Professional Documents

Culture Documents

Motor Pump Protection Relays

Uploaded by

Satyajit PatraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motor Pump Protection Relays

Uploaded by

Satyajit PatraCopyright:

Available Formats

3-Phase 3-Wire voltage monitoring &

display, Phase Failure, Unbalance, Phase

Sequence, under voltage, Over Voltage,

Auto / Manual Reset,

Adjustable unbalance trip setting,

Adjustable under/over voltage settings,

adjustable trip delay,

RS232 communication port,

2 CO output relay, True RMS Values

3-Phase 4-Wire voltage monitoring &

display, Phase Failure, Unbalance,

Phase Sequence, under voltage, Over

Voltage, Auto / Manual Reset,

Adjustable unbalance trip setting,

Adjustable under/over voltage settings,

Adjustable trip delay,

RS232 communication port,

2 CO output relay, True RMS Values

Wherever not specified

Contact Rating :

5A @ 230 V AC

(resistive)

22

Supply voltage

System

Auxiliary

Output relay contacts

Trip setting

Phase Sequence

Phase Unbalance

Under Voltage

Over Voltage

Trip Time delay

Reset

Display

Monitoring

Weight

Dimensions (mm)

Overall (L x W x D)

Mounting (L x W)

t t t t UB/SP UB/SP UB/SP

UV

UV OV

R Y B

RESET RESET RESET RESET RESET

SP UB>SET RP

OV SET

UV SET

SP

LINE

LED

RELAY

C-NO

t t t t UB/SP UB/SP UB/SP

UV

UV OV

R Y B

RESET RESET RESET RESET RESET

SP UB>SET RP

OV SET

UV SET

SP

LINE

LED

RELAY

C-NO

RS232

C2 NO2 NC2

C1 NO1 NC1 R Y B N

R

Y

B

N

Relay contact position shown in 'Power on' (Healthy) condition

V O L T A G E S C A N N E R S & C O N T R O L L E R S

F3 VSR1 F3 VSR2

Voltage Scanner 3-3W Voltage Scanner 3-4W

380 / 415 V AC (3 Ph - 3 W)

90-270 V AC/DC

2 CO & RS 232 (optional)

Yes

1 - 10 % (Adj.)

1 - 80V below nominal voltage

1 - 60V above nominal voltage

1 - 60 secs. or 1-5 mins select.

Manual / Auto

Backlit LCD (16 x 2 character)

Phase to Phase

800 gms.

96 x 96 x 130

92 x 92

RP, UV / OV and UB Protection override facility provided

RS232

C2 NO2 NC2

C1 NO1 NC1 R Y B

R

Y

B

AUX.

SUPPLY

380 / 415 V AC (3 Ph - 4 W)

Self Powered (Neutral & any Phase)

2 CO & RS 232 (optional)

Yes

1 - 20% (Adj.)

1 - 50V below nominal voltage

1 - 25V above nominal voltage

1 - 60 secs. or 1-5 mins select.

Manual / Auto

Backlit LCD (16 x 2 character)

Phase to neutral

800 gms.

96 x 96 x 130

92 x 92

RP, UV / OV and UB Protection override facility provided

These relays are useful for protection of 3-phase AC

induction motors against various hazards. With

their unique advantages they eliminate use of a

thermal/bimetal relay for motor protection. Being

current sensing, they are to be selected according to

motor rating and are available for practically all

ranges of motors. These relays are ideally suitable

for Air-conditioning Compressor motor protection,

as also for motors in machines, conveyors,

cranes/hoists and lifts, and for pumps.

MODELS

MPR D2, SPG D2, F3 DRC1,

D2 MPR1, D2MPR2, S2 CMR1

S2 CTS1,

MBMPR, M-Commander,

WTR D1, S2 WTR1

Ordering Instructions

Product Family Name

Model Name

System Supply Voltage &

frequency

Aux. Supply/Control supply

voltage

Motor/Pump rating (HP/KW)

& duty

Overload characteristics

required

No. of PTCs & Temp. graph

FEATURES

Fixed/adjustable unbalance settings

Fixed/adjustable settings for

under/over voltage, current, load

Fixed/adjustable trip delays

Resetting Auto or Manual

Output contacts : 1 CO or 2 CO

Choice of enclosures (DIN-Rail, Flush)

Models with Micro-Controller based

design

Serial Communication (RS485) port

2 line alpha-numeric LCD display

Use of SMD Technology

User-friendly LED indications

23

MOTOR / PUMP PROTECTION RELAYS

PROTECTIONS / FUNCTIONS

Phase Failure (Phase Loss/Single Phasing),

Phase sequence reversal,

Voltage Unbalance,

Under Voltage, Over Voltage

Overload protection as per motor

characteristics

No-load/dry running

Motor Winding overheating

Over-current/Short circuit/locked rotor

Earth Fault

M O T O R / P U M P P R O T E C T I O N R E L A Y S

Phase Failure, Unbalance, Phase

sequence and overloading

Auto / Manual Reset,

Adjustable current trip settings,

selectable characteristics,

1CO/2CO output relay

MPR D2

Phase Failure, Unbalance,

Phase sequence,

Overloading & Dry running

Auto/Manual Reset,

Adjustable current trip settings,

selectable overload characteristics,

1CO/2CO output relay

SPG D2

Phase Failure, Unbalance, Phase

sequence, overloading and dry

running

Auto/Manual Reset,

Adjustable current trip settings,

Adjustable overload characteristics,

1CO output relay

F3 DRC1

24

100-120 / 220-240 / 380-440 V AC 20%

110/240/380/415 V AC/DC/ 24 V AC/DC 20%, 50 / 60 Hz

1 CO (2 CO)

Wherever not specified

Contact Rating :

5A @ 230 V AC (resistive)

100-120/220-240/380-440V AC 20%

110/240/380/415/440 V AC/DC/24 V AC/DC20%, 50/60 Hz

1 CO (2 C0)

220-240/380-440 V AC 20% 50/60 Hz 3%

110 / 240 / 380/ 415 V AC 20% 50 / 60 Hz

1 CO

50% of motor Current 10%

N.A.

Above 120% of set Current (IDMTL)

50% of motor Current

50%/75% of set current

Above 120% of set current (IDMTL)

50% of I FLC

50% or 75% of I SET

Above 120% of set current (IDMTL)

Overload Protection Relay

with Phase Failure

Dry Run & Overload

Relay with Phase Failure

Protection Dry Run & Overload

Relay with Phase Failure

Protection

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

13

14

15

13

T1 T1 As per IDMTL

200 %

T2

4 to 7 sec.

T1 = O/L Trip Delay

T2 = SP Trip Delay

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

13

14

15

13

T1 T1

T2

As per IDMTL

200 %

T2

4 to 7 sec.

T1 = O/L Trip Delay

T2 = SP / DR Trip Delay

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

C

NO

NC

C

T1 T1

T2

As per IDMTL

200 %

T2

4 to 7 sec.

T1 = O/L Trip Delay

T2 = SP / DR Trip Delay

From CTS From CTS From CTS

5.5 secs. 1.5 secs.

As per selectable inverse time Characteristics

(2 secs. / 5 secs.) or 10 secs. or 15 secs. or 20 secs. (optional)

5.5 secs. 1.5 secs.

As per selectable inverse time Characteristics

2 / 5 secs (10 secs.)

