Professional Documents

Culture Documents

BR Oilfield Demulsifier Bulletin

Uploaded by

Vishnu LalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BR Oilfield Demulsifier Bulletin

Uploaded by

Vishnu LalCopyright:

Available Formats

Global Oileld Solutions

Demulsiers for the Oil Industry:

Basorol

E

V

G

1

3

8

4

e

PRODUCT RANGE

The Basorol

types are concentrated single products designed for use

as components for demulsier formulations. In order to optimize

performance, it may be necessary to blend two or more Basorol

types.

Basorol

types are classied into 5 groups:

GROUP 1 These alkoxylated butyl, amyl and nonyl phenol resins have the broadest

treating range for crudes. Normally they are the predominant part of the

formulation and they allow emulsions to be treated at lower temperatures.

GROUP 2 These are EO / PO block-co-polymers which are used to treat high-gravity

crudes, enhance the interface, clean up and improve water clarity. They

are often blended with Basorol

Group 1 products to improve the interface

and /or water clarity. High RSN value products wet solids and iron suldes.

GROUP 3 They act as polishers, brighteners and nishing compounds. They can

increase the speed of water drop similar to the alkoxylated poly ethyleneimines

(Group 5). Combination with phenolic resins (Group 1) is recommended

to treat low- to medium-gravity crudes.

GROUP 4 Consists of amine alkoxylates which help to reduce residual water and

salt content. They can be blended with Basorol

Group 1 products to

improve the interface and /or water clarity. High RSN value products wet

solids and iron suldes.

GROUP 5 These alkoxylated polyethyleneimines (PEI) are often used in combination

with Basorol

Group 1, especially in low- to medium-gravity crudes.

They often lead to improved water clarity.

Cover picture:

Cryo-SEM (Scanning Electron

Microscopy) image of a crude

oil emulsion (origin: Germany)

in false color representation.

The most important objective of any oil

production facility is the separation of

water from produced crude. The quick and

efcient breaking of these emulsions is

essential to meet tight downstream crude

oil specications. In general crude oil is

produced as a water-in-oil emulsion and

demulsiers are necessary for breaking

such emulsions. The factors involved in

treating emulsions include breaking the

lm surrounding the small water droplets

and coalescing the droplets to produce

larger drops. Finally the water drops settle

during or after their coalescence.

BASOROL

DEMULSIFIERS

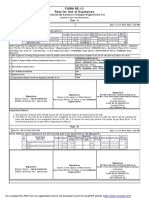

General information Solubility (10 % product) Function

Product name Product form

Active content

(%)

Viscosity

(cPs) @ 20 C

RSN Isopropanol Water Kerosene Aromatic

Water

Dropper

Treater /

Dryer

Desalter

G

r

o

u

p

1

Basorol

P DB-9429 Viscous liquid 75 90 1,200 1,600 12 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9934 Viscous liquid 75 90 8,000 12,000 14 16 Dispersible Insoluble Insoluble Dispersible

Basorol

P DB-9935 Viscous liquid 50 90 4,000 8,500 17 20 Soluble Dispersible Insoluble Soluble

Basorol

P DB-9945 Viscous liquid 50 90 6,000 12,000 8 10 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9946 Viscous liquid 85 95 2,000 5,000 10 12 Dispersible Insoluble Insoluble Soluble

Basorol

P DB-9947 Viscous liquid > 80 1,000 3,000 12 14 Dispersible Dispersible Insoluble Soluble

Basorol

P DB-9954 Viscous liquid 45 65 100 300 11 13 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9954 A Viscous liquid 60 75 700 3,000 10 12 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9955 Viscous liquid 55 70 1,500 13.5 15.5 Soluble Dispersible Insoluble Soluble

Basorol

P DB-9958 Viscous liquid 80 95 750 1,250 14 16 Soluble Insoluble Insoluble Soluble

