Professional Documents

Culture Documents

Flexural Modulus of Elasticity of Dimension Stone: Standard Test Method For

Uploaded by

Rufo CascoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flexural Modulus of Elasticity of Dimension Stone: Standard Test Method For

Uploaded by

Rufo CascoCopyright:

Available Formats

Designation: C 1352 96 (Reapproved 2002)

Standard Test Method for

Flexural Modulus of Elasticity of Dimension Stone

1

This standard is issued under the xed designation C 1352; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the procedure for determining

the exural modulus of elasticity of stone by using a simple

beam with quarter-point loading.

1.2 Stone tests may be made with load applied perpendicu-

lar to the bedding plane or rift and with load applied parallel to

the bedding plane or rift.

1.3 Stone tests may be made for wet and dry specimen

conditions.

1.4 The specier of the test shall determine which condi-

tions shall be used.

1.5 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

only.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 119 Terminology Relating to Dimension Stone

2

C 880 Test Method for Flexural Strength of Dimension

Stone

2

E 4 Practices for Force Verication of Testing Machines

3

3. Terminology

3.1 DenitionFor denitions of terms used in this test

method, refer to Terminology C 119.

3.2 Denitions of Terms Specic to This Standard:

3.2.1 modulus of elasticity, nstress per unit strain, also

known as Youngs Modulus.

4. Signicance and Use

4.1 This test method is useful for providing engineering

values for stress and deection analysis of stone panels. It is

also useful in indicating the differences in exural modulus of

elasticity between various dimension stones and stones of the

same type in different loading directions (parallel and perpen-

dicular to rift or bedding planes).

5. Apparatus

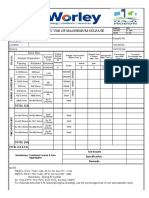

5.1 Testing Machine (see Fig. 1), conforming to the require-

ments of the applicable sections of Practices E 4. The quarter-

point loading method shall be used in making exure tests of

stone employing bearing blocks that will ensure that forces

applied to the beam will be vertical only and applied without

eccentricity. The apparatus should be capable of maintaining

the span length and distances between load-applying blocks

and support blocks constant within 61.3 mm (60.05 in.). The

load should be capable of being applied at a uniform rate and

in such a manner as to avoid shock.

5.2 Deection Gages, capable of reading to 0.002 mm

(0.0001 in.) shall be used to measure mid-span deections at

the two free edges and support deections at each end.

6. Test Specimens

6.1 The test specimens shall measure 100 mm (4 in.) wide

by 32 mm (1.25 in.) thick by 380 mm (15 in.) long with a span

as tested of 320 mm (12.5 in.). The sides of the specimens shall

be at right angles with the top and bottom. The specimens shall

have a ne abrasive nish on the planes perpendicular to the

load and a ne saw nish on the other four planes. The

dimensions of the specimen shall be measured and recorded to

the nearest 0.2 mm (0.01 in.). A minimum of ve specimens

shall be tested for each condition of test. The average value

calculated from plots of the test results is reported as the

exural modulus of elasticity for that condition.

6.2 Where the job thickness has been set (the thickness of

the stone panels for the project has been established), it is often

requested to perform exural modulus of elasticity tests at the

job thickness. The following shall govern the specimen size

where it is requested to test at the job thickness, and the job

thickness is other than 32 mm (1.25 in.). The span as tested

shall be ten times the thickness. The specimen lengths shall be

not less than 50 mm (2 in.) and not more than 100 mm (4 in.)

greater than the span as tested. Where the thickness is less than

70 mm (2.67 in.), the width of the specimen shall be 100 mm

(4 in.). Where the thickness is greater than 70 mm (2.67 in.) the

1

This test method is under the jurisdiction of ASTM Committee C-18 on

Dimension Stone and is the direct responsibility of Subcommittee C18.01 on Test

Methods.

Current edition approved Sept. 10, 1996. Published November 1996.

2

Annual Book of ASTM Standards, Vol 04.07.

3

Annual Book of ASTM Standards, Vol 03.01.