5.5 secs. 1.5 secs.

As per selectable inverse time Characteristics

2 - 10 secs. (variable)

Auto / Manual / Remote Auto / Manual / Remote Auto / Manual / Remote

76 x 56.5 x 117.5

425 gms.

67 x 46 / 35 mm Rail Mounting

76 x 56.5 x 117.5

67 x 46 / 35 mm Rail Mounting

425 gms.

96 x 96 x 76

92 x 92

425 gms.

Supply Voltage

System

Auxiliary

Output Relay Contact

Input

Trip Setting

Phase to phase unbalance

Under current (Dry running)

Overload

Trip Time delay

On phase failure

For overloading

Resetting

Dimensions (mm)

Overall (L x W x D)

Panel mounting (L x W)

Approx Weight

UV/OV

UV/OV RP N.A. N.A. N.A.

N.A. N.A. N.A.

Relay contact position shown in 'Power off' condition

R

Y

B

MPR D2

AUX.

SUPPLY

R B

S2 CTS1

IN IN OUT OUT

R

Y

B

SPG D2

AUX.

SUPPLY

R B

S2 CTS1

IN IN OUT OUT

R B

S2 CTS1

IN IN OUT OUT

R

Y

B

MOTOR

C

NO

NC

D

D

EXT.

P. B.

A/M

LINK

DRY

RUN LINK

A

B

C

E

F

G

H

N/ V

ON

OFF

DOL STARTER

AUX.

SUPPLY

Phase Failure, Unbalance,

Phase sequence, overloading

and dry running (Under current)

Microcontroller based design,

SMD technology,

Auto/Manual Reset,

Adjustable current trip settings,

selectable overload

characteristics, 2CO output relay

D2 MPR1

Phase Failure, Unbalance, Phase

sequence and overloading, Under

Current, Auto/Manual Reset,

Adjustable current trip settings,

Test Facility,

UC bypass facility,

selectable overload characteristics,

2CO output relay

Sensing both voltage and

current signals, Phase Failure,

Unbalance, Phase sequence,

under over voltage,

overloading and dry running.

Manual Reset, Delayed auto

reset, fixed trip settings, fixed

overload characteristics,

2CO output relay

25

M O T O R / P U M P P R O T E C T I O N R E L A Y S

Dry Run & Overload

Relay with Phase Failure

Protection

D2 MPR2

Dry Run & Overload

with Phase Failure & UV+OV

Protection

S2 CMR1

Dry Run & Overload

Relay with Phase Failure

Protection

C US

R

C US

R

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

16 13

17 14

18 15

16 13

T1 T1

T2

As per IDMTL

200 %

T2

T1 = O/L Trip Delay

T2 = SP / DR Trip Delay

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

16 13

17 14

18 15

16 13

T1 T1

T2

As per IDMTL

200 %

T2

T1 = O/L Trip Delay

T2 = SP / DR Trip Delay

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

10 7

11 8

12 9

10 7

T1 T1

T2

As per IDMTL

200 %

T2

T1 = O/L Trip Delay

T2 = SP / DR Trip Delay

100-120/220-240/380-440V AC 20%, 48-63 Hz

100-120/220-240VAC20%, 24V DC+10%-15%

2 CO

As per inverse time characteristics

4 Sec 1 Sec (Fixed)

50% of Motor Current (Fixed)

40% to 80% of set current

90 x 35 x 60

140 gms

35 mm Rail Mounting

Auto / Manual

As per Inverse Time Characteristics

2/5/10 Sec. (Selectable)

N.A.

N.A.

380-440 V AC 20%, 45-65 Hz

220-240 / 380-440V AC

2 CO

50% of Motor Current (Fixed)

40% to 80% of set current (Adj.with Bypass facility)

As per inverse time characteristics

76 x 56.5 x 117.5

67 x 46 /35 mm Rail Mounting

400 gms

4 Sec 1 Sec

As per Inverse Time Characteristics

2/5/10 Sec. (Selectable)

Auto/ Manual (Remote with NC Push Button)

N.A.

N.A.

380-440V AC 20%, 48-63 Hz

220-240 20% VAC

2 CO

50% of Motor Current (Fixed)

50% of set current (Fixed)

As per inverse time characteristics

4 Sec 1%

76 x 56.5 x 117.5

67 x 46 /35 mm Rail Mounting

400 gms

As per Inverse Time Characteristics

2 Sec. (Fixed)

Delayed Auto

UV = -20% (Fixed) OV = +20% (Fixed)

For UV/OV - 4 Sec 1 Sec for RP - Instant

C US

R

Current sensor

suitable for full

load motor

current of 5A.

10A. 20A. 40A. &

80A. To be used

with Minilec

relays only.

Current Sensor

S2 CTS1

C US

R

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

90 x 35 x 60

35 mm Rail Mounting

140 gms.

3-wire Output

Relay contact position shown in 'Power off' condition

R

Y

B

D2 MPR1

AUX.

SUPPLY

R B

S2 CTS1

IN IN OUT OUT

MOTOR

OFF

ON

R

Y

B

AUX.

SUPPLY

S2 CMR1

R B

S2 CTS1

IN IN OUT OUT

ON

OFF

N V

A/M Link

Link at 17-18 for

2 or 5 Sec. IDMTL

curve selection

A/M Link

Dry run Link

R

Y

B

D2 MPR2

AUX.

SUPPLY

R B

S2 CTS1

IN IN OUT OUT

MOTOR

OFF

ON

External Reset

NC PB

External Reset

NC PB

Selection Chart for S2 CTS1

4

M O T O R / P U M P P R O T E C T I O N R E L A Y S

Phase Failure, Unbalance, Phase

sequence and overloading

Auto / Manual Reset,

Adjustable current trip settings,

selectable characteristics,

1CO/2CO output relay

MPR D2

Phase Failure, Unbalance,

Phase sequence,

Overloading & Dry running

Auto/Manual Reset,

Adjustable current trip settings,

selectable overload characteristics,

1CO/2CO output relay

SPG D2

Phase Failure, Unbalance, Phase

sequence, overloading and dry

running

Auto/Manual Reset,

Adjustable current trip settings,

Adjustable overload characteristics,

1CO output relay

F3 DRC1

24

100-120 / 220-240 / 380-440 V AC 20%

110/240/380/415 V AC/DC/ 24 V AC/DC 20%, 50 / 60 Hz

1 CO (2 CO)

Wherever not specified

Contact Rating :

5A @ 230 V AC (resistive)

100-120/220-240/380-440V AC 20%

110/240/380/415/440 V AC/DC/24 V AC/DC20%, 50/60 Hz

1 CO (2 C0)

220-240/380-440 V AC 20% 50/60 Hz 3%

110 / 240 / 380/ 415 V AC 20% 50 / 60 Hz

1 CO

50% of motor Current 10%

N.A.

Above 120% of set Current (IDMTL)

50% of motor Current

50%/75% of set current

Above 120% of set current (IDMTL)

50% of I FLC

50% or 75% of I SET

Above 120% of set current (IDMTL)

Overload Protection Relay

with Phase Failure

Dry Run & Overload

Relay with Phase Failure

Protection Dry Run & Overload

Relay with Phase Failure

Protection

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

13

14

15

13

T1 T1 As per IDMTL

200 %

T2

4 to 7 sec.