G

r

o

u

p

2

Basorol

17 R 4 Liquid 100 600 16.2 Soluble Dispersible Insoluble Soluble

Basorol

25 R 2 Liquid 100 680 12.3 Soluble Insoluble Insoluble Soluble

Basorol

L 31 Liquid 100 175 15.6 Soluble Soluble Insoluble Soluble

Basorol

L 61 Liquid 100 325 11.3 Soluble Insoluble Insoluble Soluble

Basorol

L 62 Liquid 100 450 16.5 Soluble Dispersible Insoluble Soluble

Basorol

L 101 Liquid 100 800 9.6 Soluble Insoluble Insoluble Soluble

Basorol

PE 10100 Liquid 100 800 9.7 Soluble Dispersible Insoluble Soluble

Basorol

P 17 R 2 Liquid 100 450 13.9 Soluble Soluble Insoluble Soluble

Basorol

PE 6400 Liquid 100 1,000 20.1 Soluble Soluble Insoluble Soluble

G

r

o

u

p

3

Basorol

G 3218 Liquid 100 600 13.9 Soluble Dispersible Insoluble Soluble

Basorol

G 6523 Liquid 100 880 1,000 10.7 Soluble Insoluble Insoluble Soluble

Basorol

K 1026 Liquid 100 1,329 12.1 Soluble Soluble Insoluble Soluble

Basorol

K 1135 I Liquid 100 420 16.9 Soluble Insoluble Insoluble Soluble

Basorol

K 2090 Viscous liquid 100 1,100 9.5 Soluble Insoluble Insoluble Soluble

Basorol

K 3800 Viscous liquid 100 1,370 9.4 Soluble Insoluble Insoluble Soluble

G

r

o

u

p

4

Basorol

150 R 1 Liquid 100 1,840 7.6 Soluble Insoluble Insoluble Soluble

Basorol

904 Paste 100 320 (@ 60 C) 33.8 Dispersible Soluble Insoluble Dispersible

Basorol

P DB-5951 Liquid 100 1,100 1,300 11.0 Soluble Insoluble Insoluble Soluble

G

r

o

u

p

5

Basorol

P DB-9390 Liquid 75 90 740 (@ 50 C) 13.4 Dispersible Insoluble Insoluble Dispersible

Basorol

P DB-9392 Liquid 80 100 2,050 (@ 50 C) 8.3 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9360 Liquid 76 91 5,700 7.0 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9393 Viscous liquid 80 100 500 2,000 5 7 Soluble Insoluble Insoluble Soluble

Demulsier kits are available upon request from your local

sales representative.

The majority of the crudes worldwide

can be treated with a combination of

alkoxylated alkyl phenol resins (Group 1)

and alkoxylated polyethyleneimines

(Group 5) from BASF. Proven in

> 20 years of eld experience in the

Eastern Hemisphere.

BASOROL

DEMULSIFIERS

General information Solubility (10 % product) Function

Product name Product form

Active content

(%)

Viscosity

(cPs) @ 20 C

RSN Isopropanol Water Kerosene Aromatic

Water

Dropper

Treater /

Dryer

Desalter

G

r

o

u

p

1

Basorol

P DB-9429 Viscous liquid 75 90 1,200 1,600 12 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9934 Viscous liquid 75 90 8,000 12,000 14 16 Dispersible Insoluble Insoluble Dispersible

Basorol

P DB-9935 Viscous liquid 50 90 4,000 8,500 17 20 Soluble Dispersible Insoluble Soluble

Basorol

P DB-9945 Viscous liquid 50 90 6,000 12,000 8 10 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9946 Viscous liquid 85 95 2,000 5,000 10 12 Dispersible Insoluble Insoluble Soluble

Basorol

P DB-9947 Viscous liquid > 80 1,000 3,000 12 14 Dispersible Dispersible Insoluble Soluble

Basorol

P DB-9954 Viscous liquid 45 65 100 300 11 13 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9954 A Viscous liquid 60 75 700 3,000 10 12 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9955 Viscous liquid 55 70 1,500 13.5 15.5 Soluble Dispersible Insoluble Soluble

Basorol

P DB-9958 Viscous liquid 80 95 750 1,250 14 16 Soluble Insoluble Insoluble Soluble

