Professional Documents

Culture Documents

Check List For Haul, Placement, and Finishing of Bridge Deck Concrete

Uploaded by

MIbrAHim0 ratings0% found this document useful (0 votes)

16 views2 pages1) The document provides a checklist for hauling, placing, and finishing bridge deck concrete. It lists 14 items to check for hauling concrete, 13 items for concrete placement, and 4 items to check for concrete testing.

2) Key steps include ensuring trucks have working counters, inspecting mixing drums and blades, recording mixing times and proportions, lightly wetting forms, depositing concrete near its final position, vibrating properly, and checking the concrete surface for flatness while plastic.

3) Testing requirements include having the required equipment, using ACI certified testers, and having enough personnel and molds to perform all necessary testing.

Original Description:

Original Title

revdeck4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document provides a checklist for hauling, placing, and finishing bridge deck concrete. It lists 14 items to check for hauling concrete, 13 items for concrete placement, and 4 items to check for concrete testing.

2) Key steps include ensuring trucks have working counters, inspecting mixing drums and blades, recording mixing times and proportions, lightly wetting forms, depositing concrete near its final position, vibrating properly, and checking the concrete surface for flatness while plastic.

3) Testing requirements include having the required equipment, using ACI certified testers, and having enough personnel and molds to perform all necessary testing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views2 pagesCheck List For Haul, Placement, and Finishing of Bridge Deck Concrete

Uploaded by

MIbrAHim1) The document provides a checklist for hauling, placing, and finishing bridge deck concrete. It lists 14 items to check for hauling concrete, 13 items for concrete placement, and 4 items to check for concrete testing.

2) Key steps include ensuring trucks have working counters, inspecting mixing drums and blades, recording mixing times and proportions, lightly wetting forms, depositing concrete near its final position, vibrating properly, and checking the concrete surface for flatness while plastic.

3) Testing requirements include having the required equipment, using ACI certified testers, and having enough personnel and molds to perform all necessary testing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

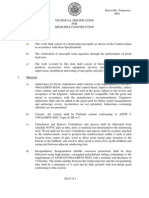

CHECK LIST FOR HAUL, PLACEMENT, AND FINISHING OF

BRIDGE DECK CONCRETE

HAULING

1.) Are all trucks used for transporting concrete equipped with working revolution

counters?

2.) Have trucks been checked to insure the drums and blades are adequate and in

good repair?

3.) Are all trucks equipped with a method of accurately measuring water added at

the job site?

4.) Are initial mixing revolutions being placed on the haul tickets?

5.) If water is added at the site are an additional 30 mixing revolutions being

accomplished and is this recorded on tickets?

6.) Are the total mixing and agitating revolutions being placed on the haul

tickets? This number can not exceed 300.

7.) Are the batch (when cement contacts aggregate) and discharge times being

placed on the tickets?

8.) Are the proper batch proportions being placed on the haul tickets?

PLACEMENT

1.) Are forms and reinforcing steel being lightly wetted in front of placement?

2.) Has all debris been removed from forms?

3.) Is concrete being deposited at or near it final position?

4.) Is the free fall of the concrete from the end of the pump or bucket 5 or less?

5.) Is the required pour rate being met? Unless otherwise shown in the contract

the minimum pour rate should be 30 ft/hr for entire width of pour or 20 ft/hr

for slab bridges.

6.) If epoxy coated re-bar is used is the vibrator covered with nonmetallic sleeve?

7.) Are vibrators being used properly? They should not be used to move concrete

around.

8.) Have vibrators been properly certified within the last 90 days to insure proper

impulses per minute?

9.) Does the contractor have adequate tools and personnel to properly place and

finish the deck? There should be back up vibrators, concrete pump or crain

and bucket, and generator.

10.) If more than 45 minutes have elapsed since concrete has been placed the

contractor should place a bulk head and stop the pour.

11.) If the temperature of the superstructure concrete is 80F. or above the

time of discharge is 60 minutes. If below 80F. the time of discharge is 90

minutes or 300 revolutions.

12.) Are instruments available on site to measure wind velocity, concrete

temperature, air temperature, and relative humidity? These are needed to

determine the rate of surface evaporation of concrete. The evaporation rate

cant exceed 0.20 lbs/sq.ft./hr (0.98 kg/m/hr).

13.) If the wind should increase during the pour does the contractor have

material to erect windbreaks?

14.) Does the contractor have 10 foot straight edge or float to check the

trueness of the deck so corrections can be made while the concrete is still

plastic?

