Professional Documents

Culture Documents

Torkian 2003

Uploaded by

Walther Millones QuesquenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torkian 2003

Uploaded by

Walther Millones QuesquenCopyright:

Available Formats

Resources, Conservation and Recycling 40 (2003) 111

The effect of organic loading rate on the

performance of UASB reactor treating

slaughterhouse efuent

Ayoob Torkian

, A. Eqbali, S.J. Hashemian

Institute of Water and Energy, Sharif University of Technology, P.O. Box 11365-688,

Azadi Avenue, Tehran, Iran

Received 24 January 2002; accepted 24 January 2003

Abstract

Organic loading rate (OLR) is an important parameter signicantly affecting microbial ecology and

characteristics of UASB systems. In this study, UASB performance was evaluated in a 1000 1 reactor

receiving feed from a traditional medium-size slaughterhouse. The initial seed for granules formed

earlier was froma mesophilic municipal anaerobic digester sludge with a VSS content of 29 g l

1

. The

temperature of inuent was adjusted by an inline thermostat around 33

C. The reactor was started

with an OLR of 5 kg SCODm

3

d

1

with gradual increase to 10 kg SCOD m

3

d

1

over a 2-week

period. Examination of VSS data showed that on the average 89.3 11.3% of bioparticle mass was

present at the lower 30% of the reactor height. Under steady state conditions, experiments were con-

ducted at OLRs of between 13 and 39 kg SCOD m

3

d

1

and hydraulic retention times (HRT) of

27 h. Removal efciencies in the range of 7590% were achieved at feed SCOD concentrations of

30004500 mg l

1

. A reduction in removal efciency to as low as 67% could have been related to a

combined effect of high OLR and low HRT. Up to 300 l of methane were produced per kilogram of

SCOD removed at OLR values of less than 30 kg COD m

3

d

1

but methane production rate seemed

to decline to below200 at higher OLRvalues. No sign of cell washout was observed at high OLRs and

sludge loading rates (SLR) of up to 2.7 kg SCOD kg

1

VSS d

1

. Elimination capacity of the reactor

consistently increased from 9 to 25 kg SCOD m

3

d

1

corresponding to 12 kg SCOD kg

1

VSS d

1

.

Solids retention time (SRT) calculations for the reactor indicated a range of 3.3 days at high upowve-

locity of 1 mh

1

to 60.3 days at lowupowvelocity of 0.33 mh

1

s during different phases of the study.

2003 Elsevier B.V. All rights reserved.

Keywords: Upow anaerobic sludge blanket; Industrial wastewater; Slaughterhouse; Upow velocity; Anaerobic

treatment

Corresponding author. Tel.: +98-21-601-5118; fax: +98-21-601-2983.

E-mail address: torkian@sharif.edu (A. Torkian).

0921-3449/$ see front matter 2003 Elsevier B.V. All rights reserved.

doi:10.1016/S0921-3449(03)00021-1

2 A. Torkian et al. / Resources, Conservation and Recycling 40 (2003) 111

1. Introduction

The slaughterhouse industry poses a signicant environmental impact by discharging ef-

uent to receiving waters containing high concentration of biodegrad-able organic matter.

Aerobic processes are not regarded as a suitable treatment option because of high energy

requirements for aeration, limitations in liquid-phase oxygen transfer rates, and large quan-

tities of sludge production. Traditional anaerobic processes are also limited by low rates of

organic matter removal, long hydraulic retention times (HRT), accumulation of excessive

residual organic matter and intermediate products, and large reactor volume requirements.

Recent developments in anaerobic treatment processes, especially high retention of biomass

in the reactor, has made it possible to decouple solids retention time (SRT) and hydraulic

residence time in high-rate anaerobic reactors. This has resulted in increased treatment ef-

ciency of these processes and gradual but steady improvement of the common perception

that anaerobic processes are not suitable for treatment of various industrial efuents.

The upow anaerobic sludge blanket (UASB) process is one of the recently developed

high-rate systems. It has been widely adopted for treatment of medium to high-strength

industrial wastewaters (Lettinga and Hulshoff Pol, 1991; Fang et al., 1995). Recent re-

search studies indicate feasibility of this process to treat domestic efuents as well (Behling

et al., 1997; Singh and Viraraghavan, 2000). The key feature of this system is the micro-

bial aggregation into a symbiotic multilayer structure called a granule. Improved process

knowledge and operational details on formation and retainment of stable granules has made

high loading possible, resulting in a more sustainable operation of these systems.

Awide range of organic and hydraulic loading rates has been reported in the literature for

UASBreactors, depending on the substrate used and the quality and quantity of the microbial

community. Syutsubo et al. (1997) reported a COD loading of 30 kg COD m

3

d

1

with a

CODremoval efciency of 85%at sludge loading rates (SLRs) of up to 3.7 g CODg

1

VSS

d

1

for thermophilic reactors (Syutsubo et al., 1998). Organic loading rates (OLR) of up to

104 kg COD m

3

d

1

have been reported for anaerobic digestion of sugar substrate under

thermophilic conditions (Wiegant and Lettinga, 1985). According to Soto et al. (1997),

excellent stability and high treatment efciency was achieved with hydraulic residence

times as low as 2 h at an OLR of 6 kg COD m

3

d

1

, the percent COD removals being 95%

(30

C) and 92% (20

C).

