Professional Documents

Culture Documents

Deutz 909 Diesel Engine Specs

Uploaded by

Theologos Daridis0 ratings0% found this document useful (0 votes)

362 views4 pagesSpecification sheet for the deutz 909 diesel engine

Original Title

Deutz 909 diesel engine specs

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSpecification sheet for the deutz 909 diesel engine

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

362 views4 pagesDeutz 909 Diesel Engine Specs

Uploaded by

Theologos DaridisSpecification sheet for the deutz 909 diesel engine

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

These are the characteristics of the 909:

Air-cooled single-cylinder engine.

0.7 litre displacement.

Advanced direct fuel injection and combustion system, in conformity with

exhaust emission standard Level II (EU-RL 97/68).

Maximum torque 38.2 Nm at 2,000 rpm.

Stiff grey-cast crankcase, with additional acoustic optimisation.

Easy access for all adjustment and service work.

Flexibility through various starting options:

manual starting using hand crank electric starter motor

manual and electric starting.

Your benefits:

u High torque at low speeds and 90% of maximum torque across a wide

speed range give you great elasticity in the use of your equipment.

u Extremely long service life thanks to heavy-duty designs.

u Low exhaust emission values ensure environmentally friendly operation.

A special version of the engines is available on request to meet strict

US exhaust emission regulations (EPA).

u High degree of reliability and long service life even in extreme operating

conditions.

u Broad power range from 1,500 to 3,000 rpm ensures the operating point

and speed range you are looking for are always available.

u Excellent rugged design places minimum demands on your operating

personnel.

909. The engine for construction equipment.

5.8- 11 kW at 1500- 3000 rpm

u Engine description

Cooling system: Air-cooled with integrated radial-flow blower. Cooling air enters via side openings in the

crankcase.

Crankcase: Grey cast iron, acoustically optimised through internal design.

Crankcase ventilation: Closed crankcase ventilation system.

Cylinder head: Cross-flow light alloy cylinder head.

Cylinder: Wear-resistant grey cast alloy with generously dimensioned cooling fins, ensures efficient

cooling of cylinder and piston.

Valve arrangement/

timing: Overhead valves in the cylinder head, one inlet and one exhaust valve, actuated from

gear-driven camshaft via tappets, push rods and rocker arms.

Piston: Three-ring piston: two compression rings and one oil scraper ring.

Piston cooling: Oil spray via nozzle.

Crankshaft: Drop-forged steel crankshaft.

Connecting rod: Drop-forged steel rod, diagonally split.

Main and big end

bearings: Ready-to-install tri-metal plain bearings.

Main bearing on

flywheel side: Roller bearings for reduction of friction losses.

Camshaft: Forged steel, induction hardened. Enables manual starting and PTO at half-speed.

Balancing of masses: Forged offset balancing of masses, mounted on the oil pump drive shaft.

Lubrication system: Forced-feed circulation lubrication with rotary pump. External pressure regulating valve for

easy cleaning of valve, if necessary.

Lube oil filter: Paper-type micro-filter as replaceable-cartridge full flow filter.

Fuel system: 14.5 litres fuel tank. Automatic breathing of the fuel injection system.

Injection pump/

governor: Mountable pump in crankcase with mechanical centrifugal governor.

Injection nozzle: Advanced 5-hole nozzle.

Fuel filter: External, easy-access replaceable cartridge.

Air filter: Dry-type air filter with easy-access arrangement in fuel tank. A conventional dry-type air

filter can be supplied separately on request.

Starter motor: 12 V; 1.4 kW.

Alternator: Three-phase alternator (flywheel alternator) 14V; 23 A.

Options: Flywheels for various applications, fine adjustment for two speed points, speed adjustment

for vehicle application, various engine monitoring systems (panel) in 12 V version, 12 V electro-

magnetic switch (release switch), industrial couplings, various V-belt options for PTO,

hydraulic pumps with various capacities, irrigation pumps (centrifugal) in low, medium and

high-pressure versions.

u Technical data

1) Power ratings to ISO 1585 and European guidelines

80/1269/CEE and 88/195/CEE.

2) Power ratings to ISO 3046/1 for industrial engines.

3) Specific fuel consumption based on diesel fuel to

DI N 51601 with a specific gravity of 0.835 kg/dm

3

at 15C.

4) Without starter motor/alternator, without liquids, but

with standard flywheel.

The values given in this datasheet are for information

purposes only and are not binding. The information

given in the offer is decisive.

Engine type D 909 L 1

Number of cylinders 1

Bore/Stroke mm 95/100

Displacement l 0.7

Compression ratio 17

Max. rated speed rpm 3000

Mean piston speed m/s 10.0

Power ratings for construction equipment engines

Power ratings for automotive

1)

and industrial engines kW 11

at speed rpm 3000

Mean effective pressure bar 6.21

Power ratings for industrial engines

2)

highly intermittent operation kW 11

at speed rpm 3000

Mean effective pressure bar 6.21

Intermittent operation kW 10.5

at speed rpm 3000

Mean effective pressure bar 5.93

Max. torque Nm 38.2

at speed rpm 2000

Minimum idle speed rpm 850

Specic fuel consumption

3)

g / kWh 236

Weight to DIN 70020, part 7A

4)

kg 106

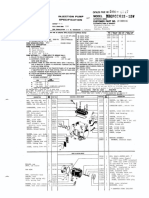

u Dimensions

Engine A B C

D 909 L 1 mm 453 400 665

u Model designation

D 909 L 1

Number of cylinders

L = In-line engine

Engine family designation

D = Diesel engine

A

C

B

1750 2000 2250 2500 2750 3000 min

-1

33

34

35

36

37

38

39

1500

T (Nm)

5

6

7

8

9

10

11

12

P (kW)

O

r

d

e

r

-

N

r

.

