Professional Documents

Culture Documents

Statistics in Hematology

Uploaded by

candiddreamsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Statistics in Hematology

Uploaded by

candiddreamsCopyright:

Available Formats

M R Tiwari

M Sc (TQM)

Hematopathology, TMH, Mumbai

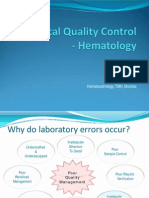

Why do laboratory errors occur?

Inadequate

Internal Quality

Control (IQC) &

Assessment (EQAS)

Poor

Workload

Management

Understaffed

&

Underequipped

Non-validated

Tests

Inadequate

Attention

To Detail

Time

Pressures

Poor Results

Verification

Poor

Sample Control

Poor

Qual i t y

Management

ISO 15189

ISO 15189

Terminologies IQC & EQAS

Precision

Accuracy

Calibration

Carryover

Control

Calibrator

Standardization

Validation

Levey-Jennings chart

Mean

Standard Deviation

Control Limits

Coefficient of Variation

Westgard Rules

Z-Score

STATISTICS

The Levey-Jennings

Chart's Inventors

In 1931, Dr. Walter Shewhart, a

scientist at the Bell Telephone

Laboratories, proposed applying

statistical based control charts to

interpret industrial manufacturing

processes.

In 1950, S. Levey and E.R.

Jennings suggested the use of

Dr. Shewharts control chart inthe

clinical laboratory.

Father of statistical quality control

What is Levey-Jennings (L-J) chart?

X-axis - the days of the month (time interval)

Y-axis. - control observations

Gaussian or "bell-shaped" curve - correlation of the curve to the chart

What is L-J chart?

Control observations are accurate or unacceptable

Nature of plot helps in error detection (systemic or random)

Normal distribution pattern

By using common materials

Manually - arithmetic graph paper

MS Excel Software in computer

Quality software program like

MedLab QC

Automated hematology analyzer inbuilt quality software program

How to create L-J chart?

By using simple statistics

Mean

Standard Deviation (SD)

1SD

2SD

3SD

Coefficient of Variation (CV %)

How to create L-J chart?

TARGET

CONTROL

LIMITS

Creating L-J chart

The mean and standard deviation of the control being used should be

determined based on at least 20 measurementsover 20 days.

Reference:

http://www.medialabinc.net/levey-jennings-keyword.aspx

Or

Statistical data should be determined based on >10 measurements.

(In case of perishable and less quantity control material).

First step Calculate Target Value

Mean ( ) is the sum of all the measurements () divided by

the number of measurements (n)

Formula = x

i

/ n

Where

x

i

= each data point

n = the number of data points in the set

=

Creating L-J chart

Mean

Second step Calculate Dispersion from target value i.e.

Standard deviation (SD)

SD quantifies the degree of dispersion of data points about

the mean.

SD is used to set limits upon which control result acceptability is

determined.

Creating L-J chart

Calculation Procedure

No. of

runs

A

(x

i

)

B

(x - x

i

)

C

(x - x

i

)

2

1. List values incolumnA

2. AddcolumnA, comes to 2000

3. Divide total of column A by

no. of values (see mean

formula), comes to 100

4. This is the average or mean

value

5. In column B list the difference

in values of column A from

the average values of column

A from the average value

100, disregard+or signs

6. Square each value and place

incolumnC

7. Addvalues in columnC

8. Divide the total of column C

by number of values minus 1

(see SDformula)

9. Determine the square root of

8.37 which comes to 2.89.

this is the standarddeviation

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

95

100

101

102

97

103

101

99

98

100

95

101

105

100

98

101

97

106

100

101

2000

-5

0

+1

+2

-3

+3

+1

-1

-2

0

-5

+1

+5

0

-2

+1

-3

+6

0

+1

25

0

1

4

9

9

1

1

4

0

25

1

25

0

4

1

9

36

0

2

157

SD Calculation

Where,

Here n =20

Mean

= 2000 / 20 =100

SD

SD = 157 / (20-1)

