Professional Documents

Culture Documents

Comparing Bond Strength of Steel Reinforcing Bars To Concrete Using Beam-End Specimens

Uploaded by

José Ramón Gutierrez100%(1)100% found this document useful (1 vote)

255 views4 pagesThis test method describes procedures to establish the relative bond strength of steel reinforcing bars in concrete. It is intended to determine the effects of surface preparation or condition (such as bar coatings) on the bond strength. The user of this standard must establish appropriate safety and health practices.

Original Description:

Original Title

A-944

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis test method describes procedures to establish the relative bond strength of steel reinforcing bars in concrete. It is intended to determine the effects of surface preparation or condition (such as bar coatings) on the bond strength. The user of this standard must establish appropriate safety and health practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

255 views4 pagesComparing Bond Strength of Steel Reinforcing Bars To Concrete Using Beam-End Specimens

Uploaded by

José Ramón GutierrezThis test method describes procedures to establish the relative bond strength of steel reinforcing bars in concrete. It is intended to determine the effects of surface preparation or condition (such as bar coatings) on the bond strength. The user of this standard must establish appropriate safety and health practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Designation: A 944 99

Standard Test Method for

Comparing Bond Strength of Steel Reinforcing Bars to

Concrete Using Beam-End Specimens

1

This standard is issued under the xed designation A 944; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes procedures to establish the

relative bond strength of steel reinforcing bars in concrete.

1.2 This test method is intended to determine the effects of

surface preparation or condition (such as bar coatings) on the

bond strength of deformed steel reinforcing bars (of sizes

ranging from No. 10 to No. 36 [No. 3 to No. 11]) to concrete.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in brackets are for information only.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 192/C 192M Practice for Making and Curing Concrete

Test Specimens in the Laboratory

2

E 4 Practices for Force Verication of Testing Machines

3

E 575 Practice for Reporting Data from Structural Tests of

Building Constructions, Elements, Connections, and As-

semblies

4

3. Terminology

3.1 Denitions of Terms Specic to This Standard:

3.1.1 bond strength, nmaximum measured load in a

tensile bond test of a steel reinforcing bar.

3.1.2 bonded length, nthe length of the test bar that is in

contact with concrete.

3.1.3 concrete cover, nminimum distance between the

surface of the test bar and the top or bottom of the test

specimen.

3.1.4 embedment length, nthe distance from the surface of

the concrete test specimen to the installed end of the steel

reinforcing bar. This equals the sum of the lead length and the

bonded length.

3.1.5 lead length, nthe length of the test bar that is not in

contact with concrete but is between the surface of the concrete

test specimen and the bonded length.

3.1.6 relative rib area, nratio of the projected rib area

normal to bar axis to the product of the nominal bar perimeter

and the center-to-center rib spacing.

3.2 Symbols:

C

b

5 Concrete cover, mm [in.].

d

b

5 Nominal diameter of reinforcing bar, mm [in.].

l

e

5 Embedment length, mm [in.].

4. Apparatus

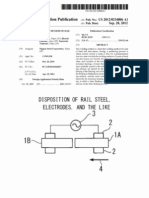

4.1 EquipmentA schematic of a suitable testing system is

shown in Fig. 1. The loading system shall be capable of

measuring the forces to an accuracy within 62 % of the

applied load, when calibrated in accordance with Practices E 4.

The test system shall have sufficient capacity to prevent

yielding of its various components and shall ensure that the

applied tensile load remains parallel to the axis of the steel

reinforcing bar during testing.

4.2 Compression Reaction PlateThe compression reac-

tion plate shall be placed a minimum clear distance equal to 0.9

l

e

measured from the center of the test bar to the edge of the

reaction plate.

4.3 Bar Displacement MeasurementsDisplacements of

the loaded and free ends of the steel reinforcing bar shall be

measured with respect to the loaded and free surfaces, respec-

tively, of the concrete using suitable measurement devices.

Dial gages having the smallest division of not more than 25 m

[0.001 in.] or linear variable differential transformers (LVDTs)

with equal or superior accuracy are examples of satisfactory

devices.

