Professional Documents

Culture Documents

Restorent Automation

Uploaded by

Jebin GeorgeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Restorent Automation

Uploaded by

Jebin GeorgeCopyright:

Available Formats

Restaurant Automation

Dept Of ECE,VJCET 1

Chapter 1

INTRODUCTION

The 'embedded system' is a combination of hardware,software and additional

mechanical parts designed to do a specific function.it is intended to perform a particular task

with or without human intervention.software is developed as per user requirements to

perform desired functions. the project ' restaurant automation ' is based on embedded

techonology that uses ATMEL'S microcontroller AT89s52.this device has wide capabilityin

communication purposes.the program as per user's requirement ,is coded in assembly

language,keil is used to stimulate and assemble written code.

Restaurant Automation

Dept Of ECE,VJCET 2

Chapter 2

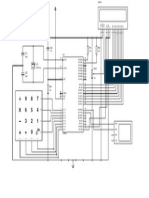

CIRCUIT DIAGRAM

Figure 2.1 Circuit diagram of receiver and customer section

Restaurant Automation

Dept Of ECE,VJCET 3

Chapter 3

INTRODUCTION TO MICROCONTROLLER AT89S52 ATMEL

Fig 3.1 AT8s52

The AT89S52 is a low-power, high-performance CMOS 8-bit microcontroller with4K

bytes of in-system programmable Flash memory. The device is manufactured using Atmels

high-density nonvolatile memory technology and is compatible with the industry standard

80C52 instruction set and pinout. The on-chip Flash allows the program memory to be

reprogrammed in-system or by a conventional nonvolatile memory programmer. By

combining a versatile 8-bit CPU with in-system programmable Flash on a monolithic chip,

the Atmel AT89S52 is a powerful microcontroller which provides a highly-flexible and cost-

effective solution to many embedded control applications

The AT89S52 provides the following standard features: 4K bytes of Flash, 128 bytes

of RAM, 32 I/O lines, Watchdog timer, two data pointers, two 16-bit timer/counters, a

fivevector two-level interrupt architecture, a full duplex serial port, on-chip oscillator, and

clock circuitry. In addition, the AT89S52 is designed with static logic for operation down to

zero frequency and supports two software selectable power saving modes. The Idle Mode

stops the CPU while allowing the RAM, timer/counters, serial port, and interrupt system to

Restaurant Automation

Dept Of ECE,VJCET 4

continue functioning. The Power-down mode saves the RAM contents but freezes the

oscillator, disabling all other chip functions until the next external interrupt or hardware reset.

3.1 FEATURES

4K Bytes of In-System Programmable (ISP) Flash Memory Endurance: 1000

Write/Erase cycles

4.0V to 5.5V Operating Range

Fully Static Operation: 0 Hz to 33 MHz

Three-level Program Memory Lock

128 x 8-bit Internal RAM

32 Programmable I/O Lines

Two 16-bit Timer/Counters

Six Interrupt Sources

Full Duplex UART Serial Channel

Low-power Idle and Power-down Modes

Interrupt Recovery from Power-down Mode

Watchdog Timer

Dual Data Pointer

Power-off Flag

Fast Programming Time

Flexible ISP Programming (Byte and Page Mode)

3.2 PORTS

Port 0 Port 0 is an 8-bit open drain bidirectional I/O port. As an output port, each pin can

sink eight TTL inputs. When 1s are written to port 0 pins, the pins can be used as high

impedance inputs. Port 0 can also be configured to be the multiplexed low-order address/data

bus during accesses to external program and data memory. In this mode, P0 has internal pull-

ups. Port 0 also receives the code bytes during Flash programming and outputs the code bytes

during program verification. External pull-ups are required during program verification.

Port 1 Port 1 is an 8-bit bidirectional I/O port with internal pull-ups. The Port 1 output

buffers can sink/source four TTL inputs. When 1s are written to Port 1 pins, they are pulled

Restaurant Automation

Dept Of ECE,VJCET 5

high by the internal pull-ups and can be used as inputs. As inputs, Port 1 pins that are

externally being pulled low will source current (IIL) because of the internal pull-ups.

Port 1 also receives the low-order address bytes during Flash programming and verification.