SD = 2.87

Creating L-J chart

Third step Calculate Control Limits ( 1SD, 2SD, 3SD)

Upper

Control

Limits

Lower

Control

Limits

Mean + (3 x SD) = + 3SD

Mean + (2 x SD) = + 2SD

Mean + (1 x SD) = + 1SD

Mean - (1 x SD) = - 1SD

Mean - (2 x SD) = - 2SD

Mean - (3 x SD) = - 3SD

L-J chart is ready for QC monitoring

L-J chart Interpretation

Westgard Rules (WR)

WR decide whether an analytical run is

in-control or out-of-control.

Dr. J ames O Westgard

1

3S

- A run is rejected when a single control measurement exceeds the mean

plus 3SD or the mean minus 3SD control limit (>3SD).

L-J chart Interpretation

1

2S

-This rule is used as a warning rule to trigger careful inspection of the

control data by the following rejection rules.

L-J chart Interpretation

2

2s

- reject when 2 consecutive control measurements exceed the same

mean plus 2SD or the same mean minus 2SD control limit.

L-J chart Interpretation

R

4s

- reject when 1 control measurement in a group exceeds the mean plus

2SD and another exceeds the mean minus 2SD.

L-J chart Interpretation

4

1s

- reject when 4 consecutive control measurements exceed the same

mean plus 1SD or the same mean minus 1SD control limit.

L-J chart Interpretation

10

x

- reject when 10 consecutive control measurements fall on one side of

the mean.

L-J chart Interpretation

8

x

- reject when 8 consecutive control measurements fall on one side of the

mean.

Modification of 10

x

L-J chart Interpretation

12

x

- reject when 12 consecutive control measurements fall on one side of

the mean.

Modification of 10

x

L-J chart Interpretation

7

T

- reject when seven control measurements trend in the same

direction, i.e., get progressively higher or progressively lower.

Look for a "trend"

L-J chart Interpretation

Summary of L-J Interpretation

There should be a

separate control chart

for :

normal and abnormal

controls of each

parameter being

monitored

How many L-Js?

WBC

(Low)

WBC

(Normal)

WBC

(High)

When a rule is violated

Warning rule = use other rules to inspect the control points

Rejection rule = out of control

Stop testing

Identify and correct problem

Repeat testing on patient samples and controls

Do not report patient results until problem is solved and controls indicate

proper performance

Dispersion simplified

Coefficient of variation (%CV )

CV is another way of indicating standard deviation, related to the actual

measurement, so that variation at different levels can be compared.

Formula

It is expressed as a percentage (%CV).

Lab can establish their own Cut Offs

CBC parameters Acceptable %CV

WBC 4.0 %

RBC 3.0 %

Hemoglobin 2.0 %

MCV 2.0 %

Platelet 9 %

Improved

%CV

3%

2.5%

1.0%

1.5%

7%

Quality Indicator %CV is continual improvement

Application in hematology

May not be limited to:

Automated 5-part and 3-part differential cell counter

Automated coagulometers

Flowcytometers

Summary

Q : Why Statistical evaluation is required?

Ans : Validates test accuracy and reliability.

You might also like

- Blood Morphometry or Blood Film CommentDocument103 pagesBlood Morphometry or Blood Film CommentYangnuu TitusNo ratings yet

- Automated Capillary Electrophoresis in The ScreeningDocument9 pagesAutomated Capillary Electrophoresis in The Screeningsomething privateNo ratings yet

- Interpretation of Peripheral SmearDocument34 pagesInterpretation of Peripheral Smearswathi bs100% (1)

- Sysmex SEED 4 2013 Automated Haematology Sample Interferences Flagging and Results Interpretation - Part 1 enDocument8 pagesSysmex SEED 4 2013 Automated Haematology Sample Interferences Flagging and Results Interpretation - Part 1 enPieter Du Toit-Enslin50% (2)

