B.4.1 In Step 3, somewhat unrealistic high stress levels may be assumed without compromising the

analysis. Since the "error" is contained in all elements of the calculation and the total damage,

(n/N), is divided by the reference cycle damage (n/N ref), the "error" tends to cancel out.

B.4.2 Damage values (n/N) exceeding 1.0 are acceptable for the reasons given in B.4.1 above.

Experience has shown that inaccuracy due to assumptions is minimal when (n/N) is in the range

of 0.2 to 5.0. Any value of (n/N) greater than 10.0 should not be used.

n

t est

(n/N)

n/N

ref

----------------- n

ref

=

n

t est

(n/N)

n/N

ref

----------------- n

ref

(6.225)

3.125

------------------- 1.25 10

5

2.49 10

5

= = =

SAE ARP1383 Revision B

- 24 -

B.4.3 The ratio of pressure to stress in Step 3 (K) should be assumed as high as is permitted by B.4.2

above. This improves the ability to read S-N curves and, hence, to distinguish among load cases.

Even with high assumed stress levels, some fatigue load cases will still have very high allowable

lives and so, will by analysis, do no fatigue damage. The cruise flight segment for the example

illustrates this condition.

B.4.4 Once a pressure to stress relationship (K) is assumed, it MUST be held constant throughout the

analysis. If a problem occurs which requires changing the assumption, the entire analysis must be

repeated.

B.4.5 Although comparative analyses can be performed using any reputable S-N curve, the basis of the

S-N curve must be examined carefully before performing a fatigue analysis and predicting the

absolute life of parts. Some considerations are:

a. The S-N curve selected should be based on a given stress concentration factor. The curve

used shall represent the closest stress concentration factor (either higher or lower value) in

published data to the condition being examined.

Material processing effects should also be considered e.g., fatigue life degradation due to:

1. Surface coatings-chrome plate, anodize, etc.,

2. Electro-discharge machining recast layers,

3. Electro-chemical or similar surface material removal processes and

4. Metal working/machining or heat treatment induced tensile residual stresses.

Where appropriate, because of high loading in a pressure vessel situation, steps should be

taken to mitigate these effects, i.e., by mechanically removing recast layers, shot peening

before application of certain coatings and by proper sequencing of manufacturing machining,

heat treating and processing operations.

Conversely, beneficial effects due to compressive residual surface stresses induced into

components via such processes as shot peening, thread rolling, cold expansion, coining, roller

burnishing, autofrettage, etc. or resulting from carburizing, nitriding, etc. should be

acknowledged as favorable (life enhancing) in the fatigue analysis.

b. The test specimens used to generate the S-N curves are often fabricated with extremely

smooth surface finishes in the test section. These finishes are much smoother than is

reasonable for many production parts.

Efforts should be made in production to control or eliminate any machine tool marks, notches,

nicks, dings, grind tears, etc. which will adversely impact fatigue life. In addition, care should be

taken to eliminate all unforeseen stress risers by proper deburring. Where applicable, contact

wear (i.e. fretting) fatigue should be taken into account. The analysis can compensate for some

of these factors by increasing the calculated stress concentration factor.

SAE ARP1383 Revision B

- 25 -

B.4.5 (Continued):

Components should be stress relieved (relaxed) during heat treatment and properly baked for

embrittlement relief after chromium, cadmium, or any other plating which introduces hydrogen

into the part.

c. The material properties of the test specimens are often significantly higher than the minimums

that can exist in production.

Material section thickness/size effects and temperature reduction factors should be applied

when fatigue calculations are made.

d. Nearly all S-N curves represent typical test lives. They have not been constructed to

statistically reflect higher reliability than typical. Probability determinations for reliability must

consider the confidence factor in the probability. For example: if it is the objective to evaluate a

component to 95% reliability with 95% confidence by testing one unit, the number of cycles

required in testing is four lifetimes.

B.4.6 Sources such as Joseph E. Shigley and Larry D. Mitchell, MECHANICAL ENGINEERING

DESIGN, Fourth Edition, McGraw-Hill Inc., 1983 discuss ways of accounting for the above in

performing detail life prediction analysis, otherwise known as fatigue analysis.

