Professional Documents

Culture Documents

Alternatives in Gearbox Seals For Main Drive Gearboxes

Uploaded by

SasankOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alternatives in Gearbox Seals For Main Drive Gearboxes

Uploaded by

SasankCopyright:

Available Formats

Paper No. 2006-1 Copyright 2006 Stein Seal Co.

1

Alternatives in Gearbox Seals for Main Drive Gearboxes

Brian P. Roche

ABSTRACT

A variety of sealing devices have been used to seal Marine Main Reduction Gears. One means of sealing Main

Reduction Gears today is the labyrinth seal. While the labyrinth seal has been successfully employed in some

applications, it has performed unsatisfactory in others. This paper discusses mechanical seals as alternatives to

labyrinth seals for use in Marine Main Reduction Gears. Along with a discussion of Labyrinth Seals, various types of

mechanical seals are considered, along with their respective advantages and disadvantages. Split Circumferential

Seals are described in particular. Seal design features, as well as test results, are presented.

KEY WORDS: Circumferential Seal; Labyrinth Seal; Lip Seal;

Hydrodynamic Seal; Marine Main Reduction Gear; Mechanical Seal,

Shaft Sealing, Gearbox

INTRODUCTION

Main Reduction Gears (MRGs) predominately utilize labyrinth seals to

provide sealing. Since no such thing as a perfect seal exists, one must

weigh associated positives and negatives when selecting a sealing

device. While one may be tempted to focus on the devices positives, if

one cannot effectively manage its negatives, then other seal devices

must be considered. Two alternatives to the labyrinth seal are the lip

and circumferential seals. A discussion of these sealing solutions is

presented here.

After a discussion of the typical MRG sealing requirements, a

discussion of labyrinth seals emphasizes its features and performance

characteristics. Lip seals are introduced as a device capable of

alleviating some of the performance problems of labyrinth seal under

certain conditions.

The circumferential seal is analyzed in some detail. Along with a

discussion of seal features, analytic design tools are highlighted. The

hydroload concept is described. Relative advantages and disadvantages

with respect to labyrinth and lip seals are discussed. Installation of the

split housing design is described, as well as replacement procedures.

Test results are presented regarding oil leakage rates, life, and shock

robustness.

SEALING REQUIREMENTS

The primary purpose of a main reduction gear seal is to prevent the loss

of lubricating oil from the gearbox. Inadequate lubrication can

adversely affect gearbox performance, and ultimately lead to failure.

This oil leakage affects not only gearbox function, but has adverse

consequences in the ship compartment as well. Leakage can occur as

oil mist, solid oil, or a combination of both. In the case of oil mist,

cleanliness problems can develop as oil settles on surfaces. Such mist

may require venting to the atmosphere, which can lead to

environmental problems. In addition, an oil mist rich environment is

undesirable for nearby personnel. Likewise, solid oil splashing from

the reduction gear can cause environmental problems when one

considers its disposal. In the typically confined areas around the MRG,

oil leakage that settles on the disk brake can be a fire hazard. This can

result in the rubber boot catching fire. The need to prevent this has been

an overriding concern when selecting a sealing device. The rolling of a

ship causes difficulties for sealing with clearance devices in particular.

In addition to keeping lubricating oil in, for the variety of reasons

described above, the seal must prevent outside debris from entering the

gearbox. Such debris can cause damage to gears and bearings,

preventing proper function and lessening working life. It may be

critical for the seal to prevent seawater from entering the gearbox under

an emergency condition.

In addition to controlling leakage into and out of the gearbox, a number

of other requirements are common. Due to the nature of the MRG

system, a split design is necessary for installation and disassembly. The

seal footprint is limited. Therefore, the design of a satisfactorily

performing seal is constrained to the dimensions available. As seals are

either close clearance or contacting devices, eccentricities of the

rotating shaft become a factor is design, possibly influencing the seal

device selected. Particularly in a military application, the ability to

continue to function adequately after sustaining a shock load may be a

critical need.

For a specific application, only a portion of the above described

requirements will be applicable. It is up to the engineer to determine the

critical requirements, and select the seal accordingly. Along with

satisfying the performance characteristics described above, consistent

performance over the lifetime of the seal is expected.

THE LABYRINTH SEAL

Labyrinth seals are commonly used in MRGs. Two major reasons for

this are simplicity and reliability. As a clearance device, one need not

worry about labyrinth wear (as long as rubs do not occur). Also, due to

the nature of clearance devices, maintenance is low, since replacements

due to wear are unusual under normal circumstances. Shaft speed,

which influences wear (and therefore life) in a contacting seal, is not an

issue with the non-contacting labyrinth seal. In a contacting device, seal

friction with the shaft results in power consumption, whereas for

labyrinth seals, little or no friction is generated.

Paper No. 2006-1 Copyright 2006 Stein Seal Co. 2

Design Features

A labyrinth seal is a clearance device that reduces fluid energy through

a series of throttles. A labyrinth seal example is shown in Figure 1.

Two major design considerations when designing the labyrinth seal are

the clearance between the teeth and the shaft, and the overall length the

sealed fluid must travel. Other considerations include the type of tooth

geometry, the number of teeth, and the placement of the teeth. Two

types of teeth are shown in Figure 1, straight and stepped. Stepped teeth

may not be possible with large axial movements. In addition, the

placement of oil drains between the labyrinth stages allows for the

collection of the escaped oil back to the MRG.

Figure 1 Three Stage Labyrinth Seal with Oil Drains

The tip clearance chosen depends on a number of factors. One would

like to decrease this clearance, since larger clearances result in larger

leakages. However, one also wants to prevent shaft rubs due to shaft

excursions. The addition of an abradable sleeve on the rotating shaft

can be used. This sleeve will wear away in the event of a rub, without

causing the negative consequences of metal on metal rubs. However,

such a sleeve may not be applicable in many circumstances.

