Professional Documents

Culture Documents

3 Deec 516026 A 53266 D

Uploaded by

Besian SinaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Deec 516026 A 53266 D

Uploaded by

Besian SinaniCopyright:

Available Formats

Bull Earthquake Eng

DOI 10.1007/s10518-010-9190-x

ORIGINAL RESEARCH PAPER

Ultimate chord rotation of RC columns with smooth

bars: some considerations about EC8 prescriptions

Gerardo M. Verderame Paolo Ricci

Gaetano Manfredi Edoardo Cosenza

Received: 30 July 2009 / Accepted: 8 May 2010

Springer Science+Business Media B.V. 2010

Abstract Current code prescriptions allow to evaluate the ultimate rotational capacity

from hybrid (mechanical-empirical) or empirical formulations, for reinforced concrete (RC)

members with ribbed bars and seismically detailed. These formulations can be extended

to non-conforming elements, including members with smooth bars, by means of correction

coefcients calibrated on experimental data. These coefcients imply a reduction in the defor-

mation capacity, which increases if lapping of longitudinal bars is present. The reliability

of empirically calibrated coefcients directly depends on the extension of the experimental

database, that is, on the number of available tests. The experimental campaign carried out

at the University of Naples on 16 real-scale columns with smooth bars allows to extend

the experimental database for this typology. Experimental results highlight that rotational

capacity of columns with smooth bars is rather large, even higher than the capacity of similar

columns reinforced with ribbed bars. This is basically due to the increase in deformability

caused by the xed-end rotation mechanism, particularly exalted when bond capacities are

low. Therefore, also based on these results, new correction coefcients are proposed.

Keywords Seismic assessment Existing RC building Non-conforming

Ultimate capacity Smooth bars Lapping

1 Introduction

The present European technical regulations (CEN 2005) allow to determine the seismic

capacity of existing reinforced concrete (RC) buildings by means of non-linear analysis

methodologies. The use of such methods of analysis, however, requires knowledge of the real

post-elastic rotational capacities of each element of the construction (beams, columns) both

in monotonic eld, for non-linear static analysis, and in cyclic eld, for non-linear dynamic

analysis. In monotonic eld, a series of parameters (yielding, peak resistance, ultimate state)

G. M. Verderame (B) P. Ricci G. Manfredi E. Cosenza

Department of Structural Engineering, University of Naples Federico II, Via Claudio 21,

80125 Naples, Italy

e-mail: verderam@unina.it

1 3

Bull Earthquake Eng

has to be dened, in order to dene the response curve of the element. In cyclic eld, hyster-

etic rules and strength and stiffness degradation models have to be dened; they significantly

inuence the assessment of ultimate rotational capacity. Nevertheless, these rules are not easy

to dene, due to the number of geometrical and mechanical parameters and to the uncertain-

ties involved. For example, the type of loading inuences in a not negligible way the response

of the RC element. Most of the code prescriptions only dene the deformation capacity at

the elastic limit (yielding) and at ultimate (collapse); therefore, based on these prescriptions,

it is not possible to completely dene the strength degradation of the monotonic envelope,

nor the hysteretic behaviour through appropriate rules.

Generally, deformation at yielding is evaluated as a chord rotation, accounting for dif-

ferent contributions corresponding to bending, shear and xed-end rotation deformation

mechanisms.

The rotational capacity is generally evaluated referring to a xed strength decay (20%)

respect to the peak resistance, evaluated on the force-displacement envelope curve. It is clear

that this definition is strongly inuenced by the maximum resistance condition, as well as

the post-peak degradation, monotonic or cyclic. It is difcult to dene a relationship between

the element parameters and the rotational capacity, due to the complex phenomena inu-

encing the post-elastic deformation behaviour and to the natural variability affecting these

phenomena. The code, consistently with the methodologies developed in literature, proposes

two main approaches: a mechanical-empirical approach, based on plastic hinge length con-

cept, and a purely empirical approach. In the present study these approaches are described

in Sect. 2, together with their background theory. Literature proposals for the evaluation of

ultimate capacity of RC elements are also presented (e.g. Panagiotakos and Fardis 2001;

Rossetto 2002; Lam et al. 2003; Perus et al. 2006; Perus and Fajfar 2007; Haselton and

Deierlein 2007; Fardis 2007; Zhu et al. 2007); development of empirically calibrated expres-

sions is allowed by experimental databases, made available by authors (Panagiotakos and

Fardis 2001; Berry et al. 2004) that collected results of experimental tests carried out by

many others.

In this study, referring to the purely empirical formulation proposed in (CEN 2005), the

applicability of this formulation to non-conforming elements with smooth bars is evaluated.

In particular, experimental data for the assessment of deformation capacity of RC elements

with smooth bars are presented in Sect. 3. Based on these data, in Sect. 4 correction coef-

cients applied to the code formulation for elements with smooth bars, with or without lapping

of longitudinal reinforcement, are proposed.

2 Evaluation of ultimate chord rotation

In this section, the theoretical background of current European code (CEN 2005) formulas

for the ultimate rotational capacity of RC members is presented. Principles and methodol-

ogies standing behind the two main approaches to the assessment of this value (mechan-

ical and empirical) are introduced. Further explanation of equation parameters introduced

herein is not reported for the sake of brevity; it is available in code or in reference literature

works.

2.1 Code formulas (EC8 part 3.3)

Eurocode 8Part 3 at section A.3.2.2 (Limit state of near collapse) provides expressions

for the evaluation of ultimate element capacity of RC elements. The value of total chord

1 3

Bull Earthquake Eng

rotation capacity under cyclic loading, following a mechanical approach, is given by [EC8

Eq. (A.1)]:

um

=

1

el

0.016

_

0.30

_

_

max

_

0.01;

_

max (0.01; )

f

c

_

0.225 _

L

V

h

_

0.35

25

_

sx

f

yw

f

c

_

_

1.25

100

d

_

(1)

where

el

, equal to 1.5 for primary seismic elements and to 1.0 for secondary seismic

elements, is meant to convert mean values of chord rotation to mean-minus-one-standard-

deviation ones. The code also provides another expression for the evaluation of the plastic

part of the ultimate chord rotation [EC8Eq. (A.3)]:

pl

um

=

um

y

=

1

el

0.0145

_

0.25

_

_

max

_

0.01;

_

max (0.01; )

_

0.3

f

0.2

c

_

L

V

h

_

0.35

25

_

sx

f

yw

f

c

_

_

1.275

100

d

_

(2)

To evaluate the total chord rotation, the plastic part calculated according to this formula

should be added to the rotation at yielding [EC8Eq. (A.10)].

The values of chord rotation calculated according to (1) and (2) apply to elements with

ribbed bars, seismically detailed and without lapping of longitudinal bars in the vicinity of

the end region where yielding is expected (plastic hinge region).

The correction coefcient applied to members with ribbed bars without seismic detailing

is equal to 0.825 for both formulas. If the longitudinal ribbed bars are lapped, expressions

(1) and (2) should be applied doubling the mechanical compression reinforcement ratio (

).

Moreover, if the lap length is less than the minimum value l

ou,min

:

l

ou,min

= d

bL

f

yL

/

__

1.05 + 14.5

1

sx

f

yw

f

c

_

_

f

c

_

(3)

another reduction factor equal to (l

o

/l

ou,min

) should be applied, calibrated only for expression

(2), that is only for the plastic part of chord rotation. Corrections applied to the chord rotation

at yielding are given at section A.3.2.4(3) of the code; they are omitted here for the sake of

brevity.

In elements with smooth bars the chord rotation evaluated according to (1) should be mul-

tiplied by 0.575, while the plastic part of chord rotation given by (2) should be multiplied by

to 0.375. Its worth noting that both coefcients already include the reduction factor equal to

0.825, accounting for the lack of seismic detailing. If longitudinal bars are lapped in members

with smooth bars, another coefcient has to be adopted, depending on the lap length (l

o

) and

the shear span (L

V

). For total chord rotation, it is given by:

0.0025 [180 + min(50, l

o

/d

bL

)] (1 l

o

/L

V

) (4)

while for the only plastic part it is:

0.0035 [60 + min(50, l

o

/d

bL

)] (1 l

o

/L

V

) (5)

Moreover, shear span in expressions (1) and (2) should be reduced by the lap length l

o

,

assuming that the ultimate condition is controlled by the region right after the end of the lap.

