Professional Documents

Culture Documents

July Techlink 2013 F1

Uploaded by

cherokewagOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

July Techlink 2013 F1

Uploaded by

cherokewagCopyright:

Available Formats

July 2013, Volume 15, No.

7

Contents

The 2014 Chevrolet Spark EV . . . . . . . . . . . . . . . . . 1

Solving Service Programming System Errors . . . . . 1

2014 Spark EV Safety Precautions . . . . . . . . . . . . . 3

2014 Spark EV Bulletin Information . . . . . . . . . . . . 4

Finding Diesel Fuel Stations . . . . . . . . . . . . . . . . . . 5

Exterior Roof Panel Sag . . . . . . . . . . . . . . . . . . . . . 5

Radio Amplier Performance . . . . . . . . . . . . . . . . . . 6

Rattle or Thump Noise above 45 MPH . . . . . . . . . . 6

Full Blower/Heat from Vents at Start-up . . . . . . . . 6

Connect Back-up Alarm during PDI . . . . . . . . . . . . . 6

Insufcient Cooling when the

A/C Compressor is On . . . . . . . . . . . . . . . . . . . . . . 7

Battery Drain during Dinghy Towing . . . . . . . . . . . . 7

Service Stability Message Condition . . . . . . . . . . . . 8

Reduced Audio Volume from Rear Speakers . . . . . . 8

Engine Bulletins Summary . . . . . . . . . . . . . . . . . . . . 8

Inspect Grounds G100 through G107 for

Electrical Conditions . . . . . . . . . . . . . . . . . . . . . . . . 8

Car Issues Fix It Right the First Time . . . . . . . . . . 9

Truck Issues Fix It Right the First Time . . . . . . . . . 9

Service Know-How . . . . . . . . . . . . . . . . . . . . . . . . . 9

Customer Care and Aftersales

TECHLINE

news

Solving Service Programming

System Errors

Service Programming System (SPS)

errors that are received during pro-

gramming may be the result of several

different occurrences that can be solved

without replacing the control module.

Most errors can be resolved by follow-

ing some basic troubleshooting steps.

Following are several specic SPS

programming errors (E4398, E4399,

E4403, E4404 E4413, E4414, E4423

or E4491, E4494) and how to resolve

the issue.

E4398 No Calibration Data

This error is the result of a missing

or incomplete data record. It is not

related to the control module being

programmed or a vehicle issue. Contact

the Techline Customer Support Center

(TCSC).

E4399/E4403 Severe Error

These general programming errors are

typically the result of a loss of com-

munication between the programming

device and the control module. The

loss of communication can be caused

by a drop in battery voltage, delay in

communication with the module, or a

continued on page 4

No calibration error

continued on page 2

The 2014 Chevrolet Spark EV (Electric Vehicle) builds on the

technology and innovation the Volt has brought to Chevrolet.

The Spark EV does not have a gasoline engine or a gasoline

fuel system. It is a ve door, four passenger vehicle that is

being sold only in California and Oregon.

The Spark EV uses GMs Global A electrical architecture,

which is common with many other Chevrolet models, such

as the Camaro, Cruze, and Volt. This requires the use of the

Global Diagnostic System 2 (GDS 2) software and the

Multiple Diagnostic Interface (MDI) module.

Electric Drive Unit

The propulsion of the Spark EV is achieved by an electric

drive transmission. The transmission is a fully automatic, front

wheel drive transaxle. It consists primarily of an 85kW drive

motor, a planetary gear set, high voltage electric auxiliary

transmission uid pump and housing, a differential gear set,

and two axles.

All Electric All the Time

The 2014 Chevrolet Spark EV

2 July 2013

The 2014 Chevrolet Spark EV continued from page 1

The planetary

gear set provides

xed forward and

reverse ratios.

Changing speed

and torque is

fully automatic

and is accom-

plished through

the use of a drive

motor generator

power inverter

control module

that receives and

monitors various

electronic sensor

inputs and uses

this informa-

tion to vary the

torque output to

the drive axles

based on throttle

position.

360V High-Voltage Battery

The Spark EV is powered by a 21.4 kilowatt hour (kW/h) lithium-

ion high-voltage battery pack located beneath the vehicle, strad-

dling the rear axle.

The heart of the Spark EV electric propulsion system is its ad-

vanced Li-Ion drive motor battery system. The high-voltage (HV)

battery is liquid cooled for long life and optimum performance.

It contains 336

cells with a nomi-

nal system volt-

age of 369V DC.

The battery cell

groups are joined

to form four

equal sections.

Battery system

diagnostics and

system status is

communicated

from the hybrid/

EV battery

energy control

module to the hybrid/EV powertrain control module 2 through

serial data. The hybrid/EV powertrain control module 2 is the host

controller for Diagnostic Trouble Code (DTC) information.

Driving the Spark EV

To start the Spark EV, with the vehicle in Park or Neutral, press

the brake pedal and then press the POWER button on the center

of the instrument panel.

The Remote Keyless Entry transmitter (key fob) must be in the

vehicle to turn on the vehicle. If the transmitter battery is weak,

a NO REMOTE DETECTED message may be displayed. To start

the vehicle with the key, remove the rubber cap on the right side

of the steering column and insert the key into the slot to start the

vehicle. The key cylinder DOES NOT rotate. Press the POWER

button to start the car.

To turn off the car, shift to Park and press the POWER button.

The Spark

EV uses a

12V battery

to wake up

and initialize

the control

modules. If the

vehicle does

not power-up,

ensure that the

12V battery

is sufciently

charged. The

12V bat-

tery, located

in the front

compartment,

is an AGM

(Absorbed Gas Mat) type that requires different charging

voltages than conventional lead acid batteries.

TIP: When using essential tool EL-50313 (GR-8), select AGM

when prompted or damage to the battery will result.

When driving the Spark EV, the transmission should be placed

in the Drive (D) position for all normal driving conditions. This

provides maximum efciency and range economy and enables

the drive unit to operate in a forward direction by electronically

varying the output torque and speed of the electric motor.

The transmission can be placed in Low (L) for the feel of engine

braking and to slow the vehicle once the throttle is lifted. While

in the Low position, the vehicle will slow more quickly and use the

motor to more aggressively collect energy during a regenerative

braking event.

The Spark EV also features a Pedestrian Friendly Alert Function

(PFAF) to alert those nearby of the vehicles presence. To acti-

vate a friendly horn, pull the turn signal lever toward you like you

are ashing the headlights. The alert will only work in Drive.

The PFAF also can be set to activate automatically. It is active in

Drive and Reverse at speeds below 18 mph (28 km/h). The sound

is intended to be barely audible in the cabin.

Operating Characteristics

Due to the quiet nature of the Spark EV propulsion system,

certain sounds will be apparent that may have been masked by a

gasoline engines natural harmonics. Among them are the electric

engine cooling fan, coolant pumps, the air conditioning com-

pressor and the HVAC blower. The drive motor battery cooling

system may be operational during charging or when the vehicle is

powered down. This may be more evident when charging or during

remote cabin conditioning.

An electric motor whine sound may be heard as the vehicle

moves. This is a normal operating characteristic.

The Spark EV has a unique brake pedal feel. The hydraulic sys-

tem is not the lone means of vehicle deceleration. Regenerative

and hydraulic braking forces are blended, depending upon vehicle

conditions.

