Professional Documents

Culture Documents

Friction Stir Welding PAPER-11

Uploaded by

robertalhaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Friction Stir Welding PAPER-11

Uploaded by

robertalhaCopyright:

Available Formats

Title: Friction stir welding of commercially pure aluminium alloy using

counter rotating twin tool

K.Kumari, Surjya K Pal

Department of Mechanical ngineering, !ndian !nstitute of Technology,

Kharagpur, !ndia

"#stract

"n attempt has #een made to study the effect of counter rotating twin tool on the commercially pure

aluminium alloy using friction stir welding. Further a comparati$e study is made #etween twin tool

%TT& and single tool using dou#le pass %ST'DP&.Twin tool helps in generating high heat caused

intense plastic deformation in the processed (one. Defect free (one not only depends on the

rotational speed #ut also on the com#ined effect of welding speed and rpm. )igher hardness profile

is o#ser$ed with highest welding and rotational speed %*+,, rpm with -. mm/min&.0oints fa#ricated

at higher rpm and higher welding speed are found to #e free from defects. Further .*.1 mm/min

welding speeds is the critical point where a sudden change in mechanical properties was o#ser$ed.

SM results confirm the e2istence of ductile failure with microscopic $oids of different shape and

si(es.

Keywords: Friction stir welding, counter rotating twin tool,

!ntroduction

specially for aluminium alloy, Friction stir welding is an impro$ed techni3ue of joining compared

to fusion welding process. !t is a solid state techni3ue where the temperature is reached #elow

melting point of the welding material, in$ented #y The 4elding !nstitute, in *55* %Mishra and Ma,

6,,1& and %7andan et al., 6,,+&.The process is ad$anced in joining materials which are difficult to

weld, re3uire no filler and shielding gas, need less s8illed wor8ers.

)owe$er, careful selection of welding process parameters %such as weld speed, rotation

speed, plunge depth or plunge force, tool geometry& which are comple2, is #eneficial for pre$enting

the formation of defecti$e weld %9eal and 9oureiro, 6,,:&.

Furthermore, some degradation in mechanical properties has #een o#ser$ed when there is a

de$iation in the welding condition. Though it is a relia#le techni3ue for joining, complete

elimination of defect is not possi#le. So a lot of researchers focussed to repair the defecti$e portion

#y using multi'pass FS4/FSP using the nominal process parameters. That means, #y using the re'

welding techni3ue, defecti$e portion of the weld is #eing repaired %;rown et al., 6,,5&. <ecent

literature reports se$eral e2amples related to multi'pass FSP/FS4.

%;rown et al., 6,,5& performed fi$e o$erlapping passes and found that there is no need of any

adjustment for multi'pass welding. Further there is a significant reduction in feed force when

welding is done o$er the pre$ious weld. )owe$er grain si(e, hardness and temperature during

welding is unaffected with num#er of passes. "gain there is a gradual reduction of residual stress

with increasing pass num#er.

%7ata8a et al., 6,,-& reported an ad$ancement of the mechanical properties in aluminium die

casting alloy using multi'pass FSP compared to the as'cast #ase metals. "s compared to #ase metal,

hardness increased #y 6,)=and the tensile strength of the multi'pass specimens were significantly

increased to a#out *.> times of as'cast #ase metal. The main reason for impro$ement of mechanical

properties is due to the remo$al of cold fla8e, uniform distri#ution of the silicon particles o$er the

aluminium matri2 which refines the grain. ?n the other hand %Ma et al., 6,,-& reported that there is

no effect of o$erlapping passes on si(e, aspect ratio or distri#ution of the Si particle while

performed fi$e'pass with 1,@ o$erlap FSP on cast ".-1.

%9eal and 9ouriero 6,,+& in$estigated the effect of o$erlapping FS4 passes using two "l alloys

%""1,+.'? and "" -,-.'T-&.They found that the 3uality and strength of the welded joint is not

only dependent on the weld parameters, #ut also on the type of material and its heat treatment

conditions. 9astly they found that weld polishing impro$ed the mechanical efficiency of the welded

joint.

"s FSP is one of the most promising techni3ues for grain refinement, remo$ing flaws, defectsA

many researchers used multi'pass FSP to impro$e the properties of as'cast material. %0ohannes and

Mishra 6,,>& used to demonstrate the effecti$eness of multiple passes to create large area of super

plastic materials with properties. They conclude that for achie$ing the super plastic deformation

grain #oundary sliding %B;S& is the most important mechanism. Similarly %Ma et al., 6,,5& noted

that two pass FSP shows enhanced super plastic elongation compared to single pass. Further the

temperature in central (one of second pass and transitional (one is more than the single pass.

%Sure8ha et al. 6,,+& reported that multi'pass FSP showed #etter corrosion resistance compared to

the #ase metal.

Csing cast "l alloy, %0ana et al., 6,*,& reported that multiple passes helped in remo$al of a#normal

grain growth %"BB& occurred during single pass runs. They also e2amined and found that higher

rotational speed was found to #e #eneficial for controlling the "BB. %;armou( and Bi$i, 6,**&

used MPFSP to impro$e metallurgical and mechanical properties of cu/sic metal matri2 composites.

<esult shows Sic particle dispersed and fragmented to smaller si(e due to se$ere stirring action in

the nugget (one of the copper matri2. !t also created strong interfacial #onding #y remo$ing the

porosity content.