Adocument has beenpresented(Corrigenda toEN1998-3Document CEN/TC250/SC

8/N437A (CEN 2009)) changing some provisions of Eurocode 8part 3 (CEN 2005), also

1 3

Bull Earthquake Eng

including prescriptions about ultimate deformation capacity of members with smooth bars,

which have been illustrated herein. The coefcients 0.575 and 0.375, applied to Eqs. 1 and

2 for elements with smooth bars, have been changed into 0.80 and 0.75, respectively. In

both cases, these coefcients already include the reduction factor accounting for the lack

of seismic detailing, which has been changed from 0.825 to (1/1.20 =0.833). Formulations

(4) and (5), for elements with lapping of longitudinal smooth bars, have been significantly

changed, too. Expression (4), applied to total ultimate chord rotation, has been replaced by:

0.019 [10 + min(40, l

o

/d

bL

)] (4a)

Expression (5), applied to the plastic part of ultimate chord rotation, has been replaced by:

0.019 min(40, l

o

/d

bL

) (5a)

In these cases, coefcients do not include the reduction factor accounting for the lack of

seismic detailingequal to 1/1.20which has to be applied.

The deformation capacity of elements with smooth barsevaluated by means of coef-

cients applied to Eq. 1 or 2according to (CEN 2009) is higher than previously prescribed

by (CEN 2005).

In the following, both the formulations given in draft 2005 of Eurocode 8part 3 and the

later proposed changes will be reported. They will by referred to as (CEN 2005) and (CEN

2009), respectively.

The ultimate rotation may also be calculated following an equivalent mechanical approach

through the evaluation of the plastic ultimate section curvature (

u

y

), assumed to be con-

stant over the plastic hinge length L

pl

, which is empirically calibrated. Hence, the ultimate

rotational capacity may be evaluated according to [EC8Eq. (A.4)]:

um

=

1

el

_

y

+ (

u

y

)L

pl

_

1 0.5

L

pl

L

V

__

(6)

Section curvatures at ultimate

u

and at yielding

y

are calculated based on the rst prin-

ciples, with the constitutive relationships given by Eurocode 2 (CEN 2004). If the concrete

connement model given in 3.1.9 in Eurocode 2 is assumed, the plastic hinge length is equal

to [EC8Eq. (A.5)]:

L

pl

= 0.10L

V

+ 0.17h + 0.24

d

bL

f

y

f

c

(7)

If the connement model proposed by Eurocode 8part 3 is adopted, better representing the

effects of connement under cyclic loading, the plastic hinge length is given by:

L

pl

=

L

V

30

+ 0.20h + 0.11

d

bL

f

y

f

c

(8)

For expressions (7) and (8) no correction factor accounting for the above mentioned decien-

cies is given. Therefore, they should only be applied to members with ribbed bars, seismically

detailed and without lapping of longitudinal bars.

2.2 Mechanical approach: background theory

Froma phenomenological standpoint, the plastic hinge region can be identied with the zone

of the element where yielding of reinforcement and concrete crushing take place. The plas-

tic hinge length used in the evaluation of the element rotational capacity is, instead, purely

conventional. It only represents the length over which ultimate section curvature, assumed

1 3

Bull Earthquake Eng

to be constant, is integrated, following an equivalent bending approach, to calculate the

effective chord rotation including shear and xed-end rotation contributions to the overall

deformability of the member; the curvature is calculated based on Bernoullis plane section

assumption.

The plastic hinge length can not be evaluated based on a purely mechanical approach. As

a matter of fact, based on section equilibrium conditions and full-interaction hypothesis, in

a post-peak phase the curvature should increase only at the base section of the element (zero

length hinge problem) (Daniell et al. 2008; Haskett et al. 2009). Moreover, a purely mechani-

cal approach, leading to the evaluation of exural deformability, would not account for other

deformation mechanisms such as shear deformability and slippage of reinforcing bars from

the connection element. These contributions are not negligible at all. Shear mechanisms may

contribute in the overall post-elastic member deformability up to 30% (Fenwick and Megget

1993), whilst the end rotation due to the slippage of reinforcing bars may contribute up to

40% (Sezen 2002).

Therefore, researchers over years have empirically calibrated the plastic hinge length

over which theoretical ultimate section curvature is integrated, aiming at achieving the best

agreement with experimental values of ultimate chord rotation.

Following this approach, rotational capacity of an element may be expressed as:

u

=

y

+ (

u

y

)L

pl

(9)

where the plastic hinge length L

pl

is made up of three terms, corresponding to different

deformation mechanisms:

L

pl

= L

pl,ex

+ L

pl,shear

+ L

pl,slip

(10)

Table 1 reports main formulations that have been proposed over years, starting from the rst

fundamental work by Baker (1956). These expressions show that the shear span L

V

and

the section depth h are the major variables inuencing the plastic hinge length, while the

term corresponding to xed-end rotation is generally proportional to diameter and yielding

strength of longitudinal reinforcement bars. First proposed formulations are mainly calibrated

based on experimental tests on beam elements, therefore the xed-end rotation contribution

is not clearly evaluated. In recent formulations, calibrated also on column elements, this

contribution is clearly represented instead.

Moreover, in (9) the ultimate condition is given in terms of curvature

u

, depending,

based on plane section hypothesis, on steel or concrete failure. Nevertheless, the evaluation

of ultimate curvature is not easy or univocal, due to the inuence of some aspects as concrete

connement, spalling of the concrete cover or buckling of compressive reinforcing bars. For

example, the use of different connement models may significantly inuence the determi-

nation of the ultimate curvature, therefore the plastic hinge length can assume very different

values.

The plastic hinge formulation proposed in Panagiotakos and Fardis (2001) is the most

interesting among the expressions presented in literature. It is based on an extensive experi-

mental database, which will be discussed in the next paragraph.

The ultimate chord rotation is given by:

u

=

y

L

V

3

+ (

u

y

)L

pl

_

1 0.5

L

pl

L

V

_

(11)

1 3

Bull Earthquake Eng

Table 1 Empirically derived

plastic hinge lengths

Reference Plastic hinge length (L

pl

)

Baker (1956) k

1

k

2

k

3

(z/d)

1/4

d

Mattock

(1964)

d

2

_

1 +

_

1.14

_

z

d

1

_

_

1

_

qq

q

b

_

_

d

16.2

__

Corley (1966)

d

2

+ 0.2

z

d

Mattock

(1967)

d

2

+ 0.05z

Park et al.

(1982)

0.4h

Priestley and

Park (1987)

0.08L

v

+ 6d

b

Paulay and

Priestley

(1992)

0.08L

v

+ 0.022d

b

f

y

Panagiotakos

and Fardis

(2001)

0.12L

v

+ 0.014

sl

d

b

f

y

for cyclic loading

0.18L

v

+ 0.021

sl

d

b

f

y

for monotonic loading

Fardis (2007) 0.09L

v

+ 0.2h for cyclic loading

0.04L

v

+ 1.2h for monotonic loading

and the plastic hinge length L

pl

is given as a linear function of shear span L

V

(bending

contribution) and of the product (f

y

d

bL

) (xed-end contribution):

L

pl

= L

V

+ (f

y

d

bL

) (12)

Coefcients and are derived from a regression analysis on experimental data; they are

equal, respectively, to 0.12 and to 0.0014 for cyclic tests and to 0.18 and 0.0021 for monotonic

ones. The ultimate curvature

u

is evaluated accounting both for the concrete connement

and for the spalling of the concrete cover. In particular, for cyclic tests the mean and median

of the experimental-to-predicted ratio for expression (11), using (12), are equal to 1.23 and

0.99, respectively, with a C.o.V. of 83%; while for monotonic tests the mean and median are

equal to 1.37 and 1.01, respectively, with a C.o.V. of 94%.

