Professional Documents

Culture Documents

NT NDT 013 - Welds in Thin Materials - Ultrasonic Examination - Nordtest Method

Uploaded by

ngtchung0 ratings0% found this document useful (0 votes)

184 views9 pagesUT NDT

Original Title

NT Ndt 013_Welds in Thin Materials_Ultrasonic Examination_Nordtest Method

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUT NDT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

184 views9 pagesNT NDT 013 - Welds in Thin Materials - Ultrasonic Examination - Nordtest Method

Uploaded by

ngtchungUT NDT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

WELDS IN THIN MATERIALS:

UDC 620. 179. 1

ULTRASONIC EXAMINATION

Key words: NDT, welding, testing

TABLE OF CONTENTS

1 INTRODUCTION

1.1 Scope

1.2 Reporting level

1.3 Acceptance criteria

1.4 Extent of examination

1.5 References

1.6 Definitions

2 APPLICATION

2.1 General

2.2 Required information

3 PERSONNEL

4 SURFACE PREPARATION

5 COUPLANT

6 PERIODIC CHECK OF EQUIPMENT

6.1 General

6.2 Periodic quality checks

6.3 Periodic checks during operation

2

2

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

7 DESCRIPTION OF EQUIPMENT 3

7.1 Ultrasonic apparatus 3

7.2 Probes 3

7.2.1 General 3

7.2.2 Aluminium 3

7.2.3 Carbon steel 4

7.2.4 Austenitic steel 4

7.3 Calibration blocks 4

7.4 Reference blocks 4

7.5 Control blocks 5

8 PROCEDURE FOR EXAMINATION OF WELDS 5

8.1 General 5

8.2 Calibration of probes 5

8.3 Adjustment of time base 5

8.4 Sensitivity setting 6

8.5 Examination of parent metal 6

8.6 Examination routines 8

9 REPORTING 8-9

Published by NORDTEST Tekniikantie 12, FIN-02150 ESPOO, FINLAND Phone +358 9 455 4600 Fax +358 9 455 4272

ISSN 0283-720X Proj. 864-89 www.nordtest.org

NORDTEST METHOD NT NDT 013 2

1 INTRODUCTION

1.1 Scope

This Nordtest method specifies procedures for weld examin-

ation in thin materials by manually operated ultrasonics. The

method is limited to ordinary carbon steel, aluminium alloys

and austenitic steel with commonly accepted qualities for

conventional ultrasonic testing. The thickness range covered

is from 7 mm down to 3 mm, i.e. below the ranges covered by

ordinary procedures for ultrasonic weld examination which

often apply a lower limit of around 8 mm.

1.2 Reporting level

This Nordtest method does not specify reporting level.

1.3 Acceptance criteria

This Nordtest method does not specify acceptance criteria.

Reference is to be made to relevant codes or other documents

specifying such criteria.

1.4 Extent of examination

This Nordtest method does not specify the extent of examin-

ation in terms of areas to be examined, examination coverage

(percentage of total test specimen surface) or examination

intervals.

1.5 References

For common ultrasonic practices, reference is to be made to

relevant parts of DOC IIS/IIW -527-76 Handbook on the

Ultrasonic Examination of Welds. The International Institute

of Welding.

1.6 Definitions

Probe stand-off

The probe stand-off is the gap between the probe shoe

and the test object surface.

TR (twin crystal) probe

A transmitter-receiver (TR) probe has two crystals, one

for transmitting the sound and the other for receiving, and

is often also referred to as a twin crystal probe. The TR

arrangement can be either straight beam probes or angle

beam probes.

Probe log

A collection of probe data sheets and calibration data for

the probes used in the examination.

2 APPLICATION

2.1 General

Whenever an ultrasonic examination is specified to be per-

formed according to this document, the applications are re-

stricted to:

Weld examination.

Ordinary carbon steel, austenitic steel, aluminium alloys

and materials of comparable ultrasonic properties.