Multi'pass o$erlapping FSP %MP? FSP& has #een applied #y %7i et al., 6,**& to transform the

coarse as'cast 7a# alloy #ase metal to get defect free material with fine microstructure, which was

feasi#le to modify the large si(ed plates. Similar type of study had #een conducted #y %!(adi and

Berich, 6,*6& to study the effect of multi'pass FSP on distri#ution and sta#ility of car#on nano'tu#e

and to fa#ricate "9 1,15 and M4D7Ts metal matri2 composite %MMD&.

To a$oid the use of multi'pass FS4/FSP, the two'tool'FS4 concept is #eing de$eloped at T4! in

se$eral $ariations %Thomas, *555&. ?ne of those techni3ues is named as Tandem twin'stir techni3ue

%Thomas et al., 6,,1&. Tandem Twin'Stir uses two FS4 tools %with or without counter rotation&

positioned one in front of the other.

The aim of this in$estigation to determine the effect of two contra rotating FS4 tool %Tandem

Twin'stir& on the friction stir processing/welding region of commercially pure aluminium alloys.

6. 2perimental wor8

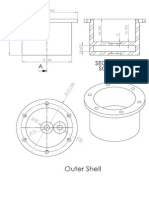

!n order to demonstrate the characteristics of twin tool, a self designed twin tool setup is designed,

fa#ricated and used for friction stir welding is shown in Fig *. The twin tool system is composed of

two tools which are rotating in opposite direction to each other. The primary tool is mounted on the

main spindle shaft. Therefore, the main tool rotates at the same rotational speed and in the same

direction as the spindle during the welding process. The secondary tool is connected with the

primary tool with the help of gear assem#ly. The power transmission from the primary to secondary

tool is similar to the transmission of power from dri$er to dri$en gear, So that the rotation of the

secondary tool is just opposite to the primary tool.

Fig.*: Twin tool attachment

Friction stir welding using twin tool and single tool with dou#le pass were produced in 6.1 mm

thic8 plate of commercially pure **,, aluminium alloy. !n #oth the cases welds made with

complete o$erlapping passes. ;oth the plates were clamped using specially designed E2ture as

shown in Fig 6. The nominal chemical composition of the plate is shown in Ta#le *.The FS4

carried out at 8nee type $ertical milling machine %;F4, =F..1&, which has wide range of rotational

speed %:1 to *+,, rpm& and welding speed/feed rate %*- to +,, mm/min&.

Fig.6: Specially designed Fi2ture

Ta#le *.

Dhemical composition of the wor8 piece material

Dhemical composition %weight @& of wor8 piece material

Si Fe Du Mn Mg Fn Ti Ba 7a ?thers

<emainder

"luminium

,.>,11 .+.* .,,1,1 ,.,*. ,.,,:-1 ,.,,.* ,.,,:+ ,.,**+ ,.,,6:1

Ma2.

,.,1@

5+.>

" non'consuma#le tool made of stainless steel SS.*- with *- mm shoulder diameter, a cylindrical

pin of 1 mm diameter and 6 mm length was used for welding. ;y using four rotational speeds %5,,,

**6,, *:,,, *+,, rpm& and three welding speeds %*-, .*.1,-. mm/min&, total *6 e2periments were

performed using twin tool and single tool with dou#le pass. Therefore, total 6: e2periments ha$e

#een carried out at this stage. The coupled plate with simultaneous dou#le pass using the twin tool

setup is shown in Fig ..

Fig..: Schematic diagram of welded plate using twin tool setup

To e2amine the superficial defects macroscopic analysis was done using 9eica S-D Trinocular

stereo (oom microscope with 9eica G4in'=. image analysis software. Specimen for

metallographic analysis are sectioned comprising of welded (one, heat affected (one, thermo'

mechanical (one and unaffected #ase metal region. Samples are polished with a set of emery papers

with different grades. Further diamond paste is used for final polishing in $aria#le speed grinder

polishing machine. Kellers reagent was used to e2amine the macroscopic $iew. The ;uhlerHs

=ic8ers hardness indentation machine with 6,, gmf with *1 sec dwell time was used to get the

hardness profile of the welded sample on a cross section normal to the welding direction. To

e$aluate the tensile strength of the welded samples, specimens were cut using electro discharge

machine trans$erse to the direction of the weld line. The tensile test was carried out at normal room

temperature using !7ST<?7'++-6 machine with a ram speed of *mm/min. Fig : shows the

dimension of the tensile test specimen. The fractured tensile surfaces were studied using scanning

electron microscope %0?9'0SM 1+,,& to analyse the failure patterns.

Fig. :: Shape of the tensile test samples

.. <SC9TS

..* Macrostructural analysis

Porosity, solidification crac8ing, inclusions are some of the defects in fusion welding process

which degrades the 3uality of the weld and the property of the joint. Mainly these types of

defects are not generated in case of friction stir welding, in which there is no melting of metal

occurs. 0oining ta8es place due to the stirring action of metal and heat generation #y friction.

)owe$er due to improper selection of process parameters defects li8e pinhole, tunnels, piping

defect, 8issing #ond, crac8s are generated in the friction stir welded joints. Stereo (oom

microscope with magnification of *,I was used to analyse the 3uality of the welded region.

