Professional Documents

Culture Documents

PIT Report on 4 Spun Piles

Uploaded by

Je M'appelle NofreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PIT Report on 4 Spun Piles

Uploaded by

Je M'appelle NofreCopyright:

Available Formats

PT.

GEO PRIMA

Geotechnical Consultant

J l. Mahkota Raya Blok H1 No. 12A

Telp. (021) 70218911, (021) 5529233

Fax. (021) 5529233

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

`

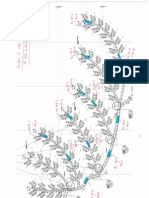

PILE INTEGRITY TESTER on (4) Spun Piles

CORRALIUM VILLA FUNTASY ISLAND PROJECT

Pulau Manis - Batam

Prepared for

PT. BATAM ISLAND MARINA

IBN Executive Lounge Sekupang Ferry Terminal

Jl. R.E. Martadinata, Sekupang - Batam

May 26, 2014

t

&

ffi

l',1t.

M

ffi

I|day 26,

fl}.-Sli*"flffigH*

{ir*1t:clr*ritiil {-\;*lr;lr,*l*r

.ii i',iiril,i;li;r. .i.r,r.,,,i ]ji+ii lli lri+.

j;...i

'i'riii

i-'ii": i,i 7.,"1.1 yr)

i

j

. i ii? !

i

;i i Ji: i3,1

,,

t.,' , ,,,=*) i.(: ],,1 \ i

2104

PT. BATAM ISLAI\D MARINA

IBN Executive Lounge Sekupang Ferry Terminal

Jt. RE. Martadinata, Sekupang - Batam

Attention : Mr. Ade Soehari,

Subject : Result of Pile Integrity Tester (PITs) on (4) Spun Piles on Coralium

Villa

-

Funtasy Island Project.

Dear Sir,

We are pleased to submit (3) copies of this final report presenting the result of

Pile Integrity Tester (PITs) tests on (a) Spun Piles on Coralium Yilla

-

Funtasy

Island Project.

Should you have any questions, please call us at (021) 552-9233.

Sincerely,

PT. GEO PRIMA

Masagung- S.ST

Bobb* Soediono

Senior Engineer

TABLE OF CONTENT

1 INTRODUCTION .......................................................................... 1

2 PILE INTEGRITY TESTER (PIT) ................................................. 1

2.1 Principal of Testing.................................. ........................................ 1

2.2 PIT Equipment & Test Preparation.................................. ................. 1

2.3 Test Procedure.................................. ............................................... 1

2.4 Test Results...................................................................................... 2

APPENDICES

APPENDIX A PIT Results

APPENDIX B Brochure of PIT Analyzer

PT. GEO PRIMA

1

1. INTRODUCTION

This report presents the results of Pile Integrity Tester (PIT) that have been conducted

on (4) Spun Piles at Corralium Villa Funtasy Island Project.

Our service is to perform the PIT test on (4) Spun Piles that were prepared by PT.

BATAM ISLAND MARINA (BIM). The purpose of PIT was to verify pile integrity (or if

the pile contained any major discontinuities, such as cracks or reduction in cross sectional

area) below top of pile.

2. PILE INTEGRITY TESTER (PIT)

Pile Integrity Tester (PIT) is a compact equipment that consists of mini computer,

accelerometer, and hand-held hammer. The purpose of conducting PIT on pile is to verify the

pile integrity.

2.1. Principal of Testing

Pile is tested dynamically by pounded top of pile and then analyze the characteristic

of transferred wave. The blow is done by hand hammer, which has soft head, so the

deformation of pile will not significant and it remain in elastic condition. Analyzing of testing

result is performed by one dimensional wave theory. When waves transfer along the pile,

wave of blow will reflect if there is any pile impedance change.

2.2. PIT Equipment & Test Preparation

The transferring wave due to given blow will be measured by sensitive accelerometer, which

installed at the top pile surface, If piles has damage in certain location, the wave will be

reflected. The reflecting wave will be measured by an accelerometer and will be recorded by

the computer.

Ideally, the testing with PIT equipment must be done on smooth surface, where a

single blow is sufficient. However, rough surface of top pile will cause double blows. Thus,

the top of pile has to be smoothened by a grinding tool where the blow of hand hammer must

be at the point of accelerometer.

2.3. Test Procedure

PIT test will be carried out in accordance with ASTM D5882-00. The analyzing of pile

integrity is based on characteristic interpretation of recorded wave velocity. The damage of

cross section will be shown by reflection of the velocity curve at that particular location.

