Professional Documents

Culture Documents

Air Content Test Apparatus

Uploaded by

Golam Masud0 ratings0% found this document useful (0 votes)

198 views10 pagesThis test method covers the determination of the air content of freshly mixed concrete. It is exclusive of any air that may exist inside voids within aggregate particles. Working pressures of 7. To 30. Psi (51 to 207 kPa) have been used satisfactorily.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis test method covers the determination of the air content of freshly mixed concrete. It is exclusive of any air that may exist inside voids within aggregate particles. Working pressures of 7. To 30. Psi (51 to 207 kPa) have been used satisfactorily.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

198 views10 pagesAir Content Test Apparatus

Uploaded by

Golam MasudThis test method covers the determination of the air content of freshly mixed concrete. It is exclusive of any air that may exist inside voids within aggregate particles. Working pressures of 7. To 30. Psi (51 to 207 kPa) have been used satisfactorily.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 10

Page 1 of 10

Air Content Test Apparatus

(ASTM C231 & AASHTO T )

PRESSURE METHOD

This test method covers determination

of the air content of freshly mixed

concrete from observation of the

change in volume of concrete with a

change in pressure.

This test method covers the

determination of the air content of

freshly mixed concrete. The test

determines the air content of freshly

Page 2 of 10

mixed concrete exclusive of any air that

may exist inside voids within aggregate

particles. For this reason, it is

applicable to concrete made with

relatively dense aggregate particles and

requires determination of the aggregate

correction factor

Meter Type A

The operational principle of this meter

consists of introducing water to a

predetermined height above a sample of

concrete of known volume, and the

application of a predetermined air pressure

over the water. The determination consists of

Page 3 of 10

the reduction in volume of the air in the

concrete sample by observing the amount the

water level is lowered under the applied

pressure, the latter amount being calibrated

in terms of percent of air in the concrete

sample. [ H Ac ]

Page 4 of 10

Meter Type B

The operational principle of this meter

consists of equalizing a known volume of air

at a known pressure in a sealed air chamber

with the unknown volume of air in the

concrete sample, the dial on the pressure

gage being calibrated in terms of percent air

for the observed pressure at which

equalization takes place. Working pressures

of 7.5 to 30.0 psi (51 to 207 kPa) have

been used satisfactorily.

Page 5 of 10

Page 6 of 10

COVER ASSEMBLY

The cover assembly shall be fitted with a means of direct

reading of the air content. The cover for the Type A

meter shall be fitted with a standpipe, made of a

transparent graduated tube or a metal tube of uniform

bore with a glass water gage attached. In the Type B

meter, the dial of the pressure gage shall be calibrated to

indicate the percent of air.

Graduations shall be provided for a range in air content

of at least 8 % readable to 0.1 % as determined by the

proper air pressure calibration test.

The cover assembly shall be fitted with air valves, air

bleeder valves, and petcocks for bleeding off or through

which water may be introduced as necessary for the

particular meter design. Suitable means for clamping the

cover to the bowl shall be provided to make a pressure-

tight seal without entrapping air at the joint between the

flanges of the cover and bowl. A suitable hand pump

Page 7 of 10

shall be provided with the cover either as an attachment

or as an accessory.

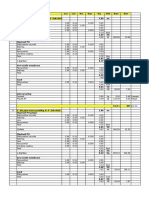

CALIBRATION VESSEL

A measure having an internal volume equal to a percent

of the volume of the measuring bowl corresponding to the

approximate percent of air in the concrete to be tested;

or, if smaller, it shall be possible to check calibration of

the meter indicator at the approximate percent of air in

the concrete to be tested by repeated filling of the

measure. When the design of the meter requires placing

the calibration vessel within the measuring bowl to check

calibration, the measure shall be cylindrical in shape and

of an inside depth 12 in. (13 mm) less than that of the

bowl.