Slaughterhouse wastewater contains high amounts of organic matter with a soluble frac-

tion in the range of 4060%. The suspended and colloidal components in the form of

fats, proteins, and cellulose can have an adverse impact on the performance of UASB re-

actors, leading to deterioration of the microbial activity and washout of active biomass

(Lettinga et al., 1997; Nez and Martnez, 1999). This may limit the operation to OLRs of

46 kg COD m

3

d

1

(Lettinga and Hulshoff Pol, 1991). Ruiz et al. (1997) reported sludge

oatation and increased efuent solids concentration at OLR values higher than 5 kg COD

m

3

d

1

. Others (Sayed et al., 1988; Sayed and De Zeeuw, 1988) have shown satisfactory

treatment of slaughterhouse efuent with OLR values as high as 11 kg COD m

3

d

1

at a

process temperature of 30

C; Borja and Banks (1994) reported COD removal efciencies

of 6499% at OLR values of 1217 kg COD m

3

d

1

. Higher OLR values of up to 45 kg

COD m

3

d

1

have been reported only for hybrid reactors using a combination of UASB

reactor and a bentonite packing as a biomass support (Borja et al., 1995).

A. Torkian et al. / Resources, Conservation and Recycling 40 (2003) 111 3

In this study, the effect of loading rate on UASB reactor treating slaughterhouse efuent

was investigated. This is an important parameter and only limited information is available

about the steady-state performance of UASB reactors under high OLRs. Biomass gradi-

ent along the height of reactor and methane production rate during different operational

conditions were also examined.

2. Materials and methods

2.1. Experimental setup

A 1000 l effective volume square (50 50 cm) Plexiglas pilot used in this study is

shown in Fig. 1. It was set up downstream of a medium-sized traditional slaughterhouse.

A perforated piping system was used at the bottom of the reactor to ensure homogenous

distribution of ow into the reactor. Nine sampling ports (20 and 30 cm apart at bottom

and top, respectively) were provided to quantify sludge characteristic at different elevations

along the reactor. The temperature of inuent was adjusted by an inline thermostat prior to

reactor entry. No recirculation of efuent was practiced.

2.2. Feed

The wastewater stream from a traditional slaughterhouse used in this study consisted of

efuent from a combination of several stages. It included blood from killing operations,

wash waters from stomach and intestines, and wastewater from the refrigerated chambers

Fig. 1. Schematic diagram of UASB system (1, feed tank; 2, ow control weir; 3, recycle pump; 4, inuent

distribution; 5, sampling taps; 6, water seal; 7, gas meter). See text for operational details.

4 A. Torkian et al. / Resources, Conservation and Recycling 40 (2003) 111

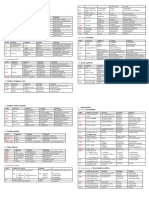

Table 1

Wastewater characteristics of UASB reactor at different periods of study

Parameter Range Average Std. Dev.

BOD

5

(mg

l1

) 9141917 1748 541

SCOD (mg l

1

) 22584956 3799 429

TCOD (mg l

1

) 326514285 6037 1092

PPO

4

3

(mg l

1

) 726 17 12

NNH

3

(mg l

1

) 35104 89 50

Temperature (

C) 2736 33.3 2.8

PH 6.87.8 7.2 0.3

Alkalinity as CaCO

3

(mg l

1

) 12081713 1351 181

VFA as acetic acid (mg l

1

) 309565 440 124

and toilets. There was no separation of efuent from these operations and because of the

inherent nature of the process, characteristics varied at different times (Table 1). Addition of

nutrients was not deemed necessary since wastewater characteristics indicated an adequate

concentration of essential proteins and trace elements. No dilution or recycling of feed was

made in the beginning or at any of the phases of the study.

2.3. Operation

The reactor contained granulated sludge formed previously in the reactor. The initial

seed was from a mesophilic municipal anaerobic digester sludge with a VSS content of

29 g l

1

. The temperature of inuent was adjusted by an inline thermostat prior to reactor

entry. Slaughterhouse efuent was pumped into a reservoir from the main slaughterhouse

sewer containing composite efuent from different units. After separating inert particles in

a cyclonic grit chamber, efuent was pumped into a container at the top and then fed by

gravity into the inuent distribution line of thereactor.

Two schemes of operation were selected. In the rst three phases of the study, feed

reservoir was lled at different times during the day to allow different concentrations to

be investigated at constant HRT. In the subsequent two phases, both OLR and HRT were

changed simultaneously by increasing inow to the reactor. Temperature was maintained

around 33

C. There was no need to externally regulate pH of the reactor since it remained

relatively constant throughout the study period.

2.4. Analytical methods

Routine analyses including soluble (ltered sample with a 0.45 m pore size glass mi-

crober lter) and total BOD

5

and COD, alkalinity, nitrogen, and phosphorus were per-

formed using procedures outlined in Standard Methods (APHA, 1985). Samples were cen-

trifuged prior to volatile fatty acid analysis using distillation method. Gas evolution was

measured by a cumulative gas ow meter located downstream of a water trap and analyzed

by Schimadzu (5A with molecular sieve and carbon active columns and FID and ECP de-

tectors) gas chromatograph. Most of the parameters were monitored daily during the start

up phase and every other day during the normal operations.

A. Torkian et al. / Resources, Conservation and Recycling 40 (2003) 111 5

2.5. Experimental design

The experimental protocol was designed to examine the effect of different OLRs on the

operational (e.g. efciency of COD removal) and performance (e.g. volumetric and micro-

bial elimination capacity as dened in the next section below) indicators. All experiments

were performed under steady state conditions. The attainment of the steady state was veried

by checking whether the mean of the efuent characteristics for the last two measurements

done within 5HRT were remaining relatively constant. All the performance and operation

results reported are the average values of at least two measurement data.