Integrity testing is performed by affixing an accelerometer to the pile top and striking the pile

with a hand-held hammer. Since the hammer impact causes a low strain wave to travel down

the pile, the term low strain integrity testing is adopted.

PT. GEO PRIMA

2

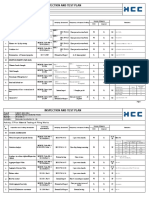

2.4. Test Results

The results of PIT are presented in table below, and the record curves of PIT result are

attached in Appendix A.

No. Pile No.

Testing

Date

Pile Type

Pile Diameter

(m)

Pile Length

(m)

(1)

Result Remark

1 CVA3A 22 No.5

21-May-14

Spun

Piles

0.30 10.00 BTA 63% Damage

2 CVA3A 22 No.6 0.30 10.00 BTA 74% Damage

3 CVA3A 22 No.7 0.30 10.00 BTA 83% Slight Damage

4 CVA3A 22 No.8 0.30 10.00 BTA 54% Damage

Note:

(1)

Pile length was obtained from piling records provided by PT. BIM.

APPENDIX A

PIT Results

Ge o- Op tima In c 5/ 2 6 / 2 01 4

CORA L L IUM V IL L A

D:\...\PIT B a tam\ CORA LL IUM V ILL A . PIT PIT- W 20 09 - 1

5.06

2.53

cm /s

Pile: CVA3A 22 NO 5 - 30: #1 2 3 4 5 6 7 8 9 10

SPUN

5/21/2014 7:40:50 AM

2W 2.00 m 950.0 Hz

0.00

-2.53

3.00

cm /s

x 5.00 L/D=42 (D=23.99 cm)

10.00 m (3800 m/s)

0 2 4 6 8 10 12 14 m

Pile: CVA3A 22 NO 6 - 27: #11 12 13 14 15 16 17 18 19

V 1.846 cm/s (2.323)

1.50

SPUN

5/21/2014 7:48:16 AM

2W 2.00 m 950.0 Hz

0.00

-1.50

4.50

cm /s

x 5.00 L/D=42 (D=23.99 cm)

10.00 m (3800 m/s)

0 2 4 6 8 10 12 14 m

Pile: CVA3A 22 NO 7 - 29: #20 21 22 23 24 25 26 27 28 29

V 1.707 cm/s (2.137)

2.25

SPUN

5/21/2014 7:59:08 AM

2W 2.00 m 950.0 Hz

0.00

-2.25

4.50

cm /s

x 5.00 L/D=42 (D=23.99 cm)

10.00 m (3800 m/s)

0 2 4 6 8 10 12 14 m

Pile: CVA3A 22 NO 8 - 24: #30 31 32 33 34 35 36 37

V 2.067 cm/s (2.573)

2.25

SPUN

5/21/2014 7:53:53 AM

2W 2.00 m 950.0 Hz

0.00

-2.25

x 5.00 L/D=42 (D=23.99 cm)

10.00 m (3800 m/s)

0 2 4 6 8 10 12 14 m

V 1.814 cm/s (2.250)

BTA 63%

BTA 74%

BTA 83 %

BTA 54%

APPENDIX B

Brochure of PIT Analyzer

You might also like

- Method Statement Geotechnical Investigation Works: ProjectDocument20 pagesMethod Statement Geotechnical Investigation Works: ProjectShan NawazNo ratings yet

- Inspection and Test Plan: Activity: ITP For Material Testing of Piling WorksDocument5 pagesInspection and Test Plan: Activity: ITP For Material Testing of Piling WorksjitendraNo ratings yet

- Plate Bearing Test - Jurutera AddaDocument12 pagesPlate Bearing Test - Jurutera Addactlim88No ratings yet

- MS For Pile Integrity Testing-REV01Document55 pagesMS For Pile Integrity Testing-REV01Lijo Joseph100% (1)

- Yjack - Ms 20170211 - BD For Bp600mm Wl2827kn Tl5654knDocument56 pagesYjack - Ms 20170211 - BD For Bp600mm Wl2827kn Tl5654knKS Lee100% (1)

- Rapid Load Testing of Foundation Piles in Barcelona:: IssueDocument5 pagesRapid Load Testing of Foundation Piles in Barcelona:: IssuebozarromegustaNo ratings yet

- Stress-Wave Testing of PilesDocument5 pagesStress-Wave Testing of PilesDae Yeol KimNo ratings yet

- Integrity Testing Reveals Deep Foundation DefectsDocument21 pagesIntegrity Testing Reveals Deep Foundation DefectsAjith RamuNo ratings yet

- Post-Tensioned Box Girder Design Manual: June 2016Document389 pagesPost-Tensioned Box Girder Design Manual: June 2016aandueza_1No ratings yet