The last plastic hinge expression proposed by Fardis (2007), based on a more extensive

experimental database, is depending not on the shear span L

V

but also on the height h of the

section. Moreover, the xed-end rotation contribution is evaluated with a separate term:

u

=

y

+ (

u,slip

y,slip

) + (

u

y

)L

pl

_

1 0.5

L

pl

L

V

_

(13)

with:

L

pl

= 0.09L

V

+ 0.20h (14)

where:

1 3

Bull Earthquake Eng

y

=

y

L

V

3

+ 0.0013

_

1 + 1.5

h

L

V

_

+

y

d

bL

f

y

8

f

c

(15)

y,slip

=

y

d

bL

f

y

8

f

c

(16)

u,slip

=

u

d

bL

f

y

16

f

c

(17)

The use of the illustrated relationships, together with the connement model showed in the

same work, leads to an experimental-to-predicted ratio with mean and median, on a database

of 1307 experimental tests, equal to 1.105 and 0.994, respectively, with a C.o.V. of 53.6%.

Expressions (11) e (13), although providing a different evaluation of the xed-end contri-

bution, present the same control variables of the code expression (6), which directly shows, in

the calculation of plastic hinge length, the dependence on all the above mentioned parameters.

2.3 Empirical approach: background theory

Formulas for the evaluation of rotational capacity can also be obtained with a totally empirical

approach, based on experimental data, with pure numerical regression analyses.

In Haselton and Deierlein (2007), based on 255 experimental tests from PEER database

(Berry et al. 2004), empirical expressions for characteristic parameters of a RCelement model

(e.g. stiffness, rotation capacity, etc.), also including cyclic behaviour. These parameters are

chosen according to the model proposed in Ibarra et al. (2005). Empirical expressions for the

ultimate deformation capacity are also proposed in Rossetto (2002) and Zhu et al. (2007).

This kind of formulations can also be derived from a small number of experimental data,

when a specic typology of RC element is investigated. In Lam et al. (2003), based on a

few number of experimental tests, expressions for the assessment of deformation capacity of

rectangular RC columns with low lateral connement and high-axial load are proposed.

A different approach is proposed in Perus et al. (2006); Perus and Fajfar (2007). Authors

elaborate a method for the prediction of exural deformation capacity, but also of the whole

force-drift envelope, by means of CAE method (a special type of multi-dimensional non-

parametric regression) applied to a subset of Fardis and PEER databases. This method shows

a better prediction capacity compared to EC8 formulations.

Among the different empirical expressions proposed in literature, the expression proposed

in Panagiotakos and Fardis (2001) represents a reference for the above illustrated code formu-

las (CEN 2005). This experimental database consists in 633 cyclic tests and 242 monotonic

tests on beams, columns and walls, which do not present brittle failure mechanisms. The

relationship is a linear regression of the logarithm of

u

on the control variables or their loga-

rithms, without coupling. Only control variables which turn out to be statistically significant

for the prediction of

u

are retained. Separate regression analyses for monotonic tests and

for cyclic ones are performed. To obtain a more representative experimental database, with

particular regard to members with unsymmetric reinforcement well represented in mono-

tonic tests, another regression analysis on all 875 tests is performed, leading to the following

expression:

u

=

st

cyc

_

1 +

sl

2.3

_ _

1

wall

3

_

(0.20

)

_

max

_

0.01;

_

max (0.01; )

f

c

_

0.275 _

L

V

h

_

0.45

1.1

_

100

sx

f

yw

f

c

_

(1.30

100

d

) (18)

1 3

Bull Earthquake Eng

The ratio between the experimental ultimate rotation and the numerical value provided by

(18) has mean equal to 1.06, median equal to 1.00 and C.o.V. of 47%.

During years, together with the extension of the experimental database, the coefcients

in this expression have been slightly modied. The last proposal, given in Fardis (2007), is

based on 1,307 monotonic and cyclic tests:

u

=

st

(1 0.43

cyc

)

_

1 +

sl

2

_

_

1

3

8

wall

_

(0.30

)

_

max

_

0.01;

_

max (0.01; )

f

c

_

0.225 _

L

V

h

_

0.35

25

_

sx

f

yw

f

c

_

(1.25

100

d

) (19)

The mean value of the ratio between the experimental ultimate rotation and the numerical

value provided by (19) is 1.05, the median is equal to 0.995 and the C.o.V. is of 42.8%. The

comparison between the coefcients of variation clearly shows the better prediction capacity

of (19), due to the growth of experimental knowledge state.

In the same work, a regression analysis for the only plastic part is also presented, which

was already proposed in (CEB-FIB 2003) based on 1,100 experimental tests. The expression

is:

pl

u

=

pl

st

(1 0.52

cyc

)

_

1 +

sl

1.6

_

(1 0.4

wall

)

(0.25

)

_

max

_

0.01;

_

max (0.01; )

_

0.30

f

0.20

c

_

L

V

h

_

0.35

25

_

sx

f

yw

f

c

_

(1.275

100

d

) (20)

The mean value of the ratio between the experimental ultimate rotation and the corresponding

numerical prediction is 1.05, the median is equal to 0.995 and the C.o.V. is of 42.7%, against

the 47% in the rst proposal (see Eq. 18).

Expressions (1) and (2) proposed in EC8 almost perfectly agree with (19) and (20), assum-

ing

cyc

= 1 (cyclic loading),

sl

= 1 (with slip),

wall

= 0 (only beams and columns) and

st

=

pl

st

= 0.0185 (hot-rolled ductile steel).

Consistently with the characteristic of tests included in the experimental database, the pro-

posed expressions for the ultimate rotational capacity should be applied only to members with

ribbed bars, with seismic detailing and without lapping of longitudinal bars in the vicinity

of plastic hinge region, that is, to members which are not representative of existing build-

ings. Authors dene correction coefcients allowing to extend the use of these expressions

to members with different characteristics. These coefcients are calibrated to counterbal-

ance the mean error evaluated through the comparison between values from expressions (19)

and (20) and results of experimental tests on non-conforming members, not included in the

original (primary) database.

This approach, certainly approximated, is necessary because of the small number of exper-

imental data for these members. Because of the low number of these data, it seems to be

allowed to suppose that their inclusion in the database would have not led to any significant

change in the regression expression. Moreover, applying the primary expression to members

of different typologies, only using a multiplicative coefcient, is the same as postulating that

the ultimate rotation depends on the control parameters by the same way, independently of

the specic characteristics of considered elements. Nevertheless, the assumed methodology

seems to be the only one that can be followed, due to the fewexperimental data nowavailable

for this kind of elements. A higher reliability can be obtained only by extending the experi-

mental database, so that a wider range of loading conditions and geometrical and mechanical

1 3

Bull Earthquake Eng

Table 2 Correction factors for non-detailed members

Element type Correction factor # of data MeanMedian

C.o.V. (corrected

data)

Reference

w/o seismic detailing

and w/ continuous

ribbed bars

0.85 27 () (1.00)

()

Panagiotakos et al.

(2002); CEB-FIB

(2003)

0.825 42 (1.00)(1.005)

(33.6%)

Biskinis and Fardis

(2004); CEN (2005)

w/o seismic detailing

w/ hooked smooth

bars and w/ or w/o

lap-splicing over

plastic-hinge length

0.015

(10+min (40; l

o

/d

b

))

15 (1.07)(0.975)

(32%)

Fardis (2006)

w/o seismic detailing

w/ hooked smooth

bars and w/ or w/o

lap-splicing over

plastic-hinge length

1/1.20 0.019

(10+min (40; l

o

/d

b

))

()()

()

CEN (2009)

characteristics can be covered. In Table 2 correction coefcients and the extension of the

corresponding experimental databases used for calibrations are reported.

2.4 Critical review

The expressions for the ultimate rotational capacity, as clearly shown in the previous

paragraphs, are necessarily calibrated on experimental data, due to the complex nature of

mechanisms affecting the post-elastic behaviour of RC members and their interaction.

Both the approaches presented in literature and in Code are characterized by high values

of the coefcient of variation of the experimental-to-predicted capacity ratio.

The high C.o.V. affecting expressions (19) and (20)or (1) and (2)is not only due to

the natural experimental variability, but also to the difculty in completely modelling with

a simple formulation the interaction between the complex phenomena inuencing the post-

elastic deformation behaviour of RCelement. Panagiotakos and Fardis in (2001), based on the

analysis of subgroups of tests, homogenous for geometrical and mechanical characteristics

and for loading conditions, quantify the C.o.V. associated with the only natural variability in

12.5%.

The limited prediction capacity of these expressions is also due to impossibility of intro-

ducing in the control variables some parameters which certainly affect the rotational capacity.