Material thicknesses in the range of 3 mm to 7 mm.

Surface curvature (external radius) exceeding 50 mm.

Surface temperature up to 60 C.

2.2 Required information

Reference to this document only is insufficient in order to

specify a proper ultrasonic examination. At least the following

additional information has to be given:

(i) Reporting level.

(ii) Extent of examination, i.e. areas to be

ing configuration and dimensions.

examined includ-

In addition the following information may be given:

(iii) Acceptance criteria.

(iv) Precautions in case unacceptable weld defects are

found.

3 PERSONNEL

The personnel responsible for performing ultrasonic examin-

ation of welds in thin plates according to this document shall

be examined and certified according to level 2 of the NORD-

TEST certification scheme or equivalent. Moreover, the per-

sonnel concerned shall:

(i) Be familiar with the possibilities and the limitations of this

special thin material method used to detect and size weld

defects.

(ii ) The personnel should also keep themselves informed

about developments in using ultrasonics in thin materi-

als.

(iii) Be specifically trained in the practical testing of welds in

the actual thickness range.

Whenever necessary, the personnel in question should be

submitted to qualification tests to prove their proficiency.

4 SURFACE PREPARATION

For examination of welds in thin plates the weld must be

prepared flush, i.e. weld cap and root must align with the base

material. This alignment must be good, since any remaining

material below the plate level may contain sharp edges caus-

ing more serious disturbances than the original weld.

NORDTEST METHOD NT NDT 013 3

Generally the condition of the surface that will be in contact

with the probe shall be such that satisfactory coupling between

the probe and the workpiece can be maintained, providing

satisfactory conditions for the transmission of the ultrasonic

waves. Surfaces where scanning will be performed must also

allow for free movement of the probe.

The surface roughness should not exceed 6 m rms.

For aluminium the grinding requirement may impose specific

requirements on the grinding equipment to avoid corrosion

problems. Aluminium surfaces should be metallically clean.

5 COUPLANT

A couplant such as water, oil, grease or a commercial ultra-

sonic couplant shall be used in accordance with common

practices (IIW doc. 527-76, Section 4.3).

A probe holder with a 0.05 to 0.1 mm probe stand-off may be

used with micro miniature probes when using liquid couplant,

to ensure stable coupling, less probe wear, more easy probe

handling and correct probe angle.

6 PERIODIC CHECK OF EQUIPMENT

6.1 General

Whenever personnel discovers irregularities in equipment per-

formance, or the equipment has been exposed to rough treat-

ment which could influence the equipment performance, a

quality check is required. Documents of quality checks shall

be available.

6.2 Periodic quality checks

The ultrasonic apparatus, probes and cables shall be checked

at intervals not exceeding 6 months. The check shall ensure

that all the operating modes function satisfactory.

6.3 Periodic checks during operation

In order to ensure that the ultrasonic equipment is properly

calibrated at any time during examination, the operator shall

perform checks at regular intervals as outlined below:

- Ultrasonic apparatus

At approximately

performed:

two-hourly intervals, the following shall be

* check of time-base range or display range using blocks

manufactured for the purpose.

* check of sensitivity.

- Angle beam probes

The angle probes shall be checked frequently and always

before and after a specific ultrasonic examination.

If wear has caused an angular deviation of more 2

from the nominal value, the probe shall be replaced. When

replacing a probe, all calibration, adjustment of time-base and

sensitivity setting shall be repeated.

- Straight beam probes

The straight beam probes shall be checked frequently and

always before and after a specific ultrasonic examination.

Echo amplitude and number of echoes (if applicable) from a

calibration/reference block can be used in the check pro-

cedure.

7 DESCRIPTION OF EQUIPMENT

7.1 Ultrasonic apparatus

An oscilloscope type ultrasonic flaw detector (A-scan display

or similar) covering at least the frequency range of 4-12 MHz

shall be used.

The apparatus must be able to work in single as well as twin

crystal modes.