1

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

width shall be 1.5 times the thickness. Where the thickness is

other than 32 mm (1.25 in.) and the specimen size is in

accordance with the job thickness criteria noted in the forego-

ing, the average value of the test results for each condition shall

be reported as the exural modulus of elasticity of the stone at

the job thickness for that condition. All other requirements

shall be in accordance with 6.1.

6.3 Where the job surface nish has been set (the architec-

tural nish on the panels for the project has been established),

it is often requested to perform exural modulus of elasticity

tests on specimens with the nish the same as on the job. The

following shall govern when it is requested to test at the job

surface nish. The specimens shall have a nish on one plane

perpendicular to the load in accordance with the nish speci-

ed for the job. Unless there are data to the contrary, the

positioning of the specimen shall be with the nished face in

exural tension. The average value of the test results for each

condition shall be reported as the exural modulus of elasticity

of the stone at the job surface nish for that condition. All other

requirements shall be in accordance with 6.1 and 6.2.

6.4 Where the specimens conform to the requirements of 6.2

and 6.3, the average value calculated from plots of the test

results for each condition shall be reported as the exural

modulus of elasticity of the stone at the job thickness and

surface nish for that condition.

7. Conditioning

7.1 For specimens with uneven surfaces, prepare at bear-

ing areas for the span supports and quarter point loading blocks

by applying a water resistant capping compound 15 mm (

1

2 in.)

wide centered on these areas. Allow the capping compound to

dry or cure per the manufacturers recommendations before

continuing conditioning the specimens in accordance with 7.2

or 7.3.

7.2 Before testing the specimens in a dry condition, dry

them for 48 h at 60 6 2C (140 6 4F). At the 46th, 47th, and

48th h, weigh the specimens to ensure the weight is the same.

If the weight continues to drop, continue to dry the specimens

until there are three successive hourly readings with the same

weight. After removing the specimens from the oven, cool

them to room temperature in a desiccator before testing.

7.3 Before testing the specimens in a wet condition, im-

merse them in water for 48 h at 22 6 2C (72 6 4F). Test

them immediately upon removal from the bath, wiping the

specimens free of surface water.

8. Procedure

8.1 Assemble the apparatus, place the specimen on the span

supports, and adjust the quarter-point loading blocks into

contact with the specimens.

8.2 Preload the specimen twice to a maximum load corre-

sponding to 50 % of the anticipated ultimate strength and then

back to zero (Note 1). Increase the load at a rate that

corresponds to a change in exural stress no greater than 4.14

MPa (600 psi) per min.

NOTE 1Ultimate exural strength values are best determined by Test

Method C 880.

8.3 Apply a preload of 44 N (10 lbf), zero the deection

gages, and load reading apparatus (see Note 2).

8.4 Increase the load in increments of approximately 10 %

of the anticipated failure load. Stop the loading at each

increment and record both of the two sample midspan edge

deections. Continue load increments and deection readings

until failure of the specimen occurs.

NOTE 2It is frequently difficult to set the deection gages to read zero

when there is no load on the specimen. A common practice is to apply a

small initial load to the specimen such as 44 N (10 lbf) and set the

deection gages to read zero for this load. Since it is only the slope of the

stress-strain curve that is desired, this initial load does not affect the nal

result.

9. Calculation

9.1 Plot the load-deection readings to a convenient scale

using the average net midspan deection and draw a straight

line to represent, as nearly as possible, the average of the

plotted points for the linear portion of the curve. (See Fig. 2.)

If the line does not pass through the zero point, draw a

corrected line through this point and parallel to the stress-strain

line. Calculate the exural modulus of elasticity, E, from the

coordinates of a convenient Point A on the corrected line as

follows:

E 5

11WL

3

64Dbd

3

(1)

D 5

S

D

c1

1 D

c2

2

D

2

S

D

s1

1 D

s2

2

D

FIG. 1 Diagrammatic View of a Suitable Apparatus for Flexural Modulus of Elasticity of Stone Test

C 1352 96 (2002)

2

where:

E = exural modulus of elasticity, MPa (psi),

W = total load applied to specimen, N (lbf),

W8 = load coordinate of the point, N (lbf),

D = average net midspan deection, mm (in.),

D

c1

= midspan deection 1, mm (in.),

D

c2

= midspan deection 2, mm (in.),

D

s1

= support deection 1, mm (in.),

D

s2

= support deection 2, mm (in.),

D8 = deection coordinate of the point, mm (in.),

L = span, mm (in.),

b = width of specimen, mm (in.), and

d = depth of specimen, mm (in.).