5. Test Specimen

5.1 Beam-End SpecimenThe test specimen shall consist

of the test bar cast in a block of reinforced concrete 600 6 25

mm [24 6 1 in.] long by d

b

+ 200 6 13 mm [d

b

+ 8 6

1

2 in.]

wide by a minimum of d

b

+ C

b

+ l

e

+ 60 mm [d

b

+ C

b

+ l

e

+ 2

1

2

in.] high. A typical test specimen is illustrated in Fig. 2. The

specimen shall be reinforced by four closed stirrups oriented

parallel to the sides of the specimen and two exural steel

1

This test method is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.05 on Steel Reinforcement.

Current edition approved Nov. 10, 1999. Published January 2000. Originally

published as A 944 95. Last previous edition A 944 95.

2

Annual Book of ASTM Standards, Vol 04.02.

3

Annual Book of ASTM Standards, Vol 03.01.

4

Annual Book of ASTM Standards, Vol 04.07.

1

Copyright ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

reinforcing bars parallel to the test bar, as shown in Fig. 2.

Transverse steel reinforcing bars similar to those illustrated in

Fig. 2 may be used to aid in fabrication and testing. The test bar

shall extend from the front surface a distance that is compatible

with the test system. Two polyvinyl chloride (PVC) pipes shall

be used as bond breakers to control the bonded length of the

bar and to avoid a localized cone-type failure of the concrete at

the loaded end of the specimen. The free end of the test bar

shall butt against a hollow steel conduit or other device to

provide access to the free end for measuring slip during the

test. The closed stirrups shall be fabricated from Grade 420

[Grade 60] No. 10 [No. 3] bars for test bars up to and including

No. 25 [No. 8] and No. 13 [No. 4] bars for test bars larger than

No. 25 [No. 8]. The two exural steel reinforcing bars shall be

selected so as to provide a total area not less than that of the test

bar.

NOTE 1The lead length, shown in Fig. 2, is typically between 13 and

100 mm [0.5 and 4 in.]. This unbonded region is used to prevent a

cone-type pullout failure at the surface of the concrete. Increases in lead

length generally result in an increase in bond strength.

5.2 FabricationThe concrete block shall be fabricated

using concrete designed to produce a strength at the time of test

between 31 and 38 MPa [4500 and 5500 psi]. The specimen

shall be cast in approximately equal layers not exceeding 250

mm [9 in.] in depth. Each layer shall be adequately consoli-

dated with an internal vibrator to ensure removal of entrapped

air.

NOTE 2The nominal maximum size course aggregate should be less

than or equal to

3

4 of the minimum clear space between reinforcement or

between reinforcement and the concrete surface of the beam-end speci-

men.

6. Conditioning

6.1 Specimen Conditioning and CuringThe test specimen

shall be cured in the forms using a curing compound or a

plastic membrane, or both, to prevent rapid evaporation of

FIG. 1 Schematic of Test Apparatus

A 944

2

water until the concrete has attained a strength of at least 14

MPa [2000 psi]. Specimen conditioning and curing shall be

such that the concrete strength shall be between 31 and 38 MPa

[4500 and 5500 psi] at the time of test, unless another concrete

strength is required. Standard concrete cylinders shall be

prepared in accordance with Practice C 192 using a represen-

tative sample of the concrete used to make the test specimen.

The concrete cylinders shall be cured adjacent to and in the

same manner as the test specimen. A minimum of two test

cylinders are required.

7. Procedure

7.1 A tensile load shall be applied to the test bar, as

illustrated in Fig. 1. The loading rate shall be such that failure

will not occur prior to 3 min after starting to load the test

specimens. Data recorded for a test shall include, as a mini-

mum, the initial load and displacement readings and the

maximum load.

NOTE 3The load rate should be between 10 to 33 % of the bond

strength per min. At least 10 intermediate displacement and load readings

should be taken.