G

r

o

u

p

2

Basorol

17 R 4 Liquid 100 600 16.2 Soluble Dispersible Insoluble Soluble

Basorol

25 R 2 Liquid 100 680 12.3 Soluble Insoluble Insoluble Soluble

Basorol

L 31 Liquid 100 175 15.6 Soluble Soluble Insoluble Soluble

Basorol

L 61 Liquid 100 325 11.3 Soluble Insoluble Insoluble Soluble

Basorol

L 62 Liquid 100 450 16.5 Soluble Dispersible Insoluble Soluble

Basorol

L 101 Liquid 100 800 9.6 Soluble Insoluble Insoluble Soluble

Basorol

PE 10100 Liquid 100 800 9.7 Soluble Dispersible Insoluble Soluble

Basorol

P 17 R 2 Liquid 100 450 13.9 Soluble Soluble Insoluble Soluble

Basorol

PE 6400 Liquid 100 1,000 20.1 Soluble Soluble Insoluble Soluble

G

r

o

u

p

3

Basorol

G 3218 Liquid 100 600 13.9 Soluble Dispersible Insoluble Soluble

Basorol

G 6523 Liquid 100 880 1,000 10.7 Soluble Insoluble Insoluble Soluble

Basorol

K 1026 Liquid 100 1,329 12.1 Soluble Soluble Insoluble Soluble

Basorol

K 1135 I Liquid 100 420 16.9 Soluble Insoluble Insoluble Soluble

Basorol

K 2090 Viscous liquid 100 1,100 9.5 Soluble Insoluble Insoluble Soluble

Basorol

K 3800 Viscous liquid 100 1,370 9.4 Soluble Insoluble Insoluble Soluble

G

r

o

u

p

4

Basorol

150 R 1 Liquid 100 1,840 7.6 Soluble Insoluble Insoluble Soluble

Basorol

904 Paste 100 320 (@ 60 C) 33.8 Dispersible Soluble Insoluble Dispersible

Basorol

P DB-5951 Liquid 100 1,100 1,300 11.0 Soluble Insoluble Insoluble Soluble

G

r

o

u

p

5

Basorol

P DB-9390 Liquid 75 90 740 (@ 50 C) 13.4 Dispersible Insoluble Insoluble Dispersible

Basorol

P DB-9392 Liquid 80 100 2,050 (@ 50 C) 8.3 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9360 Liquid 76 91 5,700 7.0 Soluble Insoluble Insoluble Soluble

Basorol

P DB-9393 Viscous liquid 80 100 500 2,000 5 7 Soluble Insoluble Insoluble Soluble

INITIAL RECOMMENDATION

FOR BOTTLE-TESTING

1. Screen Group 1 and Group 5 as single components.

2. Combine the best out of each class (usually 1:1,

1:2, 2:1 ratios).

3. To achieve the desired performance you can also

screen for the blockcopolymers (Group 2 + 4) and

polyol alkoxylates (Group 3).

4. The use of DDBSA (dodecylbenzylsulfonic acid)

can improve formulation performance if added

in small amounts (1 2 %).

Remarks

Dilute all products to be screened to 5 10 % in an aromatic

solvent (add isopropanol if necessary for solubilization) before

addition to the crude oil emulsion.

Shake vigorously after addition to ensure complete mixing of

the demulsier.

Do not add more than approx. 300 uL of the diluted demulsier

to avoid solvent effects.

FUNCTION GUIDE

The base components of a demulsier can generally be

characterized by their function in breaking up emulsions.

In addition it is also noted that several demulsier bases

can be multipurpose in their function depending on the

nature of the emulsion.

DROPPERS The function of these components is to help coalesce water

droplets and release free water. The most common types are

based on alkoxylated resins.

TREATERS The function of these components is to help occulate

sub-micron water particulates that are dispersed in the crude.

They are also referred to as drying agents. Alkoxylated

polyethyleneimines (PEI) are one of the most successful

treater classes within BASFs portfolio.

DESALTERS Emulsions in a desalter unit usually contain low amounts of

water and are less stable due to the removal of emulsing

agents in previous demulsication stages. In addition, a

high potential electric eld is applied to help coalesce the

polar salt water droplets. A desalter demulsier base will

exhibit rapid water separation and be able to handle

crudes from various origins.

WETTING AGENTS These components primary function is to interact with solids,

e. g. sands or iron suldes, contained in the crude. High RSN

value products serve to change the wettability of their surfaces.

The descriptions, designs, data and information contained herein are presented in good faith, and are based on BASFs

current knowledge and experience. They are provided for guidance only, and do not constitute the agreed contractual

quality of the product or a part of BASFs terms and conditions of sale. Because many factors may affect processing or

application / use of the product, BASF recommends that the reader carry out its own investigations and tests to determine

the suitability of a product for its particular purpose prior to use. It is the responsibility of the recipient of product to ensure

that any proprietary rights and existing laws and legislation are observed. No warranties of any kind, either express or

implied, including, but not limited to, warranties of merchantability or tness for a particular purpose, are made regarding

products described or designs, data or information set forth herein, or that the products, descriptions, designs, data or

information may be used without infringing the intellectual property rights of others. Any descriptions, designs, data and

information given in this publication may change without prior information. The descriptions, designs, data, and information

furnished by BASF hereunder are given gratis and BASF assumes no obligation or liability for the descriptions, designs,

data or information given or results obtained, all such being given and accepted at the readers risk. ( 12/2013)

= registered trademark of BASF SE

North America

Global Headquarters

BASF Corporation

Global Oileld Solutions

3120 Hayes Road

Suite 200

Houston, TX 77082

US

Phone: +1 800 7941019

Fax: +1 877 2451806

Europe

BASF SE

Global Oileld Solutions

G-EVG/GM J542 S

67056 Ludwigshafen

Germany

Phone: +49 621 60-56587

Fax: +49 621 60-6656587

Asia

BASF South East Asia Pte. Ltd.