NOTE 1A satisfactory calibration vessel to place within the

measuring bowl may be machined from No.16 gage brass tubing, of a

diameter to provide the volume desired, to which a brass disk 12 in.

in thickness is soldered to form an end. When design of the meter

requires withdrawing of water from the water-filled bowl and cover

assembly, to check calibration, the measure may be an integral part

Page 8 of 10

of the cover assembly or may be a separate cylindrical measure

similar to the above-described cylinder.

Page 9 of 10

Page 10 of 10

You might also like

- Design and Analysis of Flat Slab Floor SDocument93 pagesDesign and Analysis of Flat Slab Floor SKousalya MkNo ratings yet

- Compressive Strength of Hydraulic CementDocument3 pagesCompressive Strength of Hydraulic CementEr Mansoor HussainNo ratings yet

- Cube TestDocument15 pagesCube TestFAHIEMAH ZAHRA YAAKUBNo ratings yet

- Group H Civil Materials Lab 2A ReportDocument21 pagesGroup H Civil Materials Lab 2A ReportLanceNo ratings yet

- Sieve AnalysisDocument3 pagesSieve AnalysisArchana KushwahaNo ratings yet

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationFrom EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationNo ratings yet

- Sri Lanka Institute of Information Technology Faculty of Engineering Department of Civil EngineeringDocument21 pagesSri Lanka Institute of Information Technology Faculty of Engineering Department of Civil EngineeringmalithNo ratings yet

- Comparison Between Flexural and Tensile Modulus of Fibre CompositesDocument8 pagesComparison Between Flexural and Tensile Modulus of Fibre CompositesmehtabpathanNo ratings yet

- Experiment No. 2: Determination of Specific Gravity and Water Absorption of Coarse Aggregates SignificanceDocument4 pagesExperiment No. 2: Determination of Specific Gravity and Water Absorption of Coarse Aggregates SignificanceM Zeeshan HaiderNo ratings yet

- Blocks and Inserts: Aims of This ChapterDocument16 pagesBlocks and Inserts: Aims of This ChapterFasil Getachew100% (1)

- Tests Determine Aggregate PropertiesDocument9 pagesTests Determine Aggregate PropertiesRuthra ManickamNo ratings yet

- California Bearing RatioDocument8 pagesCalifornia Bearing RatioairpavsetNo ratings yet

- ICAR Rheometer: Eric Koehler W.R. Grace & CoDocument34 pagesICAR Rheometer: Eric Koehler W.R. Grace & CoHafiezul HassanNo ratings yet

- Building Mat 08-09Document39 pagesBuilding Mat 08-09takishiNo ratings yet

- Astm c131 06 LaavDocument4 pagesAstm c131 06 LaavRasya FiezaNo ratings yet

- Principal Construction Inspector: Passbooks Study GuideFrom EverandPrincipal Construction Inspector: Passbooks Study GuideNo ratings yet

- Chemical Water Proofing Rate Ana As Per SunandaDocument5 pagesChemical Water Proofing Rate Ana As Per SunandaVinodPotphodeNo ratings yet

- FM Lab ManualDocument76 pagesFM Lab ManualsidharthNo ratings yet

- Basf Masterflow 950 TdsDocument3 pagesBasf Masterflow 950 TdsplmoNo ratings yet

- Commonly Used Metric System Units and SymbolsDocument2 pagesCommonly Used Metric System Units and Symbolsgaylmm100% (2)

- Compressive Strength ConcreteDocument5 pagesCompressive Strength ConcreteMuhammad Sufian Sarwar100% (1)

- Cube TestDocument10 pagesCube Testridhuanzainal100% (1)

- Types of gas compressors explainedDocument5 pagesTypes of gas compressors explainedThivin RajNo ratings yet

- ArcSwat - WATERSHED TUTORIALDocument34 pagesArcSwat - WATERSHED TUTORIALBernard KitosiNo ratings yet

- Materials and Methods: Chapter-3Document8 pagesMaterials and Methods: Chapter-3javedsaqi100% (1)