You might also like

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Maa - Potential of Micro Perforated Panel Absorber - 1998Document6 pagesMaa - Potential of Micro Perforated Panel Absorber - 1998ciszybratNo ratings yet

- Astm E498-00 PDFDocument4 pagesAstm E498-00 PDFJORGE ARTURO TORIBIO HUERTA100% (1)

- Standard Specification For Materialsl: This IY L)Document6 pagesStandard Specification For Materialsl: This IY L)Dŕáğøņ RyzhonNo ratings yet

- MilSpec CatalogDocument26 pagesMilSpec Catalogdavid yau100% (3)

- Radome Moisture TesterDocument13 pagesRadome Moisture TesterInterogator5100% (1)

- A318 - A319 - A320 - A321 - NTM - 01-Nov-2022 - DeSC 51-00-00-002 CONF A - Nondestructive Testing MethodsDocument4 pagesA318 - A319 - A320 - A321 - NTM - 01-Nov-2022 - DeSC 51-00-00-002 CONF A - Nondestructive Testing MethodsGladys Reyes RodriguezNo ratings yet

- TSO-C77b Gas Turbine APU MPSDocument25 pagesTSO-C77b Gas Turbine APU MPSMartha Mariana MB0% (1)

- P&W Standard Practices Manual Consumable Materials ListDocument23 pagesP&W Standard Practices Manual Consumable Materials ListBrayhan Alexander PalominoNo ratings yet

- Downing Simple Rainflow Counting AlgorithmsDocument10 pagesDowning Simple Rainflow Counting Algorithmsridzim4638No ratings yet

- AWS D17.1 D17.1M 2017 - Fusion WeldingDocument111 pagesAWS D17.1 D17.1M 2017 - Fusion Weldingbenkendimbizzat56No ratings yet

- A123281 Aircraft Random Vibration Test CriteriaDocument13 pagesA123281 Aircraft Random Vibration Test CriteriarobNo ratings yet

- F1685 PDFDocument10 pagesF1685 PDFDaniel LodiNo ratings yet

- Al 2219 Dot Faa MmpdsDocument34 pagesAl 2219 Dot Faa MmpdsdiegobhiNo ratings yet

- AN912 Rev10Document7 pagesAN912 Rev10MAI_QualityNo ratings yet

- A418 99 PDFDocument7 pagesA418 99 PDFJohano AraújoNo ratings yet

- Din en 957 1 e 2005Document20 pagesDin en 957 1 e 2005Matteo PeddisNo ratings yet

- Design Guide - O-Ring, Quad-Ring, TrelleborgDocument32 pagesDesign Guide - O-Ring, Quad-Ring, TrelleborgDerekNo ratings yet

- E192-13 Standard Reference Radiographs of Investment Steel Castings For Aerospace ApplicationsDocument3 pagesE192-13 Standard Reference Radiographs of Investment Steel Castings For Aerospace ApplicationsLorena Jimenez100% (1)

- Repair Assessment Procedure and Integrated Design (RAPID Ver 3.0)Document90 pagesRepair Assessment Procedure and Integrated Design (RAPID Ver 3.0)gansito23100% (1)

- Standard Test Method For Shear Properties Composites MaterialDocument13 pagesStandard Test Method For Shear Properties Composites MaterialJoaquín Olivares JerezNo ratings yet

- Astm B446-08Document5 pagesAstm B446-08Srinivasan KrishnamoorthyNo ratings yet

- Parker TubingDocument85 pagesParker TubingPatrick StivénNo ratings yet

- CFM56-5B: Lufthansa Technik AG Engine Parts & Accessories Repair (EPAR)Document154 pagesCFM56-5B: Lufthansa Technik AG Engine Parts & Accessories Repair (EPAR)özkanNeşeliNo ratings yet

- HSB 53211-01 e - 91Document5 pagesHSB 53211-01 e - 91ozlem ozdemirNo ratings yet

- LM6000 Turbine-Generator Spare Parts GuideDocument190 pagesLM6000 Turbine-Generator Spare Parts Guidealziane50% (2)

- Swashplate assembly componentsDocument2 pagesSwashplate assembly componentsaugustinhodjNo ratings yet

- Ceb A 72 4095Document10 pagesCeb A 72 4095turboshaftNo ratings yet

- Ams 2471JDocument8 pagesAms 2471JMarco ChiereghinNo ratings yet

- Mil A 21180D PDFDocument25 pagesMil A 21180D PDFb4upalaniNo ratings yet

- EMC Directive 2014 - 30 PDFDocument36 pagesEMC Directive 2014 - 30 PDFJoannes Lenny EstibeiroNo ratings yet

- Liquid Penetrant Testing: Standard Practice ForDocument11 pagesLiquid Penetrant Testing: Standard Practice Forhahec950802No ratings yet

- 19790011945Document227 pages19790011945Gabriel GiorgisNo ratings yet

- Chapter 12Document28 pagesChapter 12lufro100% (1)