T1 = O/L Trip Delay

T2 = SP Trip Delay

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

13

14

15

13

T1 T1

T2

As per IDMTL

200 %

T2

4 to 7 sec.

T1 = O/L Trip Delay

T2 = SP / DR Trip Delay

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

C

NO

NC

C

T1 T1

T2

As per IDMTL

200 %

T2

4 to 7 sec.

T1 = O/L Trip Delay

T2 = SP / DR Trip Delay

From CTS From CTS From CTS

5.5 secs. 1.5 secs.

As per selectable inverse time Characteristics

(2 secs. / 5 secs.) or 10 secs. or 15 secs. or 20 secs. (optional)

5.5 secs. 1.5 secs.

As per selectable inverse time Characteristics

2 / 5 secs (10 secs.)

5.5 secs. 1.5 secs.

As per selectable inverse time Characteristics

2 - 10 secs. (variable)

Auto / Manual / Remote Auto / Manual / Remote Auto / Manual / Remote

76 x 56.5 x 117.5

425 gms.

67 x 46 / 35 mm Rail Mounting

76 x 56.5 x 117.5

67 x 46 / 35 mm Rail Mounting

425 gms.

96 x 96 x 76

92 x 92

425 gms.

Supply Voltage

System

Auxiliary

Output Relay Contact

Input

Trip Setting

Phase to phase unbalance

Under current (Dry running)

Overload

Trip Time delay

On phase failure

For overloading

Resetting

Dimensions (mm)

Overall (L x W x D)

Panel mounting (L x W)

Approx Weight

UV/OV

UV/OV RP N.A. N.A. N.A.

N.A. N.A. N.A.

Relay contact position shown in 'Power off' condition

R

Y

B

MPR D2

AUX.

SUPPLY

R B

S2 CTS1

IN IN OUT OUT

R

Y

B

SPG D2

AUX.

SUPPLY

R B

S2 CTS1

IN IN OUT OUT

R B

S2 CTS1

IN IN OUT OUT

R

Y

B

MOTOR

C

NO

NC

D

D

EXT.

P. B.

A/M

LINK

DRY

RUN LINK

A

B

C

E

F

G

H

N/ V

ON

OFF

DOL STARTER

AUX.

SUPPLY

Phase Failure, Unbalance,

Phase sequence, overloading

and dry running (Under current)

Microcontroller based design,

SMD technology,

Auto/Manual Reset,

Adjustable current trip settings,

selectable overload

characteristics, 2CO output relay

D2 MPR1

Phase Failure, Unbalance, Phase

sequence and overloading, Under

Current, Auto/Manual Reset,

Adjustable current trip settings,

Test Facility,

UC bypass facility,

selectable overload characteristics,

2CO output relay

Sensing both voltage and

current signals, Phase Failure,

Unbalance, Phase sequence,

under over voltage,

overloading and dry running.

Manual Reset, Delayed auto

reset, fixed trip settings, fixed

overload characteristics,

2CO output relay

25

M O T O R / P U M P P R O T E C T I O N R E L A Y S

Dry Run & Overload

Relay with Phase Failure

Protection

D2 MPR2

Dry Run & Overload

with Phase Failure & UV+OV

Protection

S2 CMR1

Dry Run & Overload

Relay with Phase Failure

Protection

C US

R

C US

R

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

16 13

17 14

18 15

16 13

T1 T1

T2

As per IDMTL

200 %

T2

T1 = O/L Trip Delay

T2 = SP / DR Trip Delay

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

16 13

17 14

18 15

16 13

T1 T1

T2

As per IDMTL

200 %

T2

T1 = O/L Trip Delay

T2 = SP / DR Trip Delay

700 %

600 %

400 %

120 %

100 %

10 %

0 %

Motor

Current

(%)

3 ph

O/L

Phase Fail

R Y B R B

/ / / / / / / / / /

10 7

11 8

12 9

10 7

T1 T1

T2

As per IDMTL

200 %

T2

T1 = O/L Trip Delay

T2 = SP / DR Trip Delay

100-120/220-240/380-440V AC 20%, 48-63 Hz

100-120/220-240VAC20%, 24V DC+10%-15%

2 CO

As per inverse time characteristics

4 Sec 1 Sec (Fixed)

50% of Motor Current (Fixed)

40% to 80% of set current

90 x 35 x 60

140 gms

35 mm Rail Mounting

Auto / Manual

As per Inverse Time Characteristics

2/5/10 Sec. (Selectable)

N.A.

N.A.

380-440 V AC 20%, 45-65 Hz

220-240 / 380-440V AC

2 CO

50% of Motor Current (Fixed)

40% to 80% of set current (Adj.with Bypass facility)

As per inverse time characteristics

76 x 56.5 x 117.5

67 x 46 /35 mm Rail Mounting

400 gms

4 Sec 1 Sec

As per Inverse Time Characteristics

2/5/10 Sec. (Selectable)

Auto/ Manual (Remote with NC Push Button)

N.A.

N.A.

380-440V AC 20%, 48-63 Hz

220-240 20% VAC

2 CO

50% of Motor Current (Fixed)

50% of set current (Fixed)

As per inverse time characteristics

4 Sec 1%

76 x 56.5 x 117.5

67 x 46 /35 mm Rail Mounting

400 gms

As per Inverse Time Characteristics

2 Sec. (Fixed)

Delayed Auto

UV = -20% (Fixed) OV = +20% (Fixed)

For UV/OV - 4 Sec 1 Sec for RP - Instant

C US

R

Current sensor

suitable for full

load motor

current of 5A.

10A. 20A. 40A. &

80A. To be used

with Minilec

relays only.

Current Sensor

S2 CTS1

C US

R

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

N.A.

90 x 35 x 60

35 mm Rail Mounting

140 gms.

3-wire Output

Relay contact position shown in 'Power off' condition

R

Y

B

D2 MPR1

AUX.

SUPPLY

R B

S2 CTS1

IN IN OUT OUT

MOTOR

OFF

ON

R

Y

B

AUX.

SUPPLY

S2 CMR1

R B

S2 CTS1

IN IN OUT OUT

ON

OFF

N V

A/M Link

Link at 17-18 for

2 or 5 Sec. IDMTL

curve selection

A/M Link

Dry run Link

R

Y

B

D2 MPR2

AUX.

SUPPLY

R B

S2 CTS1

IN IN OUT OUT

MOTOR

OFF

ON

External Reset

NC PB

External Reset

NC PB

Selection Chart for S2 CTS1

4

CT INPUT

N

M1

M1

B

Y

R

EXTERNAL CBCT OF

5Amp OUTPUT

CT MODULE

S1 S2

R

B

Y

M2

M3

OFF ON

1 2 3 4 5 6 7

8 9 10 11 12 13 14

C1 N01 NC1 C2 N02 NC2

AUX.

SUPPLY 485 O/P PTC I/P

MICROPROCESSOR BASED MOTOR PROTECTION RELAY

Microcontroller based. Sensing voltage, current and temperature. Protecting

against Phase Failure, Unbalance, Phase sequence, Under/over voltage,

overloading, winding over temperature, Over current/Short circuit, locked

rotor, Auto/Manual resetting, Adjustable trip settings for UV/OV, UC/OC, O/L,

Locked rotor & earth fault. On delay & start-up delay adjustable, 2x1CO output

relays and serial communication port.