- Skin Friction and Pile DesignDocument7 pagesSkin Friction and Pile DesignNaveen RNo ratings yet

- Bored Pile InstallationDocument134 pagesBored Pile InstallationadnanNo ratings yet

- Specification For Testing of Bored PileDocument22 pagesSpecification For Testing of Bored PileAlly KhooNo ratings yet

- 1.2 Advantages Types of Prestressing Section4.6 2IN1Document124 pages1.2 Advantages Types of Prestressing Section4.6 2IN1Tanmaya Kumar SahooNo ratings yet

- MOS Soil Nailing - PMSB PDFDocument7 pagesMOS Soil Nailing - PMSB PDFMohd Norzahimi Bin IbrahimNo ratings yet

- Geotechnical Report SummaryDocument11 pagesGeotechnical Report Summaryjuliyet strucNo ratings yet

- Boiling or Heaving in CofferdamsDocument2 pagesBoiling or Heaving in Cofferdamsslawek780303No ratings yet

- Challenges To Quality Control in Bored Cast In-Situ Piling in Growing Urban Environment by Karandikar (PPR) PDFDocument17 pagesChallenges To Quality Control in Bored Cast In-Situ Piling in Growing Urban Environment by Karandikar (PPR) PDFsandip0002No ratings yet

- Method Statement - Test PilingDocument5 pagesMethod Statement - Test PilingMcr Kumara0% (1)

- Comparative Study of BS5930 and ISO 14688 StandardsDocument14 pagesComparative Study of BS5930 and ISO 14688 StandardsNathan VincentNo ratings yet

- Especifications For Jet Grouting PDFDocument7 pagesEspecifications For Jet Grouting PDFMarco Dos Santos NevesNo ratings yet

- Plate Bearing Test Report from Kuching Site VisitDocument13 pagesPlate Bearing Test Report from Kuching Site VisitTeddy TP100% (1)

- 2 - Load Testing of Deep FoundationsDocument119 pages2 - Load Testing of Deep FoundationsTalis BattleNo ratings yet

- Institution of Civil Engineers (1988) Specification For Piling - Contract Documentation and MeasurementDocument35 pagesInstitution of Civil Engineers (1988) Specification For Piling - Contract Documentation and MeasurementBobNo ratings yet

- Bentonite slurry uses in construction excavationDocument4 pagesBentonite slurry uses in construction excavationMajor Tushar100% (3)

- Bored Piling Using Rotary Kelly Drilling KLCC Lot L&M, A New World Record in Bored Piling Has Probably Been Set Again in MalaysiaDocument2 pagesBored Piling Using Rotary Kelly Drilling KLCC Lot L&M, A New World Record in Bored Piling Has Probably Been Set Again in MalaysiaVincentNo ratings yet

- Mos Survey WorkDocument4 pagesMos Survey Workaniesbaek100% (1)

- Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components - Complementary Guidance To That Given in SS EN 13791Document10 pagesAssessment of In-Situ Compressive Strength in Structures and Precast Concrete Components - Complementary Guidance To That Given in SS EN 13791md tan5381No ratings yet

- GE Sept 2011 A Simple Stability Check For Piling Rigs CorkeDocument3 pagesGE Sept 2011 A Simple Stability Check For Piling Rigs CorkepaulombatistaNo ratings yet

- Chpater 82 Piling ProblemsDocument12 pagesChpater 82 Piling ProblemsGan Khai SianNo ratings yet

- G&P Digest Issue 6Document8 pagesG&P Digest Issue 6Chua Chim HueeNo ratings yet

- A Lecture Notes 2012 Dda2132 CHP 3b Pile TestDocument13 pagesA Lecture Notes 2012 Dda2132 CHP 3b Pile Testmkpasha55mpNo ratings yet

- USDA Engineering Classification of Rock MaterialsDocument61 pagesUSDA Engineering Classification of Rock MaterialsTanNo ratings yet

- YJACK Indonesia, Type C - June 2019Document61 pagesYJACK Indonesia, Type C - June 2019rizki afynNo ratings yet

- CHAPTER 1. Serviceability and Durability - COVER & FIRE RESISTANCEDocument20 pagesCHAPTER 1. Serviceability and Durability - COVER & FIRE RESISTANCEmuhammad nuruddin che ab malikNo ratings yet

- Malaysia ReportDocument47 pagesMalaysia ReportAgim Derguti100% (1)

- Bi-Directional Pile Load Testing ProceduresDocument22 pagesBi-Directional Pile Load Testing ProceduresHemant YesajiNo ratings yet