TESTING

1.) Do the project personnel have all of the required equipment to perform the

testing? This should include 2 pressure meters or two roll-a-meters, slump

cone. thermometers, scales, wheelbarrow, tamping rods, rubber mallet, and

all of the scoops and shovels needed to complete the tests.

2.) Are the testers ACI certified?

3.) Are there sufficient personnel to adequately accomplish the testing? Should

be 2 to 3.

4.) Are there sufficient cylinder molds?

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Check List For Foundation OHE - 001 - Rev - 00Document4 pagesCheck List For Foundation OHE - 001 - Rev - 00Varadharajalu Gopal100% (2)

- Day 8 - Materials-Engineer-Test-ReviewerDocument3 pagesDay 8 - Materials-Engineer-Test-Reviewerwe are the gamersNo ratings yet

- Check List For Ohe Mast Grouting - 003 - Rev - 00Document4 pagesCheck List For Ohe Mast Grouting - 003 - Rev - 00Varadharajalu Gopal100% (2)

- Method Statement For Asphalt Paving WorksDocument5 pagesMethod Statement For Asphalt Paving WorksGokulakrishnan Govindarajan100% (1)

- Lean Concrete Base Course: Specification RequirementsDocument6 pagesLean Concrete Base Course: Specification RequirementsHeng KimsanNo ratings yet

- Replacement of Waste Water Piping From Neutralization Sump in Utility Area To Manhole at Al Hamra Gulf ClubDocument2 pagesReplacement of Waste Water Piping From Neutralization Sump in Utility Area To Manhole at Al Hamra Gulf ClubMirza AliNo ratings yet

- Method Statement For Exterrnal PlasteringDocument7 pagesMethod Statement For Exterrnal PlasteringSagar ParabNo ratings yet

- Civil Constraction Method - DrainaseDocument7 pagesCivil Constraction Method - DrainaseIrvan MaulaNaNo ratings yet

- Drift Work MethodologyDocument8 pagesDrift Work MethodologyTheodore Teddy Kahi100% (2)

- 204 - Subgrade Compaction and Proof Rolling-Test Rolling (2012)Document6 pages204 - Subgrade Compaction and Proof Rolling-Test Rolling (2012)roldski100% (1)

- Concrete WorksDocument4 pagesConcrete WorksmrameshceNo ratings yet

- Method Statement For ConstructionDocument8 pagesMethod Statement For ConstructionTin DanNo ratings yet

- Section 5-Part 8-Transportation and Placing of ConcreteDocument6 pagesSection 5-Part 8-Transportation and Placing of ConcreteAdamNo ratings yet

- Method Statement For VDFDocument7 pagesMethod Statement For VDFSagar Parab100% (2)

- PQC Methodology-2Document7 pagesPQC Methodology-2venkateswara rao Pothina100% (1)

- Method Statement of Consolidation Grouting - V0Document8 pagesMethod Statement of Consolidation Grouting - V0Mike Eugene Collins50% (2)

- 02 Spec Guniting Works Rev20200610Document8 pages02 Spec Guniting Works Rev20200610Tony JamesNo ratings yet

- Guidelines For Concrete WorksDocument6 pagesGuidelines For Concrete WorksFaysal MadiNo ratings yet

- 1.1 Consumable Materials (All Details To Be in Appendix)Document17 pages1.1 Consumable Materials (All Details To Be in Appendix)Thimira Bandara EkanayakeNo ratings yet

- Auxiliary Boiler MSDocument10 pagesAuxiliary Boiler MSsharif339No ratings yet

- Materials Engineer Examination With Answers SET1 PDFDocument24 pagesMaterials Engineer Examination With Answers SET1 PDFArmie May Rico100% (1)

- 05-7 QCS 2014Document8 pages05-7 QCS 2014Raja Ahmed HassanNo ratings yet

- Guniting Slope, Ed.1, Rev.0Document8 pagesGuniting Slope, Ed.1, Rev.0Andrei Radu100% (2)

- Method Statement For Roof Water Proofing 24.12.2021Document6 pagesMethod Statement For Roof Water Proofing 24.12.2021Sagar ParabNo ratings yet

- Method of Statement For Pipeline WorkDocument15 pagesMethod of Statement For Pipeline WorkHalil Güney100% (3)

- PCC Slab Full Depth Repair MethodologyDocument4 pagesPCC Slab Full Depth Repair Methodologypascua.jpmNo ratings yet

- T-242 - Method Statement For Excavation & BackfillDocument9 pagesT-242 - Method Statement For Excavation & Backfillsindalisindi100% (1)

- ARAMCO Test Questions-1Document13 pagesARAMCO Test Questions-1AHMAD YAGHI67% (6)