Table 3.1 port 1 pin functions

Port 2 Port 2 is an 8-bit bidirectional I/O port with internal pull-ups. The Port 2 output

buffers can sink/source four TTL inputs. When 1s are written to Port 2 pins, they are pulled

high by the internal pull-ups and can be used as inputs. As inputs, Port 2 pins that are

externally being pulled low will source current (IIL) because of the internal pull-ups.

Port 2 emits the high-order address byte during fetches from external program memory and

during accesses to external data memory that use 16-bit addresses (MOVX @ DPTR). In this

application, Port 2 uses strong internal pull-ups when emitting 1s. During accesses to external

data memory that use 8-bit addresses (MOVX @ RI), Port 2 emits the contents of the P2

Special Function Register.

Port 2 also receives the high-order address bits and some control signals during Flash

programming and verification.

Port 3 Port 3 is an 8-bit bidirectional I/O port with internal pull-ups. The Port 3 output

buffers can sink/source four TTL inputs. When 1s are written to Port 3 pins, they are pulled

high by the internal pull-ups and can be used as inputs. As inputs, Port 3 pins that are

externally being pulled low will source current (IIL) because of the pull-ups.

Port 3 receives some control signals for Flash programming and verification.

Port 3 also serves the functions of various special features of the AT89S51, as shown in the

following table.

Restaurant Automation

Dept Of ECE,VJCET 6

Table 3.2 port 3 pin functions

3.3 PIN CONFIGURATION

Fig 3.2 Pin Configuration

3.4 PIN DESCRIPTION

VCC Supply voltage.

GND Ground.

Restaurant Automation

Dept Of ECE,VJCET 7

RST Reset input. A high on this pin for two machine cycles while the oscillator is running

resets the

device. This pin drives High for 98 oscillator periods after the Watchdog times out. The

DISRTO bit in SFR AUXR (address 8EH) can be used to disable this feature. In the

default state of bit DISRTO, the RESET HIGH out feature is enabled.

ALE/PROG Address Latch Enable (ALE) is an output pulse for latching the low byte of

the address during accesses to external memory. This pin is also the program pulse input

(PROG) during Flash

programming. In normal operation, ALE is emitted at a constant rate of 1/6 the oscillator

frequency and may be used for external timing or clocking purposes. Note, however, that

one ALE pulse is

skipped during each access to external data memory. If desired, ALE operation can be

disabled by setting bit 0 of SFR location 8EH. With the bit set, ALE is active only during

a MOVX or MOVC instruction. Otherwise, the pin is weakly pulled high. Setting the

ALE-disable bit has no effect if the microcontroller is in external execution mode.

PSEN Program Store Enable (PSEN) is the read strobe to external program memory.

When the AT89S51 is executing code from external program memory, PSEN is activated

twice each machine cycle, except that two PSEN activations are skipped during each

access to external data memory.

EA/VPP External Access Enable. EA must be strapped to GND in order to enable the

device to fetch code from external program memory locations starting at 0000H up to

FFFFH. Note, however,

that if lock bit 1 is programmed, EA will be internally latched on reset. EA should be

strapped to VCC for internal program executions. This pin also receives the 12-volt

programming enable voltage (VPP) during Flash programming.

XTAL1 Input to the inverting oscillator amplifier and input to the internal clock operating

circuit.

XTAL2 Output from the inverting oscillator amplifier

Restaurant Automation

Dept Of ECE,VJCET 8

3.5 BLOCK DIAGRAM

Fig 3.3 block diagram of at89s52

Restaurant Automation

Dept Of ECE,VJCET 9

Chapter 4

INTRODUCTION TO XBEE

Fig 4.1 XBEE module

XBEE is a specification for a suite of high level communication protocols used to

create personal area networks built from small, low-power digital radios. XBEE is based on

an IEEE 802.15 standard. Though low-powered, XBEE devices can transmit data over long

distances by passing data through intermediate devices to reach more distant ones, creating a

mesh network; i.e., a network with no centralized control or high-power transmitter/receiver

able to reach all of the networked devices. The decentralized nature of such wireless ad hoc

networks make them suitable for applications where a central node can't be relied upon.

XBEE is used in applications that require only a low data rate, long battery life, and

secure networking. XBEE has a defined rate of 250 kbit/s, best suited for periodic or

intermittent data or a single signal transmission from a sensor or input device. Applications

include wireless light switches, electrical meters with in-home-displays, traffic management

systems, and other consumer and industrial equipment that requires short-range wireless

Restaurant Automation

Dept Of ECE,VJCET 10

transfer of data at relatively low rates. The technology defined by the XBEE specification is

intended to be simpler and less expensive than other WPANs, such as Bluetooth or Wi-Fi.