Global Oileld Solutions

#35-01 Suntec Tower One

7 Temasek Boulevard

038987 Singapore

Singapore

Phone: +65 6393-5208

Fax: +65 6430-9899

South America

BASF S.A.

Global Oileld Solutions

Avenida das Naes Unidas,

14.171 Morumbi

04794-000 So Paulo

Brazil

Phone: +55 11 2039-3482

Fax: +55 11 2039-2786

Middle East / North Africa

BASF FZE

Global Oileld Solutions

P. O. Box 61309

Dubai

United Arab Emirates

Phone: +971 4 8072222

Fax: +971 4 8877381

Russia / CIS

ZAO BASF

14 / 3, Kadashevskaya nab.

119017 Moscow

Russian Federation

Phone: +7 495 2317200

Fax: +7 495 2317201

For further information:

oilfieldsolutions@basf.com

www.oilfield-solutions.basf.com E

V

G

1

3

8

4

e

You might also like

- RPG Cable GlandsDocument6 pagesRPG Cable GlandsAhamed AshithNo ratings yet

- AstmDocument1 pageAstmVishnu LalNo ratings yet

- Hazardous Locations: Guide To Equipment Certification Requirements ForDocument1 pageHazardous Locations: Guide To Equipment Certification Requirements ForVishnu LalNo ratings yet

- G1 Test Answers G1 Cheat Sheet PDFDocument64 pagesG1 Test Answers G1 Cheat Sheet PDFRowan Rodrigues71% (14)

- Area Classification IEC NECDocument18 pagesArea Classification IEC NECin107247100% (1)

- Duct Mounting FGS DetectorsDocument1 pageDuct Mounting FGS DetectorsVishnu LalNo ratings yet

- Type of ThreadDocument13 pagesType of ThreadVils ArabadzhievaNo ratings yet

- American Wide Flange Beams - W BeamDocument4 pagesAmerican Wide Flange Beams - W BeamVishnu LalNo ratings yet

- FD-410Ex User Manual ConnectionsDocument1 pageFD-410Ex User Manual ConnectionsVishnu LalNo ratings yet

- 501 453 UnivDocument1 page501 453 UnivVishnu LalNo ratings yet

- XCD PDFDocument4 pagesXCD PDFVishnu LalNo ratings yet

- 1 11 020 Is l101l Datasheet - PDF Red IndicationDocument2 pages1 11 020 Is l101l Datasheet - PDF Red IndicationVishnu LalNo ratings yet

- Detronic Product CatlogDocument244 pagesDetronic Product CatlogVishnu LalNo ratings yet

- Mvi56e MCMMCMXT User ManualDocument199 pagesMvi56e MCMMCMXT User ManualfernandoNo ratings yet

- XCD PDFDocument4 pagesXCD PDFVishnu LalNo ratings yet

- Type of ThreadDocument13 pagesType of ThreadVils ArabadzhievaNo ratings yet

- 501 453 UnivDocument1 page501 453 UnivVishnu LalNo ratings yet

- Properties of Carbon SteelDocument1 pageProperties of Carbon SteelVishnu LalNo ratings yet

- SS-810-6-Swagelok FittingsDocument1 pageSS-810-6-Swagelok FittingsVishnu LalNo ratings yet

- 0001 Total CatlogDocument152 pages0001 Total CatlogVishnu LalNo ratings yet

- 501 453 UnivDocument1 page501 453 UnivVishnu LalNo ratings yet

- H S81 HS BrochureDocument5 pagesH S81 HS BrochureVishnu LalNo ratings yet

- Welding Difficult Steels - SUPERINOX 312 Flux Cored WireDocument1 pageWelding Difficult Steels - SUPERINOX 312 Flux Cored WireVishnu LalNo ratings yet

- Atex A2 WallplannerDocument1 pageAtex A2 WallplannerVishnu LalNo ratings yet

- Vetron IcsDocument17 pagesVetron IcsVishnu LalNo ratings yet

- Modbus TCP TrainingDocument45 pagesModbus TCP TrainingVishnu Lal100% (1)