Another design feature is the overall axial length of the seal. The more

teeth one has, and the more drain holes, the more tortuous the path oil

must follow to escape. However, practical concerns limit ones available

length. Especially in cramped compartments, this consideration can

become a major factor.

For assembly and disassembly, the seal must be split. This should not

affect seal performance when compared to a non-split seal assembly.

Challenges in the Marine Environment

While the advantages of a labyrinth seal are numerous, certain

drawbacks lead one to rethink their applicability under certain

circumstances. The oil system in the MRG can be such that oil is

directly impinging in the vicinity of the seal. One example would be if

the input shaft bearing is located nearby. For a labyrinth, which has a

clearance, this oil can escape through the clearance in the form of solid

oil or oil mist. Oil mist is disagreeable for the reasons described earlier.

In the case of solid oil, leakage onto the disk brake has been suspected

of causing fires. The many advantages of a labyrinth will be negated if

a compartment fire results from its use. Rolling of the ship can also

facilitate the leakage of oil. This escape of oil is due mainly to the

clearance nature of the seal.

While oil leakage from the MRG is unacceptable, one must also look at

material entry into the MRG as well. Debris entering the MRG can

cause wear, affect performance, and shorten component life. Debris

passes through a clearance device more easily than debris through a

contacting device.

Especially in military applications, the ability of the seal to prevent

water leakage into the MRG in the event of compartment flooding is

usually of importance. The labyrinth seal provides no protection under

these conditions. Water will pass through the clearance, and flood the

MRG, adversely affecting functionality.

It has been observed that in some cases, a pressure differential will

develop across the seal. Reverse pressures, where the area outside the

gearbox is at a slightly lower pressure (typically under 1 PSI, usually

under 5 inches of water), will draw oil from the MRG into the area

outside the gearbox.

THE LIP SEAL

Lip seals differ from labyrinth seals in a number of ways. Perhaps the

most significant of these is lip seals are contacting devices, whereas

labyrinth seals are clearance devices. Depending on the operating

conditions, a lip seal can outperform labyrinths, and alleviate many of

the drawbacks associated with them. However, lip seals have operating

limitations.

Design Features

Figure 2 shows a typical lip seal. Lip seals are ubiquitous, and the

number of design variables makes for a wide variety of types to choose

from. Each type has features specific to the environment that it is

designed for. In Figure 2 for example, a dust prevention lip is added,

possibly an important feature in a MRG application.

A typical lip seal consists of a flexible elastomeric leg held in contact

with the rotating shaft by a garter spring or some other form of spring.

Additional load is provided by an interference fit between the flexible

leg and the shaft. A balance occurs here between making sure the radial

load is great enough to prevent loss of contact due to surfboarding on

oil and shaft eccentricities, but not high enough to result in high wear.

Figure 2 Lip Seal with Dust Prevention Lip (Buchter 1979)

A thin film of oil is desirable between the flexible leg and the rotating

shaft. A film thickness of ~0.0001 inch has been empirically shown to

be the best in terms of preventing leakage and assuring low wear.

Garter Spring

Flexible Leg Dust Lip

Paper No. 2006-1 Copyright 2006 Stein Seal Co. 3

(Buchter 1979) Using the equation for flow between plane parallel

walls, for an incompressible fluid in the laminar region, the total flow

is,

Q 2 R

h

3

12

P

L

Equation 1

wherein R is the sealing radius, h the clearance, the viscosity, P the

pressure differential, and L the axial length of the sealed surfaces. We

have integrated the unit circumference parallel plate flow over the

circumference of the seal.

An analysis of Equation 1 clearly shows the importance of controlling

the film thickness. Whereas other variables linearly affect flow,

clearance affects flow as a cubic. This sensitivity of leakage to

clearance results is the need to carefully control this variable. A

knowledge of the operating conditions is necessary to do this. For

example, in the case of a slight negative pressure, outside the gearbox

pressure being less than the MRG pressure, one must control the forces

on the seal in order to prevent a clearance developing greater than the

optimal. Also, one must prevent large downward forces, which will

increase friction, wear, and power consumption.

The flexible leg can be modified to include hydrodynamic features. In

the Helixseal configuration, ribs on the back side of the lip function as

hydrodynamic elements, abating oil leakage. Similarly, the Hydroseal

makes use of hydrodynamic grooves on the sealing surface. Since these

features are angled and depend on shaft windage, they are

unidirectional. Care must then be taken to ensure that upon assembly,

the hydrodynamic features pump oil back into the MRG, and not out of

it.

The axial length required for a lip seal is no more than that of a

labyrinth, and can be less. For assembly and disassembly, the seal must

be split. This should not affect seal performance when compared to a

non-split seal assembly.

Lip seals have been successfully used in preventing oil leakage in

MRGs. Oil splash onto the lip must pass through the small film

between the lip and the shaft. This has two consequences. It reduces the

kinetic energy of the oil, allowing any leaked oil to be drained more

easily, and also helps condense any oil mist.

A desirable feature in some applications is to prevent water from

entering the MRG in the event of compartment flooding. Figure 3

illustrates a solution to this requirement using the lip seal. In this

double seal arrangement, one seal seals oil from escaping the MRG,

while the other seals water, debris, or any gases from entering the

MRG.

All of these design features make the lip seal a considerable alternative

to the labyrinth seal. Being a contacting seal, oil does not have a direct

clearance path out of the MRG. Also, with the double seal in Figure 3,

water influx into the MRG can be abated.

The MRG application necessitates the installation of a split lip seal.

This is possible, and does not affect seal performance. Replacement kits

allow for change out of worn seals which no longer satisfy sealing

requirements.

Challenges in the Marine Environment

Speed limitations reduce the applicability of the lip seal. It is generally

regarded that the maximum surface speed for adequate performance is

30 ft/sec. While the MRG output shaft may fall into this category, the

input shaft usually exceeds this speed. At speeds about 30 ft/sec,

friction and associated wear result in reduced sealing effectiveness.