- (Type Here) : P H o N E: 4 8 0 - 8 2 4 - 2 7 0 0Document18 pages(Type Here) : P H o N E: 4 8 0 - 8 2 4 - 2 7 0 0arun RajannaNo ratings yet

- To 33B-1-1 01jan2013Document856 pagesTo 33B-1-1 01jan2013izmitlimonNo ratings yet

- Measurement of Fuel System Icing Inhibitors (Ether Type) in Aviation FuelsDocument5 pagesMeasurement of Fuel System Icing Inhibitors (Ether Type) in Aviation FuelsMuhammad KhairuddinNo ratings yet

- A320 IAE V2500 Engine Identification SystemDocument3 pagesA320 IAE V2500 Engine Identification SystemhhgaffadfNo ratings yet

- D 2116 - 02 - RdixmtyDocument6 pagesD 2116 - 02 - Rdixmtyjamaljamal20No ratings yet

- Aviation Maintenance Alerts July 2006 Issue Provides Updates on Aircraft, Engine, and Component IssuesDocument192 pagesAviation Maintenance Alerts July 2006 Issue Provides Updates on Aircraft, Engine, and Component IssuesAllyamacita NaibahoNo ratings yet

- Aeroflex IFR6000 Test Set Operations Manual 6093Document258 pagesAeroflex IFR6000 Test Set Operations Manual 6093chrismosf100% (1)

- MSRR 6523Document5 pagesMSRR 6523pradelles100% (1)

- Predicting How a Centrifugal Compressor's Slip Factor Varies With Flow RateDocument13 pagesPredicting How a Centrifugal Compressor's Slip Factor Varies With Flow Ratetorrent0cataclysmNo ratings yet

- 1 716554253262394595 PDFDocument3 pages1 716554253262394595 PDFAfzaalUmairNo ratings yet

- 7175 PDFDocument19 pages7175 PDF孙俊磊No ratings yet

- Technical Trend of Aircraft BearingsDocument5 pagesTechnical Trend of Aircraft BearingsnrNo ratings yet

- At575 234W TNCF 000 RG 29.5 NMDocument3 pagesAt575 234W TNCF 000 RG 29.5 NMMarlene SalazarNo ratings yet

- 340 Operators ManualDocument119 pages340 Operators Manualcutefrenzy100% (2)

- CH20Document14 pagesCH20Juan pablo Valencia jaramilloNo ratings yet

- Gas Pressure Regulator ManualDocument25 pagesGas Pressure Regulator ManualaminNo ratings yet

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document30 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkNo ratings yet

- A485 PDFDocument4 pagesA485 PDFProduction DepartmentNo ratings yet

- UH-60 Helicopter Maintenance ManualDocument559 pagesUH-60 Helicopter Maintenance Manualjoel alvarado100% (1)

- Parts ListDocument295 pagesParts Listtamasradu0% (1)

- Case 2203-1Document2 pagesCase 2203-1Tahfiz AhlamNo ratings yet

- Astm b160Document6 pagesAstm b160Kevin Almeida100% (1)

- Fluent Meshing 18.2 Module03 CFDSurf ImportDocument65 pagesFluent Meshing 18.2 Module03 CFDSurf ImportcansuyusNo ratings yet

- Miners RuleDocument2 pagesMiners Ruleபிரபாகரன் ஆறுமுகம்No ratings yet

- Magnetic Particle Testing: Standard Practice ForDocument22 pagesMagnetic Particle Testing: Standard Practice ForKevin Reyes VegaNo ratings yet

- ISO 6772 - Impulse Test AereoDocument8 pagesISO 6772 - Impulse Test Aereomaurobruno1973No ratings yet

- Helicoil Plus en 0100Document56 pagesHelicoil Plus en 0100vaseaNo ratings yet

- Schnorr - Handbook For Disc SpringsDocument151 pagesSchnorr - Handbook For Disc SpringsPieter van der MeerNo ratings yet

- Airbus Reference Language AbbreviationsDocument66 pagesAirbus Reference Language Abbreviations862405No ratings yet

- ORD 5700 Parker O-Ring HandbookDocument292 pagesORD 5700 Parker O-Ring Handbookcalaverilandia100% (1)

- Universal Joint EfficiencyDocument8 pagesUniversal Joint Efficiencychrisrae23No ratings yet

- The Lee Company, Technical Hydraulic HandbookDocument635 pagesThe Lee Company, Technical Hydraulic Handbookchrisrae23100% (1)