2.6. Operational and performance parameters

Operational and performance parameters include OLR, SLR, elimination capacity, and

detention time. Loading rates can be looked at from the pollution indicator, empty reactor

bed volume, and microbial mass. OLR takes into account the liquid ow rate and contam-

inant concentration and is dened as the mass of pollutant introduced in a unit volume of

UASB reactor per unit time (e.g. kg COD m

3

s

1

). As such, this parameter integrates

reactor characteristics, operational characteristics, and bacterial mass and activity into the

volume of media. SLRor food to microorganismratio (F/M) integrates contaminant concen-

tration and microbial mass and is the mass of pollutant applied to a unit mass of microbial

mass per unit time (e.g. kg COD kg

1

VSS d

1

).

Elimination capacity is related to OLR and SLR in that it is dened as the fraction of the

organic load biodegraded in a unit volume of the UASB reactor or a unit mass of microbial

mass. This parameter can be expressed either volumetrically (EC

V

, kg pollutant removed

per unit volume of reactor per day) or on the basis of microbial mass (EC

m

, kg pollutant

removed per unit mass of microorganisms in the reactor per day).

Methanogenic activity (MA) can be expressed on the basis of pollutant (liter biogas

produced per unit mass of pollutant removed, MA

scod

) or on the basis of microbial mass

(liter biogas produced per unit mass of microbial population, MA

vss

).

Mass loading rate (kg m

3

d

1

), SLR (kg kg

1

d

1

), and elimination capacity

(kg m

3

d

1

or kg kg

1

VSS d

1

) were determined using the relationships between in-

uent and efuent contaminant concentration, efuent ow rate, the effective volume of

UASB reactor, and applying appropriate conversion factors as follows:

OLR =

Q

V

r

C

in

(1)

SLR = Q

C

in

VSS

(2)

EC

V

=

Q

V

r

(C

in

C

out

) (3)

EC

m

=

EC

V

VSS

(4)

6 A. Torkian et al. / Resources, Conservation and Recycling 40 (2003) 111

MA

scod

=

V

CH

4

Q(C

in

C

out

)

(5)

MS

VSS

=

V

CH

4

Q(VSS)

(6)

where Qis the efuent owrate (m

3

h

1

); V

r

, the effective volume of reactor bed (m

3

); VSS,

the microbial concentration of the reactor (mg VSS l

1

), V

CH

4

, the volume of biogas pro-

duced per day (l d

1

); and C

in

and C

out

are the contaminant concentrations (mg SCODl

1

)

in the inuent and efuent stream, respectively.

3. Results and discussion

3.1. Startup

The startup of the reactor was rapid because the system had been adapted to the slaugh-

terhouse efuent previously. The reactor was started with an OLR of 5 kg SCOD m

3

d

1

to keep the initial loading rate below approximately 50% of the intended loading after the

start-up period (Lettinga et al., 1997). The loading rate was gradually increased over a

2-week period to 10 kg SCOD m

3

d

1

.

3.2. Steady state performance

The total and soluble COD of the feed and of the efuent during the operation period,

and the results for different organic and hydraulic loading rates along with performance

indicators are presented in Table 2.

3.2.1. Removal efciency

The performance of UASB reactor based on soluble COD removals at various upow

velocities and OLRs is shown in Fig. 2. At the initial three phases of the study, V

up

was maintained relatively constant at 0.330.35 mh

1

while OLR was increased from

around 10 to 18 kg SCOD m

3

d

1

. As illustrated in the gure, SCOD removal efcien-

cies showed an increasing trend from a low 62% to a maximum of 92%. At the begin-

ning of each phase where OLR was increased, there was a corresponding decrease in re-

moval efciency but the system recovered shortly and adapted to the new conditions with

time.

At the beginning of phase 4 of the study, OLR was increased to 27 kg SCOD m

3

d

1

.

Upowvelocity was also increased to 0.57 mh

1

to further promote the selective process in

the cultivation of more active biomass (Campos and Anderson, 1992). The system behavior

was similar to earlier stages in that a transient decrease in performance was observed but

the system performance reached the same conditions existing before the change. The 50%

increase in OLRand 80%increase in V

up

did not seemto have any adverse effect on organics

removal and SCOD removal efciency reached 93%.