The hydraulic braking system uses a high-speed electric motor/

pump. Pump operation can sometimes be heard and felt in the

brake pedal as the system builds pressure.

Drive unit components:

1. Drive motor generator

2. Planetary gears

3. Differential

4. Auxiliary transmission uid pump

5. 3-Phase cable connections

continued on page 3

High-voltage battery

Remove the rubber cap on the steering

column to start the vehicle with the key.

The key cylinder does not rotate.

July 2013 3

TIP: Over several braking events, drivers may perceive that

they are applying a consistent brake force and yet the vehicle may

decelerate at slightly different rates. This is a normal operating

characteristic to maximize battery efciency.

Charging

There are cur-

rently two ways

to charge the

Spark EV: 120V

outlet and 240V

outlet.

The provided

120-volt AC

portable vehicle

charge cord is

located in the

storage com-

partment under

the cargo oor.

With the vehicle parked, press the Leaf button on the center stack

to review the Charge Level Preference on the touch screen for the

selected Charge Mode. There are three different charge modes:

Immediate; Delayed based on departure time; and Delayed based

on electric rate and departure time.

Select the Change Charge Level screen button if an increased

charging level is desired. Once the charge level is selected, turn

off the vehicle.

TIP: The Charge

Level selection re-

turns to the reduced

level (8 amps) each

time the vehicle is

cycled on/off.

Do not use an

extension cord when

plugging the AC

charge cord into

an electrical outlet.

Charge cord indica-

tors should be green.

With the charge

cord plugged

into the vehicles

charge port, the

Charge Status

Indicator on top

of the instrument

panel will illumi-

nate. The Charge Status Indicator will be green and the horn will

chirp when properly connected.

The Charge Status Indicator glows green or yellow to display the

charging status. If there is no indicator, the drive motor battery

charger cable is not working properly or is not connected.

Wheels and Tires

The 2014 Spark EV features low rolling resistance Bridges-

tone ECOPIA tires. The sizes are P185/55R15 in the front and

P195/55R15 in the rear, to handle the additional weight from the

battery pack.

TIP: Because the tires are different sizes, they cannot be

rotated front to back.

If the vehicle will be driven in snow or mud, all-season tires are

recommended. Both front and rear tires must be replaced with

all-season tires.

Special Tools and Technical Support

Essential tools will be shipped to selling and servicing dealers.

A specialized Technical Assistance Center (TAC) team has been

established to provide diagnostic support for the Spark EV. All

issues are encouraged to be reported to TAC.

Thanks to Kristin Curran, Chuck Wieseckel

Special safety precautions are required

during service of the 2014 Spark EV.

To reduce the risk of severe shock and

burns, treat all high voltage cables and

connectors as though they are energized

until it can be veried that they are not.

Always perform the High Voltage

Disabling procedure outlined in the

appropriate Service Information before

servicing any High Voltage component or

connection. The High Voltage Disabling

procedure involves:

Identifying how to disable high voltage

Identifying how to test for the presence of

high voltage

Identifying conditions under which high

voltage is always present and Personal

Protection Equipment (PPE) and proper

procedures must be followed.

Before working on any high voltage

system, be sure to wear the following

personal protection equipment:

Safety glasses with appropriate side

shields when within 50 feet (15 m) of the

vehicle, either indoors or outdoors

Certifed and up-to-date Class 0 insula-

tion gloves rated at 1000V with leather

protectors

Visually and functionally inspect the

gloves before use

Wear the insulation gloves at all times

when working with the high voltage

battery assembly, whether the system is

energized or not

Thanks to Kristin Curran and

Chuck Wieseckel

2014 Spark EV Safety Precautions

120-volt AC portable vehicle charge cord

Charge Status Indicator

Charging Volts Charging Time

120V

8 amps

12 amps

Greater than 20 hours

Less than 20 hours

240V 7 hours

Light Indication

Solid green Vehicle charging

Fast ashing green Charging delayed

Slow ashing green Charging complete

Solid yellow Vehicle not able to accept charge

4 July 2013

2014 Spark EV Bulletin Information

The following bulletins have been released

to provide information about the Spark

EV. Be sure to read each bulletin for full

information.

11-08-49-001H Transport Mode

On Message covers how to turn off

Transport Mode.

PI1012 Spark EV New Model

Features and Service Guide high-

lights the operation and service features of

the new Spark EV.

PI0994 Normal Characteristic

Electric Parking Brake (EPB)

Auto-Apply for System Self Test

explains that the EPB will perform a self

test if it has not been applied during the

past 50 ignition cycles. This is normal

operation and no service is required.

PI0985A High Voltage Battery

Gauge Displaying Less Than Full

Charge (10 Bars) explains that this

may occur

at low

battery tem-

peratures

(below 32F,

0C) and

when charg-

ing in cold

ambient

tempera-

tures (less

than 32F,

0C) at

240 volts. The vehicles control system

must learn the state of charge of the new

battery pack. This is accomplished by fully

charging the battery pack. If a new battery

pack is charged for the rst time when the

battery is less than 32F (0C), the control

system is unable to complete the learn

process. Repeated charge attempts or a

warmer battery pack are required to nish

the learn process.

PIC5880 Spark EV TAC Parts

Restriction Program explains that

certain listed components are on restric-

tion through the TAC.

PIP5112 Spark EV High Voltage

Drive Motor Battery Restriction

and Exchange Process explains how

to establish a case number and obtain

authorization for replacing the drive

motor battery. It also provides diagnos-

tic information, safety procedures and

service procedures to be followed for the

exchange process.

Do not remove the Drive Motor Battery

assembly covers unless instructed to do so

by TAC or Engineering. The Drive Motor

Battery may also be referred to as the

Rechargeable Energy Storage System

(RESS). If the failure is due to one of the

non-serviceable components, the battery

will be exchanged.

TECHLINE

news

vehicle issue such as interruption on the

BUS (wiring, connector issue, aftermar-

ket components, etc.).

Make sure a minimum of 12.5 volts

is maintained during programming.

Attempt to re-establish communication

with the control module using GDS2

or a Tech 2. If communication can be

established, reattempt programming

using Replace and Program ECU as

the programming method. If communica-

tion cannot be re-established, deplete

retained power by disconnecting the

negative battery terminal for a minimum

of ve minutes. Re-establish and main-

tain battery power, attempt to commu-

nicate with the control module using the

MDI or Tech 2. Reattempt programming

using Replace and Program ECU.

TIP: Some pre-2007 model vehicles may

require using the Tech2 and the Legacy

Tech 2 programming option in SPS

in order to use a slower programming

communication speed.

E4413/E4414 Calibrations

marked with an ( * )

An asterisk ( * ) indicates that the SPS

application is not recognizing the cali-

brations being read from the control

module, which can be caused by a non-

GM calibration programmed into the

control module or an incomplete SPS

data record.

Refer to the latest version of Bulletin

#08-06-04-006. If this bulletin does not

apply, restart the SPS application and

select Replace and Reprogram as the

programming method. This procedure

will overwrite the unidentied software

and calibrations.

E4404/E4494 No

Communication with

Diagnostic Tool

This is a loss of communication between

the programming device (MDI or Tech

2) and the Techline PC. It is not a mod-

ule or vehicle problem.

Conrm the connection from the PC. If

the programming device is connected by

USB, select a different USB port on the

Techline PC. If using a wireless network

for the MDI connection, conrm the

wireless connection or switch to a USB

connection. Disable the MDI wireless

connection in the MDI wireless manager

when using a USB connection.