The major among these parameters is the load path, that is, the energy dissipated in hyster-

etic cycles. This aspect has been experimentally investigated by Pujol et al. (2006), who

analyzed the inuence of displacement history on the decay of element resistance capacity.

The experimental tests showthat, given equal the geometrical and mechanical characteristics

and the applied axial load (that is, all the input parameters of code and literature regression

formulations), it is possible to predetermine the value of element chord rotation correspond-

ing to a conventional drop of 20% of peak resistance, by imposing a given load path (see

Fig. 1).

Panagiotakos and Fardis, in the above mentioned work, try to explicitly account for the

effect of cyclic loading by another regression, where the type of loading is evaluated with a

1 3

Bull Earthquake Eng

Fig. 1 Inuence of displacement

history on ultimate chord rotation

(Pujol et al. 2006)

variable expressing the equivalent number of inelastic imposed cycles (

|

i

|

u

), instead of

the coefcient (

cyc

). Nevertheless, contrary to expectations, the inclusion of this parameter

makes worse the prediction capacity of the formulation. The C.o.V. of the ratio between the

experimental and the predicted value, in fact, increases up to 51%. On the other hand, the

usual structural modelling approaches do not allow to introduce the dissipated energy in

the control variables.

A critical analysis of expressions (19) and (20), based on mechanical considerations

regarding the absence of a direct relationship between the median estimation of the ulti-

mate rotation and some parameters that certainly inuence the member capacity, seems to

be without foundation. Due to the purely statistical nature of the expression, in fact, the

retaining of these variables turns out to be not significant because of their strong corre-

lation with other parameters, already present in the formulation (Panagiotakos and Fardis

2001).

Its worth noting that the higher coefcient of variation affecting the hybrid mechani-

cal-empirical formulation (plastic hinge length) with respect to the purely empirical one is

probably related to the difculty in expressing the ultimate rotation as a function of element

characteristics based on a statistical regression analysis restrained to a mechanical relation-

ship.

3 Deformation capacity of RC members with smooth bars

Smooth reinforcing bars have been widely used in the construction of European RC build-

ings. In Italy and in the whole Mediterranean area their use was widely spread up to 1970s,

in north-American countries and in New Zealand constructions with smooth bars are present

until 1950. The wide spreading of RC buildings with smooth bars among existing buildings

can be deduced if it is considered that 50% of Italian existing buildings has been constructed

between earliest 1940s and latest 1970s, when RC structures with smooth bars were the

prevailing construction typology.

The correct evaluation of deformation capacity of RC elements has to account for the

effective bond capacities between reinforcing bars and the surrounding concrete. For mem-

bers with smooth bars, low bond capacities directly inuence the three main deformation

mechanisms: bending, shear and xed-end rotation.

As shown by experimental evidence, the scarce capacities of load transfer between the

reinforcing bars and the surrounding concrete makes the deformation contribution associ-

ated with the xed-end rotation effect very important. This contribution, in fact, due to the

1 3

Bull Earthquake Eng

cyclic and post-elastic decay of bond capacities, may represent up to (8090)% of overall

deformability of the element (Verderame et al. 2008a, b).

Bond capacities also inuence the development of cracks along the element. A lower

number of wider cracks is observed when bond decreases. This greatly inuences both shear

and bending deformability, reducing the former and increasing the latter.

Therefore, formulations able to provide a reliable assessment of ultimate deformation

capacity of elements with smooth bars are of a particular interest for assessment of existing

buildings.

The ultimate rotational capacities for members with smooth bars, according to code, as

already shown at paragraph 2.1, is evaluated by applying a correction coefcient, based on

experimental data, to the capacity formulations calibrated on members with ribbed bars and

seismically detailed.

Most of literature data about the experimental behaviour of RC elements comes from

test executed on members with ribbed bars. During last years, the need for a reliable

assessment of seismic capacity of existing structures has produced an increasing number

of experimental campaigns aimed at the study of behaviour of non-conforming elements.

In the following, experimental results of columns with smooth bars, including recent tests

carried out in the laboratory of the Department of Structural Engineering at the Univer-

sity of Naples Federico II, in the research project ReLUIS-DPC 2005-2008 Linea 2, are

introduced.

Based on these data, it will be possible to extend the experimental database for the cali-

bration of correction coefcients applied to the regression relationships for the evaluation of

ultimate rotational capacity of members with smooth bars.

Tested columns with lapping of longitudinal reinforcement are included in this database

only if hooks are provided at the end of lapped bars. Literature offers experimental data

on members without this anchorage detail (Ilki et al. 2004; Yalcin et al. 2008); in these

cases, brittle lap splice failures are present. Therefore, in the following these data will not be

considered.

3.1 Bousias et al. database (2005)

According to (CEB-FIB 2006), coefcients proposed in (CEN 2005), which have been

reported at 2.1, are calibrated on very few experimental tests. The correction factor pro-

posed by code (CEN 2005), applied both when lapping of longitudinal reinforcement is

present and when it is not, has been evaluated based on experimental results from tests car-

ried out at the University of Patras (Bousias et al. 2004, 2005). Experimental tests are six

in all (Bousias et al. 2005): in two cases there is no lapping of longitudinal reinforcement

(l

o

= 100d

bL

), while in the remaining four cases longitudinal bars are lapped: l

o

=15d

bL

in

twospecimens andl

o

=25d

bL

inthe other two. Transverse sectionis squared(250250) mm

2

and ratio (L

V

/h) is equal to 6.4; axial load level varies between 0.41 and 0.44; concrete

compressive strength f

c

is included between 27.0 and 30.3 MPa, and yield strength of lon-

gitudinal reinforcement f

y

is equal to 313 MPa. In Fig. 2, for each couple of testswith

l

o

= 15, 25, 100d

bL

the experimental force-displacement relationship of a representative

specimen is reported.

Table 3 reports, for each test, the ratio between the experimental ultimate rotation and

the value obtained by (2). The ratio between the experimental value of the ultimate rotation

and the theoretical value, obtained by (2) and multiplied by the code correction coefcient,

evaluated for all tests, has mean equal to 1.07 and median equal to 0.975, with a C.o.V. of

32.1%.

1 3

Bull Earthquake Eng

Fig. 2 Force-displacement relationship of column with a l

o

= 15d

bL

, b l

o

= 25d

bL

, c l

o

= 100d

bL

reported

in Bousias et al. (2004)

Table 3 Ratios between

experimental ultimate rotations

and corresponding theoretical

values from Bousias et al. (2005)

n Test Reference Loading l

o

/d

bL

u,exp

/

u

1 Bousias et al. (2005) Cyclic 15 0.33

2 Cyclic 15 0.62

3 Cyclic 25 0.39

4 Cyclic 25 0.41

5 Cyclic 100 0.58

6 Cyclic 100 0.60

3.2 Fardis database (2006)

Expression proposed in Fardis (2006), reported in Table 2, are, instead, based on 15 exper-

imental tests, including the original Bousias database, see Table 4. In particular, 9 of these

tests without lapping (l

o

/d

bL

= 100) and 6 with a lap length l

o

varying between 15, 25 and 40

times the diameter d

bL

of longitudinal reinforcing bars. 5 of the 9 newintroduced teststests

#1115 in Table 4come from the University of Naples (Verderame et al. 2008b).

In Table 4 the ratios between the experimental values of the ultimate rotation and the values

obtained by (2) are reported. Figure 3 shows, for each experimental test, the ratio between

the experimental ultimate rotation and the corresponding theoretical value (

u,exp

/

u

) and

the correction coefcient proposed in (Fardis 2006).

The comparison between the correction coefcient given by CEN (2005) and the one pro-

posed in Fardis (2006) shows the considerable conservativeness of the prescription proposed

by Eurocode 8. As a matter of fact, the ultimate rotation of members with smooth bars and

without lapping of longitudinal reinforcement, according to this coefcient, is equal to 0.75

times the ultimate rotation of members with ribbed bars and seismically detailed, given by

(2), while prescriptions of CEN (2005) suggest a correction factor equal to 0.575. It is to be

noted that the widening of the database by adding further experimental results from columns

with lapping of longitudinal reinforcement makes lower the reduction of the ultimate rota-

tion, compared to the code prescriptions (CEN 2005). The ratio between the experimental

value of the ultimate rotation

u,exp

and the corresponding theoretical value, obtained by (2)

and multiplied by the correction coefcient proposed by Fardis, evaluated on all tests in the

experimental database, has mean equal to 1.07 and median equal to 0.975, with a C.o.V. of

32.1%.