In the next phase of study, OLR was increased another 30% to above 40 kg SCOD

m

3

d

1

and V

up

to 1 mh

1

. Removal efciency was drastically decreased to below 70%

A. Torkian et al. / Resources, Conservation and Recycling 40 (2003) 111 7

Table 2

Summary of the conditions during the operation period of the UASB reactor

Variable Unit Phase of study

1 2 3 4 5

Time day 138 3964 6591 92112 113136

Upow velocity, V

up

Mh

1

0.33 0.34 0.35 0.57 1.0

Hydraulic res-

idence time,

HRT

H 7.1 6.8 6.7 4.1 2.3

SRT day 60.3 23.4 14.0 14.4 3.3

SCOD in Mg l

1

3143 661 3695 662 4153 364 4288 564 3290 722

TCOD in Mg l

1

8201 3937 5719 1280 5256 589 5495 622 5514 1469

TSS Gl

1

11.6 2.2 10.9 6.8 11.6 1.3 12.8 1 18.3 1.2

VSS g l

1

10.2 1.9 9.9 6.7 10.5 1 11.9 1.2 14.9 0.9

VSS out g l

1

0.09 0.09 0.16 0.13 0.36 0.20 0.24 0.14 0.59 0.36

SCOD removal % 76 9 75 12 85 6 85 8 68 8

TCOD removal % 78 14 73 11 77 15 83 7 68 10

OLR kg SCOD m

3

d

1

13 2.9 16.7 3.3 17.4 1.1 27.4 4.8 39.5 9

SLR kg SCOD kg

1

VSS d

1

1.3 0.2 1.7 0.3 1.7 0.1 2.4 0.3 2.7 0.6

Elimination ca-

pacity, EC

v

kg SCOD m

3

d

1

9.5 1.8 12.6 3.6 15 1.7 25 4.8 27 6.9

Elimination ca-

pacity, EC

M

kg SCOD kg

1

VSS d

1

1.0 0.2 1.3 0.4 1.4 0.2 2.1 0.4 1.8 0.5

Methanogenic

activity,

MA

vss

l kg

1

VSS 222 32 347 66 458 54 464 58 395 68

Methanogenic

activity,

MA

scod

l kg

1

SCOD 213 21 254 54 283 23 201 38 199 36

and there was no indication that a recovery was to ensue. As a result, OLR was decreased

to try a more gradual increasing trend but V

up

was maintained around 1 mh

1

. Variation of

OLR in the 3040 kg SCOD m

3

d

1

did not improve SCOD removal efciencies from the

65 to 68% range. As such, OLR value of about 30 kg SCOD m

3

d

1

was regarded as the

upper limit for satisfactory performance for this type of wastewater under the conditions

of this study. Considering the fact that HRT at this phase was low at 2.3 h, the decrease

in performance could have also been attributed to insufcient time available for substrate

transfer from the liquid to biomass.

The results obtained in this study showed better performance when compared with the

values of 92% SCOD removal at 5.2 kg SCOD m

3

d

1

and HRT of 1.2 day (Ruiz et al.,

1997) and 93.4% COD removal at 20.8 kg SCOD m

3

d

1

and HRT of 0.5 days for this

type of wastewater under similar operating conditions and 87% SCOD removal at 30 and

HRT of 7.2 h for alcohol distillery wastewater under thermophilic conditions (Syutsubo

et al., 1997). This could have been due to a combination of factors including lack of blood

separation in the slaughterhouse operations, high solids content, and long adaptation of

granules to the slaughter-house efuent prior to this study.

8 A. Torkian et al. / Resources, Conservation and Recycling 40 (2003) 111

Fig. 2. Variation of SCOD removal efciencies (%) at different OLRs (kg SCOD m

3

d

1

) and upow

velocities (mh

1

).

3.2.2. Sludge loading rate

Fig. 3 illustrates performance of the reactor at different SLRs. As shown in the gure, the

SLR practiced in this study ranging from 1 to above 2.5. This was in line with the recom-

mended range of 0.11 kg COD kg

1

VSS d

1

for anaerobic processes (Ndon and Dague,

1997). Another important aspect of the performance is to prevent anaerobic microorgan-

ism washout and to provide a margin of safety under transient inhibitory conditions in the

reactor. This is assured by maintaining a minimum value of biological SRT even at low

hydraulic residence times. SRT calculations for the reactor indicated a range of 3.3 days at

high upow velocity of 1 mh

1

to 60.3 days at low upow velocity of 0.33 mh

1

s during

different phases of the study. This was within the recommended range of 410 days to

prevent washout of hydrolytic anaerobic bacteria (Eastman and Feguson, 1981) for cases

where hydrolysis of insoluble organic matter is the rate-limiting step (Parkin and Owen,

1986) and 2.55 days for soluble wastewaters containing acetate as the primary organic

(Stronach et al., 1986) constituent.

3.2.3. Methane production

Fig. 4 illustrates MA based on microbial capacity and SCOD conversion. The gure

shows more uctuation of methane produced on the basis of unit SCOD removed than unit

VSS mass. This may be due to seasonal variability of biological degradability of efuent

and potential presence of various organic and inorganic materials inhibiting treatment per-

formance (Kroeker, 1979). Table 1 shows a steady increase in methane production capacity

up to an OLR of 27 kg SCOD m

3

d

1

. As OLR was increased, MA

vss

(at 25

C and 1 atm)

increased to a maximum of 283 l kg

1

VSS at organic load of 17.4 kg SCOD m

3

d

1

.

From there on, incremental increase in MA

vss

declined and eventually decreases to 199 l

CH

4

kg

1

VSS d

1

at an OLR value of 39.5 kg SCOD m

3

d

1

corresponding to SLR

A. Torkian et al. / Resources, Conservation and Recycling 40 (2003) 111 9

Fig. 3. SLRs (kg COD kg

1

VSSd

1

) applied and microbial elimination capacities (kg SCODkg

1

VSS d

1

) at

different HRTs (days).

of 2.7 kg SCOD kg

1

VSS d

1

. This apparent instability was manifested in Fig. 4 by the

widening and erratic behavior of MA

vss

and MA

scod

curves at high organic loads.

Attachment of gas bubbles is a usual problem of ordinary UASB systems at high OLR

values leading to biomass suspension and cell washout as methane production rate increases.

Even though the system experienced a lower efciency at high OLR values, there was no

drastic increase in efuent VSS. The maximum efuent solids concentration of 590 mg

VSS l

1

observed at the highest OLR studied, was around 3.3% of the reactor biomass

concentration. The fact that no special gas separation system was used in the enlarged

Fig. 4. Methane production per unit mass of biomass (l CH

4

kg

1

VSSd

1

) and SCOD removal

(l CH

4

kg

1

SCOD) throughout the study period.

10 A. Torkian et al. / Resources, Conservation and Recycling 40 (2003) 111

Fig. 5. Prole of solids content along the reactor height.

settling zone suggested good granule stability and characteristics. This was in conformity

with the data on the prole of sludge behavior along the reactor height during the study.