- Test of AggregateDocument24 pagesTest of AggregatePriyank BhimaniNo ratings yet

- Quantification of Errors in Rapid Prototyping ProcessesDocument6 pagesQuantification of Errors in Rapid Prototyping ProcessesBalu ZerofourNo ratings yet

- Curved BeamDocument3 pagesCurved BeamOluwasegunfunmi AladegboyeNo ratings yet

- KNC 1101 Chemical Engineering Laboratory I Experiment ManualDocument36 pagesKNC 1101 Chemical Engineering Laboratory I Experiment ManualIzzatiHazwaniNo ratings yet

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- Cube Test ReportDocument2 pagesCube Test ReportyapluyiNo ratings yet

- 15mel57 - Fluid Mechanics and Machinery LabDocument44 pages15mel57 - Fluid Mechanics and Machinery LabVikas D NayakNo ratings yet

- Materials & loading details for hospital buildingDocument2 pagesMaterials & loading details for hospital buildingashishNo ratings yet

- Test 1 - Concrete Mix Design DishanDocument20 pagesTest 1 - Concrete Mix Design DishanYasndra AbeygunewardhaneNo ratings yet

- Improving Oman Airport With Stone ColumnsDocument6 pagesImproving Oman Airport With Stone ColumnsMAJ1980No ratings yet

- C6- Standard Consistency Cement PasteDocument4 pagesC6- Standard Consistency Cement PasteMuhamad FarhanNo ratings yet

- Heat of HydrationDocument3 pagesHeat of HydrationvigneshwarimahamuniNo ratings yet

- Water Cement Ratio (Gate60 Short Notes)Document4 pagesWater Cement Ratio (Gate60 Short Notes)akash rathodNo ratings yet

- Compaction TestDocument9 pagesCompaction TestFernando PascualNo ratings yet

- Curved BeamsDocument2 pagesCurved Beamsivan bolañosNo ratings yet

- QTO Tutorial PDFDocument11 pagesQTO Tutorial PDFJanesha100% (1)

- Concrete Mix Design and Casting of Sample For Different TestDocument4 pagesConcrete Mix Design and Casting of Sample For Different TestAqeel AliNo ratings yet

- Concrete Lab Manual - Standard Consistency TestDocument3 pagesConcrete Lab Manual - Standard Consistency TestMazharYasin100% (1)

- Asphalt Test Specific GravityDocument2 pagesAsphalt Test Specific GravityabualamalNo ratings yet

- Chapter 1 PDFDocument22 pagesChapter 1 PDFJoylyn Agapay LorenNo ratings yet

- Shear Force and Bending Moment DiagramDocument11 pagesShear Force and Bending Moment DiagramfreonxzNo ratings yet

- Introduction To ZWCAD: Drawing Plane FiguresDocument26 pagesIntroduction To ZWCAD: Drawing Plane FiguresKapil MannNo ratings yet

- Material Testing Lab Manual GuideDocument39 pagesMaterial Testing Lab Manual Guidemisbahuddin mdNo ratings yet

- Problem of RehologyDocument4 pagesProblem of RehologyShagufta AfaqueNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Structural Desktop and Structural Desktop LT TutorialDocument56 pagesStructural Desktop and Structural Desktop LT TutorialDe Jesus Cerqueira MarcioNo ratings yet

- Introduction To Auto CadDocument31 pagesIntroduction To Auto CadazhiNo ratings yet

- Calibrate Venturi and Orifice Flow MetersDocument12 pagesCalibrate Venturi and Orifice Flow MetersAaron Fraka Riches100% (1)

- Design of Tension MembersDocument22 pagesDesign of Tension MembersashishbnNo ratings yet

- Project Report Group 4Document28 pagesProject Report Group 4Akame TakashitaNo ratings yet

- Jce 69 2017 1 2 1574 enDocument10 pagesJce 69 2017 1 2 1574 enMarco Dos Santos NevesNo ratings yet