It must be possible to adjust the time base of the apparatus

down to a range of 10 mm corresponding to full screen width.

It must be possible to draw a reference curve directly on the

screen.

7.2 Probes

7.2.1 General

Single crystal probes should be chosen so that sound paths

exceed 60 % of the near field length.

Twin crystal probes should be chosen so that the sound path

is typically 50-200 % of focal distance.

High frequencies, 4-10 MHz, should be used for good sensi-

tivity. The highest frequency probes are needed for the

smallest plate thicknesses.

The probe angle should be in the range of 60 to 80. The

advantage of using different probe angles may be less for thin

plate examination because the ultrasonic beam may fill the

inspection volume. This will depend on plate thickness, probe

frequency and probe crystal size. For high frequency micro

miniature probes this effect will be less pronounced.

7.2.2 Aluminium

Ultrasonic probes with the following characteristics shall be

used:

(i) Micro miniature angle beam probes or TR probes,

- Frequency in the range of 4-10 MHz

- A probe angle of approximately 70 should be used.

The probe angle in aluminium will depend on the type

of alloy and treatment of the material. The nominal

probe angle will normally be given for steel, and the

actual probe angle has to be established by cali-

bration as described in Clause 8.2.

- Transversal wave mode.

NORDTEST METHOD NT NDT013 4

(ii) Straight beam TR probes,

- Frequency in the range of 10 MHz

Focus at 50-200 % of nominal thickness.

7.2.3 Carbon steel

Ultrasonic probes with the following characteristics shall be

used:

(i) Micro miniature angle beam probes or TR probes,

- Frequency in the range of 4-10 MHz

- Beam angle of 70

(ii) Straight beam TR probes,

- Frequency in the range of 4-10 MHz

- Focus at 50-200 % of nominal thickness.

7.2.4 Austenitic steel

Ultrasonic probes with the following characteristics shall be

used:

(i) Micro miniature angle beam probes or TR probes,

- Frequency in the range of 4-10 MHz

- Beam angle of 70

- Twin crystal probe

- Transverse wave mode, since the lower attenuation

of longitudinal waves gives no advantage for the short

7.3 Calibration blocks

The following calibration blocks shall be applied:

( i ) The IIW Calibration Block No. 2, the V2 block, shall be

used for determination of probe index point, as described

in the examination procedure 8.2.

( i i ) A calibration and reference block shall be used for deter-

mination of probe angle and for adjustment of time base.

The block shall be made of the same material or a

material with the same ultrasonic properties as the test

object. The calibration/reference block is described

below and is shown in Figure 7.1.

7.4 Reference blocks

A reference block shall be made of the same material or a

material with the same ultrasonic properties as the test object.

The dimensions of the reference block shall be:

Thickness (T) Same as the test object.

Length (L) Minimum 70 mm.

Width (W) Minimum 40 mm.

A cylindrical bore hole of 1.0 mm diameter and two notches of

1.0 mm depth and max. 0.2 mm width, with lengths equal to

half the reference block width, shall be positioned as shown in

Figure 7.1.

(i) The notches shall be used to determine probe angle.

(ii) The time base should be calibrated using the cylindrical

path lengths in thin plates. bore hole as reflector.

W/2

Notches shall have rounded ends (side milling cutter)

1 mm bore hole of max 20 mm length

Figure 7.1. Calibration and reference block with side drilled hole and notches.

NORDTEST METHOD NT NDT 013 5

(iii) Sensitivity setting shall be performed with the cylindrical

bore hole of 1 mm diameter. The construction of the

reference curve should be carried out as recommended

by DOC IIS/IIW - 527-76.

7.5 Control blocks

It is recommended, but non-mandatory, to have control blocks

with real defects for the purpose of increased detection re-

liability. The control block shall have the same material quality,

thickness, surface geometry and surface condition as the body

to be examined.