3.2.4. Sludge gradient along the reactor height

As illustrated in Fig. 5, a distinct stratication of solids was maintained through the

experimental period with larger solids (granules) settling down to lower part of the reaction

zone and smaller ones in the upper part. Solids concentration at sampling ports 1 and 2

had a range of 4151 and 3252 mg l

1

, respectively. Examination of VSS data showed

that on the average 89.3 11.3% of bioparticle mass was present at the lower 30% of the

reactor height (sampling ports 13) and the remaining aggregates were suspended due to

the mixing by owing liquor and rising gas bubbles. Reports in the literature indicate that

cell washout is attributed exclusively to sludge blanket erosion (De Zeeuw, 1987) that is

selective for well-aggregated granules. The combined effect of high substrate load and good

granule characteristics along with the physical selection brought about by high OLR and

upow velocity played a positive role in maintaining stable and efcient solids in thelower

part of the reactor.

4. Conclusions

The results of this study showed slaughterhouse wastewater can be satisfactorily treated

by means of high-rate anaerobic processes, specically with the use of USAB reactor. High

SCODremovals of between 75 and 90%at OLRs of 1330 kg CODm

3

d

1

were achieved

in this study. Indication of erratic behavior was observed at organic loads higher than 30 kg

CODm

3

d

1

. There was no sludge washout even at OLRvalues above 30 kg CODm

3

d

1

at HRT values as low as 2.3 h. Methane yields of 200280 l CH

4

kg

1

SCOD

removed

were

in the same order of magnitude as the rates achieved in earlier studies.

A. Torkian et al. / Resources, Conservation and Recycling 40 (2003) 111 11

References

APHA. Standard Methods for the Examination of Water and Wastewater, 16th ed. Washington, DC: American

Public Health Association.

Behling E, Diaz A, Colina G, Herrera M, Gutierrez E, Chacin E, Fernandez N, Forster CF. Domestic wastewater

treatment using a UASB reactor. Bioresour Technol 1997;61(3):23945.

Borja R, Banks CJ. Performance and kinetics of an upow anaerobic sludge blanket (UASB) reactor treating

slaughterhouse wastewater. J Environ Sci Health 1994;A29:206385.

Borja R, Banks CJ, Wang Z. Performance of a hybrid anaerobic reactor, combining a sludge blanket and a lter,

treating slaughterhouse wastewater. Appl Microbiol Biotechnol 1995;43:3517.

Campos CMM, Anderson GK. Effect of liquid upow velocity and the substrate concentration on the start-up and

steady-state periods of lab-scale UASB reactors. Water Sci Technol 1992;25(7):4150.

De Zeeuw WJ. Granular sludge in UASB reactors. In: Lettinga G, Zehnder AJB, Grotenhuis TC, Hulshoff Pol

LW, editors. Proceedings of the GASMAT-Workshop, Granular Anaerobic Sludge: Microbiology and Tech-

nology. Wageningen, Netherlands: Pudoc, 1987:13245.

Eastman JA, Feguson JF. Solubilization of particulate organic carbon during the acid phase of anaerobic digestion.

J Water Pollut Control Fed 1981;53(3):35266.

Fang HHP, Li YY, Chui HK. UASB treatment of wastewater with concentrated mixed VFA. ASCE J Environ Eng

1995;121(2):15360.

Kroeker EJ. Anaerobic treatment process stability. J Water Pollut Control Fed 1979;51:71821.

Lettinga G, Hulshoff Pol LW. UASB-process design for various types of wastewaters. Water Sci Technol

1991;24(8):87107.

Lettinga G, Field J, van Lier J, Zeeman G, Hulshoff Pol LW. Advanced anaerobic wastewater treatment in the

near future. Wat Sci Technol 1997;35(10):512.

Ndon UJ, Dague RR. Effects of temperature and hydraulic retention time on anaerobic SBR treatment of

low-strength wastewater. Water Res 1997;31(10):245566.

Nez LA, Martnez B. Anaerobic treatment of slaughterhouse wastewater in an expanded granular sludge bed

(EGSB) reactor. Water Sci Technol 1999;40(8):99106.

Parkin GF, Owen WF. Fundamentals of anaerobic digestion of wastewater sludges. J Environ Eng Div Am Soc

Civil Eng 1986;112:867920.

Ruiz I, Veiga MC, de Santiago P, Blzquez R. Treatment of slaughterhouse wastewater in a UASB reactor and an

anaerobic lter. Bioresour Technol 1997;60:2518.

Sayed S, De Zeeuw W. The performance of a continuously operated occulent sludge UASB reactor with slaugh-

terhouse wastewater. Biol Wastes 1988;24:199212.

Sayed S, Van Campen L, Lettinga G. Anaerobic treatment of slaughterhouse waste using a granular sludge UASB

reactor. Biol Wastes 1988;21:1128.

Singh KS, Viraraghavan T. Performance of UASB reactor at 6 to 32

C in municipal wastewater treatment. Water

Quality Res J Can 2000;35(1):11324.

Soto M, Ligero P, Vega A, Ruiz I, Veiga MC, Blazquez R. Sludge granulation in UASB digesters treat-

ing low strength wastewaters at mesophilic and psychrophilic temperatures. Environ Technol 1997;18(11):

113341.

Stronach SM, Rudd T, Lester JN. Anaerobic Digestion Processes in Industrial Wastewater Treatment, Berlin:

Springer, 1986.

Syutsubo K, Harada H, Ohashi A, Suzuki H. Effective start-up of thermophilic UASB reactor by seeding

mesophilically-grown granular sludge. Water Sci Technol 1997;36(67):3918.