8. Report

8.1 The report shall include the applicable information

listed in Practice E 575, and shall specically include the

following:

8.1.1 Dates of test and report,

8.1.2 Test sponsor and agency,

8.1.3 Identication of the bars tested: size, grade, mean

deformation height, mean deformation spacing, and, if re-

quired, the relative rib area,

8.1.4 Description of the steel reinforcing bar surface condi-

tion and coating (if used): manufacturer, trade name, and

coating designation,

8.1.5 Description of the fabrication and testing procedures,

if these deviated in any way from this test method,

8.1.6 Description of the concrete used, including mix de-

sign, aggregate type, compressive strength at the time of test

(average of a minimum of two cylinders), and age of the

concrete at the time of test,

8.1.7 Moisture condition of the concrete at the time of test:

saturated surface dry, air dry,

8.1.8 Concrete cover, embedment length and lead length of

FIG. 2 Beam-End Test Specimens

A 944

3

the installed reinforcement, in mm [in.],

8.1.9 Description of the test method, loading procedure

used, the displacements measured at each load step, and the

actual rate of loading,

8.1.10 Individual maximum load value (bond strength), in N

[lb], for each test specimen,

8.1.11 Photographs, sketches, word descriptions, or combi-

nations thereof, of the failure modes observed, and

8.1.12 Summary of ndings.

9. Precision and Bias

9.1 No statement is made on the precision or bias of this test

method since the test results indicate only whether there is

conformance to given criteria and since no generally accepted

method for determining precision and bias of this test method

is currently available. General guidelines provided herein for

the specimens, instrumentation, and procedures make the

results intractable to calculation of meaningful values by

statistical analysis for precision and bias at this time.

10. Keywords

10.1 beam-end test; coatings; concrete bond; steel reinforc-

ing bars

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at

610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org).

A 944

4

You might also like

- Flexural Strength ConcreteDocument3 pagesFlexural Strength ConcreteShantanu DuttaNo ratings yet

- Astm A266Document4 pagesAstm A26609122912680No ratings yet

- GCSE Combined Science SpecificationDocument120 pagesGCSE Combined Science Specificationpukhtoon92100% (2)

- Rebound Number of Hardened Concrete: Standard Test Method ForDocument3 pagesRebound Number of Hardened Concrete: Standard Test Method ForSNOWTOOSNo ratings yet

- A 829Document4 pagesA 829Gustavo SuarezNo ratings yet

- Astm C-496Document5 pagesAstm C-496Carlos R Martinez100% (2)

- Slab Track Laboratory Test ProgramDocument92 pagesSlab Track Laboratory Test ProgramYuvita ValentinaNo ratings yet

- C1150Document4 pagesC1150jodapero13No ratings yet

- Astm C-42Document8 pagesAstm C-42thescubatater100% (3)

- Acid Number Guide: Understanding AN TestsDocument11 pagesAcid Number Guide: Understanding AN Testsrajeevup2004No ratings yet

- Astm E1381-95Document7 pagesAstm E1381-95AngelPenumbrasNo ratings yet

- Is Iso 8528 6 2005Document21 pagesIs Iso 8528 6 2005Alaa SobhNo ratings yet

- Astm C273-00Document4 pagesAstm C273-00Arash AghagolNo ratings yet

- Calibration FundamentalsDocument39 pagesCalibration Fundamentalssina123100% (4)

- Astm C 1399Document5 pagesAstm C 1399Gabriel Cachi CernaNo ratings yet

- Astm C 393Document4 pagesAstm C 393Arash Aghagol0% (1)

- Astm C131Document4 pagesAstm C131Devi Suryono ArselorNo ratings yet

- Dedu404 Methodology of Educational Research and Statistics English PDFDocument332 pagesDedu404 Methodology of Educational Research and Statistics English PDFIT Admin100% (1)

- Flash Butt Welding Method for Rail Steel with Controlled Heat-Affected ZoneDocument20 pagesFlash Butt Welding Method for Rail Steel with Controlled Heat-Affected ZoneRakesh SrivastavaNo ratings yet

- A Practical Approach To Biological Assay ValidationDocument106 pagesA Practical Approach To Biological Assay ValidationEderveen100% (2)

- Astm C 497 PDFDocument9 pagesAstm C 497 PDFSerdarYumuk100% (2)