1 3

Bull Earthquake Eng

Table 4 Ratios between

experimental ultimate rotations

and corresponding theoretical

values used for the correction

coefcient proposed in Fardis

(2006)

n Test Reference Loading l

o

/d

bL

u,exp

/

u

1 Fardis (2006) Cyclic 15 0.33

2 Cyclic 15 0.62

3 Cyclic 25 0.39

4 Cyclic 25 0.41

5 Cyclic 100 0.58

6 Cyclic 100 0.60

7 Cyclic 100 0.54

8 Cyclic 100 0.74

9 Cyclic 100 0.83

10 Cyclic 100 1.25

11 Cyclic 40 1.26

12 Cyclic 40 0.83

13 Cyclic 100 1.21

14 Cyclic 100 1.13

15 Cyclic 100 0.81

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0 10 20 30 40 50 60 70 80 90 100 110 120

u,exp

/

u

lap length, l

o

/d

bL

# 15 tests

0.015[10+min(40,l

o

/d

bL

)]

Fig. 3 Correction coefcient proposed by Fardis (2006)

Correction coefcients reported in CEN (2009) are very similar to the ones proposed in

Fardis (2006). For members with continuous longitudinal bars, they are equal to 0.80 and

0.75, respectively. If longitudinal bars are lapped, Eq. 4a proposed by CEN(2009), multiplied

by the coefcient 1/1.20 accounting for the lack of seismic detailing, is almost equal to the

expression 0.015 [10 + min(40, l

o

/d

bL

)] given by Fardis (2006).

3.3 University of Salerno database

In Faella et al. (2008) results of four experimental tests on columns with smooth bars, carried

out at the University of Salerno, are reported. Three of these tests are cyclic and one is mono-

tonic; in all of these tests longitudinal reinforcement is lapped. Transverse section is squared

(300 300) mm

2

and ratio (L

V

/h) is equal to 5.67; axial load level varies between 0.14

1 3

Bull Earthquake Eng

Table 5 Geometrical and mechanical characteristics of tested elements from Faella et al. (2008)

n test Reference L

V

/h l

o

/d

bL

Reinforcement Loading

u,exp[10%]

u,exp[20%]

[%] [%]

a

1 Faella et al.

(2008)

5.67 0.14 43 Smooth Monotonic 8.80

2 5.67 0.14 43 Smooth Cyclic 3.62 3.89

3 5.67 0.40 43 Smooth Cyclic 3.06 3.21

4 5.67 0.40 43 Smooth Cyclic 2.47 3.11

a

Cyclic ultimate chord rotations corresponding to a strength decay equal to 20% of peak resistance were

evaluated and provided by the authors

Fig. 4 Force-displacement relationship of column a C3-S, b C16-S, c C18-S reported in Faella et al. (2008)

and 0.40; concrete compressive strength f

c

is included between 13.5 and 27.5 MPa, and yield

strength of longitudinal reinforcement f

y

is equal to 346 MPa. Lap length of longitudinal

bars is equal to 43 times the bars diameter.

Table 5 reports the main geometrical and mechanical parameters of tested specimens and

corresponding ultimate chord rotations

u,exp

, evaluated for a 10 and 20% decay of the peak

resistance; Fig. 4 shows the experimental force-displacement response of cyclic tests.

3.4 University of Naples database (20052009)

In recent times, in the Department of Structural Engineering at the University of Naples

Federico II, a great attention has been addressed to the experimental study of members with

smooth bars, both through test aimed at the characterization of bond capacities in cyclic

(Verderame et al. 2009a, b) and post-elastic eld and through tests on real-scale column

elements under monotonic and cyclic loading.

In the rst phase of the experimental activity 6 monotonic tests and 6 cyclic ones

(Fabbrocino et al. 2005; Verderame et al. 2008a, b) have been performed, on elements

with square section (300 300) mm

2

, for different values of the applied axial load

( = 0.12 0.24). In this phase particular attention has been addressed to the detail of

longitudinal bars, by executing tests on elements without lapping of longitudinal bars at the

base of the element and on elements with a lap length l

o

equal to 40 times the diameter d

bL

of

longitudinal bars. In Table 6 the main parameters of twelve tested columns and correspond-

ing ultimate chord rotations

u,exp

, corresponding to a 20% decay of the peak resistance, are

reported.

Experimental results show that rotational capacity in cyclic eld is strongly inuenced by

axial load level ; as a matter of fact, as this parameter doubles from 0.12 to 0.24 rotational

capacity decreases about by 45%, see Fig. 5a. Moreover, with regard to cyclic tests, columns

with lapping of longitudinal bars equal to l

o

= 40d

bL

show a rotational capacity, on average,

1 3

Bull Earthquake Eng

Table 6 Geometrical and mechanical characteristics of tested elements from Verderame et al. (2008a, b) and

Di Ludovico et al. (2010)

n Test Reference B [mm] L

V

/h

l

[%] l

o

/d

bL

Reinforcement Loading

u,exp

[%]

1 Verderame et al.

(2008a, b)

300 5.23 0.12 0.8 40 smooth Cyclic

a

6.23

2 300 5.23 0.12 0.8 40 Smooth Cyclic

a

5.82

3 300 5.23 0.12 0.8 100 Smooth Cyclic

a

6.49

4 300 5.23 0.24 0.8 40 Smooth Cyclic

a

3.72

5 300 5.23 0.24 0.8 100 Smooth Cyclic

a

3.81

6 300 5.23 0.24 0.8 100 Smooth Cyclic

a

2.77

7 300 5.23 0.12 0.8 40 Smooth Monotonic

b

7.90

8 300 5.23 0.12 0.8 40 Smooth Monotonic

b

7.40

9 300 5.23 0.12 0.8 100 Smooth Monotonic

b

11.00

10 300 5.23 0.12 0.8 100 Smooth Monotonic

b

9.40

11 300 5.23 0.24 0.8 40 Smooth Monotonic

b

7.87

12 300 5.23 0.24 0.8 100 Smooth Monotonic

b

4.97

13 Di Ludovico et al.

(2010)

300 5.00 0.20 1.0 100 Smooth Monotonic 8.53

14 300 5.00 0.20 1.0 100 Smooth Cyclic 5.43

15 300 3.00 0.10 0.9 100 Smooth Cyclic 5.27

16 500 5.00 0.10 0.9 100 Smooth Cyclic 6.23

17 300 5.00 0.20 1.0 100 Ribbed Monotonic 6.86

18 300 5.00 0.20 1.0 100 Ribbed Cyclic 3.87

19 300 3.00 0.10 0.9 100 Ribbed Cyclic 3.65

20 500 5.00 0.10 0.9 100 Ribbed Cyclic 4.66

a

Ultimate chord rotations have been evaluated for a strength decay equal to 20% of peak resistance, whilst

values reported in Verderame et al. (2008b) have been evaluated for a strength decay equal to 15%

b

Ultimate chord rotations have been evaluated for a strength decay equal to 20% of peak resistance by means

of a linear extrapolation along the softening branch of monotonic response reported in Verderame et al. (2008a)

equal to columns with continuous reinforcement (l

o

= 100d

bL

), independently of the axial

load level, see Fig. 5b.

The second phase of the experimental campaign (Di Ludovico et al. 2010) is focused on the

comparison between rotational capacity and deformation mechanisms of RC elements with

smooth and ribbed bars. In particular, (4 +4) tests have been executed on elements equal for

the geometry of the transverse section, the geometric ratio of longitudinal and transverse rein-

forcement, the axial load level and the load path, varying the geometry of the transverse sec-

tion. Columns have three different transverse sections(300300) mm

2

, (300500) mm

2

and (500 300) mm

2

corresponding to a (L

V

/h) ratio equal to 5.0 and 3.0, respectively.

Yield strength of longitudinal reinforcement f

y

is equal to 330 and 505 MPa for smooth and

ribbed bars, respectively. Concrete compressive strength f

c

varies between 17.9 and 22.0

MPa.

Characteristics of tested elements are reported in Table 6, where the ultimate drift corre-

sponding to 20% decay of peak resistance is also given.