Macrostructure of the welded regions are shown in Fig 1 using twin tool attachment with

different rotational and welding speed. "t higher rpm and high welding speed joints using twin

tool shows defect free welds. )ence formation of defect free weld is #oth dependent on the

rotational speed and welding speed.

900-16

1120-16

1400-16 1800-16 900-31.5 1120-31.5

1400-31.5

1800-31.5 900-63

1120-63 1400-63

1800-63

Fig.1: Macrographs of welded samples using twin tool

..6 )ardness Testing

Fig 1 shows the hardness profiles of the welds made with twin tool as well as single tool with

dou#le pass. 4elds made with twin tool shows higher $alue of hardness compared to the two pass

FS4 joints for most of the welding parameters. This is due to the hardening effect caused #y

intense plastic deformation in the processed (one. "s materials in the nugget (one are su#ject to two

stirring actions so materials undergo se$ere plastic deformation due to which it gains a higher

cooling rate as compared to single pass material. 4ith su#se3uent processing of one tool o$er the

other intense plastic deformation is occurred #y which hardness caused due to second pass is more

than the first pass. Similarly in case of two pass using single tool, the material is su#jected to two

stir effects #ut there is a time delay in #etween the two passes. Therefore, cooling rate is somewhat

less as compared to twin tool passes. From the Fig 1 %l&, it is re$ealed that welds made with twin

tool shows higher hardness $alue compared to single tool with dou#le pass corresponding to *+,,

rpm with -. mm/min welding speed. Further from Fig 1 %a'l& it is o#ser$ed that at high rotational

speed of *+,, rpm with all constant welding speed, twin tool gi$es the higher $alue of hardness

profile in comparison to two pass using single tool. Fig > %a'd& shows the effect of welding speed on

a$erage micro hardness of welded samples at constant rpm. !t can #e seen that .*.1 mm /min is the

critical welding speed where there is drastic change in the a$erage micro hardness of a particular

sample with a definite welding parameter. So harness $alue is not only depends on the rotational

speed or welding speed it depends on the re$olutionary pitch i.e. %welding speed/rotational speed&

in mm per re$.

-10 -5 0 5 10

20

25

30

35

40

45

50

55

60

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld centre (mm)

900-16()

900-16(!-D")

-10 -8 -6 -4 -2 0 2 4 6 8 10

30

35

40

45

50

55

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld centre (mm)

1120-16()

1120-16(!-D")

-10 -8 -6 -4 -2 0 2 4 6 8 10

15

20

25

30

35

40

45

50

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld centre (mm)

1400-16()

1400-16(!-D")

-12 -10 -8 -6 -4 -2 0 2 4 6 8 10 12

20

25

30

35

40

45

50

55

60

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld centre (mm)

1800-16()

1800-16(!-D")

-10 -8 -6 -4 -2 0 2 4 6 8 10

20

25

30

35

40

45

50

55

60

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld center (mm)

900-31.5()

900-31.5 (!-D")

-10 -5 0 5 10

20

25

30

35

40

45

50

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld centre (mm)

1120-31.5()

1120-31.5(!-D")

-10 -8 -6 -4 -2 0 2 4 6 8 10

10

15

20

25

30

35

40

45

50

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld centre (mm)

1800-31.5()

1800-31.5(!-D")

-10 -8 -6 -4 -2 0 2 4 6 8 10

30

35

40

45

50

55

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld centre (mm)

1400-31.5()

1400-31.5(!-D")

-10 -5 0 5 10

25

30

35

40

45

50

H

a

r

d

n

e

s

s

(

H

V

)

Distance from t#e weld center (mm)

900-63()

900-63(!-D")

-10 -8 -6 -4 -2 0 2 4 6 8 10

30

35

40

45

50

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld centre(mm)

1120-63()

1120-63(!-D")

-10 -8 -6 -4 -2 0 2 4 6 8 10

30

35

40

45

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld centre (mm)

1400-63()

1400-63(!-D")

-10 -8 -6 -4 -2 0 2 4 6 8 10

30

35

40

45

50

H

a

r

d

n

e

s

s

(

H

V

)

Distance from weld centre (mm)

1800-63()

1800-63(!-D")

Fig.1 %a'l&: ffect of TT, ST'SP, and ST'DP on the nugget (one hardness

900-16 1120-16 1400-16 1800-16

35

40

45

H

a

r

d

n

e

s

s

(

H

V

)

sam$le $arameter

!-D"

%eldin& s$eed 16mm'min(const.)

900-31.5 1120-31.5 1400-31.5 1800-31.5

30

35

40

45

%eldin& s$eed 31.5 mm'min(const.)

H

a

r

d

n

e

s

s

(

H

V

)

!am$le $arameter

!-D"

900-63 1120-63 1400-63 1800-63

30

35

40

45

50

%eldin& s$eed 63 mm'min(const.)

H

a

r

d

n

e

s

s

(

H

V

)

!am$le $arameter

!-D"

Fig.- %a'c&: ffect of rotational speed on a$erage micro hardness of FS4 (one using TT J

ST'DP

900-16 900-31.5 900-63

35

40

45

50

(otational s$eed 900 (const.)

H

a

r

d

n

e

s

s

(

H

V

)

!am$le $arameter

!-D"

1120-16 1120-31.5 1120-63

30

32

34

36

38

40

42

44

(otational s$eed 1120 (const.)