If programming with a Tech 2, per-

form a Tech 2 self-test, found in SPS

under Settings > Diagnostics > Test

Connections. Be sure to use a known

good Techline PC serial port connector

and RS232 cable.

Conrm and maintain proper battery

voltage before attempting programming.

E4491/E4423 Programming

Failed

These programming errors can occur

from different areas. If encountered on

a service module, conrm the correct

part number is being used and conrm

programming is possible by attempting

to program the original module.

For assistance from TCSC, be sure to

have the original and service module

part numbers and error detail available.

If a programming error cannot be

resolved, do not replace the control

module before contacting TCSC. TCSC

can be reached at 1-800-828-6860

(English) or 1-800-503-3222 (French).

Thanks to Bob Kerzka

continued from page 1

continued on page 5

Check for a loss of communication

with the programming device.

Solving Service

Programming

System Errors

High-voltage

battery gauge

July 2013 5

Exterior Roof Panel Sag

A sag/depression area may appear on the roof of 2013 Express

and Savana vans with 15 passenger seating (RPO ZP3) at times

and then go away. This condition is most prevalent on dark

colored vehicles. The affected area is 3 to 7 feet (0.9-2.1 m) from

the rear edge of the roof with the deepest depression at 5 feet

(1.5 m) from rear edge.

The sag appears

when the van is

sitting outside in

the sun and will

go away when van

roof surface cools

down, but will reap-

pear when parked

back in the sun.

This sag is most

prevalent on the

passengers side

of the vehicle, but

may also appear on

the drivers side.

The sag on the roof is caused by an insufcient amount of (anti-

utter) sealer between the third and fourth roof bows and the

outer panel. As the roof panel expands in the sunlight, the sealer

does not expand as intended, causing the low areas to appear.

Remove the (anti-utter) sealer in the affected area and install

shim material. If possible, perform the repair in direct sunlight.

This will cause the roof outer skin to expand and increase the gap

between the roof panel and the roof bows for easier installation of

the shim material.

TIP: Use care to not damage the roof outer sheet metal while

cutting the sealer. Do not use utility knives, putty knives or any

hard metal tools to cut the sealer material, which may create out

dings in the roof panel.

The sealer can be

cut using a wire

windshield cut out

tool. The loose

sealer can be

removed using a

plastic trim stick or

plastic putty knife.

Install 3/4 x 5/16

inch adhesive-

backed foam

shim stock and

3/4 x 7/16 inch

adhesive-backed

foam shim stock

between the roof

panel and the

third roof bow

and fourth roof

bow. Position the

5/16-inch mate-

rial closest to the

outer end of the

roof bow. The

7/16-inch mate-

rial should be

positioned toward

the center of the

roof bow.

Refer to #PI1005 for complete repair instructions and adhesive-

backed foam shim stock information.

Thanks to Gary Kirrkamm

The sag may appear when the

van is sitting in the sun.

Cut the sealer using a wire windshield

cut out tool.

Position the 5/16-inch material closest to the

outer end of the roof bow.

Finding Diesel Fuel Stations

using XM Travel Link

The new 2014 Cruze Clean Turbo

Diesel model is available with XM

Travel Link (subscription required).

XM Travel Link provides fuel loca-

tions and prices as well as weather

and other travel information. By

conguring XM Travel Link to show

fuel stations that sell diesel fuel,

owners have access to a conve-

nient list of local diesel fuel stations

(omitting from the list those that

do not.).

To customize the menu to show

only diesel fuel stations:

1. From the main menu on the touch screen, select Fuel (the Fuel selection may

be on the second or third page of the main menu depending on how the menu

has been congured)

2. Select Menu

3. Select Fuel Type

4. Select Diesel

Thanks to Tod Stump

Select the Fuel icon to

access the fuel menu.

PIP5131 SPARK EV 1ET35 Drive Unit

Exchange Program explains the exchange

program for the Spark EV drive unit. It also pro-

vides diagnostic information, safety procedures

and service procedures to be followed for the

exchange process.

Current serviceable Drive Unit-related compo-

nents:

Drive Unit

Oil cooler lines

Replacement seals for oil cooler joints

External wiring harness from the vehicle to the

Drive Unit

Drive Motor/Generator Power Inverter Module

Cable Housing Cover Seal

Drive Unit mount

Repairs involving any other Drive Unit components

may require a Drive Unit exchange. Serviceable

components are subject to change as the program

progresses.

Thanks to Kristin Curran and Chuck Wieseckel

6 July 2013

Full Blower/

Heat from

Vents at

Start-up

When the 2013 Malibu with manual HVAC

(RPO C67) is started, the HVAC blower

may be at full speed and/or full heat may

be coming from the vents. This intermit-

tent condition may be present with the

blower and temperature knobs in any

position.

Reprogram the Electronic Climate Control

Module (ECC) using the Service Program-

ming System (SPS); select ECC Remote

Heater and Air Condition Control Module

Programming. Once completed, perform

ECC Remote Heater and Air Condition

Control Module Setup. Evaluate the

performance of both systems.

Thanks to Christopher Crumb

Trunk-Mounted Radio

Amplier Performance

On some

2010-2013

LaCrosse;

2011-2013

Regal; 2013

ATS, XTS,

Malibu; and

2014 Impala

models

equipped with a

trunk-mounted

radio speaker

amplier, the

speakers may

have intermit-

tent poor audio

quality, such as

a buzz, pop, or

static noise.

Check the trunk-mounted radio amplier for any signs of moisture. Remove

all connectors and inspect the terminals for corrosion.

If evidence of moisture is present, or it appears water may have run over

the amplier, inspect the rear sunroof drain tubes, if equipped, for leaks

or blockage. Also water test the trunk, sunroof, back glass and roof areas.

Repair any leaks identied.

Replace the amplier if water is present and replace any corroded termi-

nals that have corrosion.

Thanks to David Roat

Rattle or Thump

Noise above 45 MPH

A utter or

thumping

noise may

be heard

on some

2011-2014

Cruze and

2012-2014

Verano

models

from the

side or

underneath

of the

vehicle at

speeds of

45 mph and above. If this condition is present, check

the air deectors mounted on either side under the

vehicle. Make sure that all fasteners are in place and

secure. Replace any fasteners as needed.

If all fasteners are secure, it may be necessary to apply

felt to the underbody of the vehicle above the inside

edge of each air deector (between each fastener loca-

tion) to eliminate the noise.

TIP: If the customer makes frequent trips on a gravel

road, it may be necessary to remove the deectors,

clean off any debris and reinstall before making any

repairs.

Thanks to Christopher Crumb

Amplier location on the Malibu

Apply felt to the underbody of the vehicle

above each air deector.

Connect Backup Alarm during PDI

On 2014 Silverado

2500/3500 and Sierra

2500/3500 models

equipped with the Backup

Alarm (RPO 8S3), it may be

noticed during PDI that the

backup alarm is inoperative.

The backup alarm also is

available on the 2008-2013

Silverado and Sierra.

The backup alarm is inten-

tionally left disconnected

at the assembly plant. It

must be connected at the

dealership.

The alarm is located on the

right rear of the frame and the chassis harness alarm connector is located on the left

rear of the frame. Route the harness up and over the spare tire hoist tube and con-

nect it to the backup alarm.