Experimental results conrm a rather large rotational capacity of columns with smooth

bars, already highlighted during the previous experimental campaign. Moreover, each of these

1 3

Bull Earthquake Eng

0

2

4

6

8

10

12

normalized axial load,

u,exp

[%]

l

o

= 100d

bL

l

o

= 40d

bL

cyclic tests

(a)

0

2

4

6

8

10

12

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0 20 40 60 80 100 120

lap length, l

o

/d

bL

cyclic tests

= 0.12

= 0.24

u,exp

[%]

(b)

Fig. 5 Experimental results from Verderame et al. (2008a, b): ultimate cyclic chord rotation versus axial load

level (a) and lap length (b)

Fig. 6 Experimental results from

Di Ludovico et al. (2010):

ultimate cyclic chord rotation

versus the type of reinforcement

(smooth or ribbed)

0

2

4

6

8

10

12

smooth ribbed

u,exp

[%]

reinforcement type

mon (= 0.2 - L

V

/h=5)

cyc (= 0.2 - L

V

/h=5)

cyc (= 0.1 - L

V

/h=3)

cyc (= 0.1 - L

V

/h=5)

columns has regularly shown a higher rotational capacity compared with the corresponding

column with ribbed bars, see Fig. 6: ultimate rotations of columns with ribbed bars are lower

by 18 and 28% compared to corresponding columns with smooth bars, for monotonic and

cyclic loading, respectively. This is certainly due to the higher weight of the deformation

mechanism given by the slippage of longitudinal bars from the foundation element when

reinforcement is smooth.

4 Calibration of correction factor

The correction coefcient applied to code expressions for the ultimate rotation of members

with smooth bars is calibrated, based on experimental data introduced in Sect. 3.

The correction coefcient will be calibrated according to the methodology already illus-

trated at 2.3, with regard to the following expression:

u

=

y

+

pl

u

(21)

where

pl

u

is evaluated according to Eq. 2, with

el

= 1.

1 3

Bull Earthquake Eng

Fig. 7 Ratio between cyclic and

monotonic rotational capacities

versus the axial load level from

Verderame et al. (2008a, b) and

Di Ludovico et al. (2010)

0.0

0.2

0.4

0.6

0.8

1.0

0.00 0.05 0.10 0.15 0.20 0.25 0.30

(

u,cyc

/

u,mon

)

normalized axial load,

0.57 ribbed bars

(Fardis, 2007)

0.69 smooth bars

smooth bars

ribbed bars

The considered database is made up only of cyclic tests. As a matter of fact, ultimate

rotational capacity given by code prescriptions (CEN 2005) is meant to be cyclic. Monotonic

tests could be included in the database for the calibration of correction coefcient only by

means of a coefcient accounting for the type of loading, as

cyc

, applied to the expression

of the ultimate rotation. On the other hand, this would be the same as postulating that the

reduction in rotational capacity due to cyclic loading, evaluated by this coefcient, is, on

average, not depending on bond capacities. As a matter of fact, this coefcient, as previously

illustrated, is calibrated on a database made up of members with ribbed bars; therefore, the

evaluation of the correction coefcient should be executed supposing that the reduction given

by

cyc

can also be extended to members with smooth bars.

Nevertheless, rst experimental results highlight that the reduction in rotational capacity

due to cyclic loading is lower for columns with smooth bars compared to columns with ribbed

bars; this is shown, in particular, by test results from the University of Naples (Verderame

et al. 2008a, b; Di Ludovico et al. 2010). Figure 7 reports the ratio (

u,cyc

/

u,mon

) between

cyclic and monotonic experimental ultimate rotations for each possible couple of tests, given

equal the axial load level, the longitudinal reinforcement detail (with or without lapping) and

the geometrical and mechanical characteristics of the elements, versus the axial load level .

The reduction in cyclic rotational capacity clearly increases as the axial load level increases.

However, the ratio (

u,cyc

/

u,mon

) has a mean equal to 0.69 with a C.o.V. =0.17 for columns

with smooth bars, independently of the axial load level and the longitudinal reinforcement

detail. On the contrary, the average value of ratio (

u,cyc

/

u,mon

), for columns with ribbed

bars and seismically detailed, is equal to 0.57 as indicated in Fardis (2007); it is to be noted

that this value is conrmed by the only couple of tests characterized by ribbed longitudinal

reinforcement.

Therefore, due to the uncertainties related to the inclusion of monotonic tests, the cor-

rection coefcient will now be calibrated based on the only cyclic tests. Hence, elements

included in the database are: six columns from Bousias database, ve columns added in

Fardis database, except the tests carried out at the University of Naples, three columns from

the University of Salerno and, nally, nine columns tested at the University of Naples.

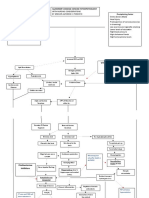

Table 7 reports the description of the database, including the lap length and the

ratio between the experimental ultimate rotation and the corresponding theoretical value

(

u,exp

/

u

), according to (21); Figure 8 shows the ratio (

u,exp

/

u

) versus the lap length

l

o

/d

bL

.

The ratio (

u,exp

/

u

) for members without lapping of longitudinal bars (conventionally

reported as l

o

/d

bL

= 100) has mean equal to 1.03 and median equal to 0.98, with a C.o.V. =

0.39. Therefore, based on the experimental tests, expression (21) shows a very good agree-

1 3

Bull Earthquake Eng

Table 7 Ratios between

experimental ultimate rotations

and corresponding theoretical

values

n Test Reference Loading l

o

/d

bL

u,exp

/

u

1 Bousias et al. (2005) Cyclic 15 0.33

2 Cyclic 15 0.62

3 Cyclic 25 0.39

4 Cyclic 25 0.41

5 Cyclic 100 0.58

6 Cyclic 100 0.60

7 Fardis (2006) Cyclic 100 0.54

8 Cyclic 100 0.74

9 Cyclic 100 0.83

10 Cyclic 100 1.25

11 Faella et al. (2008) Cyclic 43 0.77

12 Cyclic 43 0.79

13 Cyclic 43 0.85

14 Verderame et al.

(2008b)

Cyclic 40 1.26

15 Cyclic 40 0.83

16 Cyclic 40 0.60

17 Cyclic 100 1.21

18 Cyclic 100 1.13

19 Cyclic 100 0.81

20 Di Ludovico et al.

(2010)

Cyclic 100 1.41

21 Cyclic 100 1.42

22 Cyclic 100 1.76

Fig. 8 Ratio

u,exp

/

u

versus

lap length l

o

/d

bL

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0 10 20 30 40 50 60 70 80 90 100 110 120

u,exp

/

u

lap length, l

o

/d

bL

# 22 tests

ment with the cyclic rotational capacity of elements with smooth bars without lapping of

longitudinal reinforcement.

The use of expression (21) for members with lapping of longitudinal bars overestimates

even more the experimental rotational capacity; in fact, the ratio (

u,exp

/

u

) for members

with lapping of longitudinal bars has mean equal to 0.69 and median equal to 0.69, with

a C.o.V. =0.41. With regard to members with lapping of longitudinal bars, a linear regres-

sion performed on the ratio (

u,exp

/

u

) gives the following expression for the correction

coefcient:

1 3

Bull Earthquake Eng

Fig. 9 Proposed correction

factor

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0 10 20 30 40 50 60 70 80 90 100 110 120

u,exp

/

u

lap length, l

o

/d

bL

# 22 tests

0.020min(50,l

o

/d

bL

)

1

= 0.020(l

o

/d

bL

) (22)

The ratio

u,exp

/(

1

u

) has mean equal to 1.07 and median equal to 0.93, with a C.o.V. =

0.38.

Based on mean and median values shown by columns with continuous longitudinal rein-

forcement, it is possible to provide one expression for the correction coefcient, both for

elements with and without lapping of longitudinal bars:

= 0.020 min(50, l

o

/d

bL

) (23)

The ratio

u,exp

/(

u

), calculated on all tests in the experimental database, has mean equal

to 1.06, median equal to 0.96 and a C.o.V. = 0.38 while for members without lapping of

longitudinal bars it has mean equal to 1.03 and median equal to 0.98, with a C.o.V. = 0.39.

Figure 9 reports the ratio between the experimental ultimate rotation and the correspond-

ing theoretical value (

u,exp

/

u

), together with the proposed correction coefcient given by

(23), applied to (21).