10. Report

10.1 The report shall include the following:

10.1.1 Stone type and nish,

10.1.2 Sizes of the specimens used,

10.1.3 Direction of bedding plane or rift,

10.1.4 Preconditioning procedure used,

10.1.5 Individual test results for each specimen, including

loads, deections, and plots,

10.1.6 Average value of the calculated test results for each

condition of test using the following relation,

E

5

sum of observed values

number of tests

(2)

10.1.7 Standard deviation, s, of the test results for each

condition of test using the following relation, and

s 5

=sum of ~value 2 E

!

2

number of tests 2 1

(3)

10.1.8 Any variations from the above procedural tech-

niques.

11. Precision and Bias

11.1 Individual variations in a natural product may result in

deviation from accepted values. A precision section will be

added when sufficient data are available to indicate acceptable

tolerances in repeatability and reproducibility.

12. Keywords

12.1 dimension stone; exure; modulus of elasticity; stone

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

FIG. 2 Typical LoadDeection Plot

C 1352 96 (2002)

3

You might also like

- Practicing Oil AnalysisDocument62 pagesPracticing Oil AnalysisCristian SNo ratings yet

- Differences of Classical and Modern Views On GravityDocument4 pagesDifferences of Classical and Modern Views On GravityJose Miguel Lopez83% (6)

- Aircraft MaintenanceDocument207 pagesAircraft MaintenanceSenthil Kumar100% (1)

- Electroconvulsive Therapy: Presented By: Shweta Surwase F.Y. M.Sc. (Mental Health Nursing) MIMH, PuneDocument48 pagesElectroconvulsive Therapy: Presented By: Shweta Surwase F.Y. M.Sc. (Mental Health Nursing) MIMH, PuneShweta KateNo ratings yet

- Care of Older Adults Notes PT 1Document5 pagesCare of Older Adults Notes PT 1Edson John Demayo100% (1)

- D 2168 - 02 Rdixnjgtukve PDFDocument7 pagesD 2168 - 02 Rdixnjgtukve PDFLupita CarelyNo ratings yet

- BS 812-109Document12 pagesBS 812-109ShahryarNo ratings yet

- ISRM TestsDocument3 pagesISRM Testsyatin pratapNo ratings yet

- .Methods of Physical Tests For Hydraulic Cement: Indian StandardDocument8 pages.Methods of Physical Tests For Hydraulic Cement: Indian StandardRS EngineeringNo ratings yet

- ASTM D2940 Agregates For Base CourseDocument1 pageASTM D2940 Agregates For Base Courseتوفيق عبداللهNo ratings yet

- Spraying TechniquesDocument12 pagesSpraying TechniquesX800XLNo ratings yet

- A History of OrnamentDocument488 pagesA History of OrnamentBrad Sommers100% (12)

- Sieve Analysis of Mineral Filler For Bituminous Paving MixturesDocument2 pagesSieve Analysis of Mineral Filler For Bituminous Paving MixturesArnold RojasNo ratings yet

- Facemasks Manufacturers DirectoryDocument54 pagesFacemasks Manufacturers DirectoryAlex Kharchuk100% (1)

- Fluent-Intro 16.0 L02 IntroCFD PDFDocument45 pagesFluent-Intro 16.0 L02 IntroCFD PDFAnonymous 8209ZTNo ratings yet

- C142 PDFDocument2 pagesC142 PDFRajesh Kumar50% (2)

- 440 3R-12Table1 3Document1 page440 3R-12Table1 316562306No ratings yet

- Astm D1621-00Document4 pagesAstm D1621-00hegiro1974No ratings yet

- D 3345 - 74 R99 Rdmzndu - PDFDocument3 pagesD 3345 - 74 R99 Rdmzndu - PDFRufo CascoNo ratings yet