Shaft orbiting can pose problems for lip seals. If orbiting conditions are

such that clearances develop between the shaft and lip seal leg, oil

leakage can occur. Lip seals can only track the shaft to the extent of the

flexibility of the sealing leg. In addition to developing leakage path

clearances, orbiting can results in higher wear rates, and the need for

more frequent replacement. In addition, any misalignment of the shaft

will results in an asymmetric interference fit around the circumference

of the seal.

Figure 3 Double Lip Seal (Buchter 1979)

THE FACE SEAL

The face seal design is widely used in industrial applications. Faces

seals can be designed to be either contacting (rubbing) or non-

contacting (film riding). Choice of a contacting or non-contacting

depends of the demands of the application in question.

Design Features

In Figure 4, we can see the major components of a rubbing face seal.

The face seal consists of two radial flat surfaces, with one rotating with

the shaft and the other stationary with the machine housing. By an

analysis of the forces on the system, the designer can ensure that the

two surfaces will stay in contact over the range of machine operating

conditions. Of critical importance is the flatness and surface finish of

these mating surfaces. Flatness is held to 0.3 microns to 0.6 microns in

many applications. Since the leakage is a cubic function of the

clearance between these two surfaces, contact is critical.

In addition to a primary sealing surface between the carbon element

and the mating ring, sealing also takes place by the secondary seal. In

Figure 4, an o-ring is used for secondary sealing. Other types of

secondary seals used include bellows and piston rings. While the

secondary seal is sealing across two stationary surfaces, one should

carefully design the secondary seal to prevent leakage. Being a sealing

system, the successful operation of a face seals requires successful

sealing for the secondary as well as the primary seal.

Oil Seal

Water Seal, Dust Lip

Paper No. 2006-1 Copyright 2006 Stein Seal Co. 4

A face seal can perform successfully at higher rotational speeds. At

high speeds, one must consider the inertia generated, and design to

ensure contact of the primary sealing surfaces. In addition, rotational

speed, as well as unit loading, affect wear rates and thereby seal life.

Figure 4 - Rubbing Face Seal with O-ring Secondary Seal

Hydrodynamic Face Seal

Hydrodynamic lift (or suction) can be generated between the primary

sealing surfaces. If the case of high rotational speeds, creating a suction

force will aid in keeping sealing surfaces in contact with one another. If

high unit loading is developed, a lift force can lessen the unit loading,

and therefore increase seal life. A face seal with hydrodynamic features

is shown in Figure 5.

Figure 5 - Hydrodynamically Lifted Face Seal

Challenges in the Marine Environment

While a face seal can be split, it creates technical challenges to keeping

the primary sealing surfaces flat. While flatness can be achieved, it is a

challenging task which results in a complex design. Unlike the lip seal,

it can perform well at high rotational speeds, but will wear, unlike a

non-contacting seal. Due to the requirement of a split design for MRG

applications, the design complexity of a face seal has prevented them

from being used.

THE CIRCUMFERENTIAL SEAL

The circumferential seal is a contacting segmented device which has

been used successfully in the MRG environment. It has performed

satisfactory is cases where the labyrinth seal has failed. Being a

contacting device, it shares many of the advantages over a labyrinth

seal in common with the lip seal. It has a wider range of applicability

than the lip seal, which make it suitable for use under many operating

conditions.

Design Features

A typical circumferential seal is shown in Figure 6. The various

components of the seal are highlighted. The segmented circumferential

ring is held in contact with the shaft by a garter spring. Also, axial

springs seat the ring along the sealing face of the housing. These spring

forces are adjusted to assure contact throughout the operational range of

the seal. The backplate can be used to anti-rotate the circumferential

seal ring, while the retaining ring holds the assembly together. Anti-

rotation locking can also be achieved using an anti-rotation feature on

the sealing face of the housing.

Figure 6 - Cross Section of Circumferential Seal

The segmented circumferential seal ring in Figure 6 has a number of

features detailed in Figure 7. Since sealing takes place on two surfaces,

the bore (dynamic) and the face (static), both surfaces must be carefully

controlled. In addition, a close fit tongue and socket abates leakage

through the joints. Bleed grooves in the bore and face of the

circumferential seal ring provide pressure relief to the seal, lessening

loading due to pressure differentials.

Paper No. 2006-1 Copyright 2006 Stein Seal Co. 5

Figure 7 - Circumferential Seal Ring

The net loading on a circumferential seal is an important factor. If the

loading is too low, unseating can occur, resulting in a clearance

developing and increasing leakage. Likewise, if loading is too high,

frictional effects will be high, resulting in high heat generation and high

wear. This balance is critical to proper function.

When considering force balance of a circumferential seal, an important

factor is shaft eccentricity. Since the inertia increases as the square of

the shaft speed, at low speeds, this inertia effect is less important.

However, at high speeds, this effect should be considered along with

spring forces and pressure.

Figure 8 shows us the force balance on a circumferential seal, taking

into account pressure and spring forces. Radial and axial forces are

considered. One can see that the pressure relief grooves minimize

pressure loading to the sealing dams, where pressure breakdown

occurs. By controlling spring and pressure forces, and taking into

account inertia and frictional effects, one can be confident in

maintaining contact, and minimizing wear and friction.

High runouts, discussed as a concern for lip seals, are more easily

handled by the circumferential seal. The garter spring around the

segmented circumferential seal ring allows for tracking of the shaft and

constant contact.

Figure 8 - Circumferential Seal Force Diagram

Power consumption

Especially for contacting sealing devices, a look at the power

consumption should be considered. An approximation of the power

consumption of a seal has been devised (Stein 1961). This quantity

depends on both the frictional force generated, and the speed of the

rotating shaft.

HP

F U

550 12

Equation 2

where F is frictional force in pounds, and U is the surface speed in

inches/second. This frictional force may be found by,

F

2 R U L

h

Equation 3

Where R is the shaft radius, L is the sealing width, is the viscosity in

lb-sec/in.

2

, and h is the clearance in inches.