XBEE networks are secured by 128 bit symmetric encryption keys. In home

automation applications, transmission distances range from 10 to 100 meters line-of-sight,

depending on power output and environmental characteristics.

[1]

4.1 Features

DSSS transceiver

250kbps data rate, 2 MChip/s chip rate

O-QPSK with half sine pulse shaping modulation

Very low current consumption

RX (receiving frame, -50 dBm): 18.5 mA

RX (waiting for frame): 22.3 mA

TX (+5 dBm output power): 33.6 mA

TX (0 dBm output power): 25.8 mA

Three flexible power modes for reduced power consumption

Low power fully static CMOS design

Very good sensitivity (-98dBm)

High adjacent channel rejection (49 dB)

High alternate channel rejection (54 dB)

On chip VCO, LNA, PA and filters.

Low supply voltage (1.8 - 3.8 V)

Programmable output power up to +5 dBm

I/Q direct conversion transceiver

Restaurant Automation

Dept Of ECE,VJCET 11

Table 4.1 Pin Assignments for the XBeePRO Modules

Restaurant Automation

Dept Of ECE,VJCET 12

4.2 BLOCK DIAGRAM

Fig 4.2 blockdiagram of XBEE module

Restaurant Automation

Dept Of ECE,VJCET 13

4.4 INTERFACING XBEE WITH 8051

We want to interface the XBEE module with 8051 Primer Board for accessing the

mobiles without wires through UART0. The data communication is done in internet by using

the XBEE module through MAX232 into the SBUF register of 8051 microcontroller (refer

serial interfacing with 8051). The serial data from the XBEE receiver is taken by using the

Serial Interrupt of the controller. +5V and ground is connected to provide power to the

module. While TX and RX pin is connected for communication.

Circuit diagram

Fig 4.3 interfacing XBEE with 8052

Restaurant Automation

Dept Of ECE,VJCET 14

Chapter 5

LCD MODULE

Fig 5.1 Lcd module

LCD (Liquid Crystal Display) screen is an electronic display module and find a wide

range of applications. A 16x2 LCD display is very basic module and is very commonly used

in various devices and circuits. These modules are preferred over seven segments and other

multi segment LEDs. The reasons being: LCDs are economical; easily programmable; have

no limitation of displaying special & even custom characters (unlike in seven segments),

animations and so on.

A 16x2 LCD means it can display 16 characters per line and there are 2 such lines. In

this LCD each character is displayed in 5x7 pixel matrix. This LCD has two registers,

namely, Command and Data.

The command register stores the command instructions given to the LCD. A

command is an instruction given to LCD to do a predefined task like initializing it, clearing

its screen, setting the cursor position, controlling display etc. The data register stores the data

to be displayed on the LCD. The data is the ASCII value of the character to be displayed on

the LCD.

Restaurant Automation

Dept Of ECE,VJCET 15

5.1 PIN DESCRIPTION

Table 5.1 lcd pin description

PIN

NO

NAME

FUNCTION

1 VSS Ground pin

2 VCC Power supply pin of 5V

3 VEE Used for adjusting the contrast commonly attached to the potentiometer.

4 RS

RS is the register select pin used to write display data to the LCD (characters), this

pin has to be high when writing the data to the LCD. During the initializing

sequence and other commands this pin should low.

5 R/W

Reading and writing data to the LCD for reading the data R/W pin should be high

(R/W=1) to write the data to LCD R/W pin should be low (R/W=0)

6 E

Enable pin is for starting or enabling the module. A high to low pulse of about

450ns pulse is given to this pin.

7 DB0

8 DB1

9 DB2

10 DB3

11 DB4

DB0-DB7 Data pins for giving data(normal data like numbers characters or

command data) which is meant to be displayed

12 DB5

13 DB6

14 DB7

15 LED+ Back light of the LCD which should be connected to Vcc

16 LED- Back light of LCD which should be connected to ground.

5.2 COMMANDS

There are some preset commands which will do a specific task in the LCD. These

commands are very important for displaying data in LCD. The list of commands given

below:

Command Function

0F For switching on LCD, blinking the cursor.

