Professional Documents

Culture Documents

1 s2.0 S0023643805000691 Main

Uploaded by

GeorgeAzmirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S0023643805000691 Main

Uploaded by

GeorgeAzmirCopyright:

Available Formats

LWT 39 (2006) 513520

Cholesterol oxide, cholesterol, total lipid and fatty acid contents

in processed meat products during storage

S.R. Baggio, N. Bragagnolo

Department of Food Science, State University of Campinas, P.O. Box 6121, CEP 13083-970, Campinas, SP, Brazil

Received 4 October 2004; received in revised form 4 March 2005; accepted 19 March 2005

Abstract

The effects of storage time on the formation of cholesterol oxides and on alterations in the fatty acid composition of processed

meat products manufactured by Brazilian industries were investigated in this study. Cholesterol oxides and cholesterol were

determined by HPLC using photodiode array and refractive index detectors. Samples of jerked beef, Italian-type salami, chicken

mortadella and Chester mortadella were analysed at 30 day intervals starting at zero time, for 90 days for the mortadella and 120

days for the jerked beef and salami. The mortadellas were stored under refrigeration at 6 1C and the jerked beef and salami at room

temperature, but protected from the light. No cholesterol oxides were formed during the storage time in any of the samples. The

cholesterol content, the fatty acid composition and total lipid contents showed no signicant differences during storage with the

exception of the total lipid content of the jerked beef, which varied from 3.5 at zero time to 2.4 g/100 g after 120 days storage.

r 2005 Swiss Society of Food Science and Technology. Published by Elsevier Ltd. All rights reserved.

Keywords: Storage; Cholesterol oxidation products; Cholesterol; Fatty acid; Meat products

1. Introduction

Lipids can undergo alterations during the storage of

food with consequent losses in nutritional value. Lipid

oxidation is one of the main reactions, which can occur

during the storage of food in conditions such as heat,

presence of light, metals, natural sensitisers and oxygen,

affecting the fatty acid composition and cholesterol,

with the formation of compounds potentially harmful to

human health, such as cholesterol oxides.

Cholesterol oxides are present in our diet, being

identied in cholesterol-containing foods such as meat

and meat products, eggs and egg containing products

and milk and milk products (Finocchiaro & Richardson,

1983; Bo ssinguer, Luf, & Brandl, 1993; Rodriguez-

Estrada, Penazzi, Caboni, Bertacco, & Lercker, 1997).

High cooking and processing temperatures, storage

conditions and the type of packaging used can inuence

the formation of cholesterol oxides (Paniangvait, King,

Jones, & German, 1995). Thus the use of packaging

materials capable of avoiding the entrance of air and

light, especially ultraviolet light, and the use of adequate

food storage temperatures, can delay the formation

of cholesterol oxides (Savage, Dutta, & Rodriguez-

Estrada, 2002).

Saturated fatty acids, trans fatty acids, fat, cholesterol

and cholesterol oxides in foods, are related to the

development of cardiovascular diseases, which are

responsible for the greatest number of natural deaths

in Brazil and in many other countries. Trans fatty acids

are of more concern than saturated fatty acids, since, in

addition to increasing the level of low-density lipopro-

teins (LDL), they decrease the level of high-density

lipoproteins (HDL) (Lambertson, 1992).

Few integrated studies can be found in the literature

on cholesterol, cholesterol oxides, total lipids and the

fatty acid composition of processed meat products and

virtually none verifying the effect of storage on these

products. Thus the objective of this study was to

ARTICLE IN PRESS

www.elsevier.com/locate/lwt

0023-6438/$30.00 r 2005 Swiss Society of Food Science and Technology. Published by Elsevier Ltd. All rights reserved.

doi:10.1016/j.lwt.2005.03.007

Corresponding author. Tel.: 55 19 37882160; fax: 55 19 37882153.

E-mail address: neura@fea.unicamp.br (N. Bragagnolo).

determine the effect of storage time on the fatty acid

composition and cholesterol oxide formation in pro-

cessed meat products commercialized in Brazil.

2. Material and methods

2.1. Sample preparation

Four processed meat products were analysed, one being

beef (jerked beef), one pork (Italian-type salami), one

chicken (mortadella) and one Chester (mortadella). These

products were acquired from supermarkets in Campinas,

Sa o Paulo, Brazil 3 days after the date of manufacture.