H

a

r

d

n

e

s

s

(

H

V

)

!am$le $arameter

!-D"

1400-16 1400-31.5 1400-63

30

32

34

36

38

40

42

44

(otational s$eed 1400 (const.)

H

a

r

d

n

e

s

s

(

H

V

)

!am$le $arameter

!-D"

1800-16 1800-31.5 1800-63

32

34

36

38

40

42

44

(otational s$eed 1800 (const.)

H

a

r

d

n

e

s

s

(

H

V

)

!am$le $arameter

!-D"

Fig.> %a'd&: ffect of welding speed on a$erage micro hardness of FS4 (one using TT J ST'

DP

... Tensile testing

Fig + %a'l& shows all the comparati$e graphs corresponding to yield strength, ultimate tensile

strength, percentage of elongation and joint efficiency of the welded joints using twin tool

and single tool with dou#le pass. !t is seen that there is no significant $ariation in the yield

strength of the joints fa#ricated using twin tool and dou#le pass.

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

!am$le $arameter

900-16()

900-16(!-D")

)

!

4

*

!

i

n

5

$

a

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

!am$le $arameter

1120-16()

1120-16(!-D")

)

!

4

*

!

i

n

5

$

a

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

!am$le $arameter

1400-16()

1400-16(!-D")

)

!

4

*

!

i

n

5

$

a

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

!am$le $arameter

1800-16()

1800-16(!-D")

)

!

4

*

!

i

n

5

$

a

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

!am$le $arameter

900-31.5()

900-31.5(!-D")

)

!

4

*

!

i

n

5

$

a

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

!am$le $arameter

1120-31.5()

1120-31.5(!-D")

)

!

4

*

!

i

n

5

$

a

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

!am$le $arameter

1400-31.5()

1400-31.5(!-D")

)

!

4

*

!

i

n

5

$

a

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

!am$le $arameter

1800-31.5()

1800-31.5(!-D")

)

!

4

*

!

i

n

5

$

a

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

!am$le $arameter

900-63()

900-63(!-D")

)

!

4

*

!

i

n

5

$

a

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

!am$le $arameter

1120-63()

1120-63(!-D")

)

!

4

*

!

i

n

5

$

a

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

)

!

4

*

!

i

n

5

$

a

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

!am$le $arameter

1400-63()

1400-63(!-D")

)! *! +,-./ 0 12. ,33.

0

20

40

60

80

+

,

l

n

&

6

0

o

i

n

t

,

7

.

i

n

$

e

r

c

e

n

t

a

&

e

)

!

4

*

!

i

n

5

$

a

!am$le $arameter

1800-63()

1800-63(!-D")

Fig.+ %a'l&: ffect of TT and ST'DP on KS, CTS, @ age of elongation and joint efficiency of

the welded samples

Fig 5 shows the effect of rotational speed on yield strength at constant welding speed. !t is

seen that at a constant welding speed *+,, rpm shows higher yield strength in all the cases

using single tool with dou#le pass. Similarly from Fig.*, at a constant rotational speed -.

mm/min welding speed results higher yield strength using single tool with dou#le pass. ;ut

the $ariation in yield strength using #oth twin tool and single tool with dou#le pass at higher

rpm %*+,, rpm& and at higher welding speed %-. mm/min& is almost negligi#le. Further from

the comparati$e graphs it is o#ser$ed that .*.1 mm/min welding speeds is the critical point

where there is a sudden change in the mechanical strength for all the cases. This similar

scenario is o#ser$ed in case of ultimate strength, percentage of elongation and joint efficiency

also.

900-16 1120-16 1400-16 1800-16

35

40

45

50

)

!

i

n

5

"

a

!am$le $arameter

!-D"

%eldin& s$eed816 mm'min(const.)

900-31.5 1120-31.5 1400-31.5 1800-31.5

30

35

40

45

50

55

60

%eldin& s$eed831.5 mm'min(const.)

)

!

i

n

5

"

a

!am$le $arameter

!-D"

900-63 1120-63 1400-63 1800-63

38

40

42

44

46

48

50

%eldin& s$eed863 mm'min(const.)

)

!

i

n

5

"

a

!am$le "arameter

!-D"

Fig. 5 %a'c&: ffect of rotational speed on yield strength of welded joints using TT J ST'DP

900-16 900-31.5 900-63

35

40

45

50

55

60

(otational s$eed8900 r$m(const.)

)

!

i

n

5

"

a

!am$le $arameter

!-D"

1120-16 1120-31.5 1120-63

25

30

35

40

45

50

55

60

(otational s$eed81120 r$m(const.)

)

!

i

n

5

"

a

!am$le $arameter

!-D"

1400-16 1400-31.5 1400-63

35

40

45

50

55

60

(otational s$eed81400 r$m(const.)

)

!

i

n

5

"

a

!am$le $arameter

!-D"

1800-16 1800-31.5 1800-63

30

35

40

45

(otational s$eed81800 r$m(const.)

)

!

i

n

5

"

a

!am$le $arameter

!-D"

Fig.*, %a'd&: ffect of welding speed on yield strength of welded joints using TT J ST'DP

900-16 1120-16 1400-16 1800-16

40

50

60

90

80

90

100

110

120

%eldin& s$eed16 mm'min (const.)