- XN Series: Case InterpretationDocument41 pagesXN Series: Case InterpretationTanveerNo ratings yet

- Red Blood Cell Morphology: A Seminar on RBC AbnormalitiesDocument11 pagesRed Blood Cell Morphology: A Seminar on RBC AbnormalitiesChabNo ratings yet

- 04 - Haematology SOPDocument120 pages04 - Haematology SOPKailash PrajapatNo ratings yet

- Neonatal HematologyDocument83 pagesNeonatal HematologyJay-Anne RapanoNo ratings yet

- Laboratory Hematology CriteriaDocument7 pagesLaboratory Hematology CriteriaRosNo ratings yet

- QC & QA in Hematology TestingDocument22 pagesQC & QA in Hematology TestingBenjamin Lopez Carreras100% (2)

- QA in Hematology: Standards, Proficiency, and Quality ControlDocument29 pagesQA in Hematology: Standards, Proficiency, and Quality ControlAmanuel MaruNo ratings yet

- CAP Presentation On StatisticDocument88 pagesCAP Presentation On StatisticAmirul AriffNo ratings yet

- CRP vs ESR Clinical AuditDocument12 pagesCRP vs ESR Clinical AuditLuke LauNo ratings yet

- Techtalk August2010Document2 pagesTechtalk August2010Abu KhalidNo ratings yet

- ICSH Guidelines For The Evaluation of Blood Cell AnalysersDocument16 pagesICSH Guidelines For The Evaluation of Blood Cell Analyserssellappan marappanNo ratings yet

- MANI Quality Control in Hematology AnalysersDocument65 pagesMANI Quality Control in Hematology Analyserscandiddreams100% (1)

- Levey Jennings & Westgard RulesDocument31 pagesLevey Jennings & Westgard RulesMyra Kiriyuu100% (2)

- Coagulation cascade overviewDocument812 pagesCoagulation cascade overviewNikos SyrigosNo ratings yet

- Kaplan: Clinical Chemistry, 5 Edition: Clinical References - Methods of AnalysisDocument9 pagesKaplan: Clinical Chemistry, 5 Edition: Clinical References - Methods of AnalysispudjoNo ratings yet

- HB A1c Meta-Analysis - Second Edition - Final 20182304Document50 pagesHB A1c Meta-Analysis - Second Edition - Final 20182304Kader SmailiNo ratings yet

- Automated Cell Counting InstrumentationDocument33 pagesAutomated Cell Counting InstrumentationCecille AnnNo ratings yet

- Blood Tube Collection GuideDocument365 pagesBlood Tube Collection GuideFeliciadlTNo ratings yet

- Combined Set of Kaplan 900 and High Frequency Words PDFDocument17 pagesCombined Set of Kaplan 900 and High Frequency Words PDFcandiddreams100% (2)

- Hematological Investigation or Quantitative Evaluation of The Hematopoietic SystemDocument21 pagesHematological Investigation or Quantitative Evaluation of The Hematopoietic SystemMAMA LALANo ratings yet

- WBC Histogram Interpretations of 3-Part Differentiation: Sysmex Xtra Online - July 2011Document5 pagesWBC Histogram Interpretations of 3-Part Differentiation: Sysmex Xtra Online - July 2011ripangaNo ratings yet

- Statistical Approach in HematologyDocument33 pagesStatistical Approach in HematologycandiddreamsNo ratings yet

- Critical Value in HematologyDocument8 pagesCritical Value in HematologySTARK DIAGNOSTICSNo ratings yet

- Automation in Haematology - BernardDocument60 pagesAutomation in Haematology - BernardBosco Mbonimpa100% (1)

- ADVIA-2120i Hematology TrainingDocument73 pagesADVIA-2120i Hematology TrainingLoay TibiNo ratings yet