Hydroload Concept

In MRG applications, the low differential pressure environment, where

circumferential seal seating is produced mainly by the springs, surf-

boarding of the segments on a film of oil can result in high oil leakage.

Since increasing springs loads does not adequately solve this problem,

the hydroload seal was developed as a solution (Stein 1978).

A hydroload seal makes use of negative lift pockets in the bore of the

carbon. These pockets produce a downward force, preventing the

formation of the oil film. Without the surf-boarding effect, hydroload

seals have performed well in oil rich environments.

Hydroload Negative Lift Calculations

Analytic tools are available which calculate the amount of seating force

generated by a given hydroload pocket (Stein 1978). Equations 4(a),

4(b), and 4(c) calculate the bearing force per unit width (W) for the

three geometries in Figure 9 respectfully.

W

6 U B

2

h

2

ln

1 +

\

|

.

2

1 2 +

\

|

.

Equation 4(a)

W

6 U B

2

h

2

E E 2 + ( )

2 1 2 + ( ) 1 E ( ) E 2 + 2

2

( )

1 2 + ( ) +

( )

ln

1 +

\

|

.

+

2

1 2 +

(

(

Equation 4(b)

W

6 U B

2

h

2

E 1 E ( )

1 E ( )

3

E 1 + ( )

3

+

Equation 4(c)

Where is the ratio of the entering clearance h

1

to the change in

clearance h. Also of importance in Equation 4(b) and 4(c) is the E

term. E is the ratio of the parallel part of B at height h

1

to the total

length B. Of note in these equations is the relationship between the

bearing force generated and the depth of the pocket. Since the bearing

force is inversely proportional to the square of the pocket depth, a

doubling of pocket depth will decrease the bearing force by a factor of

four.

Paper No. 2006-1 Copyright 2006 Stein Seal Co. 6

Figure 9 - Negative Lift Geometries

Figure 11 illustrates the geometry of a typical hydroload seal. Except

for the bore, the seal does not differ from the standard circumferential

seal. A detailed view of the bore is shown in Figure 10. The pocket

pumps oil in the bore of the seal back into the MRG. Misty oil also has

a tendency to condense in the pocket, preventing misty oil from

escaping the gearbox. Unlike in clearance devices, like the labyrinth

seal, oil cannot directly pass through a clearance opening. Since the

negative lift generated does depend of the viscosity of the fluid in the

bore, in a air rich environment, lift forces will be lower than in an oil

rich environment. Hydroloads are unidirectional, and therefore

assembly procedures are designed to ensure proper installation.

The force breakdown of a hydroload is the same for that of a standard

circumferential seal, with the additional force generated by the

hydroload pockets taken into account. Other forces, such as inertia and

friction, must also be considered when developing a loading model of

the seal in operation.

Figure 10 - Hydroload Seal Bore

Figure 11 - Detailed view of Hydroload Seal Ring

The use of hydroload seals alleviate many of the concerns regarding

surf-boarding associated with the standard circumferential seal. Seal

assemblies employing hydroload pockets today are satisfactorily

performing in a variety of MRG units.

In one case, leakage from a labyrinth seal was unacceptably large. This

leakage was the supposed reason for several fires outside the gearbox.

The labyrinth was replaced with a face to face hydroload sealing

arrangement. As shown in Figure 13. One ring sealed oil while the

second sealed debris and water in a flooding situation. This sealing

replacement alleviated the leakage problems and associated fires

observed with the labyrinth seal.

Operating Conditions and Performance

A wide range of operating conditions can be successfully handled with

the hydroload circumferential seal. In one main drive shaft gearbox, an

8.5 sealing diameter seal has performed well at 200

o

F maximum oil

temperature, and 160 ft/sec (4320 rpm). Maximum allowable oil

leakage in this example is 1.25 cc/hr. This is a horizontally split seal.

The presence of an oil rich environment allows for possible seal lives in

excess of 20,000 hours. Throughout the lifetime of the seal, little to no

reduction in sealing performance is observed. With respect to shaft

runouts, 0.020 magnitudes can be tolerated. Depending on shaft

speeds, larger runouts also can be effectively handled.

While the hydroload seal can effectively seal oil in the MRG, the

placement of a second hydroload seal, face to face with the oil seal,

allows for the possibility of sealing water and air contaminants as well.

Where the labyrinth seal will draw oil out of the MRG under a reverse

pressure, the face to face hydroload seal will continue to stay in contact

with the shaft, and provide for continued sealing.

In addition to being able to preventing oil leakage during operation, the

ability to seal oil when the shaft is not rotating is of importance. While

the pockets actuate with shaft rotation, surf-boarding does not occur in

the static case. Therefore, with surf-boarding absent, the contacting seal

is effective at preventing leakage.

The Face to Face Hydroload seal

In Figure 12, we see a typical main reduction gear unit. This MRG

makes use of a face to face hydroload seal at location D. A cross

section of a similar seal is shown in Figure 13. This seal has an 8.5

sealing diameter, and mounts to the MRG by 18 5/8 bolts around its

flange. Two hydroload seals are used, each sealing on two locations,

the rotating bore and a housing face.

Our face to face seal assembly in Figure 13 has on the bottom vertical

centerline a radial hole drilled through the seal plate, which aligns with

a threaded hole on the lower half of the seal housing. Any liquid that

collects between the two hydroload seals will drain through the hole to

a tube installed in the lower half of the seal housing. In the case of

small quantities of oil or water leakage, a canister will collect any

liquid that passes through the tube.

BORE SEALING DAM

FEED GROOVE

EXIT GROOVE

HYDROLOAD POCKET

DIRECTION OF SHAFT

ROTATION

(a) (c) (b)

Axial Spring Holes Anti-Rotation

Bore Sealing Dam Hydroload Pockets

Paper No. 2006-1 Copyright 2006 Stein Seal Co. 7

Figure 12 - Main Reduction Gear

Figure 13 - Face to Face Hydroload Seal Assembly

Assembly / Disassembly

As will all seals, proper installation ensures proper functioning of the

seal. While installing the seal assembly shown in Figure 13 requires

some care, with attention, assembly is not a difficult process.