- High Strain Intergrity Dynamic TestDocument9 pagesHigh Strain Intergrity Dynamic Testkartick adhikaryNo ratings yet

- Foundation Design and Construction in Hong KongDocument20 pagesFoundation Design and Construction in Hong KongXet Fat100% (1)

- Pile Integrity TestDocument7 pagesPile Integrity TestFazren KamarudinNo ratings yet

- 9ARC1991 Vertical Drains Trial at Juru, Malaysia - Performance During Construction, 1991, ThailandDocument6 pages9ARC1991 Vertical Drains Trial at Juru, Malaysia - Performance During Construction, 1991, ThailandfreezefreezeNo ratings yet

- Fugro Engineering Services Limited: Interpretation of Static Cone Penetration TestsDocument2 pagesFugro Engineering Services Limited: Interpretation of Static Cone Penetration Testssabri4181No ratings yet

- Prediction of Embankment Performance Using Numerical An 2018 Computers and GDocument15 pagesPrediction of Embankment Performance Using Numerical An 2018 Computers and Grameshkaa0% (1)

- Comparison of Ultimate Bearing Capacity Obtained by Pile Driving Analyzer and Maintained Load TestDocument80 pagesComparison of Ultimate Bearing Capacity Obtained by Pile Driving Analyzer and Maintained Load Testicv.xaviNo ratings yet

- Dinamik Kazık Testi Dynamic Load TestDocument3 pagesDinamik Kazık Testi Dynamic Load TestHalil Can EryaşarNo ratings yet

- Method Statement For Survey Monitoring of Excavated SlopesDocument20 pagesMethod Statement For Survey Monitoring of Excavated Slopesmohamedamine.zemouriNo ratings yet

- Static Pile Load Test - (Kuliah-3)Document4 pagesStatic Pile Load Test - (Kuliah-3)banuardiNo ratings yet

- Soil Report Purchaudi, BaitadiDocument54 pagesSoil Report Purchaudi, BaitadiArunaNo ratings yet

- Bridge Report Barrette PilesDocument4 pagesBridge Report Barrette PilesJJ AustriaNo ratings yet

- CSL Testing MethodDocument4 pagesCSL Testing MethodGaneshalingam RamprasannaNo ratings yet

- GEESS - 22nd Minutes - Nurul - Yee TS Edit 28 Feb 2021-Tao (FINAL)Document13 pagesGEESS - 22nd Minutes - Nurul - Yee TS Edit 28 Feb 2021-Tao (FINAL)Ismacahyadi Mohamed Jais100% (1)

- Report On Plate Load Test Along With Trial Pit: Project Name Repowering Project of Ghorasal Unit #3Document12 pagesReport On Plate Load Test Along With Trial Pit: Project Name Repowering Project of Ghorasal Unit #3Mehedi HasanNo ratings yet

- Fellenius - The Analysis of Results From Pile Load TestsDocument10 pagesFellenius - The Analysis of Results From Pile Load TestsFederico MontesverdesNo ratings yet

- Engineered Concrete - Mix Design and Test Methods, Second Edition - Engineering BooksDocument4 pagesEngineered Concrete - Mix Design and Test Methods, Second Edition - Engineering BooksHampang HampangNo ratings yet

- CoreTrade BriefingDocument51 pagesCoreTrade Briefinglwin_oo2435No ratings yet

- Standard Penetration Test Method for Soil SamplingDocument9 pagesStandard Penetration Test Method for Soil SamplingFranco PretellNo ratings yet

- (Project Name) : Pile Integrity Test (Pit) On Concrete Driven PilesDocument6 pages(Project Name) : Pile Integrity Test (Pit) On Concrete Driven PilesHrv AquinoNo ratings yet

- Comparison of Static and Dynamic Load Test of PileDocument11 pagesComparison of Static and Dynamic Load Test of PilehangNo ratings yet

- In Situ Test SPTDocument6 pagesIn Situ Test SPTAnonymous fE2l3DzlNo ratings yet

- A Comprehensive Database of Tests on Axially Loaded Piles Driven in SandFrom EverandA Comprehensive Database of Tests on Axially Loaded Piles Driven in SandNo ratings yet

- FBB FinishesDocument9 pagesFBB FinishesJe M'appelle NofreNo ratings yet

- Tender B - Architectural SpecficationsDocument188 pagesTender B - Architectural SpecficationsJe M'appelle NofreNo ratings yet

- FBB FinishesDocument9 pagesFBB FinishesJe M'appelle NofreNo ratings yet

- SBA Additional Load Test at BoardwalkDocument1 pageSBA Additional Load Test at BoardwalkJe M'appelle NofreNo ratings yet