It is possible to compare the proposed coefcient, evaluated on 22 tests, with the coef-

cient proposed by Fardis (2006), evaluated on 15 tests, with the coefcient given by CEN

(2005), evaluated on 6 tests, and with the update to CEN (2005) proposed by CEN (2009).

The correction coefcient suggested in Fardis (2006) is not far from the proposed coefcient

given by (22) for members with lapping of longitudinal reinforcement.

On the other hand, the coefcient adopted by CEN (2005) shows a considerable con-

servativeness. According to this prescription, the ultimate rotation of members with a lap

length equal to l

o

has to be evaluated based on the assumption that the ultimate condition

is controlled by the region right after the end of the lap. Hence, expression (21) should be

multiplied by expression (4). In this coefcient, a further reduction in the ultimate rotation is

given by the term (1 l

o

/L

V

), expressing a reduction in the shear span L

V

by the lap length

l

o

. Moreover, shear span should be reduced by the lap length also in expressions (2).

With regard to members without lapping of longitudinal bars, based on the proposed cor-

rection coefcient the ultimate rotational capacity of members with smooth bars is equal to

that of members with ribbed bars and seismically detailed. On the contrary, according to the

expression proposed in Fardis (2006), the ratio between the former and the latter is equal to

0.75, whilst code prescriptions (CEN 2005) suggest 0.575.

Expression proposed in CEN(2009), as previously noted, is very similar to the expression

given by Fardis (2006).

1 3

Bull Earthquake Eng

Fig. 10 Comparison between the

proposed correction coefcient

and the ones reported in CEN

(2005), Fardis (2006) and CEN

(2009)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0 10 20 30 40 50 60 70 80 90 100 110 120

u,exp

/

u

lap length, l

o

/d

bL

# 22 tests

(CEN, 2005)

proposed (Eq.23)

(Fardis, 2006)

(CEN, 2009)

Figure 10 shows a comparison between different correction coefcients applied to (21); it

is to be noted that the coefcient given by (CEN 2005) is represented not taking into account

the shear span reduction.

4.1 Discussion of results

The extension of the experimental database allowed to re-calibrate the correction coefcients

applied to the assessment of the ultimate rotational capacity of elements with smooth bars,

with or without lapping of longitudinal reinforcement.

The expression of correction coefcient proposed herein highlights the conservativeness

of EC8 (CEN 2005) proposal, which is based on very few experimental tests. Moreover, EC8

assumes that, when lapping of longitudinal reinforcement is present, the ultimate condition

is controlled by the region right after the end of the lap, so that the shear span and, therefore,

the rotational capacity are further reduced. This assumption is not conrmed by the exper-

imental results reported in Verderame et al. (2008a, b) and Di Ludovico et al. (2010); the

highest plastic demand, in fact, always concentrates at the base section of the element.

The changes in correction coefcients proposed by CEN (2009)probably based on the

proposal of Fardis (2006)result in a less conservative and more reliable evaluation of

ultimate deformation capacity of members with smooth bars.

Despite the difculties in the choice of the most reliable expression for the correction

coefcient, recent experimental results clearly highlight the higher rotational capacity of

members with smooth bars with compared to members with ribbed bars, equal for structural

characteristics and details. As a matter of fact, the comparison between the ultimate rotations

of the elements fromthe experimental campaign reported in Di Ludovico et al. (2010), briey

illustrated at 3.4, highlights that the capacity of members with smooth bars are higher, on

average, by 35% compared with the corresponding members with ribbed bars (see Table 6).

From a mechanical standpoint, the higher ultimate rotational capacity of columns with

smooth bars may be explained by the comparison between two opposite mechanisms: the

increase in deformability caused by the xed-end rotation mechanism, particularly exalted

due to the low bond capacities; on the other hand, the higher degradation of global resistance

due to the increase in deformation demand on concrete in compression, localized at the base

of the element and associated with the concentrated rotation (rocking effect). According to

experimental evidence, the former seems to prevail on the latter, leading to an overall increase

of ultimate rotational capacity compared with members with higher bond capacities.

Nevertheless, the post-elastic development of a high slippage, concentrated in a low num-

ber of wide cracks, represents not only a source of deformability but also a permanent damage

1 3

Bull Earthquake Eng

for the RC element (Verderame et al. 2008b). Moreover, the higher inuence of xed-end

rotation mechanism on behaviour of elements with smooth bars, compared to elements with

ribbed bars, also leads to a decrease in the energy dissipation capacity. As a matter of fact,

RC members with smooth bars tested under cyclic loading reported in Di Ludovico et al.

(2010), at the same displacement demand, show a dissipated energy about 30% lower, on

average, than the energy dissipated by the corresponding members with ribbed bars, equal for

geometrical characteristics and applied axial load. This issue should be carefully considered,

since it could potentially lead to an underestimate of the seismic demand.

Further conservatism should be addressed to the assessment of seismic capacity of mem-

bers with smooth bars because of the particularly high uncertainties involved in modelling

their deformation mechanisms. This is due, for example, to the difculties in evaluating the

inuence of rocking effect and to the high variability affecting bond capacities (Verderame

et al. 2009a, b), also inuenced by possible corrosion (Fardis 2006).

Finally, the absence of an effective anchorage of reinforcing bars by means of end hooks

may limit the deformation capacity (Yalcin et al. 2008) and in some cases the strength (Ilki

et al. 2004) of the element.

5 Conclusions

In this work, the theoretical background of code formulas for the assessment of ultimate

rotational capacity of RC members has been presented. Most recent literature contributions

have been illustrated, together with advantages and deciencies of the approaches to the

calibration of these relationships.

Special attention has been addressed to the calibration of correction coefcients applied

to the assessment of ultimate rotational capacity of non-conforming elements, with emphasis

on members with smooth bars. Main conclusions drawn form this work are:

The evaluation of post-elastic deformation capacity of RC elements may only be based

on experimental data; any mechanical approach would not allow to evaluate accurately

the complex interaction phenomena inuencing the deformability of the element.

The reliability of regression expressions proposed in literature, some of which have been

adopted by code, is a direct result of the extension and the correct sorting of the database.

The estimate of rotational capacity of non-conforming elements is strongly inuenced by

the low number of experimental data related to these typologies.

Recent experimental tests on columns with smooth bars, carried out at the University of

Naples, allow to extend the database used for the calibration of correction coefcients

applied to the assessment of these elements, with or without lapping of longitudinal

reinforcement.

The re-calibration of correction coefcients, even within the limits of the adopted meth-

odology, allows to highlight the conservativeness of code prescriptions for elements with

smooth bars; this is conrmed by the experimental evidence, showing that the ultimate

rotation of elements with smooth bars is higher compared with elements with ribbed bars,

on average, by 35%, given equal the structural characteristics and details.

Nevertheless, the high deformation capacity of elements with smooth bars is mainly due

to the xed end rotation mechanism, given by the slippage of longitudinal bars. The

nature of this mechanism leads to lower dissipation capacity compared to elements with

ribbed bars, as experimentally demonstrated. Moreover, slippage represents a permanent

damage for the RC element.

1 3

Bull Earthquake Eng

Special attention should be addressed to the high uncertainties affecting the deformation

mechanisms of elements with smooth bars. This is due, for example, to the difculties in

evaluating the inuence of rocking effect, bond capacities and anchorage conditions on

the seismic response of these elements.

Acknowledgments This work has been developed under the research program of ReLUISRete dei Lab-

oratori Universitari di Ingegneria Sismica, with the nancial support of the Italian Department of Civil

ProtectionExecutive Project 20052008. The Authors wish to thank the Reviewers for their valuable and

useful comments, which allowed to improve this paper.

References

Baker ALL (1956) Ultimate load theory applied to the design of reinforced and prestressed concrete frames.

Concrete Publications Ltd, London

Berry M, Parrish M, Eberhard M (2004) PEER structural performance database: users manual (version 1.0).

Pacic Earthquake Engineering Research Center, University of California, Berkeley

Biskinis DE, Fardis MN(2004) Cyclic strength and deformation capacity of RCmembers, including members

retrotted for earthquake resistance. In: Proceedings of the 5th international Ph.D. symposium in civil

engineering. Delft, Balkema, pp 11251133

Bousias SN, Fardis MN, Biskinis D (2005) Retrotting of RC columns with decient lap splices. In: Proceed-

ings of the b symposium keep concrete attractive. Budapest, Hungary, 2325 May, pp 885890

Bousias SN, Spathis AL, Fardis MN (2004) Seismic retrotting of columns with lap-splices via RC jackets.