1 Clearing the screen

2 Return home.

4 Decrement cursor

6 Increment cursor

E Display on and also cursor on

Restaurant Automation

Dept Of ECE,VJCET 16

Command Function

80 Force cursor to beginning of the first line

C0 Force cursor to beginning of second line

38 Use two lines and 5x7 matrix

83 Cursor line 1 position 3

3C Activate second line

0C3 Jump to second line position 3

0C1 Jump to second line position1

Restaurant Automation

Dept Of ECE,VJCET 17

Chapter 6

MATRIX KEY PAD

Fig 6.1 keypad

Matrix Keypads are commonly used in calculators, telephones etc where a number of

input switches are required. We know that matrix keypad is made by arranging push button

switches in row and columns. In the straight forward way to connect a 44 keypad (16

switches) to a microcontroller we need 16 inputs pins. But by connecting switches in the

following way we can read the status of each switch using 8 pins of the microcontroller.

Fig 6.2 keypad connection diagram

Restaurant Automation

Dept Of ECE,VJCET 18

The status of each keys can be determined by a process called Scanning. For the sake

of explanation lets assume that all the column pins (Col1 Col4) are connected to the inputs

pins and all the row pins are connected to the output pins of the microcontroller. In the

normal case all the column pins are pulled up (HIGH state) by internal or external pull up

resistors. Now we can read the status of each switch through scanning.

1. A logic LOW is given to Row1 and others (Row2 Row-4) HIGH

2. Now each Column is scanned. If any switch belongs to 1

st

row is pressed

corresponding column will pulled down (logic LOW) and we can detect the pressed

key.

3. This process is repeated for all rows.

If you need to save more pins of your microcontroller then you can interface keypad

using the ADC module of your microcontroller.

Restaurant Automation

Dept Of ECE,VJCET 19

Chapter 7

VOLTAGE REGULATOR IC

Fig 7.1 7805

The AT80s51 ic and most of its components need 5v dc supply. Here we use 7805 ic

for the conversion of 9v battery voltage to 5v supply. 7805 is a voltage regulator integrated

circuit. It is a member of 78xx series of fixed linear voltage regulator ICs. The voltage source

in a circuit may have fluctuations and would not give the fixed voltage output. The voltage

regulator IC maintains the output voltage at a constant value. The xx in 78xx indicates the

fixed output voltage it is designed to provide. 7805 provides +5V regulated power supply.

Capacitors of suitable values can be connected at input and output pins depending upon the

respective voltage levels.

7.1 Pin Description

Table 7.1 7805 pin description

Restaurant Automation

Dept Of ECE,VJCET 20

Chapter 8

RESTAURANT AUTOMATION

8.1 INTRODUCTION

Usually when we go to any restaurant for dinner waitstaff/server provides us

with the menu book, take our orders serve us in the best way they can. But most of the time

item is listed in the menu by names only. They dont have brief or detailed description so

fearing how would they test, what would be the ingredients, whether we will like it or not

& several other thoughts, we end up eating/ordering regular items (familiar foods) even

though we are willing to experiment different cuisines.Citing these problems we have

come up with the idea of having a digital ordering system. This is a microcontroller

based system having a keypad. The concept is we can browse the menus/sub-menus by

jus fingertip. The items would be well defined & descripted . We can select the items

from the various categories like- starter, veg., non-veg, drinks, ice-creams, desserts etc.

& place the order by just a finger touch and the desired order will be served over a

conveyer belt to the particular customer table without any serving staff interference.

8.2 BLOCK DIAGRAM

The block diagram of keypad based restaurant ordering system is shown below

Restaurant Automation

Dept Of ECE,VJCET 21

Fig8.1 block diagram of transmitter section

Fig 8.2 block diagram of receivers section

8.3 WORKING

This project presents with a solution to the hotel management for providing the

fastest services to the customers. Since then we have two major problems. Firstly we

have to increase range so we use XBEE technology for the transmission purpose.

Second is reducing the service time. This paper aims to show that managing queuing

strategy that can solve this problem. This paper can help in making a restaurant fully

automated. The waiter will take the orders from the customers table and ask for the

confirmation of the order when the order is confirmed the order will be send to the

concerned chef automatically through the wireless transmission by using XBEE module.