- E 519 - 02 Standard Test Method For Diagonal Tension (Shear) in Masonry AssemblagesDocument5 pagesE 519 - 02 Standard Test Method For Diagonal Tension (Shear) in Masonry Assemblagesenea3000No ratings yet

- Lead Scoring Case Study Summary-Mamta Lohani and Garima BansalDocument2 pagesLead Scoring Case Study Summary-Mamta Lohani and Garima BansalGopesh Singh100% (1)

- C1583 101932-1TensileBondPullOffDocument5 pagesC1583 101932-1TensileBondPullOffcarsongbakerNo ratings yet

- Dextra Headed Bar Calculation Tool For Griptec 2020 ENDocument6 pagesDextra Headed Bar Calculation Tool For Griptec 2020 ENKevin ArNo ratings yet

- Finite Element Analysis of Deep Beams On Nonlinear Elastic FoundationsDocument30 pagesFinite Element Analysis of Deep Beams On Nonlinear Elastic FoundationsMostafa NouhNo ratings yet

- Hilti - Anchor Systems PDFDocument38 pagesHilti - Anchor Systems PDFxpipespipescom100% (1)

- Certified Engineering Technologist A Complete Guide - 2020 EditionFrom EverandCertified Engineering Technologist A Complete Guide - 2020 EditionNo ratings yet

- Concrete StandardsDocument2 pagesConcrete StandardsOwen PerrinNo ratings yet

- Contentcode 4Document4 pagesContentcode 4mohamed ahmedNo ratings yet

- C 803 - C 803M - 97 Qzgwmy9dodazts1sruqDocument6 pagesC 803 - C 803M - 97 Qzgwmy9dodazts1sruqTemur LomidzeNo ratings yet

- B769Document4 pagesB769wpwmhatNo ratings yet

- Astm A944 10Document4 pagesAstm A944 10mohamed ellithyNo ratings yet

- Is 5816 Splitting Tesile Strength of Concrete-Method of Test.182112830Document11 pagesIs 5816 Splitting Tesile Strength of Concrete-Method of Test.182112830shinjinkuroNo ratings yet

- C 1173 - 97 Qzexnzmtotc - PDFDocument4 pagesC 1173 - 97 Qzexnzmtotc - PDFMung Duong XuanNo ratings yet

- C1399.1613807-1-Standard Test Method For Obtaining Average Residual-StrengthDocument6 pagesC1399.1613807-1-Standard Test Method For Obtaining Average Residual-Strengthsyndicate_mauliNo ratings yet

- ''C496.142250 Splitting Tensile Strength of ConcreteDocument5 pages''C496.142250 Splitting Tensile Strength of ConcreteAbu Bakar Muzamil ButtNo ratings yet

- ASTM-Designation G109 99aDocument5 pagesASTM-Designation G109 99aJorge LeconaNo ratings yet

- MTPPT6Document31 pagesMTPPT6EunnicePanaliganNo ratings yet

- Norma TestDocument3 pagesNorma TestIvan Huilcapaz MoraNo ratings yet

- Standard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Document5 pagesStandard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Lupita RamirezNo ratings yet

- C803C803M Penetration Resistance of Hardened Concrete PDFDocument5 pagesC803C803M Penetration Resistance of Hardened Concrete PDFPrasanna S KulkarniNo ratings yet

- Concrete Pipe, Manhole Sections, or Tile: Standard Test Methods ForDocument14 pagesConcrete Pipe, Manhole Sections, or Tile: Standard Test Methods ForBalmore MartinezNo ratings yet

- Astm D 897 - 01 - RDG5NWDocument3 pagesAstm D 897 - 01 - RDG5NWphaindikaNo ratings yet

- ASTM (Los Angeles Test)Document4 pagesASTM (Los Angeles Test)Efri DwiyantoNo ratings yet

- CSSBI S2-2008:: Criteria For The Testing of Composite SlabsDocument4 pagesCSSBI S2-2008:: Criteria For The Testing of Composite SlabsPhablo GustavoNo ratings yet