- PTE BroucherDocument15 pagesPTE BroucherVishnu LalNo ratings yet

- Fieldbus Communicator PDFDocument5 pagesFieldbus Communicator PDFVishnu LalNo ratings yet

- Maybank2u Snap, Post & Win Contest T&CsDocument3 pagesMaybank2u Snap, Post & Win Contest T&CsVishnu LalNo ratings yet

- Income Tax Return (India)Document3 pagesIncome Tax Return (India)Vishnu Lal100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- GIS Multi-Criteria Analysis by Ordered Weighted Averaging (OWA) : Toward An Integrated Citrus Management StrategyDocument17 pagesGIS Multi-Criteria Analysis by Ordered Weighted Averaging (OWA) : Toward An Integrated Citrus Management StrategyJames DeanNo ratings yet

- Progressive Myoclonic Epilepsies - Practical Neurology 2015. MalekDocument8 pagesProgressive Myoclonic Epilepsies - Practical Neurology 2015. MalekchintanNo ratings yet

- India Today 11-02-2019 PDFDocument85 pagesIndia Today 11-02-2019 PDFGNo ratings yet

- 2nd Pornhub Awards - WikipediaaDocument13 pages2nd Pornhub Awards - WikipediaaParam SinghNo ratings yet

- Describing-Jobs-British-English StudentDocument3 pagesDescribing-Jobs-British-English Studentrenata pedroso100% (1)

- GATE ECE 2006 Actual PaperDocument33 pagesGATE ECE 2006 Actual Paperkibrom atsbhaNo ratings yet

- GMWIN SoftwareDocument1 pageGMWIN SoftwareĐào Đình NamNo ratings yet

- Inorganica Chimica Acta: Research PaperDocument14 pagesInorganica Chimica Acta: Research PaperRuan ReisNo ratings yet

- Energy AnalysisDocument30 pagesEnergy Analysisca275000No ratings yet

- Us Virgin Island WWWWDocument166 pagesUs Virgin Island WWWWErickvannNo ratings yet

- Skuld List of CorrespondentDocument351 pagesSkuld List of CorrespondentKASHANNo ratings yet

- PLC Networking with Profibus and TCP/IP for Industrial ControlDocument12 pagesPLC Networking with Profibus and TCP/IP for Industrial Controltolasa lamessaNo ratings yet

- Top Malls in Chennai CityDocument8 pagesTop Malls in Chennai CityNavin ChandarNo ratings yet

- Service and Maintenance Manual: Models 600A 600AJDocument342 pagesService and Maintenance Manual: Models 600A 600AJHari Hara SuthanNo ratings yet

- Thin Film Deposition TechniquesDocument20 pagesThin Film Deposition TechniquesShayan Ahmad Khattak, BS Physics Student, UoPNo ratings yet

- Book Networks An Introduction by Mark NewmanDocument394 pagesBook Networks An Introduction by Mark NewmanKhondokar Al MominNo ratings yet

- PandPofCC (8th Edition)Document629 pagesPandPofCC (8th Edition)Carlos Alberto CaicedoNo ratings yet

- PESO Online Explosives-Returns SystemDocument1 pagePESO Online Explosives-Returns Systemgirinandini0% (1)

- FR Post-10Document25 pagesFR Post-10kulich545No ratings yet

- Built - in BeamsDocument23 pagesBuilt - in BeamsMalingha SamuelNo ratings yet

- DLP in Health 4Document15 pagesDLP in Health 4Nina Claire Bustamante100% (1)

- Nokia MMS Java Library v1.1Document14 pagesNokia MMS Java Library v1.1nadrian1153848No ratings yet

- TOGAF 9 Foundation Part 1 Exam Preparation GuideDocument114 pagesTOGAF 9 Foundation Part 1 Exam Preparation GuideRodrigo Maia100% (3)

- New Education Policy 2019Document55 pagesNew Education Policy 2019Aakarshanam VenturesNo ratings yet

- SD8B 3 Part3Document159 pagesSD8B 3 Part3dan1_sbNo ratings yet

- Motor Master 20000 SeriesDocument56 pagesMotor Master 20000 SeriesArnulfo Lavares100% (1)

- Break Even AnalysisDocument4 pagesBreak Even Analysiscyper zoonNo ratings yet

- 15 - 5 - IoT Based Smart HomeDocument6 pages15 - 5 - IoT Based Smart HomeBhaskar Rao PNo ratings yet

- LM1011 Global ReverseLogDocument4 pagesLM1011 Global ReverseLogJustinus HerdianNo ratings yet