Thanks to Scott Fibranz

A. Backup Alarm/Connector

B. Spare Tire Hoist Tube

July 2013 7

Insufcient Cooling when the

A/C Compressor is On

The 2012-2013 Equinox

and Terrain equipped with

the V6 engine (RPO LFX)

may have erratic or insuf-

cient cooling when the A/C

compressor is turned on.

This condition may be due

to the A/C compressor

not being torqued properly

at the time of assembly,

causing a load on the

compressor shaft.

Loosen the A/C com-

pressor mounting bolts

and re-torque. The A/C

compressor should be held

tight/ush to the engine block during the nal torque sequence to ensure proper align-

ment. Refer to the appropriate Service Information for the A/C Compressor Mounting

torque and tightening sequences.

After the compressor mounting bolts have been torqued, run the vehicle with the A/C on

for a minimum of two minutes to ensure sufcient A/C performance.

Thanks to Doug Daugherty

Battery Drain during Dinghy Towing

After several hours of dingy

towing (i.e. being towed

behind another vehicle

with all four wheels on the

ground), the battery of

the 2010-2011 LaCrosse

may be completely dis-

charged. The reason for

this is because the ve-

hicles transmission must

remain in Neutral and the

ignition mode must remain

in Accessory while dinghy

towing the vehicle.

TIP: As stated in the

vehicles owner manual,

2012-2014 LaCrosse

models should NOT be

dinghy towed.

For 2010-2011 LaCrosse models, the owner manual does not provide instructions on

dinghy towing. The following procedures should be followed to avoid battery drain while

dinghy towing a 2010-2011 LaCrosse.

Key Ignition Vehicles To prevent the battery from draining, remove fuse #22

(Discrete Logic Ignition Switch) from the instrument panel fuse block.

Pushbutton Ignition Vehicles To prevent the battery from draining, disconnect

the negative battery cable from the battery.

In each of these cases, the vehicle should be securely connected to the tow vehicle and

the transmission placed in Neutral before disabling the electrical system.

Thanks to David Roat

1. A/C compressor upper bolt

2. A/C compressor rear bolt

3. A/C compressor lower bolt

GM TechLink is published for all

GM retail technicians and service

consultants to provide timely

information to help increase know-

ledge about GM products and

improve the performance of the

service department.

Publisher:

John Meade

GM Customer Care and Aftersales

Editor:

Lisa G. Scott

GM Customer Care and Aftersales

Technical Editor:

Mark Spencer

/mspencer@gpstrategies.com

Production Manager:

Marie Meredith

Desktop Publishing:

5by5 Design LLC

/dkelly@5by5dzign.com

FAX number: 3

1-248-729-4704

Write to: *

TechLink

PO Box 500

Troy, MI 48007-0500

GM TechLink on the Web: :

GM GlobalConnect

General Motors service tips are intended

for use by professional technicians, not

a do-it-yourselfer. T hey are written to

inform those technicians of conditions

that may occur on some vehicles, or to

provide information that could assist in

the proper service of a vehicle. Properly

trained technicians have the equipment,

tools, safety instructions and know-how to

do a job properly and safely. If a condition

is described, do not assume that the

information applies to your vehicle or that

your vehicle will have that condition. See a

General Motors dealer servicing your brand

of General Motors vehicle for information

on whether your vehicle may benet from

the information.

Inclusion in this publication is not

necessarily an endorsement of the

individual or the company.

Copyright 2013 General Motors

All rights reserved.

A. Fuse 22 in the instrument panel fuse block

8 July 2013

Service Stability

Message

Condition

If the 2013 LaCrosse, Regal, or Malibu dis-

plays a Service Stability message on the Driver

Information Center and has an illuminated

ABS MIL, check for DTC C0800 Symptom 07

(Control Module Power Circuit High Voltage).

DTC C0800 may be set along with any of the

following wheel speed sensor DTCs:

C0035 (Left Front Wheel Speed Sensor

Circuit)

C0040 (Right Front Wheel Speed Sensor

Circuit)

C0045 (Left Rear Wheel Speed Sensor Circuit)

C0050 (Right Rear Wheel Speed Sensor Circuit

TIP: Do not replace the Electronic Brake

Control Module (EBCM) for DTC C0800.

Diagnose and repair any wheel speed sensor

fault before addressing DTC C0800.

Thanks to Christopher Crumb

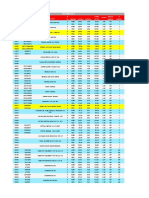

Engine

Bulletins

Summary

A summary of important engine-

related bulletins and Preliminary

Information (PI) has been recently

released to help build awareness

of the latest engine informa-

tion available. The list provides a

convenient resource for engine

technicians when performing

engine repairs.

In the Inspect Grounds article, in

the second image caption, delete

G104 with glue contamination.

The caption should read: Clean or

repair any poor connections.

Prior to beginning any repairs, its

critical to always follow Strategy-

Based Diagnostics and check the

appropriate Service Information for

any bulletins or PIs that may apply.

Thanks to the TAC team

Reduced Audio

Volume from

Rear Speakers

Owners of the 2011-2013 Cruze

equipped with Premium Audio (RPO

UQA) may notice a volume difference

between the front and rear speakers.

With the Premium Audio option, the

audio is ltered through the amplier,

which separates the high, midrange and

low frequencies.

If this condition is present, compare

the audio system operation with a like

vehicle with the same RPO. Use the

same music selection to get a good

comparison between the two vehicles.

If the comparison results are identical,

no further repairs are necessary. This

is a normal characteristic of the audio

system.

Thanks to Christopher Hightower

Inspect Grounds G100 through G107 for Electrical

Conditions

When

diagnosing

electrical

conditions,

such as no

air condi-

tioning; air

conditioning

performance;

engine crank,

no start; en-

gine no crank;

instrument

panel cluster

concerns,

etc., on some

2012-2013

Sonics,

inspect grounds G100 through G107.

If an electrical condition cannot be veried during diagnosis and/

or if the appropriate Service Information does not easily isolate

the cause, refer to the Service Information locations and inspect

grounds G100 through G107.

Check the

grounds for

any condi-

tions may

that affect

electrical

performance,

such as glue

contamina-

tion, loose or

disconnected,

or poor termi-

nal crimp or

contact.

If necessary,

follow the

Measuring

Voltage Drop procedure in the Service Information to determine

if excessive voltage drop is present, which is also an indication of

a poor ground connection.

Clean, repair and/or torque the ground as necessary and

re-evaluate the concern.

Thanks to James Parkhurst

G104 with glue contamination Clean or repair any poor connections.

July 2013 9

Car Issues Fix It Right the First Time

Model

Year(s)

Vehicle Line(s)/Condition Do This Dont Do This

Reference

Information/Bulletin

2013 Sonic Unable to make a call using phone icon on

radio

Reprogram the radio using the SPS

with the latest calibrations available

on TIS2Web.

Replace the radio. PI0953

2012-2013 Sonic Hatchback liftgate will not open using remote

key fob and touchpad

New software update. Replace BCM. PI0945

2012-2013 Sonic Engineering Information Front compartment

(underhood) fuse block replacement

Engineering phone call. Replace UBEC. PIE0252

2013 ATS Front brake squeal or squeak noise

intermittently on initial brake applies

Apply grease as specied. Replace brake pads or rotors. PI0917A

2013 ATS Driver or passenger power seatback recliner

stuck and/or will not recline

Free the recliner following this

procedure.