26

A

U

X

. S

U

P

P

L

Y

S

Y

S

T

E

M

S

U

P

P

L

Y

ALARM

TRIP

R

Y

B

CON3

CON6

CON1

C

T

IN

P

U

T CON2

CON4

E

T

1

T

2

T

3

T

4

N

C

2

N

O

2

C

2

N

C

1

N

O

1

C

1

PTC-1 FOR ALARM

N

M1

M1

B

Y

R

PTC-2 FOR TRIP

EXTERNAL CBCT OF

5Amp OUTPUT

CT MODULE ( CTS / CT20 / CT50 )

S1 S2

R

B

Y

R

S

-2

3

2

O

U

T

P

U

T

M2

M3

OFF ON

N

L

R

G

B

R

E

L

A

Y

O

U

T

P

U

T

MBMPR

Comprehensive Motor Protection Relay

F3 MPR1

Motor Protection Relay

MBMPR

CT Module

CT Module is specially

designed for use with

Minilec relays only like

F3 MPR1. MBMPR and

M-Commander Available in

2 modules, CT20 and CT50.

I nt erconnect i ng cabl e

(2.5mtrs) is provided with

this module.

Input from R.Y.B. phases and CBCT

CT

Range

CT Module Selection Chart

Settings Trip Level Trip Delay LED Reset Mode

Power ON

Unbal/Ph.Rev 1% - 20%

Under Voltage 75% - 95%

Over Voltage

Over Current/

Short Circuit

105% - 120%

Overload

Lock Rotor

Earth Fault 30% - 80% 0.5 - 10 Secs. Manual

Winding Overheat

Supply Voltage

System

Auxiliary

Output

Input

Power Consumption

T

r

i

p

S

e

t

t

i

n

g

415V AC +20%,-25% 3, 3 Wire, 50 / (60)Hz 3%

90-270V AC / DC

1 CO for Trip & 1 CO for Alarm/RS 232 Port (Optional)

External CTS ( CT5/CT20/CT50 )

8 VA

2/5/10/15/20 Sec. As per IDMTL char. Manual

Manual 200%-500% of Imax 1-10 Secs.

1-20 Secs. 4K1 - 5K6 Auto / Manual

300% - 800%

of Imax

2-25 Secs. Multi Attempt

1-10 Secs.

1-10 Secs.

1-10 Secs. Auto / Manual

Auto / Manual

Auto / Manual

Current unbalance

Current phase Loss

Under Current

(dry run)

20-60% of Imax

30-90% of Imax

1-10 Secs.

1-10 Secs.

1-10 Secs.

MMu ullt tii AAt ttteemmppt t

MMu ullt tii AAt ttteemmppt t

MMu ullt tii AAt ttteemmppt t

}

for

CDR-M

Display

Dimensions (mm)

Overall (L x W x D)

Panel mounting (L x W)

Approx Weight

16x2 Ch. ( LCD Display) Back lit

166 x 216 x 80

153 x 203

600 gms

MBMPR

Protection Setting Trip Delay Resetting

Over load Trip Setting As per

IDMTL Char

Supply Voltage

System

Auxiliary

Output Relay Contact

Serial Communication

T

r

i

p

S

e

t

t

i

n

g

220-440 V AC 20%, 45-65Hz

90-270 V AC/DC

2 CO

Provision of RS485 Output

Display

Dimensions (mm.)

Overall (L x W x D)

Mounting (L x W)

Approx Weight Unit

16x2 ( LCD Display) Back lit

96 x 96 x 80

Panel Mounting - 92 x 92

400 gms

F3 MPR 1

Parameter Range

LCD Display

Mode

2/5/10/15/20 Sec N.A Over Load Manual

Unbalance Trip Setting 20% 60% 1-10 Sec Current Unbalanced Multi Attempt

Phase Faliure N.A 1-10 Sec Current S.P. Multi Attempt

Reverse Phasing N.A Instant Manual Phase Reversal

Under Current 30%-90% 1-60 Sec

}Multi Attempt

Under Current

Over Current 300%-800% 2-25 Sec Over Current

Lock Rotor 200%-500% 1-10 Sec Manual Rotor Lock

Earth Fault Setting 30%-80% 0.5 - 10 Sec Manual Earth Fault

Over Temp.

o o

70 to 180 1-20 Sec Sensor Fail,

Motor Temp. High

Auto/Manual

F3 MPR1

Interconnection cable

102 x 35 x 81

90mm Rail Mounting centre to centre

600 gms

For motor currents

(FLA) upto 20 Amp

For motor currents

(FLA) upto 50 Amp

Relay contact position

shown in 'Power off' condition

CT20

CT50

PC Side Software

N

e

w

( CT 20 / CT 50 )

Input External CTS ( CT5/CT20/CT50 )

27

MICROPROCESSOR BASED PUMP AUTOMATION SYSTEM

Motor protection Includes

Over voltage protection

Single/Reverse phasing protection

Voltage / Current unbalance

Overload trip

Over current protection

Dry running protection

Earth fault protection

PTC based winding overheating protection

Pump Management System Features

Auto Change over between two pumps

Intelligent resetting facility

On-site programming facility

Password protection for programming

Pump On-Off timer programmable for 10

times a day, with advance programming of

7 days

Provision for water level control

Run-time compensation

Ideal for Pump Automation & Unmanned

Pumping Stations.

Under/

PARAMETERS SPECIFICATIONS

Supply Voltage

System 415 V AC +20%,-25% 50/60Hz 3%

Auxiliary 90-270 VAC/DC 20%, 50Hz

Output Contacts 4 x 1 CO Relays (for 2 pumps)

Current sensor External CT5 / CT20 / CT50

Reset Auto/ Multi-Attempt / Manual

Unbalance 1-20% 6V for Voltage Unbalance

20-60% 5% of current unbalance

Overload As per inverse time characteristics

Over Current / 300% - 800%

Short Circuit

Locked Rotor 200% - 500%

Earth Fault 30% - 80%

Winding Overheating As per PTC temperature characteristics

Under Voltage 75% - 95% of system supply (adjustable)

Over Voltage 105%-120% of system supply (adjustable)

Dry Running 30-90% of Imax

Display 16x2 Ch. (Backlit LCD)

Level Control Upper tank full

Lower tank empty

Weight 800gms

Wherever not specified Contact Rating : 5A @ 230 V AC (resistive)

M-Commander is a micro-processor based

Motor protection and Pump management

system, suitable for 2 pumps.

Sensing voltage, current and temperature.

Protecting against Phase Failure, Unbalance,

Phase sequence, Under/over voltage,

overloading, dry running, winding over

temperature, Over current/Short circuit,

locked rotor, earth fault. Auto/Manual

resetting, Adjustable trip settings for UV/OV,

UC/OC, O/L, Locked rotor & earth fault.

On delay & start-up delay adjustable,

2x1CO output relays RTC based time settings

Water level control.