Three batches of each product were analysed, with

different expiry dates. Each batch consisted of 12 units

for the mortadellas and 15 units for the jerked beef and

salami, 3 units being analysed at each period, that is,

zero time, 30, 60 and 90 days of storage for the

mortadellas and zero time, 30, 60, 90 and 120 days of

storage for the jerked beef and salami.

The zero time samples were analysed immediately

after acquisition. The rest of the mortadella samples

(chicken and Chester) were stored in their original

packaging inside cardboard boxes at 6 1C (refrigerator).

The rest of the jerked beef and salami samples were

stored under the same conditions but at room tempera-

ture (25 1C) in the dark. At the end of each storage

period, the appropriate samples were analysed. The

processed products were completely ground and homo-

genised in a multi-processor. Fifty-gram samples of

these homogenates were analysed in duplicate.

2.2. Methods

Lipids were extracted with chloroformmethanol (2:1)

according to Folch, Less, and Stanley (1957). Aliquots

were taken and the total lipid content determined

gravimetrically. Other aliquots were cold saponied

(Sander, Addis, Park, & Smith, 1989), the unsaponiable

material extracted and the cholesterol oxides and

cholesterol quantied by high performance liquid chro-

matography (HPLC) (Baggio & Bragagnolo, 2004,

Baggio, Miguel, & Bragagnolo, 2005). Aliquots of the

lipid extract were also saponied, the fatty acids esteried

with a solution of ammonium chloride and sulphuric acid

in methanol (Hartman & Lago, 1973) and the fatty acid

composition determined by gas chromatography (GC).

For HPLC, a Shimadzu (Kyoto, Japan) chromato-

graph was used, equipped with a quaternary solvent

delivery system (LC-10ATVP), rheodyne injector with a

20 ml loop, photodiode array (SPD-M10AVP) and

refractive index (RID-10A) detectors, oven heated

column (CTO-10ASVP) and software (CLASSLC

10). The analytical column was a Nova Pak CN HP,

300 3.9 mm column, 4 mm (Waters, Milford, MA,

USA) preceded by a Hypersil BDS CN 7.5 4.6 mm,

5 mm guard column and the column temperature was

32 1C. The mobile phase consisted of hexane/isopropa-

nol (96+4) at a ow rate of 1.0 ml/min. Absorption

spectra were taken from 200 to 400 nm and the

chromatograms at 210 nm.

Cholesterol, cholesta-3,5-dien-7-one, 20a-hydroxy-

cholesterol, 25-hydroxycholesterol, 7-ketocholesterol,

5,6a and 5,6b-epoxycholesterol and 7b-hydroxycholes-

terol were purchased from Sigma Chemical Company

(St. Louis, USA). 7a-Hydroxycholesterol was obtained

from Steraloids Inc. (Newport, NI, USA). HPLC grade

n-hexane and isopropanol were obtained from Mscience

(Darmstadt, Germany) and all other analytical grade

solvents were from Merck (Darmstadt, Germany). The

HPLC solvents were ltered through a 0.22 mm mem-

brane lter Millipore (Cork, Island) under vacuum and

degasied by ultrasound prior to use.

Quantication was done by external standardization,

with a concentration range from 0.5 to 2.22 mg/ml for

cholesterol and from 0.5 to 64.0 mg/ml for the cholester-

ol oxides. Cholesterol and a and b-epoxycholesterol

were quantied using a refractive index detector, the

cholesterol because it is better separated from interfering

substances in this case and the a and b-epoxycholester-

ols because they do not absorb ultraviolet light. The

other cholesterol oxides were quantied using the

photodiode array detector. The detection limits were

0.14 mg/g of the sample to 20a-hydroxycholesterol and

25-hydroxycholesterol, 0.12 mg/g of the sample to a and

b-epoxycholestrol and 7a and 7b-hydroxycholesterol

and 0.09 mg/g of the sample to 7-ketocholesterol

and cholesta-3,5-dien-7-one, calculated according to

Chairman et al. (1983).

Identication of cholesterol and its oxides was

performed by comparison of the retention times of the

samples with those of the standards, co-chromatogra-

phy and the characteristics of the absorption spectra.