Replace the seat back frame. PI0948A

2013 ATS Engineering Information Active grille aero

shutter malfunction

Call engineer before work on aero

shutter if DTCs P069E and P059F or

P069E and U0284 are present.

Grab or attempt to move the

shutter louvers, disassemble

the shutter assembly, or

remove the actuator from the

shutter assembly.

PIE0256

2011-2013 Trax, Sonic, Cruze, Encore Diagnostic tips for front

cover oil leak

Use oil dye to determine the leak

location and repair as necessary.

Replace front timing chain

cover for oil leak.

PI0957

2012-2013 Cruze Pulsating/rotational noise from right rear of

vehicle on brake apply

Replace right rear brake drum, shoes,

and apply high temp grease.

Don't turn the drum. PI0887B

2010-2014 LaCrosse, Verano, Sonic, Regal, Malibu, Impala,

Cruze Intermittent unwanted trunk opening while

vehicle is parked

Install "2-Shot" trunk relay per PI. Replace any other

component.

PI0924

Truck Issues Fix It Right the First Time

Model

Year(s)

Vehicle Line(s)/Condition Do This Dont Do This

Reference

Information/Bulletin

2011-2013 Captiva Engine no crank/no start and/or

inoperative HVAC control

Replace module with new part

number known.

Use the old part number. PI0944A

2012-2013 Captiva Engineering Information Power rear door

lock difcult to operate, binds

Call the Engineer prior to repair. Repair car prior to calling the

engineer.

PIE0244A

2012 Traverse, Acadia Left rear side door molding loose

at front edge, contacting rear edge of left front door

or door side molding

Modify molding before installing. Use the locator on the molding

to align the molding.

PI0947

2007-2014 Enclave, Acadia, Outlook Diagnostic Tip DIC

switch buttons are inoperative

Remove battery power to the IPC

after service is performed to either

the DIC switch or the IPC for

return of DIC function.

Replace multiple modules for

DIC function to return.

PIT4534D

2013 Traverse, Acadia, Enclave Diagnostic Tip No

communication with the right side blind zone module

Follow instructions for

programming module.

Replace multiple modules

because of inability to

communicate.

PIT5211

Customer Care and Aftersales

Service

Know-How

10213.07D Emerging Issues

To view Emerging Issues seminars:

Log in to www.centerlearning.com

Select Resources, and then Video on Demand; or

Select Catalog to search for the course number, and then

select View > Take or Continue Course

July 11, 2013

1

Important Bulletins and PIs for Engine Technicians

This listing is based on information available as of June 15, 2013.

Follow strategy-based diagnostics and check the Service Information for the latest bulletins and PIs.

Engine RPO Models Bulletin/PI Subject

4 CYL

1.4 LUV/LUJ

2011 Chevrolet Cruze PIP5036D Possible oil consumption or blue smoke from the exhaust CEL or

fuel trim codes

2011 2012 Chevrolet Cruze

2012 Sonic

PI0851A Turbocharger oil feed and return line inspection when servicing

turbocharger assembly

2011-2012 Chevrolet Cruze PI0850 Whistle noise heard from engine compartment, rough idle and/or

DTC P0171 set

1.6 LXV 1.8 LUW/2H0

2009-2011 Chevrolet Aveo

2011-2013 Chevrolet Cruze

20122013 Chevrolet Sonic

2009-2010 Pontiac Wave/G3

2008-2009 Saturn Astra

PIP4977A Diagnostic Tip - Information regarding oil flow and the oil restrictor

orifice in the engine block deck

2009-2011 Chevrolet Aveo

2011-2012 Chevrolet Cruze

2012 Chevrolet Sonic

2009-2010 Pontiac G3, Wave

PI0725 Normal engine cylinder bore marks

2009-2011 Chevrolet Aveo

2011-2013 Chevrolet Cruze

2012-2013 Chevrolet Sonic

PI0867 Intermittent engine no crank, intermittent exhaust Camshaft Position

(CMP) sensor signal

1.8 LAY 2009 Pontiac Vibe AIP3423 MIL on after CMP actuator gear replacement

2.0L LTG

2013 Cadillac ATS

2013 Chevrolet Malibu

PI0768C Engine exchange

2.4 LAF/LUK/LEA

2011-2012 Buick LaCrosse, Regal

2011-2012 Chevrolet Equinox

2011-2012 GMC Terrain

PI0562F Cold start rattle noise

2.4 LAF

2010-2011 Buick Lacrosse

2011 Buick Regal

2010-2011 GMC Terrain

PIP5025A Oil consumption

2.4 LAF

2010 Buick LaCrosse

2010 Chevrolet Equinox

2010 GMC Terrain

PIP4872 MIL on with P0171 P0089 and/or P228d and high fuel pressure after

engine replacement

2.5L LCV

2013 Cadillac ATS

2013 Chevrolet Malibu

PI0768C Engine exchange

2.5 LKW 2014 Chevrolet Impala PIP5106 Engine exchange

2

Engine RPO Models Bulletin/PI Subject

6 CYL

All HFV6

2013 Cadillac ATS

2007-2013 Cadillac CTS

2007-2013 Cadillac SRX

2007-2011 Cadillac STS

2013 Cadillac XTS

2007-2013 GMC Acadia

2010-2013 GMC Terrain

2007-2009 Pontiac G6

2007-2010 Saturn Outlook

2007-2009 Saturn Aura

2007-2013 Buick Lacrosse, Allure (Canada only)

2008-2013 Buick Enclave

2008-2010 Saturn Vue

2010-2013 Chevrolet Camaro

2012-2013 Chevrolet Impala

2008-2012 Chevrolet Malibu

2008-2013 Chevrolet Equinox

2009-2013 Chevrolet Traverse

2008-2009 Pontiac Torrent

PIP4384G Supplement to SI timing procedure for high feature V-6 engine

3.0 LF1/LFW

3.6 LFX/LLT

2011-2013 Buick Enclave

2011-2013 Buick LaCrosse

2013 Cadillac ATS

2011-2013 Cadillac CTS

2011 Cadillac STS

2011-2013 Cadillac SRX

2013 Cadillac XTS

2011-2013 Chevrolet Camaro

2012-2013 Chevrolet Caprice PPV

2012-2013 Chevrolet Captiva Sport

2011-2013 Chevrolet Equinox

2012-2013 Chevrolet Impala

2011-2013 Chevrolet Traverse

2011-2013 GMC Terrain

PIP4959C Cold start misfires

LY7, LLT

2008-2011 Buick Enclave

2007-2011 Chevrolet Malibu

2009-2011 Chevrolet Traverse

2007-2011 GMC Acadia

2007-2010 Saturn OUTLOOK

PI0746C Poor acceleration, throttle body freezing, multiple DTCs set, ice

deposits and/or oil deposits present in air inlet duct

3

Engine RPO Models Bulletin/PI Subject

6 CYL

ALL HVV6 3.5 /3.9

2009-2011 Buick Lucerne

2006 Buick Rendezvous

2005-2006 Buick Terraza

2007-2011 Chevrolet Impala

2007-2010 Chevrolet Malibu

2006-2007 Chevrolet Monte Carlo

2005-2006 Chevrolet Uplander

2005-2008 Pontiac G6

2005-2006 Pontiac Montana SV6

2007-2008 Saturn Aura

2005-2006 Saturn Relay

2007 Saturn Vue

PIP5064C Rough running - idle surge - CEL on or CMP actuator codes after

installation of reman HVV6

4.3LVIN H RPO

LV3

2014 Chevrolet Silverado, GMC Sierra PIP5114 Engine exchange

4.6 LHU

2007 - 2009 Cadillac SRX, STS, XLR PIP4577M SES light with DTCs P0171 and P0174 - Possible air leaks