0

0

3

1

2

0

2

1

/

0

2

/

2

0

0

3

/

V

M

-

V

u Standard engine

u D 909L 1

DEUTZ AG

DEUTZ MOTOR

Deutz-Mlheimer Str. 147-149

D-51063 Kln

Telephone: + 49 (0) 2 21 - 8 22- 0

Fax: + 49 (0) 2 21 - 8 22- 25 68

Internet: www.deutz.de

eMail: info@deutz.de We move your world.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Johnsered 2036Document5 pagesJohnsered 2036BobbyMageeNo ratings yet

- QR-25 Series: Reciprocating Air CompressorsDocument8 pagesQR-25 Series: Reciprocating Air CompressorszaidNo ratings yet

- bBGFCC633 2DWDocument2 pagesbBGFCC633 2DWMiguel RojasNo ratings yet

- Ntorq Cat 21 3 18Document39 pagesNtorq Cat 21 3 18David ManjgaladzeNo ratings yet

- General Arrangement and Bill of Materials Stirling Hot Air EngineDocument3 pagesGeneral Arrangement and Bill of Materials Stirling Hot Air Enginecibyk fender santos pariasNo ratings yet

- Power Cell Generator Technical Data 62.5 KVA PDFDocument2 pagesPower Cell Generator Technical Data 62.5 KVA PDFMousum KabirNo ratings yet

- GB Instructions LPG CNG Injector Cleaner SystemDocument2 pagesGB Instructions LPG CNG Injector Cleaner SystemChristian Arias MontoroNo ratings yet

- 13Document18 pages13Catherine GuthrieNo ratings yet

- United States Patent (19) 4,513,568: BajulazDocument9 pagesUnited States Patent (19) 4,513,568: BajulazQwerty UiopNo ratings yet

- HAR-1018 VORTEC Harness Instructions 8Document14 pagesHAR-1018 VORTEC Harness Instructions 8Jacob HernandezNo ratings yet

- Makelsan Jenerator Mjs Series 220 Kva enDocument1 pageMakelsan Jenerator Mjs Series 220 Kva enСемен ГассеевNo ratings yet

- BSA Bantam D14-4 Workshop ManualDocument120 pagesBSA Bantam D14-4 Workshop ManualPeter Theodosiussen100% (1)

- Land Range Rover - Engine NP10 V8 508PS JLR AJ-133 Gen III 5.0 TECH Manual 2009Document118 pagesLand Range Rover - Engine NP10 V8 508PS JLR AJ-133 Gen III 5.0 TECH Manual 2009RedacTHOR100% (2)

- Caterpillar 3306 Diesel Engine Service ManualDocument8 pagesCaterpillar 3306 Diesel Engine Service Manualrayendra80% (5)

- 29 Yaris Verso / Echo Verso (Cont. Next Page) 29 Yaris Verso / Echo Verso (Cont' D) (Cont. Next Page) 29 Yaris Verso / Echo Verso (Cont' D)Document1 page29 Yaris Verso / Echo Verso (Cont. Next Page) 29 Yaris Verso / Echo Verso (Cont' D) (Cont. Next Page) 29 Yaris Verso / Echo Verso (Cont' D)Adanaque Villacorta Jd100% (2)

- Wiring Diagram ISB CM2150 and ISB CM2150 E: Engine Control ModuleDocument1 pageWiring Diagram ISB CM2150 and ISB CM2150 E: Engine Control ModuleOmar HernándezNo ratings yet

- Stationary Natural Gas Engine LubricationDocument9 pagesStationary Natural Gas Engine Lubricationiyan22suryana_827197No ratings yet

- Motor 3304 Inyeccion Directa - Scroll Fuel SystemDocument36 pagesMotor 3304 Inyeccion Directa - Scroll Fuel SystemMiguel Chacon100% (9)

- D 51 Ex PX-22 Código de Peças PDFDocument495 pagesD 51 Ex PX-22 Código de Peças PDFJulia Coitinho SilvaNo ratings yet

- TAD1241GE: Volvo Penta Genset EngineDocument2 pagesTAD1241GE: Volvo Penta Genset EngineMuhammad rizki100% (1)

- Electronic EngineDocument16 pagesElectronic EngineSelazinap LptNo ratings yet

- How To Check The Turbocharger Oil Leakage ConditionDocument11 pagesHow To Check The Turbocharger Oil Leakage ConditionMyo minNo ratings yet

- TM 9-1787a M1 Tractor Allis-Chalmers TD-10WDocument174 pagesTM 9-1787a M1 Tractor Allis-Chalmers TD-10WAdvocate100% (3)

- Catalogo Camiones SkaniaDocument284 pagesCatalogo Camiones SkaniaAngel AdrianNo ratings yet

- KOMATSU PC300-7 Hydraulic Excavator: FOR Atmospheric Temperature From - 30C Up To + 40CDocument10 pagesKOMATSU PC300-7 Hydraulic Excavator: FOR Atmospheric Temperature From - 30C Up To + 40CYadie Doomeastvan0% (1)

- D5967Document42 pagesD5967jbaquerizo31No ratings yet

- GP1200 Ingles PDFDocument253 pagesGP1200 Ingles PDFJuan Luis Romero Ramirez100% (1)

- TVS Motorcycle Spare Parts Job Card ReportDocument5 pagesTVS Motorcycle Spare Parts Job Card ReportRakesh Ekka100% (1)

- Marine Engineering Progress in 1997: Annual ReviewDocument42 pagesMarine Engineering Progress in 1997: Annual Reviewнелля могурянNo ratings yet

- En EG-Dynamic User Manual v110Document12 pagesEn EG-Dynamic User Manual v110safvanshaikhNo ratings yet