- E190 1044228-1Document4 pagesE190 1044228-1mantra2010No ratings yet

- C 651Document4 pagesC 651Asep TheaNo ratings yet

- B 565 - 94 R00 - Qju2ns05nfiwmaDocument3 pagesB 565 - 94 R00 - Qju2ns05nfiwmamalika_00No ratings yet

- C 273-00Document4 pagesC 273-00Khan ShahzebNo ratings yet

- Astm c131 06 LaavDocument4 pagesAstm c131 06 LaavRasya FiezaNo ratings yet

- B 565 - 04 - Qju2nqDocument3 pagesB 565 - 04 - Qju2nqmalika_00No ratings yet

- C 158 Â " 95 R00 QZE1OC1SRUQDocument12 pagesC 158 Â " 95 R00 QZE1OC1SRUQCesar PazNo ratings yet

- Wind Resistance of Concrete and Clay Roof Tiles (Mechanical Uplift Resistance Method)Document6 pagesWind Resistance of Concrete and Clay Roof Tiles (Mechanical Uplift Resistance Method)Ahmed Alzubaidi100% (1)

- Reconfirmation Notice: AS 1012.10-2000 (Reconfirmed) 2014-10-24Document9 pagesReconfirmation Notice: AS 1012.10-2000 (Reconfirmed) 2014-10-24heyh jdjNo ratings yet

- Reconfirmation Notice: AS 1012.3.4-1998 (Reconfirmed) 2014-10-24Document9 pagesReconfirmation Notice: AS 1012.3.4-1998 (Reconfirmed) 2014-10-24heyh jdjNo ratings yet

- Aashto M-33-99Document5 pagesAashto M-33-99Ba Lestari Wijanarko100% (1)

- C 947 PDFDocument3 pagesC 947 PDFGrato Jr Singco100% (1)

- Aashto T-97-10Document5 pagesAashto T-97-10Roberto VasquezNo ratings yet

- C 158 - 02 - Qze1oaDocument9 pagesC 158 - 02 - Qze1oaStuartNo ratings yet

- Is 5816:1999Document14 pagesIs 5816:1999DarsHan MoHan100% (1)

- ASTM D 1634-00 Standard Test Method For Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method)Document3 pagesASTM D 1634-00 Standard Test Method For Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method)Pablo Antonio Valcárcel VargasNo ratings yet

- D 4543 - 85 R91 - (Ingles)Document7 pagesD 4543 - 85 R91 - (Ingles)FrancisNo ratings yet

- A 74 - 03 Qtc0lvjfraDocument5 pagesA 74 - 03 Qtc0lvjfraMarko's Brazon'No ratings yet

- Norma ASTM A 413Document4 pagesNorma ASTM A 413Elvin Leonardo Encarnacion PeraltaNo ratings yet

- Evaluating Bond Strength For 15.2 MM (0.6 In.) Diameter Prestressing Steel Strand, Grade 270, Uncoated, Used in Prestressed Ground AnchorsDocument3 pagesEvaluating Bond Strength For 15.2 MM (0.6 In.) Diameter Prestressing Steel Strand, Grade 270, Uncoated, Used in Prestressed Ground AnchorsProduction DepartmentNo ratings yet

- Test Procedure A S Per EN 1994-1-1 2004 (E)Document5 pagesTest Procedure A S Per EN 1994-1-1 2004 (E)nrtparNo ratings yet

- Comparing Concrete On The Basis of The Bond Developed With Reinforcing SteelDocument4 pagesComparing Concrete On The Basis of The Bond Developed With Reinforcing SteelEvert RiveraNo ratings yet

- Tensile Stress-Strain of Carbon and Graphite: Standard Test Method ForDocument12 pagesTensile Stress-Strain of Carbon and Graphite: Standard Test Method Forsj19330No ratings yet

- D 1628 - 94 R00 Rde2mjgDocument4 pagesD 1628 - 94 R00 Rde2mjgJosé Ramón GutierrezNo ratings yet

- D 1758 - 02 Rde3ntgDocument8 pagesD 1758 - 02 Rde3ntgJosé Ramón GutierrezNo ratings yet

- D 6 - 95 R00 RdyDocument3 pagesD 6 - 95 R00 RdyJosé Ramón GutierrezNo ratings yet