An assembly procedure is used for installation. During the assembly

process, it is important that critical sealing surfaces do not develop

nicks or scratches, and that all parts are clean and free from potentially

damaging debris. Care must be used when handling the seal rings, as

any damage incurred on them may affect sealing performance.

Assembly requires a number of steps due to the split nature of the seal.

The horizontally split housing is seen in Figure 14. Two people are

required for complete assembly. Scribe marks are located on the seal

housing for ensuring proper alignment. After installing the split seal

plate, in the correct direction, the two sets of hydroload rings are

assembled. A service manual provided by seal manufacturers provides

a step by step procedure on assembly.

Likewise, disassembly is done following a disassembly procedure. As

with assembly, preventing damage to the seal rings is important.

Disassembly involves removing the upper housing, the backplates, and

then the lower half of the housing. Then, each set of seal rings are

removed, and finally the seal plate.

Figure 14 Horizontally Split Seal Housing

Test Results

The seal assembly shown in Figure 13 was tested under a variety of

conditions. The oil side seal was tested sealing air with oil mist as well

as with solid oil. Oil leakage observed ranges from zero to 0.5 cc per

hour when sealing oil laden air. In the case of oil flooding, the seal

showed no leakage up to 4000 RPM and 35 psi. (Stein 1978)

The hydroload seal ring used for sealing water was tested at

typical and higher water pressures one would expect. Table 1

shows the leakage rates found at various pressure differentials for a

given speed. (Stein 1978)

Further testing has shown that expected leakage rates range

from 0 cc/hr up to ~2 cc/hour, depending on the application.

With these quantities of leakage, a small container connected to

the drain hole provided in the seal assembly would be sufficient

in collecting any escaped oil.

0

1.33

3.62

7

0

10

20

30

Water Pressure (psi) Leakage Rate (cc/hr)

Table 1 - Water Leakage Rates at 1860 RPM (Stein 1978)

Shock Test Results

One seal requirement, especially in military applications, is the ability

to survive a shock load without unacceptably affecting seal

performance. High impact medium weight mechanical shock per MIL-

S-901C Section 4.2.3.2 and 4.2.4.2 testing was performed on a face to

face assembly such as that shown in Figure 13.

Two shock tests were performed; with the second including a

modification of the seal rings with the intent to lower stress

Paper No. 2006-1 Copyright 2006 Stein Seal Co. 8

concentrations. Static air leakage rates were determined for the air side

hydroload seal ring before and after each shock test. In addition to a

Pre-test air leakage measurement, the oil side hydroload seal ring was

tested for oil leakage before and after the shock was applied.

SHOCK TEST 1

Air Side Hydroload

Oil Side Hydroload

Air Side Hydroload

Oil Side Hydroload

SHOCK TEST 2

Air Side Hydroload

Oil Side Hydroload

Air Side Hydroload

Oil Side Hydroload 0 0

0.28

Leakage Values in Drops/Min

Pre-Shock Test Post-Shock Test

Leakage Values in SCFM

Pre-Shock Test Post-Shock Test

0.155 0.105

Leakage Values in Drops/Min

Pre-Shock Test Post-Shock Test

0 0

0.155

0.285

Leakage Values in SCFM

Pre-Shock Test Post-Shock Test

0.1375

Table 2 - Shock Test Results

In Table 2, the results of shock testing are shown. For each set of oil

side hydroloads, no oil leakage was observed before or after the shock

test. Surprisingly, the air side leakage decreased after the shock was

applied. One possible reason for this is that the shock more firmly

seated the rings, closing down any small gaps that were present in the

per-shock arrangement. In addition to quantitative values, a visual

inspection of the rings after testing revealed no apparent .

Challenges in a Marine Environment

Proper assembly of any seal is important for proper function. There is a

danger of damaging the seal rings during assembly if attention and care

are not used. By following a step by step procedure, assembly damage

will be infrequent.

We have seen from test results that we can expect some small amounts

of leakage from the seal. The addition of the housing drain hole and a

collection canister are needed to capture this oil. The ability to manage

this leakage into the canister has not been a major issue.

While the garter spring allows the ring to move freely and follow the

shaft, a large amount of shaft movement can affect performance. Inertia

effects increase as the square of shaft speed. If both of these variables

are high, inertia effects must be considered to prevent unseating of the

seal rings. Also a concern with high runouts is the possibility of shaft to

housing rubs. While the seal can be designed to handle such cases,

unexpected large shaft movements can result in a rub.

CONCLUSIONS

The selection of a suitable sealing device for a given MRG application

requires analysis of a number of positives and negatives of the variety

of sealing devices available today. In this paper, we discuss four types

of seals, the labyrinth, lip, face, and circumferential seal. Each seal is

presented, showing where its performance strengths lie, and its

weaknesses. In the selection of a seal, one must weigh the advantages

and disadvantages in each seal design. If a disadvantage is great, and

cannot be managed, then the advantages of that seal will be negligible.

The engineer, by considering the capabilities of each sealing device in

the environment in question, can successfully select a seal which meets

the performance requirements.

References

Buchter, Industrial Sealing Technology, Wiley, New York, 1979.

McNickle, Mechanical Seals for Turbine Engines and

Turbomachinery, Presented at the Institution of Mechanical Engineers,

1997

Schmal, Robert J., Labyrinth Seals, Presented at the Society of

Tribologists and Lubrication Engineers, 1992.

Schmal, Robert J., Seal Theory, Presented at the Society of

Tribologists and Lubrication Engineers, 1990

Shigley, Mischke, Budynas, Mechanical Engineering Design,

McGraw Hill, 2004

Stein, P. C., A Discussion of The Theory of Sealing Devices,

Presented to The Society of Automotive Engineers, 1961.