On the advancement this paper can became more reliable by using digital touchable

screens given to the waiter or hardware is embedded over the table on which customer

is sitting for giving the orders to the chef. The whole of the ordering, billing information can

be send to the microcontroller on the chef receiver side. This will help the higher

management to get noticed about billing and each dish ordered.This will really help them

Restaurant Automation

Dept Of ECE,VJCET 22

during their auditing, and knowing there strength and weaknesses and also improvising on

it.

This project is a whole automated system designed to get orders from the customers,

make them ready and the delivered to them. The project has a system that is given to

every waiter to take the orders. As the person takes the order and finalizes the dishes, the

order number with dish codes are sent to the main chef automatically in the form of

packets using a XBEE wireless technology. The chef makes the dishes according to the

order. When the dish will be ready the chef sends a ready command back to the waiter.

There will be MCU (microcontroller unit) section to perform all the controlling oftaking

orders, sending it and receiving back the ready command. Order will be taken by

using a matrix pad or by using digital touchable screen. Transmission is done by using

XBEE transceiver.

8.4 FLOWCHART

Receiver section

Restaurant Automation

Dept Of ECE,VJCET 23

Customer side

Restaurant Automation

Dept Of ECE,VJCET 24

8.5 PCB LAYOUT

Fig 8.3 Pcb Layout

Restaurant Automation

Dept Of ECE,VJCET 25

Chapter 9

RESULTS

In our project we are basically focused on the time delay which

occurs during manual ordering of foods in restaurant.Our project helps the customers to alert

the chef their dishes directly and there by avoiding the time lag occurring during the original

existing system.in this modern era where time is money this project emerges out as best to

save unnecessary time lag in restaurants.

Restaurant Automation

Dept Of ECE,VJCET 26

Chapter 10

CONCLUSION AND FUTURE EXPANSION

After completing this project, the objectives of this project were successfully

accomplished on time. With this project, hopefully it can provide many benefits and

gains to consumers where they can save time to users and ease of use and greatly helpful in

the hotels. In conclusion, Zigbee based chef alerting system clearly shows improvements

in the use and effectiveness as it is more systematic and effective than the existing manual

ordering system. The middle man (waiter) is now removed by this project. User can give

orders directly to the chef simply by using this project.

In future this technology can be extended to the LAN connections by which the

order information and calculation of bills can be send to the distance places to the owners of

the hotels. The billing system can also be improved by using an ATM Swapping machine

along with this project. The programming should be done in such manner that order

can only be transfer to the chef if and only if the bill has been given.Another

expansion to be done is using gprs technology to pre order foods from outside the restaurant

using a mobile application.

Restaurant Automation

Dept Of ECE,VJCET 27

BIBLIOGRAPHY

[1] Microcontrollers and Embedded System by Ali Mazidi

[2] 8051 Microcontroller: An Application Based

Introduction by David Calcutt, Frederrick Cowan, and

Hassan Parchizadeh

[3] Keil website.[online].Available:www.keil.com/dd/

docs/datasheet Atmel AT89S52 microcontroller

datasheet

[4] S. Vijaya kumar, M.A. Shahid assisted Menu

Recommender to Enhance Customer Service and

Improve Restaurant (IJERT) Vol. 2 Issue 9, September -2013

[5] Interfacing www.pantechsolutions.net/accessoryboards/zigbee-interfacing-with-8051

[6] ZigBee/IEEE 802.15.4 Summary Sinem Coleri Ergen

email:csinem@eecs.berkeley.edu September 10, 2004

Restaurant Automation

Dept Of ECE,VJCET 28

You might also like

- Honor Dual Camara Focus ProblemDocument1 pageHonor Dual Camara Focus ProblemJebin GeorgeNo ratings yet

- SpectrumDocument5 pagesSpectrumJebin GeorgeNo ratings yet

- Onam Wishes PDFDocument1 pageOnam Wishes PDFJebin GeorgeNo ratings yet

- 3D Picure of A FlowerDocument1 page3D Picure of A FlowerJebin GeorgeNo ratings yet

- Kepad 8051 IntefacingDocument1 pageKepad 8051 IntefacingJebin GeorgeNo ratings yet

- LED circuit with BC107 transistorsDocument1 pageLED circuit with BC107 transistorsJebin GeorgeNo ratings yet