*

!

i

n

5

"

a

!am$le $arameter

!-D"

900-31.5 1120-31.5 1400-31.5 1800-31.5

40

50

60

90

80

90

100

110

120

%eldin& s$eed 31.5 mm'min (const.)

*

!

i

n

5

"

a

!am$le $arameter

!-D"

900-63 1120-63 1400-63 1800-63

90

95

80

85

90

95

100

%eldin& s$eed863 mm'min (const.)

*

!

i

n

5

"

a

!am$le $arameter

!-D"

Fig.** %a'c&: ffect of rotational speed on CTS of welded joints using TT J ST'DP

900-16 900-31.5 900-63

40

50

60

90

80

90

100

110

120

(otational s$eed8900 r$m (const.)

*

!

i

n

5

"

a

!am$le $arameter

!-D"

1120-16 1120-31.5 1120-63

40

50

60

90

80

90

100

110

120

(otational s$eed81120 r$m (const.)

*

!

i

n

5

"

a

!am$le $arameter

!-D"

1400-16 1400-31.5 1400-63

60

90

80

90

100

110

120

(otational s$eed81400 r$m (const.)

*

!

i

n

5

"

a

!am$le $arameter

!-D"

1800-16 1800-31.5 1800-63

60

90

80

90

100

110

120

(otational s$eed81800 r$m (const.)

*

!

i

n

5

"

a

!am$le $arameter

!-D"

Fig.*6 %a'd&: ffect of welding speed on CTS of welded joints using TT J ST'DP

900-16 1120-16 1400-16 1800-16

0

5

10

15

20

25

30

35

40

%eldin& s$eed816mm'min (const.)

+

o

f

,

l

o

n

&

a

t

i

o

n

!am$le $arameter

!-D"

900-31.5 1120-31.5 1400-31.5 1800-31.5

0

5

10

15

20

25

30

35

40

%eldin& s$eed831.5 mm'min (const.)

+

o

f

,

l

o

n

&

a

t

i

o

n

!am$le $arameter

!-D"

900-63 1120-63 1400-63 1800-63

10

15

20

25

30

35

%eldin& s$eed863 mm'min (const.)

+

o

f

,

l

o

n

&

a

t

i

o

n

!am$le $arameter

!-D"

Fig.*. %a'c&: ffect of rotational speed on @age of elongation of welded joints using TT J

ST'DP

900-16 900-31.5 900-63

5

10

15

20

25

30

35

40

45

(otational s$eed8900 r$m (const.)

+

o

f

,

l

o

n

&

a

t

i

o

n

!am$le $arameter

!-D"

1120-16 1120-31.5 1120-63

0

5

10

15

20

25

30

35

40

45

(otational s$eed81120 r$m (const.)

+

o

f

,

l

o

n

&

a

t

i

o

n

!am$le $arameter

!-D"

1400-16 1400-31.5 1400-63

5

10

15

20

25

30

35

40

45

(otational s$eed81400 r$m (const.)

+

1

3

,

l

o

n

&

a

t

i

o

n

!am$le $arameter

!-D"

1800-16 1800-31.5 1800-63

20

22

24

26

28

30

(otational s$eed81800 r$m (const.)

+

o

f

,

l

o

n

&

a

t

i

o

n

!am$le $arameter

!-D"

Fig*: %a'd&: ffect of welding speed on @age of elongation of welded joints using TT J ST'

DP

900-16 1120-16 1400-16 1800-16

30

40

50

60

90

80

90

100

%eldin& s$eed816 mm'min (const.)

0

o

i

n

t

e

:

c

i

e

n

c

;

i

n

+

a

&

e

!am$le $arameter

!-D"

900-31.5 1120-31.5 1400-31.5 1800-31.5

20

30

40

50

60

90

80

90

100

%eldin& s$eed831.5 mm'min (const.)

0

o

i

n

t

e

:

c

i

e

n

c

;

i

n

+

a

&

e

!am$le $arameter

!-D"

900-63 1120-63 1400-63 1800-63

60

65

90

95

80

85

90

95

100

%eldin& s$eed863 mm'min (const.)

0

o

i

n

t

e

:

c

i

e

n

c

;

i

n

+

a

&

e

!am$le $arameter

!-D"

Fig.*1 %a'c&: ffect of rotational speed on joint efficiency of welded joints using TT J ST'DP

900-16 900-31.5 900-63

30

40

50

60

90

80

90

100

(otational s$eed8900 r$m (const.)

0

o

i

n

t

e

:

c

i

e

n

c

;

i

n

+

a

&

e

!am$le $arameter

!-D"

1120-16 1120-31.5 1120-63

20

30

40

50

60

90

80

90

100

(otational s$eed81120 r$m (const.)

0

o

i

n

t

e

:

c

i

e

n

c

;

i

n

+

a

&

e

!am$le $arameter

!-D"

1400-16 1400-31.5 1400-63

50

60

90

80

90

100

(otational s$eed81400 r$m (const.)

0

o

i

n

t

e

:

c

i

e

n

c

;

i

n

+

a

&

e

!am$le $arameter

!-D"

1800-16 1800-31.5 1800-63

50

60

90

80

90

100

(otational s$eed81800 r$m (const.)