M-COMMANDER

Pump Management & Protection System

For more detailed specifications, refer table on page No. 26 (MBMPR)

CT Module

For Motor currents above 50Amp

Customers to use suitable external CT

of 5Amp Secondary and CT Module CT

5 for Minilec relays only like F3MPR1,

MBMPR & M-COMMANDER

( CT 5 )

1 2 5 6

CT-5

B

Y

R

EXTERNAL CBCT OF

5 Amp OUTPUT

To Unit

S2

EXTERNAL CT OF

5 Amp SECONDARY

M1

PUMP

M1

M2

M3

90 x 35 x 60

35 mm Rail Mounting

400 gms

A

U

X

. S

U

P

P

L

Y

S

Y

S

T

E

M

S

U

P

P

L

Y

PUMP-2 PRIMING

PUMP-2

PUMP-1 PRIMING

PUMP-1

CON3

CON6

C

T

IN

P

U

T

CON2

WINDING TEMP SENSOR

( PTC - 1) FOR PUMP- 1

N

M1

PUMP-1

B

Y

R

M2

WINDING TEMP SENSOR

( PTC - 2) FOR PUMP- 2

EXTERNAL CBCT OF

5Amp OUTPUT

CT MODULE (CT20 / CT50)

S1 S2

R

B

Y

OFF ON

OFF ON

M1

M2

M3

M1

M2

M3

CON1

P

3

P

2

P

1

P

6

P

5

P

4

IP

1

C

T

1

T

2

T

3

T

4

R

Y

B

CON4

E

N

L

N

C

4

N

O

4

C

4

N

C

3

N

O

3

C

3

N

C

2

N

O

2

C

2

N

C

1

N

O

1

C

1

P2

P1

P3

LOWER TANK

P5

P4

P6

UPPER TANK

PUMP-2

R

E

L

A

Y

O

U

T

P

U

T

IN

P

U

T

For Auto operation, Put link across 'ON' push button

M-COMMANDER

Relay contact position shown in 'Power off' condition

CT INPUT

N

M1

M1

B

Y

R

EXTERNAL CBCT OF

5Amp OUTPUT

CT MODULE

S1 S2

R

B

Y

M2

M3

OFF ON

1 2 3 4 5 6 7

8 9 10 11 12 13 14

C1 N01 NC1 C2 N02 NC2

AUX.

SUPPLY 485 O/P PTC I/P

MICROPROCESSOR BASED MOTOR PROTECTION RELAY

Microcontroller based. Sensing voltage, current and temperature. Protecting

against Phase Failure, Unbalance, Phase sequence, Under/over voltage,

overloading, winding over temperature, Over current/Short circuit, locked

rotor, Auto/Manual resetting, Adjustable trip settings for UV/OV, UC/OC, O/L,

Locked rotor & earth fault. On delay & start-up delay adjustable, 2x1CO output

relays and serial communication port.

26

A

U

X

. S

U

P

P

L

Y

S

Y

S

T

E

M

S

U

P

P

L

Y

ALARM

TRIP

R

Y

B

CON3

CON6

CON1

C

T

IN

P

U

T CON2

CON4

E

T

1

T

2

T

3

T

4

N

C

2

N

O

2

C

2

N

C

1

N

O

1

C

1

PTC-1 FOR ALARM

N

M1

M1

B

Y

R

PTC-2 FOR TRIP

EXTERNAL CBCT OF

5Amp OUTPUT

CT MODULE ( CTS / CT20 / CT50 )

S1 S2

R

B

Y

R

S

-2

3

2

O

U

T

P

U

T

M2

M3

OFF ON

N

L

R

G

B

R

E

L

A

Y

O

U

T

P

U

T

MBMPR

Comprehensive Motor Protection Relay

F3 MPR1

Motor Protection Relay

MBMPR

CT Module

CT Module is specially

designed for use with

Minilec relays only like

F3 MPR1. MBMPR and

M-Commander Available in

2 modules, CT20 and CT50.

I nt erconnect i ng cabl e

(2.5mtrs) is provided with

this module.

Input from R.Y.B. phases and CBCT

CT

Range

CT Module Selection Chart

Settings Trip Level Trip Delay LED Reset Mode

Power ON

Unbal/Ph.Rev 1% - 20%

Under Voltage 75% - 95%

Over Voltage

Over Current/

Short Circuit

105% - 120%

Overload

Lock Rotor

Earth Fault 30% - 80% 0.5 - 10 Secs. Manual

Winding Overheat

Supply Voltage

System

Auxiliary

Output

Input

Power Consumption

T

r

i

p

S

e

t

t

i

n

g

415V AC +20%,-25% 3, 3 Wire, 50 / (60)Hz 3%

90-270V AC / DC

1 CO for Trip & 1 CO for Alarm/RS 232 Port (Optional)

External CTS ( CT5/CT20/CT50 )

8 VA

2/5/10/15/20 Sec. As per IDMTL char. Manual

Manual 200%-500% of Imax 1-10 Secs.

1-20 Secs. 4K1 - 5K6 Auto / Manual

300% - 800%

of Imax

2-25 Secs. Multi Attempt

1-10 Secs.

1-10 Secs.

1-10 Secs. Auto / Manual

Auto / Manual

Auto / Manual

Current unbalance

Current phase Loss

Under Current

(dry run)

20-60% of Imax

30-90% of Imax

1-10 Secs.

1-10 Secs.

1-10 Secs.

MMu ullt tii AAt ttteemmppt t

MMu ullt tii AAt ttteemmppt t

MMu ullt tii AAt ttteemmppt t

}

for

CDR-M

Display

Dimensions (mm)

Overall (L x W x D)

Panel mounting (L x W)

Approx Weight

16x2 Ch. ( LCD Display) Back lit

166 x 216 x 80

153 x 203

600 gms

MBMPR

Protection Setting Trip Delay Resetting

Over load Trip Setting As per

IDMTL Char

Supply Voltage

System

Auxiliary

Output Relay Contact

Serial Communication

T

r

i

p

S

e

t

t

i

n

g

220-440 V AC 20%, 45-65Hz

90-270 V AC/DC

2 CO

Provision of RS485 Output

Display

Dimensions (mm.)

Overall (L x W x D)

Mounting (L x W)

Approx Weight Unit

16x2 ( LCD Display) Back lit

96 x 96 x 80

Panel Mounting - 92 x 92

400 gms

F3 MPR 1

Parameter Range

LCD Display

Mode

2/5/10/15/20 Sec N.A Over Load Manual

Unbalance Trip Setting 20% 60% 1-10 Sec Current Unbalanced Multi Attempt

Phase Faliure N.A 1-10 Sec Current S.P. Multi Attempt

Reverse Phasing N.A Instant Manual Phase Reversal

Under Current 30%-90% 1-60 Sec

}Multi Attempt

Under Current

Over Current 300%-800% 2-25 Sec Over Current

Lock Rotor 200%-500% 1-10 Sec Manual Rotor Lock

Earth Fault Setting 30%-80% 0.5 - 10 Sec Manual Earth Fault

Over Temp.

o o

70 to 180 1-20 Sec Sensor Fail,

Motor Temp. High

Auto/Manual

F3 MPR1

Interconnection cable

102 x 35 x 81

90mm Rail Mounting centre to centre

600 gms

For motor currents

(FLA) upto 20 Amp

For motor currents

(FLA) upto 50 Amp

Relay contact position

shown in 'Power off' condition

CT20

CT50

PC Side Software

N

e

w

( CT 20 / CT 50 )

Input External CTS ( CT5/CT20/CT50 )

27

MICROPROCESSOR BASED PUMP AUTOMATION SYSTEM

Motor protection Includes

Over voltage protection

Single/Reverse phasing protection

Voltage / Current unbalance

Overload trip

Over current protection

Dry running protection

Earth fault protection

PTC based winding overheating protection

Pump Management System Features

Auto Change over between two pumps

Intelligent resetting facility

On-site programming facility

Password protection for programming

Pump On-Off timer programmable for 10

times a day, with advance programming of

7 days

Provision for water level control

Run-time compensation

Ideal for Pump Automation & Unmanned

Pumping Stations.