L52/LL8/LLR/LK5/LLV

2004-2009 Chevrolet TrailBlazer

2004-2011 Chevrolet Colorado

2004-2011 GMC Envoy

2004-2011 GMC Canyon

2004-2009 Hummer H3

PIP3694E Belt noise rough idle and/or SES light with DTC P0014 and/or P0017

- Inspect CMP actuator solenoid and crankshaft end play

2006 - 2009 Buick Rainier

2006 - 2011 Chevrolet Colorado

2006 - 2009 Chevrolet TrailBlazer

2006 - 2011 GMC Canyon

2006 - 2009 GMC Envoy

PIP4913 SES light intermittent DTC P0017 after cylinder head replacement

engine oil debris contamination

5.3LVIN C RPO L83 2014 Chevrolet Silverado, GMC Sierra PIP5114 Engine exchange

L76, L77, L94, L99,

LC9, LFA, LH6, LMG,

LS 4, LY5, LZ1

2008 - 2009 Buick LaCrosse, Allure (Canada Only)

2007 Buick Rainier

2007 - 2012 Cadillac Escalade

2010 - 2012 Chevrolet Camaro SS

2007 - 2012 Chevrolet Avalanche, Silverado,

Suburban, Tahoe

2006 - 2009 Chevrolet Trailblazer

2006 - 2009 Chevrolet Impala SS

2006 - 2007 Chevrolet Monte Carlo SS

2006 - 2009 GMC Envoy

2007 - 2012 GMC Sierra, Yukon

2008 - 2009 Pontiac G8

2005 - 2008 Pontiac Grand Prix GXP

2006 - 2009 Saab 97x

PIP4568L Tick noise and/or misfires on AFM cylinders 1 4 6 and/or 7

4

Engine RPO Models Bulletin/PI Subject

8 CYL

L94, L99, LZ1, LC9,

LH6, L76, L92, LFA,

LMG, LY5

2007-2011 Cadillac Escalade Models

2007-2011 Chevrolet Avalanche, Silverado 1500,

Suburban, Tahoe

2010-2011 Chevrolet Camaro

2007-2011 GMC Sierra 1500, Sierra Denali, Yukon

Models

2008-2009 Pontiac G8 GT

10-06-01-

008I

Oil consumption AFM engines

V8 engine

2004-2007 Buick Rainier

2008-2009 Buick LaCrosse, Allure (Canada Only)

2006-2013 Cadillac CTS-V

2002-2013 Cadillac Escalade

2010-2013 Chevrolet Camaro

2011-2013 Chevrolet Caprice

2002-2013 Chevrolet Avalanche

1999-2013 Chevrolet Express, Silverado,

Suburban, Tahoe

2009-2013 Chevrolet Colorado

2003-2009 Chevrolet Trailblazer

2006-2009 Chevrolet Impala SS

2006-2007 Chevrolet Monte Carlo SS

2003-2006 Chevrolet SSR

2005-2013 Chevrolet Corvette

2009-2013 GMC Canyon

2003-2009 GMC Envoy

1999-2013 GMC Savana, Sierra, Yukon

2003-2010 Hummer H2

2008-2010 Hummer H3

2008-2010 Pontiac G8

2005-2006 Pontiac GTO

2005-2008 Pontiac Grand Prix GXP

2005-2009 Saab 97x

PIP4138M SES light, misfire, DTC P0300, and/or a chirp, squeak, squeal, or

tick noise

6.0 LC8

2012 Chevrolet Express

2012 GMC Savana

PI0802 Fuel gauge inoperative, P0463 DTC set, Malfunction Indicator Lamp

(MIL) light on, fuel gauge drops to empty after 1/2 tank

2013 and Prior GM Passenger Cars and Trucks 01-00-89-

010I

Comeback prevention information and using Customer Concern

Verification Sheets (CCVS)

2011 Chevrolet Express 2500, 3500 Cargo Vans

2011 GMC Savana 2500, 3500 Cargo Vans

PI0528A Intermittent engine flutter during hard braking maneuver, engine

hard to start

5

Engine RPO Models Bulletin/PI Subject

8 CYL

LFA, LY2, L20, LMG

LC9, LH6, LMF, LH8

LH9, L76, LS2,

LY5, LY6, L92, L96

LZ1, L94, L9H

2008-2011 Cadillac Escalade Models

2009-2011 Cadillac Escalade Two-Mode Hybrid

2008-2009 Chevrolet TrailBlazer

2008-2011 Chevrolet Avalanche, Colorado,

Express, Silverado, Suburban, Tahoe

2008-2011 Chevrolet Tahoe Two-Mode Hybrid

2009-2011 Chevrolet Silverado Two-Mode Hybrid

2008-2009 GMC Envoy

2008-2011 GMC Canyon, Savana, Sierra, Sierra

Denali, Yukon Models

2008-2011 GMC Yukon Two-Mode Hybrid

2009-2011 GMC Sierra Two-Mode Hybrid

2008-2009 HUMMER H2

2008-2010 HUMMER H3

11-06-04-

007c

Malfunction Indicator Lamp (MIL) illuminated, reduced engine power

message displayed, DTC P2135 set

DIESEL

2.0 (LUZ) 2014 Chevrolet Cruze PIP5116 Engine exchange

6.6 LLY

2004-2005 Chevrolet Silverado 2500HD, 3500

2004-2005 GMC Sierra 2500 HD, 3500

2004-2005 Chevrolet Kodiak

2004-2005GMC TopKick

PIP3129B Smoke, fuel knock, surging and high injector balance rates

20042005 Chevrolet Silverado

20042005 Chevrolet Kodiak C4500/C5500 Series

20042005 GMC Sierra

20042005 GMC Topkick C4500/C5500 Series

05-06-04-

047B

Service Engine Soon (SES) light on with reduction in engine power,

DTCs P0202 and P2149 or P0207 and P2146 or P1294 set (Install

revised 90 degree injector connector w/harness support bracket kit)

2004-2009 Chevrolet Express, Kodiak, Silverado,

Silverado Classic

2004-2009 GMC Savana, Sierra, Sierra Classic,

Topkick

PIP4629A Diesel engine turbo DTC P2563 or P003A

6.6L ( LGH, LML)

2010 - 2013 Chevrolet Express

2010 - 2013 GMC Savana

2011 - 2013 Chevrolet Silverado

2011 - 2013 GMC Sierra

Equipped with the 6.6 Duramax Diesel Engine

(RPO codes LML and LGH)

PIP5088 6.6L Duramax diesel engine (RPO LGH and LML) part number

12638502

6

Engine RPO Models Bulletin/PI Subject

DIESEL

6.6 LMM

2007-2009 Chevrolet Kodiak, Silverado

2007-2009 GMC Sierra, Topkick

PIP4516D Light and medium duty trucks EGR DTC P0401

20062007 Chevrolet Express, Kodiak

C4500/C5500 Series, Silverado, Silverado Classic

08-06-04-

029C

LBZ, LLY, LMM MIL/SES Light On, DTC P0087-Fuel Rail Pressure

(FRP) too low, lack of performance, no power, engine runs rough, no

start (diagnose fuel system components)