In: 13th World conference on earthquake engineering. Vancouver, B.C., Canada, August 16. Paper No.

1937

CEB-FIB (2003) Seismic assessment and retrot of reinforced concrete buildings. CEB-FIB Bulletin no. 24.

International federation for structural concrete, task group 7.1.

CEB-FIB (2006) Retrotting of concrete structures by externally bonded FRPs, with emphasis on seismic

applications. CEB-FIB Bulletin No. 35. International federation for structural concrete

CEN (2004) European standard EN1992-1-1. Eurocode 2: design of concrete structures Part 1-1: general

rules and rules for buildings. European Committee for Standardisation, Brussels

CEN (2005) European standard EN1998-3. Eurocode 8: design provisions for earthquake resistance of struc-

tures Part 3: assessment and retrotting of buildings. European Committee for Standardisation, Brussels

CEN (2009) Corrigenda to EN 1998-3, document CEN/TC250/SC8/N437A. European Committee for Stan-

dardisation, Brussels

Corley WG (1966) Rotational capacity of reinforced concrete beams. J Struct Div ASCE 92(ST5):121146

Daniell JE, Oehlers DJ, Grifth MC, Mohamed Ali MS, Ozbakkaloglu T (2008) The softening rotation of

reinforced concrete members. Eng Struct 30(11):31593166

Di Ludovico M, Verderame GM, Prota A, Manfredi G, Cosenza E (2010) Experimental investigation on

non-conforming RC columns with plain and deformed bars. ACI Struct J (submitted)

Fabbrocino G, Verderame GM, Manfredi G(2005) Rotation capacity of old type RCcolumns. In: Proceedings

of the b symposium keep concrete attractive. Budapest, Hungary, May 2325, pp 891896

Faella C, Napoli A, Realfonzo R (2008) Cyclic exural behavior of FRP-conned concrete columns under

high axial loading. In: Proceedings of the ReLUIS congress Valutazione e riduzione della vulnerabilit

sismica di edici esistenti in c.a.. Rome, Italy, May 2930, pp 510520

Fang C, Gylltoft K, Lundgren K, Plos M (2006) Effect of corrosion on bond in reinforced concrete under

cyclic loading. Cement Concrete Res 36(3):548555

Fardis MN (2006) Design rules for FRP retrotting according to Eurocode 8 and their background. Lecture

to Fib Course 2006 Retrotting of concrete structures through externally bonded FRPs with emphasis

on seismic applications, Mexico

Fardis MN (2007) LESSLOSSrisk mitigation for earthquakes and landslides. Guidelines for displacement-

based design of buildings and bridges. Report No. 5/2007. IUSS Press, Pavia

Fenwick RC, Megget LM (1993) Elongation and load deection characteristics of reinforced concrete mem-

bers containing plastic hinges. Bull NZ Soc Earthq Eng 26(1):2841

Haselton CB, Deierlein GG (2007) Assessing seismic collapse safety of modern reinforced concrete moment-

frame buildings. PEERReport No. 2007/08. Pacic Earthquake Engineering Research Center, University

of California, Berkeley

1 3

Bull Earthquake Eng

Haskett M, Oehlers DJ, Mohamed Ali MS, Wu C (2009) Rigid body momentrotation mechanism for rein-

forced concrete beam hinges. Eng Struct 31(5):10321041

Ibarra FL, Medina RA, Krawinkler H (2005) Hysteretic models that incorporate strength and stiffness deteri-

oration. Earthq Eng Struct Dyn 34(12):14891511

Ilki A, Tezcan A, Koc V, Kumbasar N (2004) Seismic retrot of non-ductile rectangular reinforced concrete

columns by CFRP jacketing. In: 13th World conference on earthquake engineering. Vancouver, B.C.,

Canada, August 16. Paper No. 2236

LamSSE, Wu B, Wong YL, Wang ZY, Liu ZQ, Li CS (2003) Drift capacity of rectangular reinforced concrete

columns with low lateral connement and high-axial load. ASCE J Struct Eng 129(6):733742

Mattock AH (1967) Discussion of rotational capacity of hinging regions in reinforced concrete beams. ASCE

J Struct Div 93(ST2):519522

Mattock AH (1964) Rotational capacity of hinging regions in reinforced concrete beams. Flexural mechanics

of reinforced concrete, SP-12, American Concrete Institute, Farmington Hills

Panagiotakos TB, Fardis MN (2001) Deformation of reinforced concrete members at yielding and ultimate.

ACI Struct J 98(2):135148

Panagiotakos TB, Kosmopoulos AJ, Fardis MN (2002) Displacement-based seismic assessment and retrot

of reinforced concrete buildings. In: Proceedings of the 1st b congress, Osaka, Japan, October 1319,

pp 269278

Park R, Priestley MJN, Gill WD (1982) Ductility of square-conned concrete columns. J Struct Div ASCE

108(ST4):929950

Paulay T, Priestley MJN (1992) Seismic design of reinforced concrete and masonry buildings. Wiley,

New York

Perus I, Fajfar P (2007) Prediction of the force-drift envelope for RC columns in exure by the CAE method.

Earthq Eng Struct Dyn 36(15):23452363

Perus I, Poljansek K, Fajfar P (2006) Flexural deformation capacity of rectangular RC columns determined

by the CAE method. Earthq Eng Struct Dyn 35(12):14531470

Priestley MJN, Park R (1987) Strength and ductility of concrete bridge columns under seismic loading. ACI

Struct J 84(1):6176

Pujol S, Sozen MA, Ramirez JA (2006) Displacement history effects on drift capacity of reinforced concrete

columns. ACI Struct J 103(2):253262

Rossetto T (2002) Prediction of deformation capacity of non-seismically designed reinforced concrete mem-

bers. In: Proceedings of the 7th U.S. national conference on earthquake engineering, Boston, July 2125

Sezen H (2002) Seismic behavior and modeling of reinforced concrete building columns. PhD Dissertation,

Department of Civil and Environmental Engineering, University of California, Berkeley, California

Verderame GM, Fabbrocino G, Manfredi G (2008a) Seismic response of RC columns with smooth reinforce-

ment. Part I: monotonic tests. Eng Struct 30(9):22772288

Verderame GM, Fabbrocino G, Manfredi G (2008b) Seismic response of RC columns with smooth reinforce-

ment. Part II: cyclic tests. Eng Struct 30(9):22892300

Verderame GM, Ricci P, De Carlo G, Manfredi G (2009a) Cyclic bond behaviour of plain bars. Part I: exper-

imental investigation. Construct Build Mat 23(12):34993511

Verderame GM, De Carlo G, Ricci P, Fabbrocino G (2009b) Cyclic bond behaviour of plain bars. Part II:

analytical investigation. Construct Build Mat 23(12):35123522

Yalcin C, Kaya O, Sinangil M (2008) Seismic retrotting of R/C columns having plain rebars using CFRP

sheets for improved strength and ductility. Construct Build Mat 22(3):295307

Zhu L, Elwood KJ, Haukaas T (2007) Classication and seismic safety evaluation of existing reinforced

concrete columns. ASCE J Struct Eng 133(9):13161330

1 3

You might also like

- Experimental Study of Fatigue Flexural Performance of Concrete Beams Reinforced With Hybrid GFRP and Steel BarsDocument11 pagesExperimental Study of Fatigue Flexural Performance of Concrete Beams Reinforced With Hybrid GFRP and Steel BarsBesian SinaniNo ratings yet

- 31295014213010Document132 pages31295014213010Besian SinaniNo ratings yet

- Hybrid FRP/Steel RC Beams Numerical AnalysisDocument46 pagesHybrid FRP/Steel RC Beams Numerical AnalysisBesian SinaniNo ratings yet

- Experimental - Kalkan 2009Document9 pagesExperimental - Kalkan 2009Ivan VoriqueNo ratings yet

- Astm D7205D7205M 06Document13 pagesAstm D7205D7205M 06Besian SinaniNo ratings yet

- Project III Notes 0910 PDFDocument221 pagesProject III Notes 0910 PDFBesian SinaniNo ratings yet