8 PROCEDURE FOR EXAMINATION OF WELDS

8.1 General

The ultrasonic weld examination shall be performed according

to commonly accepted practice, as described in DOC IIS/IIW-

527-76. The temperature of the calibration and reference block

shall be the same as that of the surface of the test object within

10 C.

8.2 Calibration of probes

( i ) The IIW Calibration Block No. 2, the V2 Block, shall be

used for initial determination of index point. See Fig. 8.1.

INDEX POINT

The echo is maximized against the 25 mm or 50 mm

diameter surface and the position of the index point is

positioned directly below the reference mark on the

calibration block. The index point should be marked on

the probe and the result should be reported in the probe

log.

( i i ) The calibration of the angle of refraction shall be per-

formed directly on the reference block by mechanically

measuring the plate thickness and horizontal distance

from the index point of the probe to the position of the

notches, and then calculating the angle. The calibration

procedure is described in Figure 8.2. At least one of the

indicated positions should be used, and the angle of

refraction then calculated from the following formula:

a = arctg(d/T)

(iii) If the probe wedge has been adapted to test body

curvature, the probe index and angle of refraction shall

be determined by using a reference block of curvature

similar to that of the test object.

8.3 Adjustment of time base

On both planar and curved contact surfaces, the cylindrical

bore hole in the reference block should be used for adjustment

of time base.

The echoes against the cylindrical bore hole should be

maximized in at least two of the positions A, B, C and D in

Figure 8.3, and the time base of the apparatus should be

adjusted so that the full length of the minimum scanning area

is within the screen.

Figure 8.1. Calibration of index point using the V2 block. Figure 8.2. Calibration of probe angle.

Figure 8.3. Calibration of time base.

NORDTEST METHOD NT NDT 013 6

Figure 8.4. Calculation of sound path s and horizontal distance d from the probe to a cylindrical bore hole.

The sound path s and the horizontal distance d from the first

probe position A to the reflector can be calculated by the

following formulas, when the plate thickness T, the probe angle

a and the radius R (0.5 mm) of the cylindrical bore hole are

known (see Figure 8.4):

s = (T/2)/cos(a) - R

d = (T/2)tg(a) - R sin(a)

The position A is approximately 1/4 skip distance from the bore

hole and the positions B, C and D correspond to 3/4, 5/4 and

7/4 skip distances, or N*(1/4) skip distances, where N is 1, 3,

5 and 7. A table of horizontal distances and sound paths

corresponding to the probe positions A, B, C and D should be

made and the probe positions for these skip distances should

be marked with a felt tip pen on the surface of the reference

block. The formulas for these positions will be

s = N(T/2)/cos(a) - R

d = N(T/2)tg(a) - R sin(a)

An example of such a table is given below, for T = 4 mm, a =

Probe ID

Probe angle

Date

Operator

Probe position A, B, C, D,

1/4 skip 3/4 skip 5/4 skip 7/4 skip

Sound path,

s [mm] 5.3 17.0 28. 7 40. 4

Horizontal distance

d [mm] 5.0 16.0 27. 0 38. 0

8.4 Sensitivity setting

The sensitivity setting shall be performed and a reference

curve shall be established by using the 1 mm diameter bore

hole in the reference block described in Fig. 7.1. The procedure

is shown in Figures 8.5 to 8.8.

The sound path from the position corresponding to the first

point on the reference curve to the cylindrical bore hole should

be not less than 60 % of the near field length of the probe.

Probe positions A(1), B(3) and C(5) shall be used for estab-

lishing the reference curve if the sound path from the probe in

position A(1) to the reflector is more than 0.6 times (60 %) the

near field length of the probe. Otherwise probe positions A(3),

B(5) and C(7) shall be used.

The echo height from the first position should be maximized

and the gain adjusted so that the echo height is 80 % of the

full screen height.

With constant gain setting echo heights from the other probe

positions shall be maximized and the maximum echo positions

should be marked on the instrument screen.

A smooth curve should be drawn through the established echo

height positions and is to be plotted on the instrument screen.