0

o

i

n

t

e

:

c

i

e

n

c

;

i

n

+

a

&

e

!am$le $arameter

!-D"

Fig.*- %a'd&: ffect of welding speed on joint efficiency of welded joints using TT J ST'DP

!-D"

900-16

1120-16

1400-16

1800-16

900-31.5

1120-

31.5

1400-

31.5

1800-

31.5

900-63

1120-63

1400-63

1800-63

Fig.*>: "ppearance of the test pieces after tensile tests

Fig.*> shows the photographs of the test pieces after tensile testing using twin tool and single

tool with dou#le pass. From the figure it is seen that the fractured position in the weld reflects

the location of minimum hardness (one. This implies that the joint strength can #e correlated

with the micro hardness property.

..: Fractography

The fractured surface of the welded plate under tension is shown in the Ta#le . for twin tool

and single tool with dou#le passes. The presence of microscopic $oids of different si(e and

shape confirms the e2istence of ductile failure using scanning electron microscope. The

fractured surfaces of the tensile sample were populated with a large num#er of fine dimples

re$ealing failure due to ductile #eha$iour. This type of situation arises due to optimal material

mi2ing with grain refinement. ?n the contrary due to comple2 process parameter a less

ductile failure occur resulted in a less ductile failure or com#ination of ductile with #rittle

fracture or clea$age type. "t 5,, rpm and *- mm per min welding speed the welded

specimen shows different nature of fractured surface. Csing twin tool welded specimen is

fractured at the #ase metal (one #ut using single tool with dou#le pass the specimen #rea8s at

the weld (one region which shows partly ductile and partly #rittle fracture. Similarly with

twin tool the specimen #rea8s at the mid'(one of the weld region with *:,, rpm and *- mm

per min welding speed. The fractured surface shows a com#ination of ductile and clea$age

type fracture. Therefore when the specimen #rea8s at the weld (one or near#y (one the

fractured surface is the com#ination of ductile and #rittle fracture due to high heat generation

in that (one which causes intense plastic deformation.

Ta#le 6.

!mages of the fractured surface.

"<(<5,,( !-D"

900-16

1400-16

1800-31.5

900-63

1400-63

Donclusions

!n this in$estigation an attempt has #een made to study the effect of twin tool and single tool

with dou#le pass on the formation of friction stir welding (one in a commercially pure

aluminium alloy with different rotational speed and welding speed. From this, the following

conclusions are deri$ed:

*. Formation of defect free weld is a function of #oth rotational speed and welding

speed. 0oints fa#ricated at *+,, rpm and -. mm/min welding speed shows the highest

hardness profile compared to the other welded joints.

6. Further from the comparati$e graphs it is o#ser$ed that .*.1 mm/min welding speeds

is the critical point where there is a sudden change in the mechanical strength %yield

strength, ultimate tensile strength, percentage of elongation and joint efficiency& for

all the cases.

.. From the SM analysis it is o#ser$ed that the presence of microscopic $oids of

different si(e and shape confirms the e2istence of ductile failure.

<eferences

;armou(, M., Bi$i, M.K.;., 6,**. Fa#rication of in situ cu/sic composites using multi'pass

friction stir processing: $aluation of microstructural, porosity, mechanical and electrical

#eha$iour. Dompos part "'"ppl S, :6%*,&, *::1'*:1..

;rown, <., Tang, 4., <eynolds, ".P., 6,,5.Multi'pass friction stir welding in alloy >,1,'

T>:1*: ffects on weld response $aria#les and on weld properties. Mater Sci ng ", 1*.'

1*:, **1'*6*.

!(adi, )., Berlich, ".P., 6,*6. Distri#ution and sta#ility of car#on nanotu#es during multi'

pass friction stir processing of car#on nanotu#e/aluminium composites. Dar#on, 1,%*6&,

:>::':>:5.

0ana, S., Mishra, <.S., ;aumann, 0."., Brant, B., 6,*,. ffect of process parameters on

a#normal grain growth during friction stir processing of a cast "l alloy. Mater Sci ng ",

16+%*&, *+5'*55.

0ohannes, 9.;., Mishra, <.S., 6,,>. Multiple passes of friction stir processing for the creation

of super plastic >,>1 "luminium. Mater Sci ng ", :-:%*'6&, 611'6-,.

9eal, <., 9oureiro, "., 6,,:.Defects formation in friction stir welding of aluminium alloys.

Mater Sci Forum. :11'-, 655'.,6.

9eal, <.M., 9oureiro, "., 6,,+. ffect of o$erlapping friction stir welding passes in the

3uality of welds of aluminium alloys. Mater Design, 65%1&, 5+6'55*.

Ma, F.K., Sharma, S.<., Mishra, <.S., 6,,-. ffects of multiple'pass friction stir processing

on microstructure and tensile properties of a cast aluminium'silicon alloy. Scr. Mat. 1:%5&,

*-6.'*-6-.

Ma, F.K., Mishra, <.S., 9iu, F.D., 6,,5. Superplastic #eha$iour of micro'regions in two'pass

friction stir processed >,>1"l alloy. Mat Sci ng ", 1,1%*'6&, >,'>+.

Mishra, <.S., Ma, F.K., 6,,1. Friction stir welding and processing. Mater Sci ng < 1,, *'>+.

7andan, <., De#roy. T., ;hadeshia. ). K.D. )., 6,,+. <ecent ad$ances in friction stir

welding'process, weldment structure and properties. Prog Mater Sci. 1., 5+,'*,6..