- Hemophilia and Factor Assay PDFDocument17 pagesHemophilia and Factor Assay PDFSumaira JunaidNo ratings yet

- CorrelationDocument17 pagesCorrelationisabel bautistaNo ratings yet

- XN Cal TraceabilityDocument5 pagesXN Cal TraceabilityAnonymous brvvLxoIluNo ratings yet

- UnityDesktop BioRadDocument269 pagesUnityDesktop BioRadJose VarelaNo ratings yet

- Use of Fresh Blood For Quality Control: Erythrocyte Sedimentation RateDocument6 pagesUse of Fresh Blood For Quality Control: Erythrocyte Sedimentation RateTriana AmaliaNo ratings yet

- 5 - Introducing XN and XN-L - Sudan PDFDocument57 pages5 - Introducing XN and XN-L - Sudan PDFAl- ImanuddinNo ratings yet

- Internal Quality Control Practices in Coagulation LaboratoriesDocument10 pagesInternal Quality Control Practices in Coagulation LaboratoriesMy LeNo ratings yet

- Laboratory Turnaround TimeDocument17 pagesLaboratory Turnaround TimeNicole HoNo ratings yet

- RBCDocument66 pagesRBCFarah mansourNo ratings yet

- Validation Cell AnalyzersDocument45 pagesValidation Cell AnalyzerscandiddreamsNo ratings yet

- Validation Cell AnalyzersDocument45 pagesValidation Cell AnalyzerscandiddreamsNo ratings yet

- Diagnostic HemoglobinopathiesLaboratory Methods and Case StudiesDocument479 pagesDiagnostic HemoglobinopathiesLaboratory Methods and Case StudiesZia Uddin100% (2)

- Lipemia: Causes, Interference Mechanisms, Detection and ManagementDocument16 pagesLipemia: Causes, Interference Mechanisms, Detection and ManagementkartikaparamitaNo ratings yet

- TE, TEa, Six-SigmaDocument36 pagesTE, TEa, Six-SigmaDr. Pillala KrishnaveniNo ratings yet

- CLIA Waived Codes ListDocument41 pagesCLIA Waived Codes ListKarunanidhi PalaniveluNo ratings yet

- Platlets DisorderDocument177 pagesPlatlets DisorderFatimah A Al-dawoodNo ratings yet

- Current Practice of Gleason Grading of Prostate Carcinoma: ReviewarticleDocument8 pagesCurrent Practice of Gleason Grading of Prostate Carcinoma: ReviewarticlecandiddreamsNo ratings yet

- Clinical1 Quality Control - 10Document36 pagesClinical1 Quality Control - 10Khansa QureshiNo ratings yet

- Manual Differential Cell Count LabDocument9 pagesManual Differential Cell Count LabFatima Mae LusanNo ratings yet

- Prof. Joy V. Lorin-Picar Davao Del Norte State College: New Visayas, Panabo CityDocument91 pagesProf. Joy V. Lorin-Picar Davao Del Norte State College: New Visayas, Panabo CityJeLo ReaNdelarNo ratings yet

- Mean Normal Prothombin Time (MNPT)Document10 pagesMean Normal Prothombin Time (MNPT)candiddreamsNo ratings yet

- The Peripheral Blood FilmDocument5 pagesThe Peripheral Blood FilmanggaririnNo ratings yet

- CE (Ra) F (SH) PF1 (MJ GG) PFA (PR SS)Document4 pagesCE (Ra) F (SH) PF1 (MJ GG) PFA (PR SS)Krishna DubeyNo ratings yet

- RT-7600 Hematology AnalyzerDocument86 pagesRT-7600 Hematology AnalyzerJesus100% (1)

- Pre-Analytical Variables in Coagulation TestingDocument20 pagesPre-Analytical Variables in Coagulation TestingTaylorNo ratings yet

- Lab Activity No. 5 - Slide PresentationDocument24 pagesLab Activity No. 5 - Slide PresentationChelsea Padilla Delos ReyesNo ratings yet