Stein, P. C., Circumferential Seals for use as Oil Seals, American

Society of Lubrication Engineers Paper #79062, 1978.

Stein, Philip C., Seals, in Handbook of Fluid Dynamics and Fluid

Machinery, Wiley, New York, 1996.

You might also like

- What Are Labyrinth Seals For BearingsDocument18 pagesWhat Are Labyrinth Seals For BearingsAthiphap SrisupareerathNo ratings yet

- Understand Ing Bearing Housing Protection and Reliable Lubricant ApplicationDocument13 pagesUnderstand Ing Bearing Housing Protection and Reliable Lubricant ApplicationRuchi Ragvendra BistNo ratings yet

- Lecture 13 & 14Document26 pagesLecture 13 & 14farah nazNo ratings yet

- Unparalleled Solutions in Clean Water PumpingDocument20 pagesUnparalleled Solutions in Clean Water PumpingkaranNo ratings yet

- Disassembly & Reassembly: RequiredDocument19 pagesDisassembly & Reassembly: RequiredChriscarl De Lima100% (1)

- Compression CalculatorDocument1 pageCompression CalculatorNakkolopNo ratings yet

- Component and Category MatrixDocument56 pagesComponent and Category MatrixMalay MukherjeeNo ratings yet

- Aspen ICARUS-Reference - Guide v7.2 (2010)Document946 pagesAspen ICARUS-Reference - Guide v7.2 (2010)Yang Gul LeeNo ratings yet

- Multistage Pump Disassembly GuideDocument24 pagesMultistage Pump Disassembly GuideHishamSayedNo ratings yet

- US Vertical Motors - In509-1dDocument48 pagesUS Vertical Motors - In509-1dcario_mak_ainsworthNo ratings yet

- Optimization of Planetary Gear Box For High Reduction RatioDocument12 pagesOptimization of Planetary Gear Box For High Reduction RatioNovriansyah BrianNo ratings yet

- Ansi or Nema Mg1-1998Document596 pagesAnsi or Nema Mg1-1998cuervohijoguachoNo ratings yet

- Radial Thrust BRG Case StudiesDocument14 pagesRadial Thrust BRG Case StudiesRajagopal100% (1)

- Introduction To Data Tables and Data Table Exercises: Tools For Excel ModellingDocument25 pagesIntroduction To Data Tables and Data Table Exercises: Tools For Excel ModellingreddoxsterNo ratings yet

- Backlash (Engineering) - Wikipedia, The Free EncyclopediaDocument4 pagesBacklash (Engineering) - Wikipedia, The Free EncyclopediadarkruseNo ratings yet

- Guide To The Application Event System (5675)Document244 pagesGuide To The Application Event System (5675)SunnyDreNo ratings yet

- Thrust CalculationsDocument2 pagesThrust CalculationsshahqazwsxNo ratings yet

- ISO General Purpose Metric Screw ThreadsDocument19 pagesISO General Purpose Metric Screw ThreadsMiguel VillalobosNo ratings yet

- Design and Analysis of Friction Clutch PDocument5 pagesDesign and Analysis of Friction Clutch PAgg GlezNo ratings yet

- Instruction For Installation Guidelines Vertical Turbine Pump PDFDocument27 pagesInstruction For Installation Guidelines Vertical Turbine Pump PDFWilliam Berrospi Garcia100% (1)

- Sim 5HPDocument78 pagesSim 5HPeduardomanuel3No ratings yet

- Self-Locking Gear - Design and Potential ApplicationsDocument7 pagesSelf-Locking Gear - Design and Potential ApplicationsVikram BalajiNo ratings yet

- Model Repair Specifications For Low Voltage Induction MotorsDocument27 pagesModel Repair Specifications For Low Voltage Induction MotorsHenryGaltNo ratings yet

- SN Hoist Brake 1Document4 pagesSN Hoist Brake 1YuseriNo ratings yet

- Vba Book PDFDocument156 pagesVba Book PDFAJ AJNo ratings yet

- Gear Manufacturing Process and Quality ImprovementDocument47 pagesGear Manufacturing Process and Quality ImprovementMuhammad UmarNo ratings yet

- Classification and Designation of Common Pump TypesDocument3 pagesClassification and Designation of Common Pump TypesPradeep KumarNo ratings yet

- 0116 GearsolutionsDocument64 pages0116 GearsolutionsignaciomarinNo ratings yet

- Structural Analysis of Multi-Plate ClutchDocument5 pagesStructural Analysis of Multi-Plate ClutchseventhsensegroupNo ratings yet

- Pump Bearing-1Document51 pagesPump Bearing-1Abel QuiangaNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiamengineeringNo ratings yet

- Typical Labyrinth Seals Straight-Thru Labyrinth: Resource ArticleDocument2 pagesTypical Labyrinth Seals Straight-Thru Labyrinth: Resource ArticleKanchana WeerasingheNo ratings yet

- Manual Pioneer PumpDocument48 pagesManual Pioneer PumpFirzan Yudhistira PutraNo ratings yet

- Steel Specification PDFDocument8 pagesSteel Specification PDFPeter AntonyNo ratings yet

- Heat Treatment Jominy TestDocument12 pagesHeat Treatment Jominy Testmayur_mechNo ratings yet

- Dawson Downie Lamont LTDDocument2 pagesDawson Downie Lamont LTDwarehouse cikalongNo ratings yet

- Nasa STD 6001bDocument108 pagesNasa STD 6001bBilal UsmaniNo ratings yet

- Swagelok Thread and ConnectionDocument56 pagesSwagelok Thread and ConnectionRashi AkmalNo ratings yet

- Nonferrous Alloys Al-6069Document16 pagesNonferrous Alloys Al-6069FMMServicesNo ratings yet

- Appendix f2-III Calculation SheetsDocument46 pagesAppendix f2-III Calculation SheetsTobi BerrospiNo ratings yet