- Lee Handbook PDFDocument635 pagesLee Handbook PDFchrisrae23No ratings yet

- JAR-25 Airworthiness Standards for Large AeroplanesDocument35 pagesJAR-25 Airworthiness Standards for Large AeroplaneserohlNo ratings yet

- Compressive Strength, Chloride Diffusivity and Pore Structure of High Performance Metakaolin and Silica Fume ConcreteDocument8 pagesCompressive Strength, Chloride Diffusivity and Pore Structure of High Performance Metakaolin and Silica Fume ConcreteAboalmaail AlaminNo ratings yet

- RRB Group DDocument35 pagesRRB Group DRITESH KUMARNo ratings yet

- 194 Sample ChapterDocument27 pages194 Sample ChapterVikas TiwariNo ratings yet

- PowerOn Fusion PDFDocument16 pagesPowerOn Fusion PDFJagan VanamaNo ratings yet

- Air Car SeminarDocument24 pagesAir Car SeminarSatyajit MenonNo ratings yet

- Understanding Operating Systems Fifth Edition: Memory Management: Virtual MemoryDocument21 pagesUnderstanding Operating Systems Fifth Edition: Memory Management: Virtual MemoryRidzuan DolahNo ratings yet

- History Gelatin DryingDocument3 pagesHistory Gelatin DryingLe Thi Kim KhanhNo ratings yet

- Language As IdeologyDocument26 pagesLanguage As IdeologyAlcione Gonçalves Campos100% (2)

- SmartPlant Instrumentation installation checklistDocument2 pagesSmartPlant Instrumentation installation checklistmnoormohamed82No ratings yet

- Date Company Code Bank RefDocument16 pagesDate Company Code Bank RefSrinivas YNo ratings yet

- AIR Intelligence Manual 33 308100 004 RemoteDocument88 pagesAIR Intelligence Manual 33 308100 004 RemoteLeChancheNo ratings yet

- Envea Dusty Manual enDocument26 pagesEnvea Dusty Manual enmikiNo ratings yet

- Hitachi SetFree MiniVRF 0120LRDocument52 pagesHitachi SetFree MiniVRF 0120LRAhmed AzadNo ratings yet

- Leadership Learnings From Chhatrapati SHDocument5 pagesLeadership Learnings From Chhatrapati SHSagar RautNo ratings yet

- Hole Cleaning PDFDocument68 pagesHole Cleaning PDFHarold AldayNo ratings yet

- Ordinary Portland Cement, 33 Grade - Specification: Indian StandardDocument12 pagesOrdinary Portland Cement, 33 Grade - Specification: Indian StandardAmbrishNo ratings yet

- SKFDocument26 pagesSKFRahul ParikhNo ratings yet

- Reaction Paper The Flight From ConversationDocument4 pagesReaction Paper The Flight From ConversationJoe NasalitaNo ratings yet

- Aztech+700WR-3G User ManualDocument57 pagesAztech+700WR-3G User Manualkero_the_hero67% (3)

- 300G IM SettingsSheets 20160122Document27 pages300G IM SettingsSheets 20160122zeljkoradaNo ratings yet

- Crisis Management PlanDocument8 pagesCrisis Management PlanNfareeNo ratings yet

- Baguio Schools Teacher Deployment AnalysisDocument2 pagesBaguio Schools Teacher Deployment AnalysisDon Mariano Marcos Elementary SchoolNo ratings yet

- Export Promotion Councils - Final UpdatedDocument14 pagesExport Promotion Councils - Final UpdatedUtkarsh SaxenaNo ratings yet

- Nested Group PowerShellDocument3 pagesNested Group PowerShellNeha SinghNo ratings yet

- ANTRICE S.A. POWER SUPPLY RACKDocument3 pagesANTRICE S.A. POWER SUPPLY RACKmichaelliu123456No ratings yet

- June 2014 Draft for Public ReviewDocument59 pagesJune 2014 Draft for Public ReviewRomel Vargas Sánchez0% (1)

- Schools Division of Pasay City outlines 5S workplace organizationDocument9 pagesSchools Division of Pasay City outlines 5S workplace organizationJhaexelle allenah AlfonsoNo ratings yet

- Service Accessories: CatalogDocument32 pagesService Accessories: CatalogdummaNo ratings yet

- Greddy E-Manage Installation ManualDocument6 pagesGreddy E-Manage Installation ManualTHMotorsports.net100% (2)

- COMPREHENSIVE MUSIC AND ARTS EXAMDocument4 pagesCOMPREHENSIVE MUSIC AND ARTS EXAMChris Patlingrao100% (1)