Under/

PARAMETERS SPECIFICATIONS

Supply Voltage

System 415 V AC +20%,-25% 50/60Hz 3%

Auxiliary 90-270 VAC/DC 20%, 50Hz

Output Contacts 4 x 1 CO Relays (for 2 pumps)

Current sensor External CT5 / CT20 / CT50

Reset Auto/ Multi-Attempt / Manual

Unbalance 1-20% 6V for Voltage Unbalance

20-60% 5% of current unbalance

Overload As per inverse time characteristics

Over Current / 300% - 800%

Short Circuit

Locked Rotor 200% - 500%

Earth Fault 30% - 80%

Winding Overheating As per PTC temperature characteristics

Under Voltage 75% - 95% of system supply (adjustable)

Over Voltage 105%-120% of system supply (adjustable)

Dry Running 30-90% of Imax

Display 16x2 Ch. (Backlit LCD)

Level Control Upper tank full

Lower tank empty

Weight 800gms

Wherever not specified Contact Rating : 5A @ 230 V AC (resistive)

M-Commander is a micro-processor based

Motor protection and Pump management

system, suitable for 2 pumps.

Sensing voltage, current and temperature.

Protecting against Phase Failure, Unbalance,

Phase sequence, Under/over voltage,

overloading, dry running, winding over

temperature, Over current/Short circuit,

locked rotor, earth fault. Auto/Manual

resetting, Adjustable trip settings for UV/OV,

UC/OC, O/L, Locked rotor & earth fault.

On delay & start-up delay adjustable,

2x1CO output relays RTC based time settings

Water level control.

M-COMMANDER

Pump Management & Protection System

For more detailed specifications, refer table on page No. 26 (MBMPR)

CT Module

For Motor currents above 50Amp

Customers to use suitable external CT

of 5Amp Secondary and CT Module CT

5 for Minilec relays only like F3MPR1,

MBMPR & M-COMMANDER

( CT 5 )

1 2 5 6

CT-5

B

Y

R

EXTERNAL CBCT OF

5 Amp OUTPUT

To Unit

S2

EXTERNAL CT OF

5 Amp SECONDARY

M1

PUMP

M1

M2

M3

90 x 35 x 60

35 mm Rail Mounting

400 gms

A

U

X

. S

U

P

P

L

Y

S

Y

S

T

E

M

S

U

P

P

L

Y

PUMP-2 PRIMING

PUMP-2

PUMP-1 PRIMING

PUMP-1

CON3

CON6

C

T

IN

P

U

T

CON2

WINDING TEMP SENSOR

( PTC - 1) FOR PUMP- 1

N

M1

PUMP-1

B

Y

R

M2

WINDING TEMP SENSOR

( PTC - 2) FOR PUMP- 2

EXTERNAL CBCT OF

5Amp OUTPUT

CT MODULE (CT20 / CT50)

S1 S2

R

B

Y

OFF ON

OFF ON

M1

M2

M3

M1

M2

M3

CON1

P

3

P

2

P

1

P

6

P

5

P

4

IP

1

C

T

1

T

2

T

3

T

4

R

Y

B

CON4

E

N

L

N

C

4

N

O

4

C

4

N

C

3

N

O

3

C

3

N

C

2

N

O

2

C

2

N

C

1

N

O

1

C

1

P2

P1

P3

LOWER TANK

P5

P4

P6

UPPER TANK

PUMP-2

R

E

L

A

Y

O

U

T

P

U

T

IN

P

U

T

For Auto operation, Put link across 'ON' push button

M-COMMANDER

Relay contact position shown in 'Power off' condition

WINDING OVER-TEMPERATURE PROTECTION RELAYS

Sensing motor winding

temperature through PTC

Thermistors.

Winding overheating, sensor

short, sensor open faults.

Suitable for single,

triple or 6/9/12 PTCs

Sensing motor winding temperature

through PTC Thermistors.

Winding overheating,

sensor short, sensor open faults.

Suitable for single,

triple or 6/9/12 PTCs

failsafe/Non fail safe

28

Wherever not specified

Contact Rating :

5A @ 230 V AC (resistive)

Supply Voltage

Auxiliary

Output Contacts

Trip Setting

Thermistor Sensor Healthy

Thermistor Sensor Trip

Thermistor Sensor Open

Thermistor Sensor Short

Trip time delay

Resetting

Dimensions (mm)

Overall (L x W x D)

Mounting (L x W)

Weight

Selection Chart for NRT of PTC Thermistors.

NRT Class Cable Colour

0

C of Ins. Code

70 White - Brown

80 White - White

90 Green - Green

100 A Red - Red

110 Brown - Brown

120 E Grey - Grey

130 B Blue - Blue

140 White - Blue

150 F Black - Black

160 Blue - Red

170 H White - Green

180 C White - Red

190 Orange - Black

PTC

THERMISTOR

CONDITION

AND TRIP

SETTINGS

RESISTANCE VS TEMPERATURE

O/P

RELAY

STATUS

OPENED

(RESISTANCE

> 5.6k)

UNHEALTHY

(RESISTANCE

>4.2k < 5.5k)

Relay Reset

Zone

(>1.5K<1.8K)

HEALTHY

RESISTANCE

>39W<4K

SHORTED

(RESISTANCE

< 3.9W

250C

ROOM TEMP.

NRT-20 NRT-5 NRT

100

200

250

500

1000

1500

2000

3000

4000

5000

5600

6000

R

E

S

IS

T

A

N

C

E

IN

O

H

M

S

NRT+5 NRT+15

TYPICAL CHARACTERISTICS OF PTC (THERMISTOR)

PTC Thermistors are semi conductor

sensors. These have typical characteristics

that change their resistance instantly at a

specified pre-defined response temperature

(NRT). As soon as the surrounding

temperature of PTC reaches it's NRT value the

body resistance of PTC Thermistor rises

sharply from 200 / 250 Ohms to more than

5000 Ohms.The PTC Thermistors are

embedded in the overhang location of the

motor windings.

The NRT value of PTC is selected according to

the Insulation Class of the copper windings of

motor or transformers.

1 3 5 6

S2 WTR1

M

M1

Aux.

Supply

R

M2 Y

M3 B

R

Y

B

2 1 3

8 7 9

14 13 15

N/V

OFF ON

DOL STARTER

M1

M2

M3

MOTOR

WTRD1

Aux.

Supply Manual

Reset

WTR D1 S2 WTR1

Winding Protection Relay PTC Thermistor Relay

PTC

Thermistor

Resetting Mode

1 CO

40 ohm - 4 K ohm

4.1 K ohm - 5.5 K ohm

5.6 K ohm & above

39 ohms & below

Less than 2 secs.

Below 1.51 K

76 x 30.5 x 117.5

68 mm centre to centre / 35 mm Rail Mounting

300 gms.