7ata8a, K., Kim, K.B., Fujii, )., Tsumura, T., Koma(a8i, T., 6,,-. !mpro$ement of

mechanical properties of aluminium die casting alloy #y multi'pass friction stir processing.

Mater sci. ng ", :.>, 6>:'6+,.

7i, D.<., Iue, P., Ma, F.K., 6,**.ffect of Multiple'Pass Friction Stir Processing

?$erlapping on Microstructure and Mechanical Properties of "s'Dast 7i"l ;ron(e. Metall

Mater Trans ", :6%+&, 6*61'6*.1.

Sure8ha, K., Murty, ;.S., <ao, K.P., 6,,+.Microstructural Dharacteri(ation and corrosion

#eha$iour of multipass friction stir processed ""66*5 aluminium alloy. Surf Doat Tech, 6,6,

:,1>':,-+.

Thomas, 4.M., Staines, D.0., 4atts, .<., 7orris, !.M., 6,,1. The simultaneous use of two or

more friction stir welding tools, T4! 9td.report, Dam#ridge, CK.

Thomas, 4.M., *555. Friction Stir 4elding of Ferrous Materials: " feasi#ility Study,

Proceedings of the first !nternational Donference on Friction Stir 4elding, Thousand ?a8s,

D",T4!, paper on DD.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Simultaneous Use of Two or More Friction Stir Welding ToolsDocument6 pagesThe Simultaneous Use of Two or More Friction Stir Welding ToolsrobertalhaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Friction Stir Welding-Process Developmentannd VariantDocument21 pagesFriction Stir Welding-Process Developmentannd VariantrobertalhaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Friction Stir Welding Twin Tool Twin Tool MainaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool MainaxlerobertalhaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Friction Stir Welding Twin Tool ColletDocument1 pageFriction Stir Welding Twin Tool ColletrobertalhaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Friction Stir Welding Twin Tool Twin Tool ToolDocument1 pageFriction Stir Welding Twin Tool Twin Tool ToolrobertalhaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Friction Stir Welding Shridhar Rev-1Document26 pagesFriction Stir Welding Shridhar Rev-1robertalhaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Friction Stir Welding Twin Tool Twin Tool SideaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool SideaxlerobertalhaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Friction Stir WeldingDocument43 pagesFriction Stir WeldingrobertalhaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Friction Stir Welding Twin Tool Twin Tool ViewsDocument1 pageFriction Stir Welding Twin Tool Twin Tool ViewsrobertalhaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Friction Stir Welding Twin Tool Twin Tool Outer ShellDocument1 pageFriction Stir Welding Twin Tool Twin Tool Outer ShellrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool FlywheelDocument1 pageFriction Stir Welding Twin Tool FlywheelrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool GearDocument1 pageFriction Stir Welding Twin Tool GearrobertalhaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Friction Stir Welding ThesisDocument63 pagesFriction Stir Welding Thesisrobertalha80% (5)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Friction Stir Welding Twin Tool 1020ball BearingDocument1 pageFriction Stir Welding Twin Tool 1020ball BearingrobertalhaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Friction Stir WeldingDocument43 pagesFriction Stir WeldingrobertalhaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Friction Stir Welding-Process Developmentannd VariantDocument21 pagesFriction Stir Welding-Process Developmentannd VariantrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool ViewsDocument1 pageFriction Stir Welding Twin Tool Twin Tool ViewsrobertalhaNo ratings yet

- The Simultaneous Use of Two or More Friction Stir Welding ToolsDocument6 pagesThe Simultaneous Use of Two or More Friction Stir Welding ToolsrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool ToolDocument1 pageFriction Stir Welding Twin Tool Twin Tool ToolrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool SideaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool SideaxlerobertalhaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Friction Stir Welding Twin Tool FlywheelDocument1 pageFriction Stir Welding Twin Tool FlywheelrobertalhaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Friction Stir Welding Twin Tool Twin Tool Outer ShellDocument1 pageFriction Stir Welding Twin Tool Twin Tool Outer ShellrobertalhaNo ratings yet

- Friction Stir Welding Shridhar Rev-1Document26 pagesFriction Stir Welding Shridhar Rev-1robertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool MainaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool MainaxlerobertalhaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Friction Stir Welding Twin Tool ColletDocument1 pageFriction Stir Welding Twin Tool ColletrobertalhaNo ratings yet

- Friction Stir Welding ThesisDocument63 pagesFriction Stir Welding Thesisrobertalha80% (5)

- Friction Stir Welding Twin Tool GearDocument1 pageFriction Stir Welding Twin Tool GearrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool 1020ball BearingDocument1 pageFriction Stir Welding Twin Tool 1020ball BearingrobertalhaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Friction Stir Welding RS REPORT-1 (17th April 13)Document52 pagesFriction Stir Welding RS REPORT-1 (17th April 13)robertalha100% (1)

- Friction Stir Welding Report Ent111Document45 pagesFriction Stir Welding Report Ent111robertalhaNo ratings yet

- TIGAS Haldor TopsoeDocument25 pagesTIGAS Haldor TopsoeGabriele CentiNo ratings yet

- Recyclingand Reuseof TextileDocument47 pagesRecyclingand Reuseof TextileRey100% (1)