2001-2007 Chevrolet Silverado Classic

2001-2007 GMC Sierra Classic

2007-2009 Chevrolet Silverado

2007-2009 GMC Sierra

PIP4526 Diesel engine fuel line repairs

6.6 LML

2011 - 2013 Chevrolet Silverado and GMC Sierra PIP5007A Exhaust fluid quality poor message difficult to clear

2010-2011 Chevrolet Express, Silverado PIP4829B Service exhaust fluid message will not clear

2010-2011 GMC Savana, Sierra PIP4949C Duramax diesel hard start no start or DTC P0087 injection pump

replacement

ALL ENGINES

All engines 2013 and Prior GM Passenger Cars and Trucks 00-06-01-

012D

Use of surface conditioning disks when cleaning engine gasket

sealing surfaces and/or reused engine parts

You might also like

- SSP-NR 550 The Passat GTE PDFDocument72 pagesSSP-NR 550 The Passat GTE PDFan89% (9)

- Designing and Tuning High-Performance Fuel Injection SystemsFrom EverandDesigning and Tuning High-Performance Fuel Injection SystemsRating: 3.5 out of 5 stars3.5/5 (7)

- Jaguar Workshop Manual X-Type 2001-2009 PDFDocument2,810 pagesJaguar Workshop Manual X-Type 2001-2009 PDFJonas Lucius100% (2)

- W221 en PDFDocument13 pagesW221 en PDFalirio0% (1)

- Ka Mk2 EnglishDocument168 pagesKa Mk2 EnglishecirstoiuNo ratings yet

- Gears Magazine January February PDFDocument120 pagesGears Magazine January February PDFcherokewag100% (2)

- Gears Magazine January February PDFDocument120 pagesGears Magazine January February PDFcherokewag100% (2)

- Rav4 Ev: Electric Vehicle Dismantling ManualDocument31 pagesRav4 Ev: Electric Vehicle Dismantling ManualDinu Lucian100% (1)

- Azure Dynamics Emergency Response Guide PDFDocument32 pagesAzure Dynamics Emergency Response Guide PDFwopontourNo ratings yet

- Ford Think Owners ManualDocument118 pagesFord Think Owners ManualDennis Jason Anti100% (5)

- Outboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairFrom EverandOutboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairRating: 3 out of 5 stars3/5 (1)

- Flexible, Safe and Reliable Suit Highly Complex Logistics Systems or Simple A-To-B Transport ScenariosDocument2 pagesFlexible, Safe and Reliable Suit Highly Complex Logistics Systems or Simple A-To-B Transport ScenariosMohit ComputerNo ratings yet

- 21.1029 Lowbed 100 Ton On Volvo FMX 480 6x4Document88 pages21.1029 Lowbed 100 Ton On Volvo FMX 480 6x4SoNo ratings yet

- Catalogo Valvulas TRWDocument41 pagesCatalogo Valvulas TRWCold SnowNo ratings yet

- Chevrolet Spark Electric Vehicle: © 2012 General Motors Company, All Rights Reserved 1 April 2013Document0 pagesChevrolet Spark Electric Vehicle: © 2012 General Motors Company, All Rights Reserved 1 April 2013Francisco RenteriaNo ratings yet

- 2012 Ram Diesel Supplement 4thDocument173 pages2012 Ram Diesel Supplement 4thlilfroger100% (1)

- 496 - SSP481 - Audi A7 Onboard Power Supply and Networking PDFDocument40 pages496 - SSP481 - Audi A7 Onboard Power Supply and Networking PDFbenjaminhuku100% (5)

- 2023 Kia Sportage Plug in Hybrid 6Document603 pages2023 Kia Sportage Plug in Hybrid 6DODO DODONo ratings yet

- ELD Hondas Dual Mode Charging SystemDocument5 pagesELD Hondas Dual Mode Charging SystemJack NapierNo ratings yet

- General Vehicle Electrical SystemDocument31 pagesGeneral Vehicle Electrical Systemabdull rehmanNo ratings yet

- UserManual Mojito ENGDocument19 pagesUserManual Mojito ENGJean François PaillerNo ratings yet

- 02 Tknog 1 eDocument112 pages02 Tknog 1 eRafalNo ratings yet

- Cycle Analyst ManualDocument23 pagesCycle Analyst ManualarnberxNo ratings yet

- 1999 Mercury Cougar ManualDocument256 pages1999 Mercury Cougar Manualsquirrel7524No ratings yet

- 5 Toyota Camry HEV ERGDocument29 pages5 Toyota Camry HEV ERGCarlos Patricio Tobar Cando100% (1)

- Ssp379 The Eos 2006 Part 1Document19 pagesSsp379 The Eos 2006 Part 1psychoreality100% (1)

- Gauge and Meter HarrierDocument14 pagesGauge and Meter HarrierbittsmanNo ratings yet

- 812FJ Operations ManualDocument18 pages812FJ Operations ManualRenato Bautista100% (1)

- DSGDocument66 pagesDSGTM12550% (2)

- Hks EvcDocument16 pagesHks EvcKok Leong WongNo ratings yet

- Challenger7 Fly by Wire - V100Document21 pagesChallenger7 Fly by Wire - V100GustavoNo ratings yet

- 06-04 PFM SeminarDocument51 pages06-04 PFM SeminarAdam BrouillardNo ratings yet

- 98 MountaineerDocument216 pages98 Mountaineerrukford1No ratings yet

- Ford FocusDocument336 pagesFord FocusapostucristianNo ratings yet

- Freightliner Diesel Engine Starter Troubleshooting GuideDocument8 pagesFreightliner Diesel Engine Starter Troubleshooting GuideАртем БоровськийNo ratings yet

- Prius: Brief GuideDocument20 pagesPrius: Brief Guidejol_6918164900% (1)

- 2012 01-15-210857 Range Rover Workshop Manual p38 TransDocument93 pages2012 01-15-210857 Range Rover Workshop Manual p38 TransAlex Maceira Graterol0% (1)

- Ignition System OperationDocument28 pagesIgnition System OperationAllen CastorNo ratings yet

- MAF MAP Enhancer English 2011Document7 pagesMAF MAP Enhancer English 2011christopherpadreprepaNo ratings yet

- L20se 0425Document24 pagesL20se 0425christian frogerNo ratings yet

- SSP 272 Phaeton ObpsDocument27 pagesSSP 272 Phaeton Obpsภูเก็ต เป็นเกาะNo ratings yet

- Powerflex AB Trouble Shooting-Chapter 4-137Document137 pagesPowerflex AB Trouble Shooting-Chapter 4-137Milky SandNo ratings yet

- Marine Engineering Study Materials: EFC InternationalDocument5 pagesMarine Engineering Study Materials: EFC InternationalBhupender RamchandaniNo ratings yet

- LADA Niva 1700 Part3Document86 pagesLADA Niva 1700 Part3g-simsNo ratings yet

- KIAsoul Emergency Responder GuideDocument30 pagesKIAsoul Emergency Responder GuideP yenNo ratings yet

- Battery Disconnect or Replacement ProblemsDocument9 pagesBattery Disconnect or Replacement ProblemsHx KhooNo ratings yet

- 2002 Ford Escort ManualDocument208 pages2002 Ford Escort ManualDavid100% (1)

- New MG ZS EV Quick GuideDocument28 pagesNew MG ZS EV Quick GuideSalva P.No ratings yet