The two curves at 50 % and 20 % of the reference curve should

also be established and plotted on the instrument screen.

For aluminium, reporting level and acceptance criteria often

require the use of a higher sensitivity, because lack of fusion

defects in aluminium are often partly transparent to ultrasound.

The required sensitivity levels must be established individually.

8.5 Examination of parent metal

Parent metal should be checked for lamination type defects in

the scanning area by using a straight beam TR probe with a

focal distance comparable to (50 to 200 % of) the material

t hi ckness.

70:

NORDTEST METHOD NT NDT 013 7

Figure 8.5. Probe positions for establishing reference curve, numbers in parentheses are number of quarter

skip distances.

100 % t

75 %

\

\

\

\

\

\ REFERENCE CURVE

A(1) B(3) C(5)

Figure 8.6. Reference curve corresponding to above probe

positions, numbers in parentheses correspond to number of

quarter skip distances.

Figure 8.7. Probe positions for establishing reference curve, numbers in parentheses correspond to number

of quarter skip distances.

100 % t

75 %

!

\

\

\

\

\

\ REFERENCE CURVE

Figure 8.8. Reference curve corresponding to above probe

positions, numbers in parentheses correspond to number of

quarter skip distances.

NORDTEST METHOD NT NDT 013 8

MINIMUM SCANNING AREA

Figure 8.9. Minimum scanning area for probes with short near field length.

I MINIMUM SCANNING AREA

I

i

I

I

s = 10 mm

Figure 8.10. Minimum scanning area using a probe with relatively long near field length.

MACHINED FLUSH

I

WELD LONGITUDINAL AXIS \

reflector position near the center of the plate, and the most far

away probe position corresponds to a reflector position near

the top (Figure 8.9) or bottom (Figure 8.10) surface of the

plate with a distance S, minimum 10 mm, from the weld

groove.

The distances from the probe positions to the weld corre-

sponding to the minimum scanning area should be established

by using the notches of the reference block. The scanning area

should then be marked on the surface of the test object.

Scanning for detection of transverse cracks should be per-

formed by moving the probe in the direction of the longitudinal

axis of the weld on the machined surface directly below the

weld, as shown in Figure 8.11.

Figure 8.11. Scanning for transverse cracks.

9 REPORTING

8.6 Examination routines

The centre of the weld should be marked on the surface. The

minimum scanning area is indicated in Figure 8.9 for probes

with short near field lengths, with reference curves established

according to Figures 8.5 and 8.6. For probes with longer near

field lengths, with reference curves established according to

Figures 8.7 and 8.8, the minimum scanning area is indicated

in Figure 8.10. The closest probe position corresponds to a

The results from the weld examination shall be given in a report

which should include all the necessary information required to:

(i) Take decisions on acceptance.

(ii) Facilitate repair or other remedial actions on unaccept-

able structures.

(iii) Enable measurements to be repeated in order to check

measurement reliability.

NORDTEST METHOD NT NDT 013 9

The test report shall therefore include the following informa-

tion:

(9) Description of calibration block and report on calibration

data

(1) Job identification

(2) Test object identification, drawings and dimensions

(3) Date, time and place of the examination

(4) Ambient conditions of the examination

(5) Name and signature of the operator

(6) Relevant material characteristics

(7) Surface condition and geometry

(8) Data related to equipment, eg. manufacturer, serial no.,

equipment type, probe description

(10) Description of reference blocks and report on reference

data

(11) Data concerning the results from the examination.

(12) Additional data which may concern limitations of the

examination because of surface geometry, coating thick-

ness or others.

(13) Specific requirements agreed upon by the parties in-

volved

(14) Drawings of affected areas, if required.