Conrmation of the identity was carried out using a gas

chromatograph-mass spectrometer (Baggio, Vicente, &

Bragagnolo, 2002). Characteristic chromatograms for

the cholesterol and cholesterol oxide standards and the

salami samples can be seen in Figs. 1 and 2. Note that in

the sample chromatogram obtained using the photo-

diode array detector, some peaks show the same

retention times as some of the cholesterol oxide

standards. However, they presented different absorption

and mass spectra than the standards, and were therefore

not cholesterol oxides.

Fatty acid methyl esters were separated on a gas chro-

matograph (HRCG 4000A, Konik, Miami, FL, USA)

equipped with a split injector (75:1), fused silica capillary

column (50 m0.25mm i.d., 0.20mm lm thickness

of polyethylene glycol) (CP-SIL 88, Cromapak, EA

Middelburg, The Netherlands), ame ionisation detector

and workstation (Borwin, Le Fontanil, France). The

ARTICLE IN PRESS

S.R. Baggio, N. Bragagnolo / LWT 39 (2006) 513520 514

initial column temperature was 180 1C for 2 min and then

programmed at 5 1C/min to 225 1C. The injector tem-

perature was set at 270 1C and the detector temperature

at 300 1C. The carrier gas was hydrogen at a ow rate of

0.5 ml/min and nitrogen was used as the make-up gas at

30ml/min. The fatty acids were identied by comparison

of the retention times of the sample with those of the

standards and by spiking. A total of 37 saturated,

monounsaturated and polyunsaturated fatty acid stan-

dards (Sulpeco

TM

37 FAME Mix 47885-U, Montgo-

meryville, PA, USA) were used to verify the identity and

the accuracy of the method. Quantication was done as

area percentages.

2.3. Statistical analysis

The results were submitted to an analysis of variance

(ANOVA). Tukeys test was used to compare the means

at a 5% signicance level.

3. Results and discussion

3.1. The effect of storage time on the formation of

cholesterol oxides

Table 1 shows the cholesterol content of the processed

meat products analysed at the various storage times. It

can be seen that in most cases there were signicant

differences in cholesterol contents between different

batches of the same sample at the same storage time.

The storage time did not alter the cholesterol contents of

the samples, there being no signicant differences

between the different storage times throughout the

entire storage period for the same sample, varying from

4074 to 4672 mg/100 g for jerked beef; from 4876 to

5774 mg/100 g for the salami; from 4573 to 5074 mg/

100 g for the chicken mortadella and from 4678 to

5376 mg/100 g for the Chester mortadella. The high

values for the standard deviation were related to

ARTICLE IN PRESS

0.0

V

o

l

t

s

-0.002

0.000

0.002

0.04

0.08

V

o

l

t

s

0

1

2

3

4

7

8

9

(a)

(b)

25

50

75

100

2.5 5.0 7.5 10.0

Minutes

12.5 15.0 17.5 20.0

0.0 2.5 5.0 7.5 10.0

Minutes

12.5 15.0 17.5 20.0

1

2

3

4

5

6

7

8

9

Fig. 1. Typical HPLC chromatogram of the cholesterol and cholesterol oxide standards. Nova Pak CN column (4 mm, 300 3.9 mm) with hexane/

isopropanol (96+4) as mobile phase at 1 ml/min (a) photodiode array detector (b) refractive index detector. Peaks: (1) cholesterol, (2) cholesta-3,5-

dien-7-one, (3) 20a-hydroxycholesterol, (4) 25-hydroxycholesterol, (5) 5,6a-epoxycholesterol*, (6) 5,6b-epoxycholesterol*, (7) 7-ketocholesterol, (8)

7b-hydroxycholesterol and (9) 7a-hydroxycholesterol. * Only using the refractive index detector.

S.R. Baggio, N. Bragagnolo / LWT 39 (2006) 513520 515

variations between the batches and not to the analytical

methodology used, since the coefcient of variation

between duplicates was lower than 1.4.