- SPT and CPTDocument57 pagesSPT and CPTGolam MasudNo ratings yet

- CAN ID MASS AND PLASTICITY CHART DATADocument12 pagesCAN ID MASS AND PLASTICITY CHART DATAGolam MasudNo ratings yet

- How Is Ground Investigation MadeDocument39 pagesHow Is Ground Investigation MadeGolam MasudNo ratings yet

- The Use and Abuse of The Slump Test For Measuring The Workability of Concrete PDFDocument11 pagesThe Use and Abuse of The Slump Test For Measuring The Workability of Concrete PDFdep_vinNo ratings yet

- Soil InvestigationDocument56 pagesSoil InvestigationGolam MasudNo ratings yet

- Sedimenmetamorfcolprful PDFDocument30 pagesSedimenmetamorfcolprful PDFPaulus PanduNo ratings yet

- C2/JMBP (Spec Extract From P.85) : Grading Requirement For Rock Used For Slope Protection of Jamuna RiverDocument1 pageC2/JMBP (Spec Extract From P.85) : Grading Requirement For Rock Used For Slope Protection of Jamuna RiverGolam MasudNo ratings yet

- Widening and Improvement of Road and Construction of Flyover at Mirpur Cantt. Estimation For Soil InvestigationDocument5 pagesWidening and Improvement of Road and Construction of Flyover at Mirpur Cantt. Estimation For Soil InvestigationGolam MasudNo ratings yet

- C 1260Document5 pagesC 1260Golam MasudNo ratings yet

- Borehole Logging Procedures SummaryDocument9 pagesBorehole Logging Procedures SummaryGolam MasudNo ratings yet

- Can Id MassDocument12 pagesCan Id MassGolam MasudNo ratings yet

- Soil InvestigationDocument56 pagesSoil InvestigationGolam MasudNo ratings yet

- SPT and CPTDocument57 pagesSPT and CPTGolam MasudNo ratings yet

- How Is Ground Investigation MadeDocument39 pagesHow Is Ground Investigation MadeGolam MasudNo ratings yet

- How Is Ground Investigation MadeDocument39 pagesHow Is Ground Investigation MadeGolam MasudNo ratings yet

- How Is Ground Investigation MadeDocument39 pagesHow Is Ground Investigation MadeGolam MasudNo ratings yet

- SPT and CPTDocument57 pagesSPT and CPTGolam MasudNo ratings yet

- ASTM Grooving ToolDocument2 pagesASTM Grooving ToolGolam MasudNo ratings yet

- GI ParagraphsDocument36 pagesGI ParagraphsGolam MasudNo ratings yet

- Geotechnical Investigation Guide - Essentials of Site Exploration and TestingDocument13 pagesGeotechnical Investigation Guide - Essentials of Site Exploration and TestingGolam MasudNo ratings yet

- Geotechnical Investigation PresentationDocument2 pagesGeotechnical Investigation PresentationGolam MasudNo ratings yet

- KarbalaDocument529 pagesKarbalaGolam MasudNo ratings yet

- GI ParagraphsDocument36 pagesGI ParagraphsGolam MasudNo ratings yet

- 1 Test Requests: /conversion/tmp/scratch/383298889Document43 pages1 Test Requests: /conversion/tmp/scratch/383298889Golam MasudNo ratings yet

- QA Manuals for Quality Assurance ProcessesDocument1 pageQA Manuals for Quality Assurance ProcessesGolam MasudNo ratings yet

- GI ParagraphsDocument13 pagesGI ParagraphsGolam MasudNo ratings yet

- Article On Asphalt Concreting PDFDocument8 pagesArticle On Asphalt Concreting PDFGolam MasudNo ratings yet

- Yazid Ibn Mu PDFDocument21 pagesYazid Ibn Mu PDFGolam MasudNo ratings yet

- Notable Feminist Says Women Consented When TheyDocument1 pageNotable Feminist Says Women Consented When TheyGolam MasudNo ratings yet