- Toyota Hybrid Camry Emergency Response GuideDocument31 pagesToyota Hybrid Camry Emergency Response GuideRobert ObremskiNo ratings yet

- PCV User'S Guide.: The Latest Software and Maps Can Be Found atDocument4 pagesPCV User'S Guide.: The Latest Software and Maps Can Be Found atfishhunter18No ratings yet

- PCV User'S Guide.: The Latest Software and Maps Can Be Found atDocument4 pagesPCV User'S Guide.: The Latest Software and Maps Can Be Found atfishhunter18No ratings yet

- PCV User'S Guide.: The Latest Software and Maps Can Be Found atDocument4 pagesPCV User'S Guide.: The Latest Software and Maps Can Be Found aticxnc1No ratings yet

- FORD EXPLORER 91-99 Códigos de FallaDocument16 pagesFORD EXPLORER 91-99 Códigos de Fallagian marco llamojaNo ratings yet

- 2002 f250 DieselDocument40 pages2002 f250 DieselEd ZacharyNo ratings yet

- Power Steering System Description and Operation (Electric Power Steering) PDFDocument2 pagesPower Steering System Description and Operation (Electric Power Steering) PDFAlonso BarrónNo ratings yet

- Chrysler Dodge TCM RelearnDocument8 pagesChrysler Dodge TCM RelearndaswineNo ratings yet

- 2004 UputsvoDocument75 pages2004 UputsvoАнгел К.No ratings yet

- Repair Manual: Gallardo MY09 - 10 - 11 - 12Document125 pagesRepair Manual: Gallardo MY09 - 10 - 11 - 12Michele Colombo100% (1)

- Ipt ReportDocument8 pagesIpt ReportSridharan Dhar100% (1)

- 2007 Bravo ManualDocument244 pages2007 Bravo ManualGustavo JesusNo ratings yet

- A Through Zs of Learning to Drive, Accident Free!: Drivers HandbookFrom EverandA Through Zs of Learning to Drive, Accident Free!: Drivers HandbookNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- A340-Le TransmissionDocument24 pagesA340-Le TransmissionLuisGonzalezNo ratings yet

- 2014 LG Filter Kit Catalog PDFDocument44 pages2014 LG Filter Kit Catalog PDFcherokewag100% (1)

- On Target (2019 - Vol. 1) Diagnostic FordDocument6 pagesOn Target (2019 - Vol. 1) Diagnostic FordcherokewagNo ratings yet

- Great Wall Steed Brochure PDFDocument7 pagesGreat Wall Steed Brochure PDFcherokewagNo ratings yet

- TD201404 Abril PDFDocument68 pagesTD201404 Abril PDFcherokewagNo ratings yet

- The Rules of Parallel CircuitsDocument6 pagesThe Rules of Parallel CircuitscherokewagNo ratings yet

- 2009 - Janua Febru PDFDocument57 pages2009 - Janua Febru PDFcherokewagNo ratings yet

- 50-42le AtsgDocument68 pages50-42le AtsgcherokewagNo ratings yet

- January Februari Buyers Guide PDFDocument124 pagesJanuary Februari Buyers Guide PDFcherokewag100% (1)

- Automatic Transmission In-Car Diagnostics PDFDocument15 pagesAutomatic Transmission In-Car Diagnostics PDFcherokewag50% (2)

- Ec (1) Engine ControlDocument794 pagesEc (1) Engine ControlcherokewagNo ratings yet

- MB Pricelist Aug 2022-UpdatedDocument5 pagesMB Pricelist Aug 2022-UpdatedLala LalianiNo ratings yet

- DPWH Region Iva Aadt (2018-2022)Document50 pagesDPWH Region Iva Aadt (2018-2022)frtanay12No ratings yet

- NNR 200 NNR Crew Cab Australiano PDFDocument4 pagesNNR 200 NNR Crew Cab Australiano PDFdionymackNo ratings yet

- Cars 20230227153655Document9 pagesCars 20230227153655NaimahSulistianingsihNo ratings yet

- Highway Traffic ActDocument19 pagesHighway Traffic ActBarbara WiśniewskaNo ratings yet

- Populasi Unit Februari 2023 HRSAGM4Document17 pagesPopulasi Unit Februari 2023 HRSAGM4Muhammad Arif RahmanNo ratings yet

- Steering and BrakeDocument170 pagesSteering and BrakeWahyu Beleng100% (1)

- Promulgated Assessment Fees As of 31 January 2021Document4 pagesPromulgated Assessment Fees As of 31 January 2021John Francis BonifacioNo ratings yet

- Catalogo Hy PowerDocument72 pagesCatalogo Hy Powerabri201024No ratings yet

- Catalogo de ReguladoresDocument784 pagesCatalogo de ReguladoressalusfrankNo ratings yet

- Lista de Partes de Suspension HendricsonDocument4 pagesLista de Partes de Suspension HendricsonLEO100% (1)

- Ud10 2018 2018102985Document2 pagesUd10 2018 2018102985Malachi BarrettNo ratings yet

- CATERPILLAR 740 Articulated Dump TruckDocument2 pagesCATERPILLAR 740 Articulated Dump TruckBogdanB100% (1)

- Heavy Earth Moving Equipment A. Dozers: Key ComponentsDocument9 pagesHeavy Earth Moving Equipment A. Dozers: Key Componentsmekonnen kasaNo ratings yet

- Husqvarna GT2254 Owner's ManualDocument52 pagesHusqvarna GT2254 Owner's ManualmdshannNo ratings yet

- INDEXDocument2 pagesINDEXAdan Darias100% (1)

- Wheel Loader Daily Inspection ChecklistDocument2 pagesWheel Loader Daily Inspection Checklistazer Azer100% (1)

- Getting Familiar With Distribution CentersDocument8 pagesGetting Familiar With Distribution Centerslibyrodriguez123No ratings yet

- NLC Grade 8 Math Enhancement Lesson 10 InequalitiesDocument18 pagesNLC Grade 8 Math Enhancement Lesson 10 InequalitiesEssaNo ratings yet

- Límites Condenatorios CATDocument2,662 pagesLímites Condenatorios CATHECTORNo ratings yet

- Torque.: Hino Genuine PartsDocument8 pagesTorque.: Hino Genuine PartsВалерий ГерасимовNo ratings yet

- Superstructure Instructions GeneralDocument54 pagesSuperstructure Instructions GeneralЕвгений АксёновNo ratings yet

- Q8 Formula Truck 8900 FE 5W 30 - en 3Document1 pageQ8 Formula Truck 8900 FE 5W 30 - en 3andistwn99No ratings yet

- EBS E1 BrochureDocument4 pagesEBS E1 BrochureVincent PriceNo ratings yet

- Draw 50 Boats, Ships, Trucks, and Trains The Step-By-Step Way To Draw Submarines, Sailboats, Dump Trucks, Locomotives, and Much More... by Lee J. AmesDocument418 pagesDraw 50 Boats, Ships, Trucks, and Trains The Step-By-Step Way To Draw Submarines, Sailboats, Dump Trucks, Locomotives, and Much More... by Lee J. AmesCeren Polat100% (5)

- 15-FG Price ListDocument8 pages15-FG Price ListManoj DoshiNo ratings yet

- Mechanics Micro ProjectDocument15 pagesMechanics Micro Project134 Bilolikar AdityaNo ratings yet