- Design of Transmission Systems: Prepared by Dr.A.Vinoth JebarajDocument148 pagesDesign of Transmission Systems: Prepared by Dr.A.Vinoth Jebarajrishi raja RajaNo ratings yet

- Protech Bearing Isolator Seal TheoryDocument8 pagesProtech Bearing Isolator Seal TheorySanjoy Kr. DeyNo ratings yet

- SKF Locknut Shaft Details InchDocument6 pagesSKF Locknut Shaft Details InchKOMATSU SHOVELNo ratings yet

- IBC Precision LocknutsDocument12 pagesIBC Precision LocknutsTUĞÇE ÖZGEN GENÇNo ratings yet

- Excel for Chemical EngineersDocument79 pagesExcel for Chemical Engineersgebreslassie gereziherNo ratings yet

- 06 Teach Yourself SQL in 21 Days 4th EdDocument27 pages06 Teach Yourself SQL in 21 Days 4th EdIsaack ItMendezNo ratings yet

- Power Stream Couplings-Specn SheetsDocument6 pagesPower Stream Couplings-Specn SheetsAmol PatkiNo ratings yet

- Install Packing Compression GuideDocument2 pagesInstall Packing Compression GuideMachineryengNo ratings yet

- Gearboxes: Overhung & Thrust LoadsDocument8 pagesGearboxes: Overhung & Thrust LoadswhatcaniputNo ratings yet

- Heat Treatment: Prepared by Approved byDocument20 pagesHeat Treatment: Prepared by Approved byBhanu Pratap ChoudhuryNo ratings yet

- SEO-Optimized Title for Springs Chapter of Shigley's Mechanical Engineering DesignDocument64 pagesSEO-Optimized Title for Springs Chapter of Shigley's Mechanical Engineering DesignMNuubhNo ratings yet

- Bearing Types and SelectionDocument22 pagesBearing Types and Selectionsivajirao70No ratings yet

- CP HorizontalDoubleCasing E00609Document5 pagesCP HorizontalDoubleCasing E00609douglas marcanoNo ratings yet

- Bearing Design and Metallurgy GuideDocument46 pagesBearing Design and Metallurgy GuideKumarNo ratings yet

- Failure Analysis For GearsDocument12 pagesFailure Analysis For GearsDavid Torres Rodriguez100% (1)

- PowerGen LifeExtension ForWebSite DRoberts 082807Document21 pagesPowerGen LifeExtension ForWebSite DRoberts 082807Craig LatimerNo ratings yet

- Hydro-Turbine Shaft Seal DesignDocument13 pagesHydro-Turbine Shaft Seal DesignAnonymous Hy5Ir9QXNo ratings yet

- Sealing Arrangement Design GuideDocument32 pagesSealing Arrangement Design GuideJurun_Bidanshi100% (1)

- Advanced Composite Bearings for Hydro Power PlantsDocument12 pagesAdvanced Composite Bearings for Hydro Power PlantsSasankNo ratings yet

- SCI Flanged Fittings PDFDocument14 pagesSCI Flanged Fittings PDFJosmar CristelloNo ratings yet

- Dismantling Joints GuideDocument2 pagesDismantling Joints GuideSasankNo ratings yet

- Thrust Ball Bearings, Double DirectionDocument1 pageThrust Ball Bearings, Double DirectionSasankNo ratings yet

- C-2208-CARB Toroidal Roller Bearings PDFDocument1 pageC-2208-CARB Toroidal Roller Bearings PDFSasankNo ratings yet

- C-2208-CARB Toroidal Roller BearingsDocument1 pageC-2208-CARB Toroidal Roller BearingsSasankNo ratings yet

- Quantifiable Crack Detection in Newly Installed Pelton TurbineDocument4 pagesQuantifiable Crack Detection in Newly Installed Pelton TurbineSasankNo ratings yet

- Dismantling Joint DN350 To DN2400 PN16 VJ DSDocument1 pageDismantling Joint DN350 To DN2400 PN16 VJ DSVignesh NadimuthuNo ratings yet

- Energies 10 00103Document19 pagesEnergies 10 00103SasankNo ratings yet

- Spherical Roller Bearings-22210 EDocument2 pagesSpherical Roller Bearings-22210 EManoj TyagiNo ratings yet

- 10 11648 J Ijepe 20150404 14 PDFDocument11 pages10 11648 J Ijepe 20150404 14 PDFbacuoc.nguyen356No ratings yet

- Thrust Ball Bearings, Double DirectionDocument1 pageThrust Ball Bearings, Double DirectionSasankNo ratings yet

- RT765E 2 Product Guide ImperialDocument1 pageRT765E 2 Product Guide ImperialAnonymous 6XyAh3DNo ratings yet

- Effects of Load Variation On A Kaplan Turbine Runner: ArticleDocument13 pagesEffects of Load Variation On A Kaplan Turbine Runner: ArticleSasankNo ratings yet

- National Pension System (Enps) - Subscriber Registration FormDocument8 pagesNational Pension System (Enps) - Subscriber Registration FormSasankNo ratings yet

- SCI Flanged Fittings PDFDocument14 pagesSCI Flanged Fittings PDFJosmar CristelloNo ratings yet

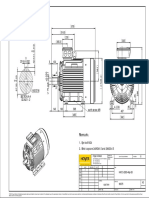

- Remark : HMC3-280S-46p-B3Document1 pageRemark : HMC3-280S-46p-B3SasankNo ratings yet

- RT765E 2 Product Guide ImperialDocument1 pageRT765E 2 Product Guide ImperialAnonymous 6XyAh3DNo ratings yet

- Pre-Proposal Conference Cum Webinar - FlyeDocument3 pagesPre-Proposal Conference Cum Webinar - FlyeSasank0% (1)

- Bolted JointsDocument3 pagesBolted JointsGiuseppe GiuseppeNo ratings yet

- Piping Elbows - Thrust Block ForcesDocument5 pagesPiping Elbows - Thrust Block ForcesSasankNo ratings yet