No cholesterol oxides were formed in any of the four

processed meat products analysed during storage, either

for those samples stored at room temperature or for

those stored under refrigeration. According to their

labels, all the processed meat products analysed

contained sodium erythorbate (INS 360) as synthetic

antioxidant, spices and natural condiments, which may

have protected them against cholesterol oxidation. The

formation of cholesterol oxides can be avoided by the

use of appropriate concentrations of antioxidant or by

the use of adequate packaging, providing a physical

barrier against the entry of air and light (Tai, Chen, &

Chen, 1999). In addition, many spices and herbs have

been shown to impart an antioxidant effect in food

systems (Chipault, Mizuno, Hawkins, & Lundberg,

1952). The antioxidant properties of spices are related

to their phenolic contents and therefore their antiox-

idant action is similar to that of synthetic phenolic

antioxidants. Osada, Hoshima, Nakamura, and Sugano

(2000) considered that cholesterol oxidation in sausages

was inhibited by the addition of sodium nitrite and

apple polyphenols, due to stabilisation of co-existing

polyunsaturated fatty acids and radical scavenging.

Torres, Pearson, Gray, and Ku (1989) showed that the

addition of rened salt with added BHA and BHT to

charqui (salted and dried beef) samples decreased the

concentration of cholesterol oxides by 2.5 times as

compared to samples prepared without the antioxidants.

Park and Addis (1985) also found no cholesterol oxides

in hamburger, jerked beef and liver sausage. Larkeson,

Dutta, and Hansson (2000) showed no increase in

cholesterol oxide content in meatballs (50% pork+50%

beef) or in beef hamburgers, both fried and stored for 2

weeks at 4 1C. However, they observed that after frying

the pre-fried samples, the levels of cholesterol oxide

(mg/g of lipid) increased from 8 to 16 in the meatballs

and from 29 to 50 in the hamburger stored for 2 weeks

at 4 1C.

Osada, Hoshina, Nakamura, and Sugano (2000)

showed that the level of cholesterol oxidation increased

accompanied by a decrease in linoleic acid content.

However, in this study even in the samples showing

higher linoleic acid contents, such as the chicken and

Chester mortadellas (Table 3), there was no signicant

change in the content of this component during storage,

and also no formation of cholesterol oxides.

Cholesterol oxides are directly related to the devel-

opment of arteriosclerotic plaque and other undesirable

biological effects such as cytoxicity, carcinogenicity and

mutagenicity (Guardiola, Codony, Addis, Rafecas, &

Boatella, 1996). Sevanian et al. (1997) observed that

low-density lipoproteins are rich in cholesterol oxides,

many of which could originate in the diet. Staprans,

ARTICLE IN PRESS

0

V

o

l

t

s

0.000

0.005

0.010

V

o

l

t

s

0

50

25

100

75

(b)

(a)

2 4 5 6

Minutes

10 12 14 16

0 2

1

1

4 5 6

Minutes

10 12 14 16

Fig. 2. Typical HPLC chromatogram of the cholesterol and cholesterol oxides in the salami. Nova Pak CN column (4 mm, 300 3.9 mm) with

hexane/isopropanol (96+4) as mobile phase at 1 ml/min (a) photodiode array detector (b) refractive index detector. Peak 1: cholesterol.

S.R. Baggio, N. Bragagnolo / LWT 39 (2006) 513520 516

Pan, Rapp and Feingold (1998) demonstrated that

arteriosclerosis in rabbits fed 25 mg cholesterol oxides/

day for 12 weeks doubled as compared to rabbits fed a

normal diet without the addition of cholesterol oxides.

Since diets containing cholesterol oxides could contri-

bute to the development of arteriosclerosis and con-

sidering that the meat products analysed in this study

presented no cholesterol oxides, their consumption

apparently represents no health risk.

3.2. The effect of storage time on the total lipid content

The total lipid contents (Table 2) did not vary during

the storage period with the exception of the jerked beef.

The jerked beef samples presented higher total lipid

contents at zero time (3.570.9 g/100 g), lower but

similar values at 30 and 60 days storage (2.670.4 g/

100 g) and slightly lower but similar at 90 and 120 days

(2.570.4 and 2.470.7 g/100 g, respectively). These

discrepancies represented variations in the samples and

not a storage effect. Jerked beef is salted and dried beef

and the total lipid contents in beef vary. Thus the

discrepancies can be attributed to natural variation

bought about by factors such as age, breed, diet and the

rearing system. Similarly the variation found amongst

the different batches of the same sample at the same

storage time for the cholesterol and lipid results can be

attributed to these same factors and some variation in

the formulation.