110-120/220-240/380-440 V AC/24 V DC 50Hz(60 Hz)10%

Auto / Manual (Optional)

2 CO

40 to 4K

4.1K 5.5K

5.6K & Above

0 - 39

Less than 1 Sec (Fixed)

Below 1.51 K

90 x 35 x 60

35 mm Rail Mounting

250 gms.

12/24V DC/100-120/220-240V AC, 50Hz(60 Hz)10%

Auto / Manual

Relay contact position shown in 'Power off' condition

Minilec offers CBCT for our Earth

fault relay & Earth Leakage Relay.

Ordering Information:

Primary & Secondary Current.

Inner Diameter.

Outer Diameter.

Minilec Relay Model Name.

You might also like

- Motor Pump Protection RelaysDocument6 pagesMotor Pump Protection RelaysSufyan HashmiNo ratings yet

- Power System Commissioning and Maintenance PracticeDocument38 pagesPower System Commissioning and Maintenance PracticeMohamed MohsenNo ratings yet

- Feeder Protection Relay SpecificationDocument4 pagesFeeder Protection Relay SpecificationMeghavahinaNo ratings yet

- Feedback Amplifiers-EDC PDFDocument45 pagesFeedback Amplifiers-EDC PDFanjanaNo ratings yet

- Time-Current Coordination ExampleDocument6 pagesTime-Current Coordination ExamplekishansaiNo ratings yet

- Study of Over Current Earth Fault RelayDocument1 pageStudy of Over Current Earth Fault RelayVirender RanaNo ratings yet

- Spec HT CapacitorDocument35 pagesSpec HT CapacitorJAY PARIKH100% (1)

- Attachment BDocument9 pagesAttachment Bamit1003_kumarNo ratings yet

- Speed Control of Ac Motor Using TriacDocument2 pagesSpeed Control of Ac Motor Using TriacHarshaNo ratings yet

- A Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyDocument67 pagesA Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyGunjan VarshneyNo ratings yet

- Switchgear & ProtectionDocument92 pagesSwitchgear & Protectionseshumlnss100% (1)

- Lecture 11 Electrification of Commercial InstallationDocument7 pagesLecture 11 Electrification of Commercial InstallationBUKENYA BEEE-2026No ratings yet

- 4029INSTRUMENTTRANSFORMERSDocument95 pages4029INSTRUMENTTRANSFORMERSmuaz_aminu1422100% (2)

- PV PQ Bus Switching Power Flow Pscc2008 - 128Document7 pagesPV PQ Bus Switching Power Flow Pscc2008 - 128kcirrenwodNo ratings yet

- Abbreviations PowergridDocument100 pagesAbbreviations PowergridJayant Kumar Das100% (1)

- EEE Job PreparationDocument12 pagesEEE Job Preparationpinare2193No ratings yet

- Electromagnetic Relay Static Relay Numerical Relay: Single Input Comparator Dual Input Comparator Multi Input ComparatorDocument34 pagesElectromagnetic Relay Static Relay Numerical Relay: Single Input Comparator Dual Input Comparator Multi Input ComparatorSathiyarajNo ratings yet

- Voltage Regulator AutoTuningDocument12 pagesVoltage Regulator AutoTuningНиколай МухаNo ratings yet

- IdmtDocument3 pagesIdmtAdeel RazaNo ratings yet

- Projects Titles For Protection - W2017Document3 pagesProjects Titles For Protection - W2017Ahmad AbunassarNo ratings yet

- Transformer Solved Examples of Basic Electrical Eng by Nagrath and KothariDocument4 pagesTransformer Solved Examples of Basic Electrical Eng by Nagrath and KothariAnurag ZwNo ratings yet

- Cba 3000Document12 pagesCba 3000RAJESH KUMARNo ratings yet

- Beginners' Electrical Design CourseDocument16 pagesBeginners' Electrical Design CourseSARATHBABU LAKSHMANANNo ratings yet

- Mason-The Art & Science of Protective Relaying (002-010)Document9 pagesMason-The Art & Science of Protective Relaying (002-010)Marian ArjonaNo ratings yet

- Bus Bar Protection: External FaultsDocument4 pagesBus Bar Protection: External FaultsChanderSinghWarkadeNo ratings yet

- Tutorial On Single Phase Induction MotorDocument1 pageTutorial On Single Phase Induction MotorHimanshu Saini0% (1)

- BCD To 7-Segment Display DecoderDocument7 pagesBCD To 7-Segment Display DecoderJohn Brix BalisterosNo ratings yet

- Experiments of High Voltage EngineeringDocument1 pageExperiments of High Voltage Engineeringarslan_engineerNo ratings yet

- Fuse and Types of Fuses - Electrical Technology-OkDocument7 pagesFuse and Types of Fuses - Electrical Technology-Okdrastir_777100% (1)

- Circuit Breaker SGPDocument34 pagesCircuit Breaker SGPSamuel BhukyaNo ratings yet

- 11.example Calculation - TransformerDocument16 pages11.example Calculation - Transformerrajpre1213No ratings yet

- Operacion Recloser RoclwillDocument54 pagesOperacion Recloser RoclwillChristian Vasquez MedranoNo ratings yet

- Psabits WithanswersDocument12 pagesPsabits WithanswersChinnareddy KarriNo ratings yet

- Selection of Current Transformers (CTS) Based On Short Circuit Study ReportDocument5 pagesSelection of Current Transformers (CTS) Based On Short Circuit Study ReportSatya VasuNo ratings yet

- Boost DesignDocument4 pagesBoost DesignmuthukumartharaniNo ratings yet

- Asynchronous and Synchronous Machines (EL-208) (IV SEM EL Session 2017-18) Tutorial Sheet 1 (Dated 08.01.2018) (3 Phase Induction MotorsDocument10 pagesAsynchronous and Synchronous Machines (EL-208) (IV SEM EL Session 2017-18) Tutorial Sheet 1 (Dated 08.01.2018) (3 Phase Induction MotorsKushagra BhatiaNo ratings yet

- ICL8038 Linear Sweep Function Generator CCTDocument2 pagesICL8038 Linear Sweep Function Generator CCTian_new100% (1)

- SwitchyardDocument33 pagesSwitchyardAafaque QureshiNo ratings yet

- Basic Motor ControlDocument17 pagesBasic Motor ControlHeizen BulanNo ratings yet

- Automatic Alternator SynchronisationDocument24 pagesAutomatic Alternator SynchronisationHemant Patel50% (2)

- 2024 Egd Pat EnglishDocument27 pages2024 Egd Pat Englishmichaeelsayed100% (1)

- Supplement To Fault CalculationDocument88 pagesSupplement To Fault CalculationCaribNo ratings yet

- What Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPDocument5 pagesWhat Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPcurazaq100% (1)

- Motor Soft StarterDocument4 pagesMotor Soft Starteralfredo_fredo_1No ratings yet

- FM Spae01 en BDocument12 pagesFM Spae01 en BSudhakar YsNo ratings yet

- Power Factor Meters - Electrodynamometer Type Power Factor MeterDocument4 pagesPower Factor Meters - Electrodynamometer Type Power Factor MeterNh Chuminda YapaNo ratings yet

- ELECTRICAL INSTALLATIONS Task1Document7 pagesELECTRICAL INSTALLATIONS Task1Akmal HazimNo ratings yet