Syutsubo K, Harada H, Ohashi A. Granulation and sludge retainement during start-up of a thermophilic-UASB

reactor. Water Sci Technol 1998;38(89 part):34957.

Wiegant WM, Lettinga G. Thermophilic anaerobic digestion of sugars in an upow anaerobic sludge blanket

reactors. Biotechnol Bioeng 1985;27:16037.

You might also like

- Hawking-Brief History of TimeDocument336 pagesHawking-Brief History of TimeAlbert Kristian0% (1)

- Gabion Retaining Wall Design GuideDocument30 pagesGabion Retaining Wall Design GuideThomas Hill80% (5)

- The Global Carbon Cycle and Climate Change: Scaling Ecological Energetics from Organism to the BiosphereFrom EverandThe Global Carbon Cycle and Climate Change: Scaling Ecological Energetics from Organism to the BiosphereNo ratings yet

- The Order of Historical Time: The Longue Durée and Micro-HistoryDocument17 pagesThe Order of Historical Time: The Longue Durée and Micro-HistoryGeorgia KoutaNo ratings yet

- Effect of Aeration and Agitation Rates and Scale-Up On Oxygen Transfer Coefficient, Kla in Exopolysaccharide Production From Enterobacter Cloacae WD7Document13 pagesEffect of Aeration and Agitation Rates and Scale-Up On Oxygen Transfer Coefficient, Kla in Exopolysaccharide Production From Enterobacter Cloacae WD7Alen AgicNo ratings yet

- Feasibility Study On Petrochemical Wastewater Treatment and Reuse Using Submerged MBRDocument6 pagesFeasibility Study On Petrochemical Wastewater Treatment and Reuse Using Submerged MBRhesammorNo ratings yet

- Verify scope acceptance of project deliverablesDocument5 pagesVerify scope acceptance of project deliverablesmypmpbooksNo ratings yet

- 000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Document22 pages000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Raul Bautista100% (1)

- Anaerobic Pre-Treatment of Slaughterhouse Wastewater UsingDocument7 pagesAnaerobic Pre-Treatment of Slaughterhouse Wastewater UsingPablo PiacentiniNo ratings yet

- 101007Document9 pages101007vk100No ratings yet

- Uasb, MBBR Domestic WastewaterDocument10 pagesUasb, MBBR Domestic WastewaterIbarra ChavezNo ratings yet

- Jang Etal 2003Document12 pagesJang Etal 2003catalinaNo ratings yet

- National Science Fellowship Seminar Yields Insights into Anaerobic Wastewater TreatmentDocument6 pagesNational Science Fellowship Seminar Yields Insights into Anaerobic Wastewater TreatmentnycoNo ratings yet

- Treatment of Slaughterhouse Plant Wastewater by Using A Membrane BioreactorDocument6 pagesTreatment of Slaughterhouse Plant Wastewater by Using A Membrane BioreactornvtrungvnNo ratings yet

- Acidification Brewery For UASBDocument11 pagesAcidification Brewery For UASBashokNo ratings yet

- Archive of SID: Optimization Studies in An Inverse Fluidized Bed Bioreactor For Starch Wastewater TreatmentDocument6 pagesArchive of SID: Optimization Studies in An Inverse Fluidized Bed Bioreactor For Starch Wastewater TreatmentMonali ChhatbarNo ratings yet

- Modified UCT Chemo SphereDocument7 pagesModified UCT Chemo SpherevaiopoulouNo ratings yet

- Nadeem Sir1Document6 pagesNadeem Sir1baquir_aligNo ratings yet

- Sewage Treatment in A Rotating Biological Contactor (RBC) SystemDocument16 pagesSewage Treatment in A Rotating Biological Contactor (RBC) SystemBelen CRNo ratings yet

- RBC in Doua TrepteDocument15 pagesRBC in Doua TrepteRoxana AvramNo ratings yet

- Rbc in Doua TrepteDocument15 pagesRbc in Doua TrepteApex LoftNo ratings yet

- Swine Effluent Treatment Using Anaerobic Digestion at Different Loading RatesDocument10 pagesSwine Effluent Treatment Using Anaerobic Digestion at Different Loading RatesSarah SucupiraNo ratings yet

- The Impact of Temperature On Nitrification Rate in Fixed Film BiofiltersDocument11 pagesThe Impact of Temperature On Nitrification Rate in Fixed Film BiofiltersMuhammed TanveerNo ratings yet

- Application of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant ProfessorDocument9 pagesApplication of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant Professorvk100No ratings yet

- ESPARZA - 2011 - Anaerobic Treatment of A Medium Strength IndustrialDocument8 pagesESPARZA - 2011 - Anaerobic Treatment of A Medium Strength IndustrialThobiasNo ratings yet

- Combination of Physico-Chemical Treatment and Nanofiltration To Reuse Wastewater of A Printing, Dyeing and Finishing Textile IndustryDocument8 pagesCombination of Physico-Chemical Treatment and Nanofiltration To Reuse Wastewater of A Printing, Dyeing and Finishing Textile IndustryChittaranjan SahooNo ratings yet

- Design criteria for UASB reactors treating tropical wastewaterDocument8 pagesDesign criteria for UASB reactors treating tropical wastewaterAbeer El ShahawyNo ratings yet

- Anaerobic Digestion of Sewage Sludge in An Anaerobic Fixed Bed DigesterDocument3 pagesAnaerobic Digestion of Sewage Sludge in An Anaerobic Fixed Bed DigesterNurul RazakNo ratings yet