- SCI Flanged Fittings PDFDocument14 pagesSCI Flanged Fittings PDFJosmar CristelloNo ratings yet

- DCP NcovDocument5 pagesDCP NcovNicoleta MNo ratings yet

- CARB Toroidal Roller Bearings PDFDocument1 pageCARB Toroidal Roller Bearings PDFSasankNo ratings yet

- Bureau of Indian Standards-List For StudentsDocument23 pagesBureau of Indian Standards-List For StudentsSasankNo ratings yet

- Calculation of The Parameters of Model Hydraulic Turbine Using The Value of The Specific SpeedDocument28 pagesCalculation of The Parameters of Model Hydraulic Turbine Using The Value of The Specific SpeedSasankNo ratings yet

- FSAF 22314: SAF and SAW Pillow Blocks With Bearings With A Cylindrical BoreDocument4 pagesFSAF 22314: SAF and SAW Pillow Blocks With Bearings With A Cylindrical BoreSasankNo ratings yet

- Article - Bolted Joint DesignDocument15 pagesArticle - Bolted Joint DesignPiyush YardiNo ratings yet

- QSMicrohydroSEP2005 PDFDocument57 pagesQSMicrohydroSEP2005 PDFSasank0% (1)

- Small Hydropower Standards GuideDocument62 pagesSmall Hydropower Standards GuideSasank100% (1)

- Review Notes in Police PhotographyDocument203 pagesReview Notes in Police PhotographyInaho KaizugaNo ratings yet

- Master'S Thesis: Simulation of An Underground Haulage System, Renström Mine, Boliden MineralDocument76 pagesMaster'S Thesis: Simulation of An Underground Haulage System, Renström Mine, Boliden MineralJosé Carlos Bustamante MoralesNo ratings yet

- CKY) Cocke-Kasami-Younger) Earley Parsing Algorithms: Dor AltshulerDocument81 pagesCKY) Cocke-Kasami-Younger) Earley Parsing Algorithms: Dor AltshulerViorel BotnariNo ratings yet

- 1 s2.0 S2352012421001156 MainDocument14 pages1 s2.0 S2352012421001156 MainBayuAgungGilangWibowoNo ratings yet

- Helios PDF HandshakeDocument2 pagesHelios PDF HandshakemilivojNo ratings yet

- Mathematics in The Modern World-FeuaDocument12 pagesMathematics in The Modern World-FeuaChachi UsiNo ratings yet

- Clutch/Gearshift LinkageDocument19 pagesClutch/Gearshift LinkagegenuineswedeNo ratings yet

- CSD Full TermDocument29 pagesCSD Full TermNishat Farha SharmiNo ratings yet

- Ferraris Wright & HaloscaleDocument4 pagesFerraris Wright & HaloscaleJORGE NAVARRONo ratings yet

- Universal Enclosures - Busbars, Distribution and Cabling Accessories - Catalogue 2013 PDFDocument140 pagesUniversal Enclosures - Busbars, Distribution and Cabling Accessories - Catalogue 2013 PDFNuengruthai WeerawattanaNo ratings yet

- Babcock and Wilcox Boiler1Document9 pagesBabcock and Wilcox Boiler1Oscar DorantesNo ratings yet

- Leader MLV Test-03 30 Oct QPDocument60 pagesLeader MLV Test-03 30 Oct QPInsane insaanNo ratings yet

- Azenabor - Oruka's Philosophic SagacityDocument18 pagesAzenabor - Oruka's Philosophic SagacityestifanostzNo ratings yet

- SpO2 and Temp Monitoring FinalDocument39 pagesSpO2 and Temp Monitoring FinalWaltas KariukiNo ratings yet

- Xtralis VESDA ASPIRE2: ASPIRE2 - Air Sampling Smoke Detection Made EasyDocument2 pagesXtralis VESDA ASPIRE2: ASPIRE2 - Air Sampling Smoke Detection Made Easy17souravNo ratings yet

- 800 Range Sensor 120ohms Strain GaugeDocument21 pages800 Range Sensor 120ohms Strain GaugeBigheti100% (1)

- KatalogDocument6 pagesKatalogMawan BentzNo ratings yet

- General Description: 8-Bit Synchronous Binary Down CounterDocument25 pagesGeneral Description: 8-Bit Synchronous Binary Down CounterspotNo ratings yet

- Esteem 11 Brochure (24032023)Document9 pagesEsteem 11 Brochure (24032023)TeaMeeNo ratings yet

- IUPAC Naming by Aravind AroraDocument30 pagesIUPAC Naming by Aravind Aroratanish gehlotNo ratings yet

- M.tech Machine SyllabusDocument41 pagesM.tech Machine SyllabusSyed Faiz Quadri0% (1)

- RNC2600 DatasheetDocument2 pagesRNC2600 DatasheetShaikh Tariq100% (1)

- DBMS Lab ManualDocument199 pagesDBMS Lab ManualMoulika Chowdary100% (1)

- Slot18 2D Graphics ImagesDocument23 pagesSlot18 2D Graphics ImagesHuy KunnNo ratings yet

- Board characteristics and risk in Tunisian banksDocument12 pagesBoard characteristics and risk in Tunisian banksdhahri nourhenNo ratings yet

- 03-Power Apps Model-Driven App Lab ManualDocument32 pages03-Power Apps Model-Driven App Lab Manualsequeesp medalviruNo ratings yet

- Part A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves FurnacesDocument25 pagesPart A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves Furnacesfujiman35100% (1)

- Tutorial Solutions Week 10Document3 pagesTutorial Solutions Week 10Jaden EuNo ratings yet

- Pile CAP CALCULATIONSDocument9 pagesPile CAP CALCULATIONSJUAN MANUEL VIZCAINONo ratings yet

- Everything You Need to Know About Hino Truck Models FD, FE, FF and SGDocument4 pagesEverything You Need to Know About Hino Truck Models FD, FE, FF and SGHS itNo ratings yet