- Astm D 217Document14 pagesAstm D 217Rosario BuonannoNo ratings yet

- IJSRD - International Journal for Scientific Research & Development| Vol. 5, Issue 09, 2017 | ISSN (online): 2321-0613Document3 pagesIJSRD - International Journal for Scientific Research & Development| Vol. 5, Issue 09, 2017 | ISSN (online): 2321-0613Luis MogrovejoNo ratings yet

- ARTO Concrete ASTM C157 Length ChangeDocument2 pagesARTO Concrete ASTM C157 Length ChangeArmandoNo ratings yet

- 5 Astm c123 c123m 2011 Lighweight Particles in AggregateDocument4 pages5 Astm c123 c123m 2011 Lighweight Particles in AggregateGeorges Abi JaoudeNo ratings yet

- The Global Commitment 2021 Progress ReportDocument39 pagesThe Global Commitment 2021 Progress ReportComunicarSe-ArchivoNo ratings yet

- D3406 - 95 (Reapproved 2006) PDFDocument3 pagesD3406 - 95 (Reapproved 2006) PDFBlack GokuNo ratings yet

- Using Significant Digits in Test Data To Determine Conformance With SpecificationsDocument5 pagesUsing Significant Digits in Test Data To Determine Conformance With SpecificationsROHITNo ratings yet

- Resistance To Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (6 Inch-Diameter Specimen)Document5 pagesResistance To Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (6 Inch-Diameter Specimen)Phuc Nguyen QuangNo ratings yet

- Evaluating Concrete Pavement Dowel Bar Alignment Using Magnetic Pulse InductionDocument6 pagesEvaluating Concrete Pavement Dowel Bar Alignment Using Magnetic Pulse Inductionmohammed karasnehNo ratings yet

- Sist en 14579 2004Document9 pagesSist en 14579 2004AnelNo ratings yet

- ASTM D 88-94 Saybolt Viscosity PDFDocument7 pagesASTM D 88-94 Saybolt Viscosity PDFanjanaNo ratings yet

- Is 8419 1 1977 PDFDocument12 pagesIs 8419 1 1977 PDFcodefinderNo ratings yet

- D946D946M 15.pdf (EngPedia - Ir)Document2 pagesD946D946M 15.pdf (EngPedia - Ir)Baba Mountain Gem ServicesNo ratings yet

- Amount of Water Required For Normal Consistency of Hydraulic Cement PasteDocument3 pagesAmount of Water Required For Normal Consistency of Hydraulic Cement PasteThurain Aung KyawNo ratings yet

- BS 5835-1-1980 PDFDocument21 pagesBS 5835-1-1980 PDFMohammad Twaha JaumbocusNo ratings yet

- ASTM D2974-20e1Document6 pagesASTM D2974-20e1Joviann Esquivel100% (1)

- Force Verification of Testing Machines: Standard Practices ForDocument10 pagesForce Verification of Testing Machines: Standard Practices ForRajan SteeveNo ratings yet

- Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocument8 pagesPreparation of Asphalt Mixture Specimens Using Marshall Apparatussumukh swaroopNo ratings yet

- ASSHTODocument3 pagesASSHTOmiguelangelNo ratings yet

- Aashto T 201Document3 pagesAashto T 201Mohammed AliNo ratings yet

- Astm C1202Document8 pagesAstm C1202liz moraNo ratings yet

- ASTM D2104-03 Tubo de Plástico de PE, Cédula 40Document7 pagesASTM D2104-03 Tubo de Plástico de PE, Cédula 40Marlon TurnerNo ratings yet

- Galva PulseDocument4 pagesGalva PulseAlex CrispimNo ratings yet

- Ultrasonic Pulse Velocity Method for Testing Concrete QualityDocument2 pagesUltrasonic Pulse Velocity Method for Testing Concrete QualitySzeJinTan100% (1)

- Astm C1064.2104017 1Document3 pagesAstm C1064.2104017 1elmer portilloNo ratings yet