- Pilot-Scale Experiment On Anaerobic Bioreactor Landfills in ChinaDocument9 pagesPilot-Scale Experiment On Anaerobic Bioreactor Landfills in Chinashelbylevine1No ratings yet

- Microbial EEA Affects Performance in A Full-Scale Modified ASPDocument8 pagesMicrobial EEA Affects Performance in A Full-Scale Modified ASPCelina SanchezNo ratings yet

- Chapter-1: 1.1 GeneralDocument33 pagesChapter-1: 1.1 GeneralAbhinay SinghNo ratings yet

- Uasb Reactor Startup For The Treatment of Municipal Wastewater Followed by Advanced Oxidation ProcessDocument12 pagesUasb Reactor Startup For The Treatment of Municipal Wastewater Followed by Advanced Oxidation ProcessCarolinaQuimbayaNo ratings yet

- Articulo Sbr Industria PapeleraDocument7 pagesArticulo Sbr Industria Papeleraandres felipe ochoa acostaNo ratings yet

- Reactor Performance and Microbial Community Dynamics During Anaerobic Biological Treatment of Wastewaters at 16-37 °CDocument10 pagesReactor Performance and Microbial Community Dynamics During Anaerobic Biological Treatment of Wastewaters at 16-37 °CDeisy Yaritza Briceño PerezNo ratings yet

- Nutrient recovery and organics removal in biofilm reactorDocument6 pagesNutrient recovery and organics removal in biofilm reactorJasmin Rose GonzalesNo ratings yet

- Comparison Between Wet and Dry Anaerobic Digestions of Cow Dung Under Mesophilic and Thermophilic ConditionsDocument11 pagesComparison Between Wet and Dry Anaerobic Digestions of Cow Dung Under Mesophilic and Thermophilic ConditionsFábio Macêdo NunesNo ratings yet

- Water 11 00806Document18 pagesWater 11 00806sanchayNo ratings yet

- Modelling of An Upflow Anaerobic Sludge Blanket Reactor: R. Rodriguez & L. MorenoDocument10 pagesModelling of An Upflow Anaerobic Sludge Blanket Reactor: R. Rodriguez & L. MorenoJhoana FalconNo ratings yet

- UASBDocument9 pagesUASBAlex BarataNo ratings yet

- Methodology For Determination of Anaerobic Digestion Kinetics Using A Bench Top DigesterDocument12 pagesMethodology For Determination of Anaerobic Digestion Kinetics Using A Bench Top DigesterJorge Froilan GonzalezNo ratings yet

- The Thermophilic Anaerobic Digestion ProcessDocument15 pagesThe Thermophilic Anaerobic Digestion ProcessoccbuziNo ratings yet

- Zero excess sludge production with ozonationDocument6 pagesZero excess sludge production with ozonationNaveed UR RehmanNo ratings yet

- ppmp44 13-22 PDFDocument10 pagesppmp44 13-22 PDFJCHNo ratings yet

- Anaerobic hybrid reactor withstands hydraulic load fluctuationsDocument7 pagesAnaerobic hybrid reactor withstands hydraulic load fluctuationsEloá PelegrinoNo ratings yet

- GS CONTINUOS Devlin2018Document33 pagesGS CONTINUOS Devlin2018Oscar FranchiniNo ratings yet

- Population Changes of Eubacteria, Sulfate-Reducing Bacteria and Methanogenic Archaea in An Anaerobic Reactor Processing Ethanol Distillery VinasseDocument13 pagesPopulation Changes of Eubacteria, Sulfate-Reducing Bacteria and Methanogenic Archaea in An Anaerobic Reactor Processing Ethanol Distillery VinasseyutefupNo ratings yet

- Bio Degradation of Distillery Spent WashDocument20 pagesBio Degradation of Distillery Spent Wash9219561870No ratings yet

- Null DikonversiDocument17 pagesNull DikonversiBayu PratamaNo ratings yet

- Evaluation of Biological Removal Efficiency in A UCT Process Treating Municipal Wastewater During Start-Up StageDocument6 pagesEvaluation of Biological Removal Efficiency in A UCT Process Treating Municipal Wastewater During Start-Up StageRose AdelineNo ratings yet

- Ajas14348 353Document6 pagesAjas14348 353srinjoyNo ratings yet

- Aerobic GranulationDocument28 pagesAerobic GranulationAdhyyan SinghNo ratings yet

- Wolf 2016Document15 pagesWolf 2016Larissa Risky AmaliaNo ratings yet

- Ethanol Plant Research2Document5 pagesEthanol Plant Research2Tosin AwonusiNo ratings yet

- Ijaret: ©iaemeDocument11 pagesIjaret: ©iaemeIAEME PublicationNo ratings yet

- UASB Reactor For Domestic Wastewater Treatment at Low Temperatures: A Comparison Between A Classical UASB and Hybrid UASB-filter ReactorDocument7 pagesUASB Reactor For Domestic Wastewater Treatment at Low Temperatures: A Comparison Between A Classical UASB and Hybrid UASB-filter Reactorsandipkulkarni27No ratings yet

- UASB reactor performance at different sludge levelsDocument7 pagesUASB reactor performance at different sludge levelskiranNo ratings yet

- WORLD'S LARGEST RETRIEVABLE FINE BUBBLE AERATION SYSTEMDocument15 pagesWORLD'S LARGEST RETRIEVABLE FINE BUBBLE AERATION SYSTEMLye YpNo ratings yet

- 1 s2.0 S0925857408002711 Main PDFDocument10 pages1 s2.0 S0925857408002711 Main PDFMaliha CheemaNo ratings yet