- Natural Fertilizer FormulationDocument11 pagesNatural Fertilizer Formulationsyamsu alamNo ratings yet

- Polymer CharacterizationDocument29 pagesPolymer CharacterizationCarlos Miguel Dacaimat0% (1)

- Bioplastic ProjectDocument15 pagesBioplastic ProjectSarthak Verma100% (1)

- Exp 2 Protein DeterminationDocument5 pagesExp 2 Protein DeterminationNur Fadhilah100% (1)

- Catalog of Harbison-Walker Refractories CO, Pittsburgh PA 1908Document188 pagesCatalog of Harbison-Walker Refractories CO, Pittsburgh PA 1908iMiklaeNo ratings yet

- Colorimeter Principle PDFDocument2 pagesColorimeter Principle PDFNicholasNo ratings yet

- Research Cold StorageDocument6 pagesResearch Cold StorageApivit MalichaiNo ratings yet

- ATP WorksheetDocument5 pagesATP WorksheetRyan De AlloNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- LS DYNA Aerospace Working Group Modeling Guidelines Document Version 19 1 Dated June 28, 2019 PDFDocument252 pagesLS DYNA Aerospace Working Group Modeling Guidelines Document Version 19 1 Dated June 28, 2019 PDFЮрий НовожиловNo ratings yet

- I-Chem Solution SDN BHD: Bmsolution Safety Data SheetDocument5 pagesI-Chem Solution SDN BHD: Bmsolution Safety Data SheetAmirHakimRusliNo ratings yet

- Mark Scheme (Results) Summer 2015: GCE Chemistry (6CH01/01) The Core Principles of ChemistryDocument21 pagesMark Scheme (Results) Summer 2015: GCE Chemistry (6CH01/01) The Core Principles of ChemistryAmeenIbrahimNo ratings yet

- Properties of Fluids: Lecture - 1Document40 pagesProperties of Fluids: Lecture - 1Nawaz441No ratings yet

- Ammonia Synthesis Process OverviewDocument31 pagesAmmonia Synthesis Process OverviewKhalid AkNo ratings yet

- Distillation Columns PDFDocument40 pagesDistillation Columns PDFJithuJohn86% (7)

- Selective Laser SinteringDocument24 pagesSelective Laser SinteringRahul GandhiNo ratings yet

- Solubility - WikipediaDocument14 pagesSolubility - Wikipediatsvmpm1765No ratings yet

- Dhuime Et Al. 2012 - ScienceDocument4 pagesDhuime Et Al. 2012 - ScienceLady Johana Buritica CortesNo ratings yet

- Effect of Sugarmill On Soil of DoiwalaDocument11 pagesEffect of Sugarmill On Soil of DoiwalaBilal BhatNo ratings yet

- Heat Exchanger Mid-Term ReportDocument18 pagesHeat Exchanger Mid-Term ReportkoanakistNo ratings yet

- 2 MS ElectrochemistryDocument7 pages2 MS ElectrochemistrysachinNo ratings yet

- Booklet 2 Topic 1Document61 pagesBooklet 2 Topic 1Sarah Al ObaidanNo ratings yet

- Dental Materials: Metals (Alloys) Non-MetalsDocument32 pagesDental Materials: Metals (Alloys) Non-MetalsShahriar honarmandNo ratings yet

- Tea Processing: How Leaves Become Black Tea in 4 StepsDocument27 pagesTea Processing: How Leaves Become Black Tea in 4 StepsSaidur Rahman KhanNo ratings yet

- Glass Fibre: Historical BackgroundDocument11 pagesGlass Fibre: Historical Backgroundapi-19731065100% (1)

- All Safe CatalogDocument94 pagesAll Safe CatalogSimon Robinson100% (1)

- Chapter 13 Oil Based MudsDocument65 pagesChapter 13 Oil Based Mudsمحمد أحمد عبداللطيفNo ratings yet

- Project Carburizing Lupu Stefan EnglezaDocument5 pagesProject Carburizing Lupu Stefan EnglezaStefan LupuNo ratings yet

- Medical Entrance Exam AnswersDocument24 pagesMedical Entrance Exam AnswersSanskruti ChavanNo ratings yet

- Eat That Frog!: 21 Great Ways to Stop Procrastinating and Get More Done in Less TimeFrom EverandEat That Frog!: 21 Great Ways to Stop Procrastinating and Get More Done in Less TimeRating: 4.5 out of 5 stars4.5/5 (3224)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterFrom EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterRating: 4 out of 5 stars4/5 (467)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingFrom EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingRating: 4.5 out of 5 stars4.5/5 (844)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Lightly: How to Live a Simple, Serene & Stress-free LifeFrom EverandLightly: How to Live a Simple, Serene & Stress-free LifeRating: 4 out of 5 stars4/5 (12)

- How To Win Friends And Influence PeopleFrom EverandHow To Win Friends And Influence PeopleRating: 4.5 out of 5 stars4.5/5 (6510)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldFrom EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldRating: 3.5 out of 5 stars3.5/5 (5)

- Plant Based Sauces and Dips Recipes: Beginner’s Cookbook to Healthy Plant-Based EatingFrom EverandPlant Based Sauces and Dips Recipes: Beginner’s Cookbook to Healthy Plant-Based EatingRating: 4.5 out of 5 stars4.5/5 (20)