- Steel, Strip, Carbon (0.25 Maximum Percent), Cold-Rolled: Standard Specification ForDocument8 pagesSteel, Strip, Carbon (0.25 Maximum Percent), Cold-Rolled: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- D 3737 - 02 Rdm3mzctukveDocument32 pagesD 3737 - 02 Rdm3mzctukveJosé Ramón GutierrezNo ratings yet

- Tension Testing of Wire Ropes and Strand: Standard Test Method ForDocument5 pagesTension Testing of Wire Ropes and Strand: Standard Test Method ForJosé Ramón GutierrezNo ratings yet

- D 2719 - 89 R01 Rdi3mtkDocument10 pagesD 2719 - 89 R01 Rdi3mtkJosé Ramón GutierrezNo ratings yet

- D 1165 - 03 RdexnjuDocument10 pagesD 1165 - 03 RdexnjuJosé Ramón GutierrezNo ratings yet

- Round Timber Piles: Standard Specification ForDocument7 pagesRound Timber Piles: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- D 5716 - 95 R00 - Rdu3mtyDocument4 pagesD 5716 - 95 R00 - Rdu3mtyRufo CascoNo ratings yet

- E 273 - 01 Rti3mwDocument4 pagesE 273 - 01 Rti3mwJosé Ramón GutierrezNo ratings yet

- E 431 - 96 RTQZMS05NGDocument7 pagesE 431 - 96 RTQZMS05NGJosé Ramón GutierrezNo ratings yet

- Sizes of Ferroalloys and Alloy Additives: Standard Specification ForDocument2 pagesSizes of Ferroalloys and Alloy Additives: Standard Specification ForGustavo SuarezNo ratings yet

- A-325 - 00Document8 pagesA-325 - 00José Ramón GutierrezNo ratings yet

- Steel Forgings, Microalloy, For General Industrial UseDocument3 pagesSteel Forgings, Microalloy, For General Industrial UseGustavo SuarezNo ratings yet

- Zinc-5 % Aluminum-Mischmetal Alloy-Coated Steel Overhead Ground Wire StrandDocument3 pagesZinc-5 % Aluminum-Mischmetal Alloy-Coated Steel Overhead Ground Wire StrandJosé Ramón GutierrezNo ratings yet

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessDocument9 pagesGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessJosé Ramón GutierrezNo ratings yet

- Life-Cycle Cost Analysis of Corrugated Metal Pipe Used For Culverts, Storm Sewers, and Other Buried ConduitsDocument5 pagesLife-Cycle Cost Analysis of Corrugated Metal Pipe Used For Culverts, Storm Sewers, and Other Buried ConduitsJosé Ramón GutierrezNo ratings yet

- Steel Castings, Austenitic Manganese: Standard Specification ForDocument2 pagesSteel Castings, Austenitic Manganese: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Metallic-Coated Steel Marcelled Tension Wire For Use With Chain Link FenceDocument3 pagesMetallic-Coated Steel Marcelled Tension Wire For Use With Chain Link FenceJosé Ramón GutierrezNo ratings yet

- Steel Forgings, Microalloy, For General Industrial UseDocument3 pagesSteel Forgings, Microalloy, For General Industrial UseGustavo SuarezNo ratings yet

- A230a230 PDFDocument4 pagesA230a230 PDFtoys_chileNo ratings yet

- Defining and Rating The Microstructure of High Carbon Bearing SteelsDocument5 pagesDefining and Rating The Microstructure of High Carbon Bearing SteelsJosé Ramón GutierrezNo ratings yet

- Astm D-664Document7 pagesAstm D-664José Ramón GutierrezNo ratings yet

- Life-Cycle Cost Analysis of Corrugated Metal Pipe Used For Culverts, Storm Sewers, and Other Buried ConduitsDocument5 pagesLife-Cycle Cost Analysis of Corrugated Metal Pipe Used For Culverts, Storm Sewers, and Other Buried ConduitsJosé Ramón GutierrezNo ratings yet