- Comparative Study On Start - Up Performance of HUASB and AF Reactors Treating Poultry Slaughterhouse WastewaterDocument10 pagesComparative Study On Start - Up Performance of HUASB and AF Reactors Treating Poultry Slaughterhouse WastewaterIndrawNo ratings yet

- Bioresource Technology: Baoning Zhu, Petros Gikas, Ruihong Zhang, James Lord, Bryan Jenkins, Xiujin LiDocument8 pagesBioresource Technology: Baoning Zhu, Petros Gikas, Ruihong Zhang, James Lord, Bryan Jenkins, Xiujin LiArif HidayatNo ratings yet

- An_integrated_pilot_scale_UASB_and_aerotank_systemDocument23 pagesAn_integrated_pilot_scale_UASB_and_aerotank_systemnguyencaocuong.090796No ratings yet

- Ijerph 17 00283Document19 pagesIjerph 17 00283IlhamSutamiNo ratings yet

- Anaerobic Treatment of Wastewater From Sugar Cane IndustryDocument12 pagesAnaerobic Treatment of Wastewater From Sugar Cane IndustryVaishnavi SrivastavaNo ratings yet

- Biohydrogen III: Renewable Energy System by Biological Solar Energy ConversionFrom EverandBiohydrogen III: Renewable Energy System by Biological Solar Energy ConversionNo ratings yet

- 51-3-368 7Document2 pages51-3-368 7Walther Millones QuesquenNo ratings yet

- Aguilar Madrid2015 ... 4Document10 pagesAguilar Madrid2015 ... 4Walther Millones QuesquenNo ratings yet

- Aguilar Madrid2015 ... 4Document10 pagesAguilar Madrid2015 ... 4Walther Millones QuesquenNo ratings yet

- Aguilar Madrid2015 ... 4Document10 pagesAguilar Madrid2015 ... 4Walther Millones QuesquenNo ratings yet

- 338040Document32 pages338040Walther Millones QuesquenNo ratings yet

- Fuerza Cortante y de MomentoDocument2 pagesFuerza Cortante y de MomentoWalther Millones QuesquenNo ratings yet

- Self Report QuestionnaireDocument6 pagesSelf Report QuestionnaireMustafa AL ShlashNo ratings yet

- Bab 8Document29 pagesBab 8Nurul AmirahNo ratings yet

- Simultaneous EquationsDocument11 pagesSimultaneous EquationsSaleena AurangzaibNo ratings yet

- Python Programming Lecture#2 - Functions, Lists, Packages & Formatting I/ODocument69 pagesPython Programming Lecture#2 - Functions, Lists, Packages & Formatting I/OHamsa VeniNo ratings yet

- Epoxy Hardeners, Water-Reducible: ProductsDocument1 pageEpoxy Hardeners, Water-Reducible: ProductsDhruv SevakNo ratings yet

- Pragathi Full Test-6, Paper-2 (Qp+Key) - 18.07.22Document14 pagesPragathi Full Test-6, Paper-2 (Qp+Key) - 18.07.22Ganesan MuthukrishnanNo ratings yet

- SBM Level of Practice Validation FormDocument43 pagesSBM Level of Practice Validation Formelvira pilloNo ratings yet

- Practice Workbook LR Method For Addition Subtraction PDFDocument4 pagesPractice Workbook LR Method For Addition Subtraction PDFEsa KhanNo ratings yet

- Instrumentation Design UTHMDocument5 pagesInstrumentation Design UTHMAnis AzwaNo ratings yet

- 13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilDocument9 pages13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilJenifer TejadaNo ratings yet

- L02-EIP Module User ManualDocument37 pagesL02-EIP Module User ManualSergio Mauricio Acuña BravoNo ratings yet

- NewsDocument26 pagesNewsMaria Jose Soliz OportoNo ratings yet

- Unit-3 BioinformaticsDocument15 pagesUnit-3 Bioinformaticsp vmuraliNo ratings yet

- GAS-INSULATED SWITCHGEAR MODELS 72kV ADVANCED ENVIRONMENTALLY FRIENDLYDocument6 pagesGAS-INSULATED SWITCHGEAR MODELS 72kV ADVANCED ENVIRONMENTALLY FRIENDLYBudi SantonyNo ratings yet

- Cantors Paradox PDFDocument16 pagesCantors Paradox PDFColectivo Utopía MoreliaNo ratings yet

- ASP Flashcards - QuizletDocument36 pagesASP Flashcards - QuizletRehman MuzaffarNo ratings yet

- LyonDCCT Technology ReviewDocument4 pagesLyonDCCT Technology Reviewrajagopal gNo ratings yet

- Bash 101 Hacks PDFDocument5 pagesBash 101 Hacks PDFAmira A MarreiNo ratings yet

- Tech Note 14Document2 pagesTech Note 14meteohrNo ratings yet

- Introducing WESAD, A Multimodal Dataset For Wearable Stress and Affect DetectionDocument9 pagesIntroducing WESAD, A Multimodal Dataset For Wearable Stress and Affect DetectionJhónatan CarranzaNo ratings yet

- Notes Measures of Variation Range and Interquartile RangeDocument11 pagesNotes Measures of Variation Range and Interquartile RangedburrisNo ratings yet

- Reference Mil-Aero Guide ConnectorDocument80 pagesReference Mil-Aero Guide ConnectorjamesclhNo ratings yet

- Affixation (Landscape)Document4 pagesAffixation (Landscape)difafalahudinNo ratings yet

- Sem 2Document128 pagesSem 2Agustin A.No ratings yet

- Seksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDocument1 pageSeksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDukagjin Ramqaj100% (1)