You might also like

- API Rp-571 - GuideDocument33 pagesAPI Rp-571 - Guidengtchung100% (1)

- 3 Overall ConsiderationsDocument65 pages3 Overall ConsiderationsngtchungNo ratings yet

- Packing ProcedureDocument67 pagesPacking ProcedurengtchungNo ratings yet

- ISO 5817-2003 Quality Levels 4 Imperfections - Fusion WeldsDocument27 pagesISO 5817-2003 Quality Levels 4 Imperfections - Fusion WeldsngtchungNo ratings yet

- 2 Regulations StandardsDocument16 pages2 Regulations StandardsngtchungNo ratings yet

- 8 EquipmentDocument148 pages8 Equipmentngtchung100% (1)

- E&I Inspector Job DescriptionDocument2 pagesE&I Inspector Job DescriptionngtchungNo ratings yet

- Repaired defects still an issueDocument4 pagesRepaired defects still an issuengtchungNo ratings yet

- 04welding EngineerengDocument3 pages04welding EngineerengngtchungNo ratings yet

- 7 Safety SystemsDocument61 pages7 Safety SystemsngtchungNo ratings yet

- 13A ExercisesDocument3 pages13A ExercisesngtchungNo ratings yet

- Course Facilities Layout Training IntroductionDocument45 pagesCourse Facilities Layout Training IntroductionngtchungNo ratings yet

- Giao An Thi Giao Vien Gioi Cap Huyen PTGTDocument7 pagesGiao An Thi Giao Vien Gioi Cap Huyen PTGTngtchungNo ratings yet

- Uvex Ambient OTG English USDocument3 pagesUvex Ambient OTG English USngtchungNo ratings yet

- 6 Specific AreasDocument98 pages6 Specific AreasngtchungNo ratings yet

- 5 Offshore Work OperationsDocument6 pages5 Offshore Work OperationsngtchungNo ratings yet

- CV Surveyor Tran Van QuyDocument7 pagesCV Surveyor Tran Van QuyngtchungNo ratings yet

- 4 Layout Facility Segregation ZoningDocument50 pages4 Layout Facility Segregation ZoningngtchungNo ratings yet

- DK Essential Managers - Managing BudgetsDocument71 pagesDK Essential Managers - Managing BudgetsSeeyian Simon Metoyu86% (7)

- Shipbuilding Process 1Document53 pagesShipbuilding Process 1tiwaripur100% (1)

- Tofd PCNDocument22 pagesTofd PCNmarforall5205No ratings yet

- 15 AbbreviationsDocument4 pages15 AbbreviationsngtchungNo ratings yet

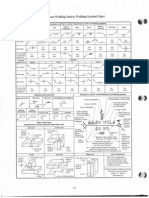

- AWS Weld Symbol ChartDocument1 pageAWS Weld Symbol ChartExsan OthmanNo ratings yet

- Vocabulary in Context - Lesson 1Document6 pagesVocabulary in Context - Lesson 1ngtchungNo ratings yet

- VISA APPLICATION FORMDocument1 pageVISA APPLICATION FORMngtchungNo ratings yet

- MEPCOM - Management Philosophy - Vision Rev 0Document1 pageMEPCOM - Management Philosophy - Vision Rev 0ngtchungNo ratings yet

- Love TestDocument4 pagesLove TestngtchungNo ratings yet

- Mind You, Even So, You Know, Believe It or Not, Just As WellDocument4 pagesMind You, Even So, You Know, Believe It or Not, Just As WellngtchungNo ratings yet

- 3-List of Main EquipmentDocument2 pages3-List of Main EquipmentngtchungNo ratings yet

- Stative VerbsDocument3 pagesStative Verbsngtchung0% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ILSAS Training Calendar 2015Document82 pagesILSAS Training Calendar 2015MrKapitalistNo ratings yet

- Almansoori Inspection Services: Magnetic Particle Inspection ReportDocument1 pageAlmansoori Inspection Services: Magnetic Particle Inspection ReportMohamed YasirNo ratings yet

- AE For Buried LPG TanksDocument8 pagesAE For Buried LPG TanksSaif EldinNo ratings yet