- The Multiple-Stress Creep-Recovery (MSCR) Test and SpecificationDocument42 pagesThe Multiple-Stress Creep-Recovery (MSCR) Test and SpecificationVinayaka RamNo ratings yet

- AASHTO T230 Compactación NúcleosDocument9 pagesAASHTO T230 Compactación NúcleosDiana MoscosoNo ratings yet

- C1611C1611M 14371Document6 pagesC1611C1611M 14371josueNo ratings yet

- Sand Content - Mud TestingDocument1 pageSand Content - Mud TestingYougchu Luan100% (2)

- 03AggregatesRID-ENSTP 2016Document95 pages03AggregatesRID-ENSTP 2016Jimmy RostantNo ratings yet

- ZTVE-StB 94 Hinweise Zur Arbeit Mit Dem LFG in EnglischDocument20 pagesZTVE-StB 94 Hinweise Zur Arbeit Mit Dem LFG in EnglischSerdar AldanmazlarNo ratings yet

- Astm E728-91Document2 pagesAstm E728-91Omar Bellido ValenciaNo ratings yet

- ASTM D5581 Resistance To Plastic Flow of Bituminous Mixtures Using MarshallDocument5 pagesASTM D5581 Resistance To Plastic Flow of Bituminous Mixtures Using MarshallVijayakrishna SingamsettiNo ratings yet

- Determination of Pack-Set Index of Portland Cement: Standard Test Method ForDocument5 pagesDetermination of Pack-Set Index of Portland Cement: Standard Test Method ForINARQ1979No ratings yet

- ASTM - D4253 16E01 - en USDocument16 pagesASTM - D4253 16E01 - en USMatias Leiva FloresNo ratings yet

- Percent Air Voids in Compacted Dense and Open Asphalt MixturesDocument4 pagesPercent Air Voids in Compacted Dense and Open Asphalt MixturesAhmad KhreisatNo ratings yet

- Is 14858 2000 Compression Testing Machine Used For Testing of Concrete and Mortar RequirementsDocument9 pagesIs 14858 2000 Compression Testing Machine Used For Testing of Concrete and Mortar RequirementsVanu VamalaiNo ratings yet

- Astm D 4318Document16 pagesAstm D 4318Camilo OrozcoNo ratings yet

- 2386 (Part-V) PDFDocument11 pages2386 (Part-V) PDFSoundar PachiappanNo ratings yet

- KEM Epoxy Grout ELV - 1Document2 pagesKEM Epoxy Grout ELV - 1BinodNo ratings yet

- Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocument8 pagesPreparation of Asphalt Mixture Specimens Using Marshall ApparatusAnbuchelvan CNo ratings yet

- Preparation of Bituminous Mixture Test Specimens by Means of California Kneading CompactorDocument4 pagesPreparation of Bituminous Mixture Test Specimens by Means of California Kneading CompactorMax100% (1)

- NBT 492Document4 pagesNBT 492Raja QammarNo ratings yet

- 672CDocument3 pages672CJGD123No ratings yet

- ASTM D 2041 - 03 - RdiwndetukveDocument5 pagesASTM D 2041 - 03 - RdiwndetukveharisahamedNo ratings yet

- ACES Riyadh-Co - Profile 2022-23-REV0 PDFDocument74 pagesACES Riyadh-Co - Profile 2022-23-REV0 PDFOmar O Fili SalehNo ratings yet

- Soundness TestDocument3 pagesSoundness Testratoooooja24No ratings yet

- AASHTO t304Document10 pagesAASHTO t304Joydev DasNo ratings yet

- BS-1377 Part-6 Standrard Test For Con Solidation PermeabilitDocument65 pagesBS-1377 Part-6 Standrard Test For Con Solidation PermeabilitAshraf Tomizeh100% (1)

- ASTM D 2664-95a Standard Test Method For Triaxial Compressive Strength of Undrained Rock Core Specimens Without Pore Pressure MeasurementsDocument4 pagesASTM D 2664-95a Standard Test Method For Triaxial Compressive Strength of Undrained Rock Core Specimens Without Pore Pressure MeasurementsPablo Antonio Valcárcel VargasNo ratings yet