- Quality Control2Document32 pagesQuality Control2Mustafa KhandgawiNo ratings yet

- Automation in HaematologyDocument67 pagesAutomation in Haematologyk11a1r18No ratings yet

- Post-Analytical Best PracticesDocument48 pagesPost-Analytical Best PracticesSaravnan RajendranNo ratings yet

- 11auto Unit Cell Counting Instruments HandoutDocument15 pages11auto Unit Cell Counting Instruments HandoutyoraikarNo ratings yet

- Reference Intervals - Direct Priori MethodDocument5 pagesReference Intervals - Direct Priori MethodMWNo ratings yet

- Clinical Chemistry Methods Guide 2010: For Labquality Data ProcessingDocument103 pagesClinical Chemistry Methods Guide 2010: For Labquality Data Processingcamilovivi100% (1)

- HarrisADVIA2120methods LabHema2005 11 47-61 PDFDocument16 pagesHarrisADVIA2120methods LabHema2005 11 47-61 PDFedu_14cNo ratings yet

- CC Lecture Reviewer - ppt3 (QC Part2)Document10 pagesCC Lecture Reviewer - ppt3 (QC Part2)Johanna Rose Cobacha SalvediaNo ratings yet

- 7 Restaurants Worth Visiting in KolkataDocument5 pages7 Restaurants Worth Visiting in KolkatacandiddreamsNo ratings yet

- Best Television SeriesDocument37 pagesBest Television SeriescandiddreamsNo ratings yet

- 2010 BaxterDocument7 pages2010 BaxtercandiddreamsNo ratings yet

- MGCTDocument11 pagesMGCTcandiddreamsNo ratings yet

- NeuroendoDocument8 pagesNeuroendocandiddreamsNo ratings yet

- Polymorphous Breast CA.Document6 pagesPolymorphous Breast CA.candiddreamsNo ratings yet

- Meningioma SDocument10 pagesMeningioma ScandiddreamsNo ratings yet

- Lung OsteomaDocument4 pagesLung OsteomacandiddreamsNo ratings yet

- MesotheliomaDocument7 pagesMesotheliomacandiddreamsNo ratings yet

- Hepatic Collision TumourDocument6 pagesHepatic Collision TumourcandiddreamsNo ratings yet

- LeiomyomaDocument3 pagesLeiomyomacandiddreamsNo ratings yet

- Male Breast CA.Document6 pagesMale Breast CA.candiddreamsNo ratings yet

- Primary Intracranial Leiomyoma: A Case Report and Literature ReviewDocument3 pagesPrimary Intracranial Leiomyoma: A Case Report and Literature ReviewcandiddreamsNo ratings yet

- Apocrine Breast LesionsDocument7 pagesApocrine Breast LesionscandiddreamsNo ratings yet

- Hyperplastic Gastric PolypDocument5 pagesHyperplastic Gastric PolypcandiddreamsNo ratings yet

- Gastric CancerDocument8 pagesGastric CancercandiddreamsNo ratings yet

- Normal Hematolymphoid TissuesDocument182 pagesNormal Hematolymphoid TissuescandiddreamsNo ratings yet

- Eye AstrocytomaDocument5 pagesEye AstrocytomacandiddreamsNo ratings yet

- BreastDocument3 pagesBreastcandiddreamsNo ratings yet

- Clonality Analysis in Hematolymphoid Malignancies: DR Jay MehtaDocument65 pagesClonality Analysis in Hematolymphoid Malignancies: DR Jay MehtacandiddreamsNo ratings yet

- AtherosclerosisDocument8 pagesAtherosclerosiscandiddreamsNo ratings yet

- TMH PBS PresentationDocument61 pagesTMH PBS PresentationcandiddreamsNo ratings yet

- Gujral FCMDocument102 pagesGujral FCMcandiddreamsNo ratings yet