3.3. The effect of storage time on the fatty acids

Table 3 shows the fatty acids (% area) found in jerked

beef, Italian-type salami, chicken mortadella and Chester

mortadella at zero time. At 30, 60 90 and 120 days the

results were very similar to those at zero time and were

therefore not shown. The main fatty acids found were

C18:1o9, C16:0, C18:2o6, C18:0 and C16:1o7. Consider-

ing the total lipid contents found in the samples analysed

and expressing the results as g of fatty acids per 100g of

edible portion, C16:0, C18:0 and C18:1o9 were found in

greatest amounts in Italian-type salami and C16:1o7 and

C18:2o6 in chicken mortadella. The jerked beef showed

the lowest concentrations of saturated fatty acids (1.3g/

100g) and the Italian-type salami showed the highest

values (8.4g/100g), the fatty acid C16:0 being found in

highest concentration, followed by C18:0. The monounsa-

turated fatty acid content was highest in Italian-type

salami (10g/100g) and C18:1o9 was found in greatest

amounts, followed by C16:1o7. The total polyunsaturated

fatty acid concentration was highest in Chester mortadella

(4.6g/100g), C18:2o6 being the fatty acid found in

ARTICLE IN PRESS

Table 1

Cholesterol (mg/100 g) contents of the processed meat products during storage

Samples/batch Cholesterol (M7SD*)

0 days 30 days 60 days 90 days 120 days

Jerked beef

B1 40.470.3c 34.670.4c 34.270.5c 44.470.7a 32.770.6b

B2 45.270.2b 40.470.2b 42.070.3b 47.170.7a 49.271.0a

B3 47.470.4a 43.470.1a 47.270.2a 47.671.4a 52.070.6a

M7SD** 4473

a

4074

a

4176

a

4672

a

4579

a

Salami

B1 50.970.1b 50.370.2c 56.070.1b 62.670.2a 42.770.2c

B2 48.470.4c 55.470.3b 61.671.0a 43.670.4c 45.670.5b

B3 59.770.4a 59.370.6a 52.271.3b 59.870.1b 56.070.3a

M7SD** 5375

a

5574

a

5774

a

5579

a

4876

a

Chicken mortadella

B1 50.270.3

%

a 49.970.3b 44.970.5b 42.470.3b

B2 42.870.3c 45.670.2c 50.070.3a 44.970.9b

B3 45.970.6b 54.970.5a 44.770.5b 48.570.5a

M7SD** 4673

a

5074

a

4773

a

4573

a

Chester mortadella

B1 59.870.5a 55.470.4a 45.270.3b 53.070.5a

B2 51.970.5b 43.770.2b 49.170.7a 48.570.4b

B3 45.870.1c 44.170.8b 45.470.5b 36.770.8c

M7SD** 5376

a

4876

a

4772

a

4678

a

B1, B2 and B3 are batches with different expire dates.

* Mean and standard deviation of samples in duplicate.

** Mean and standard deviation of three samples in duplicate during storage.

Values in the same column with the same letter do not present signicant difference between batches at the 5% level. Values in the same line with the

same upper case letters do not present signicance for storage time at the 5% level.

S.R. Baggio, N. Bragagnolo / LWT 39 (2006) 513520 517

greatest amounts. The ratio between the polyunsaturated

and saturated fatty acids found in this study was lowest in

jerked beef (0.1) and highest in Chester mortadella (0.8).

The o3 fatty acid content varied from 0.01 in jerked beef

to 0.2g/100g in chicken and Chester mortadella, only

C18:3o3 being found. The o6=o3 ratio was lowest in

jerked beef (5) and highest in salami (29).

The fatty acid composition of the samples did not

change during the storage period, there being no

signicant difference between the levels of fatty acids

at the different storage times. The lack of alteration in

the fatty acid composition of the processed meat

products could be related to the addition of antioxidant

(sodium erythorbate, spices and natural condiments) in

the formulations, avoiding the formation of radicals

derived from unsaturated fatty acids, and consequently

cholesterol oxides were not formed. Torres et al. (1989),

observed a loss of total unsaturated fatty acid content in

both the triacylglyceride and phospholipid fractions,

even when the samples contained antioxidant. Never-

theless, the presence of the antioxidant (BHA+BHT)

was effective in avoiding oxidation for a period of 1530

days. Lazarus, Deng, and Watson (1977) found no

changes in the fatty acid composition of lamb during 9

days storage at 4 1C. Kunsman, Field, and Kazantzis

(1978) explained the absence of change in the fatty acids

during the storage of meat with the suggestion that the

heme proteins might act as an antioxidant. Recently,

Carlsen, Rasmussen, Kjeldsen, Westergaard, and

Skibsted (2003) conrmed the pro- and antioxidant role

of myoglobin in muscle. Yamauchi, Nagai, and Ohashi

(1980) showed that endogenous a-tocopherol could

inuence the rate of oxidation by exerting an antiox-

idant effect in meat.