- Method For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Document4 pagesMethod For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Deepak Kumar MallickNo ratings yet

- C 120 - 90 r94 Qzeymc1sruqDocument4 pagesC 120 - 90 r94 Qzeymc1sruqJason RogersNo ratings yet

- D 3224 - 95 Rdmymjqtotu - PDFDocument2 pagesD 3224 - 95 Rdmymjqtotu - PDFRufo CascoNo ratings yet

- D 1758 - 02 Rde3ntgDocument8 pagesD 1758 - 02 Rde3ntgJosé Ramón GutierrezNo ratings yet

- C466Document2 pagesC466Rufo CascoNo ratings yet

- D 1758 - 96 Rde3ntgtukveDocument9 pagesD 1758 - 96 Rde3ntgtukveRufo CascoNo ratings yet

- D 3200 - 74 R94 Rdmymdatnzrsotrfmq - PDFDocument2 pagesD 3200 - 74 R94 Rdmymdatnzrsotrfmq - PDFRufo CascoNo ratings yet

- D 2719 - 89 R01 Rdi3mtktodlsmde - PDFDocument9 pagesD 2719 - 89 R01 Rdi3mtktodlsmde - PDFRufo CascoNo ratings yet

- D 2719 - 89 R01 Rdi3mtkDocument10 pagesD 2719 - 89 R01 Rdi3mtkJosé Ramón GutierrezNo ratings yet

- D 1990 - 00 Rde5otatmdbfmq - PDFDocument26 pagesD 1990 - 00 Rde5otatmdbfmq - PDFRufo CascoNo ratings yet

- Toughness of Wood-Based Structural Panels: Standard Test Method ForDocument3 pagesToughness of Wood-Based Structural Panels: Standard Test Method ForRufo CascoNo ratings yet

- D 2718 - 00 Rdi3mtgtmda - PDFDocument6 pagesD 2718 - 00 Rdi3mtgtmda - PDFRufo CascoNo ratings yet

- D 5055 - 02 Rduwntutmdi - PDFDocument23 pagesD 5055 - 02 Rduwntutmdi - PDFRufo CascoNo ratings yet

- D 1990 - 00 R02 Rde5ota - PDFDocument26 pagesD 1990 - 00 R02 Rde5ota - PDFRufo CascoNo ratings yet

- D 5516 - 01 Rdu1mtytmde - PDFDocument7 pagesD 5516 - 01 Rdu1mtytmde - PDFRufo CascoNo ratings yet

- D 5516 - 01 Rdu1mtytmde - PDFDocument7 pagesD 5516 - 01 Rdu1mtytmde - PDFRufo CascoNo ratings yet

- D 5764 - 97a R02 RDU3NJQ - PDFDocument5 pagesD 5764 - 97a R02 RDU3NJQ - PDFRufo CascoNo ratings yet

- D 1166 - 84 R95 Rdexnjytodrsotvfmq - PDFDocument4 pagesD 1166 - 84 R95 Rdexnjytodrsotvfmq - PDFRufo CascoNo ratings yet

- D 3737 - 02 Rdm3mzctukveDocument32 pagesD 3737 - 02 Rdm3mzctukveJosé Ramón GutierrezNo ratings yet

- D 1554 - 00 - Rde1ntqtmdaDocument3 pagesD 1554 - 00 - Rde1ntqtmdagrats_singcoNo ratings yet

- D 6007 - 96 Rdywmdctoty - PDFDocument8 pagesD 6007 - 96 Rdywmdctoty - PDFRufo CascoNo ratings yet

- D 4278 - 02 Rdqynzg - PDFDocument3 pagesD 4278 - 02 Rdqynzg - PDFRufo CascoNo ratings yet

- ASTM D 1108 - 96 (Reapproved 2001) Dichloromethane Solubles in WoodDocument2 pagesASTM D 1108 - 96 (Reapproved 2001) Dichloromethane Solubles in Woodalin2005No ratings yet

- E 1124 - 97 Rtexmjqtotc - PDFDocument7 pagesE 1124 - 97 Rtexmjqtotc - PDFRufo CascoNo ratings yet