- A 953Document3 pagesA 953José Ramón GutierrezNo ratings yet

- Astma 516Document3 pagesAstma 516EdirwinJoseChirinosNo ratings yet

- Exploring GEMBA - A New LLM-Based Metric For Translation Quality Assessment - by Dr. Varshita Sher - Sep, 2023 - Towards Data ScienceDocument10 pagesExploring GEMBA - A New LLM-Based Metric For Translation Quality Assessment - by Dr. Varshita Sher - Sep, 2023 - Towards Data SciencePooja AgrawalNo ratings yet

- BSMH2013 2 2018 2019Document7 pagesBSMH2013 2 2018 2019Muhammad SyafiqNo ratings yet

- Carbon Footprint RubricDocument1 pageCarbon Footprint Rubricgeoplex3917No ratings yet

- WIA1006 Report (OrionX)Document42 pagesWIA1006 Report (OrionX)shu minNo ratings yet

- Introduction To Business MathematicsDocument44 pagesIntroduction To Business MathematicsAbdullah ZakariyyaNo ratings yet

- Menu MerchandisingDocument73 pagesMenu MerchandisingChandan Srivastava80% (5)

- Machine Learning With Scikit-Learn: George BoormanDocument34 pagesMachine Learning With Scikit-Learn: George BoormanASNo ratings yet

- Pahang - Maran Skema Bahasa Inggeris K1K2 Trial SPM 2020Document12 pagesPahang - Maran Skema Bahasa Inggeris K1K2 Trial SPM 2020Atikah AmaranNo ratings yet

- 3 Guia Eurachem Medición de La Incertidumbre Derivada Del Muestreo (Ingles) REVISADADocument111 pages3 Guia Eurachem Medición de La Incertidumbre Derivada Del Muestreo (Ingles) REVISADAyesypaoNo ratings yet

- AutoFom III EnglishDocument6 pagesAutoFom III EnglishcarnevermelhaNo ratings yet

- NTRODUCTION Gis ArthiDocument104 pagesNTRODUCTION Gis ArthivanajaNo ratings yet

- Experiment 1 Measurement and Uncertainty: Department of Physics Addis Ababa University Sample La ReportDocument11 pagesExperiment 1 Measurement and Uncertainty: Department of Physics Addis Ababa University Sample La Reportermias gezahegnNo ratings yet

- GROUP 6 EXPERIMENT No.1 MEASUREMENTDocument8 pagesGROUP 6 EXPERIMENT No.1 MEASUREMENTRAHFAEL RADOCNo ratings yet

- Aircraft MaintenanceDocument8 pagesAircraft MaintenanceridwansadelyNo ratings yet

- Performance Monitoring ManualDocument80 pagesPerformance Monitoring ManualjalanjalancarimakanNo ratings yet

- Astm D 6230 98Document6 pagesAstm D 6230 98santisteban camposNo ratings yet

- Measurement Uncertainty According To ISO 19036:2019Document8 pagesMeasurement Uncertainty According To ISO 19036:2019ghadeerNo ratings yet

- (9702/2 M/J02 Q1) (9702/02/M/J/05 Q1) : TOPIC 1: Physical Quantities and UnitsDocument454 pages(9702/2 M/J02 Q1) (9702/02/M/J/05 Q1) : TOPIC 1: Physical Quantities and UnitsYashwinni VijayasekarNo ratings yet

- D2843 16 PDFDocument9 pagesD2843 16 PDFFernando Da RosNo ratings yet

- Authorised dealer surveying instruments GujaratDocument1 pageAuthorised dealer surveying instruments Gujaratmanish upadhyayNo ratings yet

- Sensor Measurements Using A Digital MultimeterDocument10 pagesSensor Measurements Using A Digital MultimeterGordinhorsNo ratings yet

- Research Methodology: Romi Satria WahonoDocument381 pagesResearch Methodology: Romi Satria WahonoDiar AbhistaNo ratings yet

- Ib Mathematics Internal Assessment Student Handout: Ellen Thompson Updated May 2020Document20 pagesIb Mathematics Internal Assessment Student Handout: Ellen Thompson Updated May 2020Jordy Van KollenburgNo ratings yet