- Mechanical Maintenance of Cement Rotary KilnDocument101 pagesMechanical Maintenance of Cement Rotary KilnVijaykumar Rugada97% (35)

- Ultrasonic Testing Equipment CalibrationDocument58 pagesUltrasonic Testing Equipment CalibrationGulfam HussainNo ratings yet

- ITP - PipingDocument7 pagesITP - PipingRiaz Rasool100% (2)

- Carbon and Low Alloy Steel Pipeline FlangesDocument24 pagesCarbon and Low Alloy Steel Pipeline FlangesTg Tarro100% (1)

- Inspection Report: IR No.: QETO/IR/SUD/115Document2 pagesInspection Report: IR No.: QETO/IR/SUD/115sudipta dasNo ratings yet

- 21105-87 MPT enDocument18 pages21105-87 MPT enRajeev RavindranNo ratings yet

- 6432733Document7 pages6432733Ankit JaglanNo ratings yet

- A578a578m-17 1.04Document5 pagesA578a578m-17 1.04Manjupai100% (3)

- Causes and Detection of Damages - Avinashtaru7129 - OfficialDocument13 pagesCauses and Detection of Damages - Avinashtaru7129 - Officialpratik sawantNo ratings yet

- HB D KomplettDocument181 pagesHB D KomplettGabriel BourguignonNo ratings yet

- PPL-SU-1564-F Radiographic Inspection: Operating Environment: Onshore, Pipelines, TopsidesDocument12 pagesPPL-SU-1564-F Radiographic Inspection: Operating Environment: Onshore, Pipelines, Topsidesresp-ectNo ratings yet

- Lec 4 - PressureVesselDocument79 pagesLec 4 - PressureVesselsleriphocr100% (1)

- Quality Assurance Plan Equipment: Ss 304L Storage TanksDocument11 pagesQuality Assurance Plan Equipment: Ss 304L Storage Tankssamsurendran_mech4020No ratings yet

- Tower Crane Test ReportDocument10 pagesTower Crane Test Reportguthale100% (2)

- Fabrication and Installation of Pressure Shaft Steel LinerDocument4 pagesFabrication and Installation of Pressure Shaft Steel LinerDheeraj ThakurNo ratings yet

- Glovebox FabricationDocument44 pagesGlovebox FabricationRezaNo ratings yet

- In-Corr-Tech Training CoursesDocument2 pagesIn-Corr-Tech Training CoursesapiinspectorsNo ratings yet

- Proceduer of Pmi - Rev - 03 Dec 25-2019Document14 pagesProceduer of Pmi - Rev - 03 Dec 25-2019Rajat TiwariNo ratings yet

- Saudi Aramco Typical Inspection Plan: Ultrasonic Testing (UT) On IK Projects Satip-Nde-Ut-01 15-Nov-17 Mechanical - NdeDocument12 pagesSaudi Aramco Typical Inspection Plan: Ultrasonic Testing (UT) On IK Projects Satip-Nde-Ut-01 15-Nov-17 Mechanical - NdeSyed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- CND Normes StandardsDocument4 pagesCND Normes StandardsRebecca RileyNo ratings yet

- Pressure Vessel 1Document66 pagesPressure Vessel 1gst ajahNo ratings yet

- Analysis of Food ProductsDocument114 pagesAnalysis of Food ProductsDrGajanan Vaishnav50% (2)

- Heat Exchanger Inspection & Test PlanDocument6 pagesHeat Exchanger Inspection & Test PlanakisdassasNo ratings yet

- Project Inspection and Test Plan (Clamp)Document12 pagesProject Inspection and Test Plan (Clamp)Mohd KhaidirNo ratings yet

- Eddy Current White PaperDocument25 pagesEddy Current White PapervrapciudorianNo ratings yet

- MFL Storage Tank Inspection LimitationsDocument3 pagesMFL Storage Tank Inspection LimitationsSatya RaoNo ratings yet