- Overall Heat Transfer CoefficientDocument3 pagesOverall Heat Transfer CoefficientcordobaluisfNo ratings yet

- 2a. Specs For Valves - IADocument4 pages2a. Specs For Valves - IAPraveen KasrottaranNo ratings yet

- Conveyor installation diagramDocument2 pagesConveyor installation diagramLuis PurisNo ratings yet

- Aama 501.2-83Document3 pagesAama 501.2-83Abdul Raqeeb67% (3)

- ACI Building Code Requirements for Thin Shells and Folded PlatesDocument84 pagesACI Building Code Requirements for Thin Shells and Folded PlateskrishnanunniNo ratings yet

- MICRO-M-3: Microelectronic Operation and Unit TroubleshootingDocument32 pagesMICRO-M-3: Microelectronic Operation and Unit TroubleshootinghanamanNo ratings yet

- BS 4873 2004 Aluminum Alloy WindowsDocument18 pagesBS 4873 2004 Aluminum Alloy WindowsJoseph Allan TolentinoNo ratings yet

- 39 Tractor EmulsionDocument4 pages39 Tractor EmulsionJaga NathNo ratings yet

- I. Statement of The ProblemDocument5 pagesI. Statement of The ProblemFloredelNo ratings yet

- DC 163Document2 pagesDC 163manox007No ratings yet

- Insulate Walls to Meet Building CodesDocument18 pagesInsulate Walls to Meet Building CodesAlberto LeónNo ratings yet

- Progressive Failure Analysis of Fiber-Reinforced Laminated CompositesDocument17 pagesProgressive Failure Analysis of Fiber-Reinforced Laminated Compositesjunjie yiNo ratings yet

- Asco CC T LL Coalescer Cartridges 035A CCT 22 UK 7Document2 pagesAsco CC T LL Coalescer Cartridges 035A CCT 22 UK 7Masoud AmirzadehfardNo ratings yet

- 66 DuPont MECS Alloy AcidCoolersDocument2 pages66 DuPont MECS Alloy AcidCoolersMohamed Elayachi100% (1)

- Product Catalog - YEWS Screw Chiller - EN - PUBL7578 (0315)Document7 pagesProduct Catalog - YEWS Screw Chiller - EN - PUBL7578 (0315)srmohapatra5086100% (1)

- Plasma arc cutting cost analysis and optimizationDocument5 pagesPlasma arc cutting cost analysis and optimizationLisandro GianottoNo ratings yet

- PCM70140 Primer Epoxi PPGDocument1 pagePCM70140 Primer Epoxi PPGMisaelNo ratings yet

- Melting Point Determination Experiment ResultsDocument2 pagesMelting Point Determination Experiment ResultsMaej OragaNo ratings yet

- Multi Zone Completion OptionsDocument6 pagesMulti Zone Completion OptionsTong ChaipanyakulNo ratings yet

- Instructions: BG-100 Hydro Air GunDocument2 pagesInstructions: BG-100 Hydro Air GunOscar ZavaletaNo ratings yet

- 32LC818 Lcd26v88amDocument53 pages32LC818 Lcd26v88amDaniel AvecillaNo ratings yet

- Belayab Machine Manual Last 2Document14 pagesBelayab Machine Manual Last 2abdiNo ratings yet

- Check List Roll Handling System - Tissue LineDocument17 pagesCheck List Roll Handling System - Tissue LineDinhnamsgpNo ratings yet

- Rehabilitation and Upgradation of Nipania- Bitkuli - Latuva - Baloda Bazar Road PackageDocument6 pagesRehabilitation and Upgradation of Nipania- Bitkuli - Latuva - Baloda Bazar Road PackageShrikishan Barbrik Joint Venture Pkg-07No ratings yet

- CH - Mass Transfer and Transport Phenomenon PDFDocument29 pagesCH - Mass Transfer and Transport Phenomenon PDFRaghul RockNo ratings yet

- General BrochureDocument1 pageGeneral BrochurerayscrubberNo ratings yet

- MasterPel SP 6000 - BASF July 2018 - en - NZDocument2 pagesMasterPel SP 6000 - BASF July 2018 - en - NZDan IonelNo ratings yet

- CNC Instructables PDFDocument13 pagesCNC Instructables PDFNadim AhmedNo ratings yet

- Dts-Lesson PlanDocument3 pagesDts-Lesson Plansujithaa13No ratings yet

- Chemical Engg SeminarDocument23 pagesChemical Engg SeminarAbdus Saboor KhalidNo ratings yet