- Piping Question and AnswerDocument7 pagesPiping Question and AnswerMohammed Abdul Moqeet100% (10)

- Borehole Drilling and Equiping at Bethulie StationDocument12 pagesBorehole Drilling and Equiping at Bethulie StationZack DaveNo ratings yet

- Special Note 11c For Drilled ShaftsDocument9 pagesSpecial Note 11c For Drilled ShaftsM. SanjeevNo ratings yet

- S7P2 - Casing and Cementing: MarkingDocument13 pagesS7P2 - Casing and Cementing: MarkingHunterNo ratings yet

- Method Statement For Roof Water ProofingDocument6 pagesMethod Statement For Roof Water ProofingSagar ParabNo ratings yet

- Appendixc Well Drilling ProcedureDocument7 pagesAppendixc Well Drilling Proceduremartahan manurungNo ratings yet

- Method Statement Concrete PouringDocument4 pagesMethod Statement Concrete PouringSmart ShivaNo ratings yet

- 3510 - Specification For Sand Base Course 3510 - 1 DescriptionDocument4 pages3510 - Specification For Sand Base Course 3510 - 1 DescriptionShe Timbancaya100% (1)

- Concrete ExamDocument26 pagesConcrete ExamKyra AlesonNo ratings yet

- Qcs 2010 Section 5 Part 8 Transportation and Placing of ConcreteDocument7 pagesQcs 2010 Section 5 Part 8 Transportation and Placing of Concretebryanpastor106No ratings yet

- (2021-11-22) Method Satement-Concrete Pouring Sequence & StagesDocument7 pages(2021-11-22) Method Satement-Concrete Pouring Sequence & StagesudithaNo ratings yet

- Bituminous Prime Coat: DescriptionDocument4 pagesBituminous Prime Coat: DescriptionHurriyat AliNo ratings yet

- MS - Borewell Removal (Rev.0) NDS30Document17 pagesMS - Borewell Removal (Rev.0) NDS30Suvajit BisaiNo ratings yet

- Section 3 - Specification For Soil Nailing: 3.1 GeneralDocument10 pagesSection 3 - Specification For Soil Nailing: 3.1 GeneralrowatersNo ratings yet

- HPHT Check ListsDocument15 pagesHPHT Check ListsWaleed Barakat MariaNo ratings yet

- Supply and Install of Stand Up 603 Can WasherDocument3 pagesSupply and Install of Stand Up 603 Can WasherMing ValienteNo ratings yet

- Palmer Bowlus Flume SpecificationDocument7 pagesPalmer Bowlus Flume SpecificationDevansh SharmaNo ratings yet

- Check List For Clearing and Grubbing: Pre-Construction StageDocument35 pagesCheck List For Clearing and Grubbing: Pre-Construction StageAnimesh Narayan SinghNo ratings yet

- A. Survey WorksDocument7 pagesA. Survey Worksugrasen chaudharyNo ratings yet

- Parshall Flume Specification by OpenchannelflowDocument7 pagesParshall Flume Specification by Openchannelflowmnazzal2010No ratings yet

- Method Statement FOR Concreting Work: ProjectDocument6 pagesMethod Statement FOR Concreting Work: ProjectKelvin LauNo ratings yet

- Recovery QsDocument4 pagesRecovery Qsmohamedmero2001No ratings yet

- ClayDocument4 pagesClaySaud PathiranaNo ratings yet

- Soil Boring Sampling and Procedures AdoptedDocument1 pageSoil Boring Sampling and Procedures AdoptedAamirChaudharyNo ratings yet

- Technical Detils of SiteDocument3 pagesTechnical Detils of SitePtpgStucNo ratings yet

- Especifications For Jet Grouting PDFDocument7 pagesEspecifications For Jet Grouting PDFMarco Dos Santos NevesNo ratings yet

- Method Statement GiyaniDocument3 pagesMethod Statement GiyaniryanNo ratings yet

- Street Lights SpecificationsDocument9 pagesStreet Lights SpecificationsLenard BuenaventuraNo ratings yet

- Design, Supply, and Install of Stand-Up 603 Can WasherDocument2 pagesDesign, Supply, and Install of Stand-Up 603 Can WasherMing ValienteNo ratings yet

- Technical Specification For Micropile ConstructionDocument9 pagesTechnical Specification For Micropile ConstructionFFerideKochanNo ratings yet

- AI CalculatorDocument41 pagesAI CalculatorAneeza zafarNo ratings yet

- A Simple Favor 2018 720p BluRay x264 - (YTS AM) mp4Document2 pagesA Simple Favor 2018 720p BluRay x264 - (YTS AM) mp4Dewi SartikaNo ratings yet