- PCB LayoutDocument1 pagePCB LayoutJebin GeorgeNo ratings yet

- Program Restorent AutomationDocument14 pagesProgram Restorent AutomationJebin GeorgeNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IEEE STD ANSI-IEEE STD 1004-1987Document14 pagesIEEE STD ANSI-IEEE STD 1004-1987abdou samiNo ratings yet

- Kishore Vaigyanik Protsahan Yojana - 2019: New DelhiDocument2 pagesKishore Vaigyanik Protsahan Yojana - 2019: New DelhiNishchay MagoNo ratings yet

- Tuv 15W SLVDocument2 pagesTuv 15W SLVWilliam N. CalfaNo ratings yet

- Power Contactor 1250 A - HubbellDocument4 pagesPower Contactor 1250 A - Hubbellmanuel99a2kNo ratings yet

- ATP ManualDocument270 pagesATP ManualJose Jorge Fontalvo100% (1)

- 205 Unit 1 L04 Superposition TheoremDocument5 pages205 Unit 1 L04 Superposition TheoremBINOSHI SAMUVELNo ratings yet

- T403 Surface and Volume Resisivity TestereDocument4 pagesT403 Surface and Volume Resisivity TestereAviv Al RasyidNo ratings yet

- GPS Simulator - Furuno GP-90Document8 pagesGPS Simulator - Furuno GP-90Jairo UparellaNo ratings yet

- 36.331 RRCDocument217 pages36.331 RRCBilal AwanNo ratings yet

- ELV SystemsDocument39 pagesELV SystemsPankajakumar100% (5)

- TriBand Trisector - SSC-760220020 - 2.2m AntennaDocument7 pagesTriBand Trisector - SSC-760220020 - 2.2m AntennaborisNo ratings yet

- Magnetic Resonance Imaging: Prepared By, Anand & ShonimaDocument43 pagesMagnetic Resonance Imaging: Prepared By, Anand & ShonimaMannat BhallaNo ratings yet

- 4937 DI5 3x8899 2Document17 pages4937 DI5 3x8899 2CdeKoninghNo ratings yet

- Unit - 3: Losses and Efficiency of DC MachinesDocument4 pagesUnit - 3: Losses and Efficiency of DC MachinesNisha JosephNo ratings yet

- Lab Report Process (Repaired)Document16 pagesLab Report Process (Repaired)amirulNo ratings yet

- Module 8 Three Phase Systems v3Document43 pagesModule 8 Three Phase Systems v3Pao CastillonNo ratings yet

- Power Factor Improvement Using Dual Boost Converter: Miss. R. S. More, Prof .D.D.AhireDocument6 pagesPower Factor Improvement Using Dual Boost Converter: Miss. R. S. More, Prof .D.D.Ahiresai charanNo ratings yet

- Sol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsDocument6 pagesSol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsahadsajjadiNo ratings yet

- Lab 1 Introduction To Android StudioDocument19 pagesLab 1 Introduction To Android StudioYong ShunNo ratings yet

- TSP-408L-1 P/N 32441-002: ApplicationDocument2 pagesTSP-408L-1 P/N 32441-002: ApplicationSajjad ShamimNo ratings yet

- Velocity of Longitudinal WaveDocument12 pagesVelocity of Longitudinal WaverenzoNo ratings yet

- Sl400 and Sl500 DatasheetDocument4 pagesSl400 and Sl500 DatasheetPlanner MjhNo ratings yet

- Ansys Icepak BrochureDocument4 pagesAnsys Icepak Brochurejagadees21No ratings yet

- Implementing Best Practices For Vlan Topologies: Defining VlansDocument66 pagesImplementing Best Practices For Vlan Topologies: Defining VlansArun JoyNo ratings yet

- tms320f28p559sj-q1Document268 pagestms320f28p559sj-q1heliosentricNo ratings yet

- Electrolytic CellDocument6 pagesElectrolytic CellJohn Israel R. CatedralNo ratings yet

- GSM Based Home Security SystemDocument20 pagesGSM Based Home Security SystemDhirendra Singh Rajput79% (14)

- Component Description For Single Signal Acquisition and Actuation Module (SSAM) Control UnitDocument1 pageComponent Description For Single Signal Acquisition and Actuation Module (SSAM) Control UnitrudiNo ratings yet

- Metaserv 250Document8 pagesMetaserv 250sigitdyNo ratings yet

- Automator MarkingDocument16 pagesAutomator MarkingJose Angel RodriguezNo ratings yet