- Unit 1 - Gear Manufacturing ProcessDocument54 pagesUnit 1 - Gear Manufacturing ProcessAkash DivateNo ratings yet

- Katie Tiller ResumeDocument4 pagesKatie Tiller Resumeapi-439032471No ratings yet

- CIT 3150 Computer Systems ArchitectureDocument3 pagesCIT 3150 Computer Systems ArchitectureMatheen TabidNo ratings yet

- Entity Level ControlsDocument45 pagesEntity Level ControlsNiraj AlltimeNo ratings yet

- ISO 9001:2015 Explained, Fourth Edition GuideDocument3 pagesISO 9001:2015 Explained, Fourth Edition GuideiresendizNo ratings yet

- Petty Cash Vouchers:: Accountability Accounted ForDocument3 pagesPetty Cash Vouchers:: Accountability Accounted ForCrizhae OconNo ratings yet

- Striedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsDocument22 pagesStriedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsOsny SillasNo ratings yet

- Propiedades Grado 50 A572Document2 pagesPropiedades Grado 50 A572daniel moreno jassoNo ratings yet

- Intro To Gas DynamicsDocument8 pagesIntro To Gas DynamicsMSK65No ratings yet

- DECA IMP GuidelinesDocument6 pagesDECA IMP GuidelinesVuNguyen313No ratings yet

- Phys101 CS Mid Sem 16 - 17Document1 pagePhys101 CS Mid Sem 16 - 17Nicole EchezonaNo ratings yet

- Numerical Methods Chapter 10 SummaryDocument8 pagesNumerical Methods Chapter 10 SummarynedumpillilNo ratings yet

- 3ccc PDFDocument20 pages3ccc PDFKaka KunNo ratings yet

- Change Management in British AirwaysDocument18 pagesChange Management in British AirwaysFauzan Azhary WachidNo ratings yet

- Pom Final On Rice MillDocument21 pagesPom Final On Rice MillKashif AliNo ratings yet

- Wi FiDocument22 pagesWi FiDaljeet Singh MottonNo ratings yet

- Polytechnic University Management Services ExamDocument16 pagesPolytechnic University Management Services ExamBeverlene BatiNo ratings yet

- UAPPDocument91 pagesUAPPMassimiliano de StellaNo ratings yet

- Estimation of Working CapitalDocument12 pagesEstimation of Working CapitalsnehalgaikwadNo ratings yet

- Site Visit Risk Assessment FormDocument3 pagesSite Visit Risk Assessment FormAmanuelGirmaNo ratings yet

- Audit Acq Pay Cycle & InventoryDocument39 pagesAudit Acq Pay Cycle & InventoryVianney Claire RabeNo ratings yet

- CR Vs MarubeniDocument15 pagesCR Vs MarubeniSudan TambiacNo ratings yet

- Service and Maintenance Manual: Models 600A 600AJDocument342 pagesService and Maintenance Manual: Models 600A 600AJHari Hara SuthanNo ratings yet

- 1.2 - Venn Diagram and Complement of A SetDocument6 pages1.2 - Venn Diagram and Complement of A SetKaden YeoNo ratings yet

- ESA Knowlage Sharing - Update (Autosaved)Document20 pagesESA Knowlage Sharing - Update (Autosaved)yared BerhanuNo ratings yet

- Prenatal and Post Natal Growth of MandibleDocument5 pagesPrenatal and Post Natal Growth of MandiblehabeebNo ratings yet

- Photographing Shadow and Light by Joey L. - ExcerptDocument9 pagesPhotographing Shadow and Light by Joey L. - ExcerptCrown Publishing Group75% (4)

- Sarvali On DigbalaDocument14 pagesSarvali On DigbalapiyushNo ratings yet

- Leaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeDocument6 pagesLeaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeAnonymous iTNFz0a0No ratings yet

- Federal Complaint of Molotov Cocktail Construction at Austin ProtestDocument8 pagesFederal Complaint of Molotov Cocktail Construction at Austin ProtestAnonymous Pb39klJNo ratings yet