- Introduction To Fission and FusionDocument19 pagesIntroduction To Fission and FusionZubair Hassan100% (1)

- Chapter 2 - FIR Filters - Digital Filter Design - Mikroelektronika PDFDocument114 pagesChapter 2 - FIR Filters - Digital Filter Design - Mikroelektronika PDFAnimesh NagrareNo ratings yet

- Synchronous Generators - 2 Marks Questions and AnswersDocument3 pagesSynchronous Generators - 2 Marks Questions and AnswersJoseph Harindranath67% (3)

- Iteration: Chapter GoalsDocument46 pagesIteration: Chapter GoalsAni AniNo ratings yet

- Altivar Process Ride Through Time - IE04Document3 pagesAltivar Process Ride Through Time - IE04Goran MladenovicNo ratings yet

- AZ-104-MicrosoftAzureAdministrator LAB 02a Manage Subscriptions and RBACDocument7 pagesAZ-104-MicrosoftAzureAdministrator LAB 02a Manage Subscriptions and RBACgvroctaNo ratings yet

- 9.coordination CompoundsDocument46 pages9.coordination CompoundsSeenu MNo ratings yet

- Operational AmplifiersDocument35 pagesOperational AmplifierskunwarNo ratings yet

- Definitions - Topic 9 The Periodic Table - CAIE Chemistry IGCSE PDFDocument1 pageDefinitions - Topic 9 The Periodic Table - CAIE Chemistry IGCSE PDFAtif BakhshNo ratings yet

- Elementary Data Organisation-1Document15 pagesElementary Data Organisation-1zidhi bachaNo ratings yet

- OnlineInternetBankingSystem ProjectDocument81 pagesOnlineInternetBankingSystem ProjectTeam 24x7No ratings yet

- K Type Thermocouple Extension Cable KXYY (1-50) Pairs X 1.5 MM 300 VDocument1 pageK Type Thermocouple Extension Cable KXYY (1-50) Pairs X 1.5 MM 300 VArthurNo ratings yet

- Applied Statistics For Bioinformatics Using RDocument279 pagesApplied Statistics For Bioinformatics Using RArdhi ShihabNo ratings yet

- ESDS312, ESDS314 Data-Line Surge and ESD Protection Diode ArrayDocument20 pagesESDS312, ESDS314 Data-Line Surge and ESD Protection Diode ArrayBenNo ratings yet

- Cummins 161110083846 PDFDocument18 pagesCummins 161110083846 PDFMuhammad IshfaqNo ratings yet

- More Than One Answer Is CorrectDocument182 pagesMore Than One Answer Is CorrectNikhil GandhiNo ratings yet

- Principle of StatisticsDocument6 pagesPrinciple of StatisticsMd Tarekul IslamNo ratings yet

- Machine Design-II Question BankDocument9 pagesMachine Design-II Question BankProf. Avinash MahaleNo ratings yet

- Phy Interface Pci Express Sata Usb31 Architectures Ver43 PDFDocument99 pagesPhy Interface Pci Express Sata Usb31 Architectures Ver43 PDFRaj Shekhar ReddyNo ratings yet

- Gen Nav WeOneDocument272 pagesGen Nav WeOnecaptvivekNo ratings yet

- Mwakican Joint Examination: 232/3 PhysicsDocument3 pagesMwakican Joint Examination: 232/3 Physicsandy gideonNo ratings yet

- HVAC Control in The New MillenniumDocument389 pagesHVAC Control in The New Millenniumnicky1213aNo ratings yet

- Mid Year Test: Objective QuestionsDocument3 pagesMid Year Test: Objective QuestionsNur SuHaNo ratings yet

- REVIEW TASK 1 - Capitalization, Punctuation, Fragments, Run-On Sentences and Subject & Verb Agreement Review (-1Document2 pagesREVIEW TASK 1 - Capitalization, Punctuation, Fragments, Run-On Sentences and Subject & Verb Agreement Review (-1Johao DoradoNo ratings yet

- For And: Viterbi Decoding Satellite Space CommunicationDocument14 pagesFor And: Viterbi Decoding Satellite Space CommunicationRosi Marleny Machuca rojasNo ratings yet

- Digital Microelectronic Digital Microelectronic Circuits Circuits ( (Document24 pagesDigital Microelectronic Digital Microelectronic Circuits Circuits ( (Gowtham HariNo ratings yet

- CS 515 Data Warehousing and Data MiningDocument5 pagesCS 515 Data Warehousing and Data MiningRahumal SherinNo ratings yet

- Electrolysis 4.1Document42 pagesElectrolysis 4.1Maham khanNo ratings yet