- D 6815 - 02 Rdy4mtu - PDFDocument11 pagesD 6815 - 02 Rdy4mtu - PDFRufo CascoNo ratings yet

- D 1758 - 96 Rde3ntgtoty - PDFDocument7 pagesD 1758 - 96 Rde3ntgtoty - PDFRufo CascoNo ratings yet

- D 1624 - 71 R00 Rde2mjq - PDFDocument1 pageD 1624 - 71 R00 Rde2mjq - PDFRufo CascoNo ratings yet

- D 2606 - 94 R00 Rdi2mdy - PDFDocument2 pagesD 2606 - 94 R00 Rdi2mdy - PDFRufo CascoNo ratings yet

- C 271 - 99 Qzi3mqDocument2 pagesC 271 - 99 Qzi3mqAndre AlvesNo ratings yet

- C 711 - 93 R97 Qzcxms05m1i5nw - PDFDocument3 pagesC 711 - 93 R97 Qzcxms05m1i5nw - PDFRufo CascoNo ratings yet

- D 1110 - 84 R95 Rdexmtatodrsotvfmq - PDFDocument2 pagesD 1110 - 84 R95 Rdexmtatodrsotvfmq - PDFRufo CascoNo ratings yet

- Modelacion UreaDocument20 pagesModelacion UreaJesus Enrique Alfonzo RiveroNo ratings yet

- Certification Shop Test 3Document13 pagesCertification Shop Test 3sanyam dhawanNo ratings yet

- Meter Moving CoilDocument4 pagesMeter Moving Coilabecdf100% (1)

- Donna's Score During The Third Quarter ExaminationDocument7 pagesDonna's Score During The Third Quarter ExaminationGeraldine Valdez CacabilosNo ratings yet

- Godrej Group Is An Indian Conglomerate Headquartered in MumbaiDocument4 pagesGodrej Group Is An Indian Conglomerate Headquartered in MumbairahulbastyNo ratings yet

- Comprehensive Land Use Plan in Municipality of TigbauanDocument4 pagesComprehensive Land Use Plan in Municipality of TigbauanmaygracedigolNo ratings yet

- The Long Suffering of Frederic ChopinDocument7 pagesThe Long Suffering of Frederic ChopinDaniel CiobanuNo ratings yet

- Cash Valve Product OverviewDocument16 pagesCash Valve Product OverviewestebanNo ratings yet

- CS410 Series and CS417: User's GuideDocument209 pagesCS410 Series and CS417: User's Guident11No ratings yet

- AUSC National Conference 2019-Oct19-3rd AnnouncementDocument4 pagesAUSC National Conference 2019-Oct19-3rd AnnouncementarivarasuNo ratings yet

- Latihan Akuntansi Perusahaan DagangDocument3 pagesLatihan Akuntansi Perusahaan DagangTheresya HutajuluNo ratings yet

- The Box Above Contains Words That Pertain To The Computer or The Computer Itself. Below Are The Operational Definitions of The WordsDocument4 pagesThe Box Above Contains Words That Pertain To The Computer or The Computer Itself. Below Are The Operational Definitions of The WordsMarkie Dela CruzNo ratings yet

- Incepbio Project PPT - 080124Document21 pagesIncepbio Project PPT - 080124adminpuneNo ratings yet

- Noon Fees StructureDocument8 pagesNoon Fees StructureNithin SreekumarNo ratings yet

- Ask Astrologer Report - Specific Answer To Major Concern of LifeDocument8 pagesAsk Astrologer Report - Specific Answer To Major Concern of LifecyberastroNo ratings yet

- Untitled Document-7Document13 pagesUntitled Document-7Ranjan singh BhadoriyaNo ratings yet

- BIOpolitics PDFDocument3 pagesBIOpolitics PDFalpar7377No ratings yet

- Theories and philosophies that shaped early childhood educationDocument3 pagesTheories and philosophies that shaped early childhood educationJamille Aira PascuaNo ratings yet

- Book 1Document330 pagesBook 1ismed123No ratings yet

- Bhs Inggris A - SoalDocument9 pagesBhs Inggris A - SoalKhaerul AnamNo ratings yet