- Synopsis Proposal For 2021Document4 pagesSynopsis Proposal For 20212k18-EE-243 Vethushan VinnayagamoorththiNo ratings yet

- Protection & SwitchgearDocument50 pagesProtection & SwitchgearvnrsamyNo ratings yet

- ExamAut LWD2022BDocument6 pagesExamAut LWD2022BAyman100% (1)

- Metering For Linemen: Current TransformersDocument3 pagesMetering For Linemen: Current TransformersEBENo ratings yet

- DC Machines and Transformers Lab Manual ModifiedDocument50 pagesDC Machines and Transformers Lab Manual ModifiedSuseel MenonNo ratings yet

- DCMTDocument37 pagesDCMTGloria HolcombNo ratings yet

- Novel Method PMDC Motor Speed ControlDocument15 pagesNovel Method PMDC Motor Speed ControlTravis WoodNo ratings yet

- Transmission LineDocument89 pagesTransmission LineUbaid RaufNo ratings yet

- Provisional Merit List PBBSC 202223 20221007 195219Document32 pagesProvisional Merit List PBBSC 202223 20221007 195219Satyajit PatraNo ratings yet

- Provisional Merit List Anm Course 20222023 20221008 171438Document238 pagesProvisional Merit List Anm Course 20222023 20221008 171438Satyajit PatraNo ratings yet

- Provisional Merit List Pbdiploma 202223 20221007 195152Document1 pageProvisional Merit List Pbdiploma 202223 20221007 195152Satyajit PatraNo ratings yet

- Provisional Merit List GNM Course 202223 20221009 005125Document211 pagesProvisional Merit List GNM Course 202223 20221009 005125Satyajit PatraNo ratings yet

- Provisional Merit List Basic BSC Course 202223 20221008 224212Document307 pagesProvisional Merit List Basic BSC Course 202223 20221008 224212Satyajit Patra100% (1)

- Student Academic Management System (SAMS) S PDFDocument2 pagesStudent Academic Management System (SAMS) S PDFSatyajit PatraNo ratings yet

- State/District Wise Details of COVID-19 Positive CasesDocument10 pagesState/District Wise Details of COVID-19 Positive CasesSatyajit PatraNo ratings yet

- Brochure CCQC 2016 R1Document8 pagesBrochure CCQC 2016 R1Satyajit PatraNo ratings yet

- List of Running Trains With Arrival & Departure TimingsDocument6 pagesList of Running Trains With Arrival & Departure TimingsSatyajit PatraNo ratings yet

- Siemens s7-300 ProgrammingDocument98 pagesSiemens s7-300 ProgrammingSatyajit PatraNo ratings yet

- Circuits PDFDocument10 pagesCircuits PDFSatyajit PatraNo ratings yet

- How To Pick Up Fluency in English Thro' Self-Study: FluentzyDocument20 pagesHow To Pick Up Fluency in English Thro' Self-Study: FluentzySatyajit PatraNo ratings yet

- Infineon Motor Control Drives ABR v01 00 enDocument48 pagesInfineon Motor Control Drives ABR v01 00 enbeasant100% (1)

- KAPCO Internship ReportDocument26 pagesKAPCO Internship ReportMIan MuzamilNo ratings yet

- Stone Plate Compactor Operator's Manual EnglishDocument50 pagesStone Plate Compactor Operator's Manual Englishornel jacksonNo ratings yet

- MR-J2S Renewal Tool Catalog x901307-312Document8 pagesMR-J2S Renewal Tool Catalog x901307-312Messias da SilvaNo ratings yet

- ANR96 IM125-U-A v4.1Document58 pagesANR96 IM125-U-A v4.1Hector herreraNo ratings yet

- Semi-Detailed Lesson Plan Tle 6 (Industrial Arts) Fourth QuarterDocument3 pagesSemi-Detailed Lesson Plan Tle 6 (Industrial Arts) Fourth QuarterEiram Williams78% (9)

- Parts Manual: Electric Stacker WS10S-1600MDocument23 pagesParts Manual: Electric Stacker WS10S-1600Mgargi yesareNo ratings yet

- Nissan RH10 - Service Manual Free Download, Schemat PDFDocument3 pagesNissan RH10 - Service Manual Free Download, Schemat PDFHungaga100% (8)

- SSP 298 Touareg ElectricsDocument31 pagesSSP 298 Touareg Electricsภูเก็ต เป็นเกาะ100% (3)

- Benz 968590164562 20171230224054Document5 pagesBenz 968590164562 20171230224054عمار ميسينيNo ratings yet

- List Part TristanDocument7 pagesList Part TristanNur YadieNo ratings yet

- 2014 Service & Accessory Kits PDFDocument36 pages2014 Service & Accessory Kits PDFCláudio LimaNo ratings yet

- Tech. Specifications On Power TransformerDocument2 pagesTech. Specifications On Power Transformershine1975No ratings yet

- TRCM Safe Parking: Technical InformationDocument2 pagesTRCM Safe Parking: Technical InformationMirek BudaNo ratings yet

- 4BY2-150, YanmarDocument2 pages4BY2-150, YanmarArul muuklisinNo ratings yet

- ED3150 3P 150A 240V 65KAIC Breaker: Eaton Cutler-HammerDocument3 pagesED3150 3P 150A 240V 65KAIC Breaker: Eaton Cutler-HammerOtto AcnNo ratings yet

- 7sd61 Catalog Sip E7Document26 pages7sd61 Catalog Sip E7anse1No ratings yet

- Herion Poppets PDFDocument20 pagesHerion Poppets PDFhamzaNo ratings yet

- ACTS125K PLUS Application Notes5Document4 pagesACTS125K PLUS Application Notes5mohsinNo ratings yet

- Synrgy360 Training Systems: Owner's Manual and Installation InstructionsDocument64 pagesSynrgy360 Training Systems: Owner's Manual and Installation InstructionsDennis CrossNo ratings yet

- MK SpecDocument2 pagesMK SpecBrandon TrocNo ratings yet

- Alliance 5w Remote Unit (Mrou) v2.3Document5 pagesAlliance 5w Remote Unit (Mrou) v2.3Diego ZagoNo ratings yet

- PromoveDocument6 pagesPromoveAlberto de la cruzNo ratings yet

- Triple Band Combiner Datasheet V1.1Document1 pageTriple Band Combiner Datasheet V1.1Сергей МирошниченкоNo ratings yet

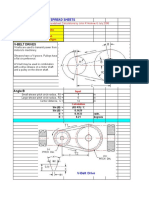

- V Belt CalculationDocument4 pagesV Belt Calculationmustufa akolawalaNo ratings yet

- 1SVR427032R0000 CP e 24 2 5Document4 pages1SVR427032R0000 CP e 24 2 5masthanNo ratings yet

- Sylvania Guide To Energy Saving Lamps Brochure 1990-1991Document16 pagesSylvania Guide To Energy Saving Lamps Brochure 1990-1991Alan Masters100% (1)

- Calc lvswgr1124423Document2 pagesCalc lvswgr1124423Ashwini KasarlaNo ratings yet

- Router Table Fence PlansDocument9 pagesRouter Table Fence PlansAfonso PraganaNo ratings yet

- PIX PowerWare Pulleys & CouplingsDocument110 pagesPIX PowerWare Pulleys & CouplingsAman ParmeswarNo ratings yet