4. Conclusions

The cholesterol content, fatty acid composition and

total lipids did not change during storage. There was no

formation of cholesterol oxides in the processed meat

products analysed during the storage period. The

presence of sodium erythorbate, spices and natural

condiments in the meat products analysed must have

avoided the formation of radicals derived from un-

saturated fatty acids, and consequently cholesterol

oxides were not formed.

The food industry has been encouraged to intensify

efforts to develop products targeting the recommended

levels of fat and cholesterol. Health and Welfare Canada

(1990) ofcially established a limit for cholesterol intake

of 300 mg, a balance in the polyunsaturated/saturated

ARTICLE IN PRESS

Table 2

Total lipid (g/100 g) contents of the processed meat products during storage

Samples/batch Total lipids (M7SD*)

0 days 30 days 60 days 90 days 120 days

Jerked beef

B1 2.670.0c 2.370.0b 2.570.0b 2.870.0a 1.470.0b

B2 3.370.0b 3.270.1a 3.170.0a 2.770.0a 2.970.0a

B3 4.770.0a 2.470.0b 2.270.0c 1.970.0b 2.870.0a

M7SD** 3.570.9

a

2.670.4

ab

2.670.4

ab

2.570.4

b

2.470.7

b

Salami

B1 28.670.2a 25.970.1a 24.870.1a 28.070.0a 27.570.1a

B2 19.870.1b 19.570.1b 19.470.0b 15.970.0c 17.270.2c

B3 18.970.1c 18.470.1c 18.570.2c 20.370.3b 20.870.2b

M7SD** 2375

a

2174

a

2173

a

2175

a

2275

a

Chicken mortadella

B1 18.970.1b 18.970.1b 18.970.0b 18.570.0c

B2 18.970.0b 18.970.0b 19.170.1a 19.270.1b

B3 19.570.6a 19.570.0a 19.270.1a 19.870.0a

M7SD** 19.170.3

a

19.170.3

a

19.070.2

a

19.170.6

a

Chester mortadella

B1 17.470.1b 17.770.0a 17.770.0b 18.270.1a

B2 17.470.0b 17.370.1b 18.070.0a 18.270.0a

B3 18.170.0a 17.670.0a 18.070.0a 16.970.0b

M7SD** 17.670.4

a

17.570.2

a

17.970.2

a

17.870.7

a

B1, B2 and B3 are batches with different expire dates.

* Mean and standard deviation of samples in duplicate.

** Mean and standard deviation of three samples in duplicate during storage.

Values in the same column with the same letter do not present signicant difference between batches at the 5% level. Values in the same line with the

same upper case letters do not present signicance for storage time at the 5% level.

S.R. Baggio, N. Bragagnolo / LWT 39 (2006) 513520 518

fatty acid ratio close to 1.0, a 10% increase in

polyunsaturated fatty acid intake and a 15% increase

in monounsaturated fatty acid intake. In addition, there

is a need to balance the o6=o3 ratio of the dietary fatty

acids. The ideal ratio is about 6:1 (Wijendran & Hayes,

2004). Of the products analysed, only the jerked beef

presented total lipid values below 5 g/100 g and can

therefore be considered a low-fat food according to the

Food Advisory Committee (1990). The cholesterol

content varied from 40 mg/100 g in the jerked beef to

57 mg/100 g in the Italian-type salami, below the

maximum recommended value of 300 mg cholesterol/

day and no cholesterol oxides were found. With the

exception of the jerked beef, the polyunsaturated/

saturated fatty acid ratio was greater than 1.0 and the

o6=o3 ratio above the adequate ratio of 6:1 in all the

products analysed. These deciencies could be compen-

sated by other components in the diet.

Acknowledgments

The authors wish to thank the Fundac-a o de Amparo

a Pesquisa do Estado de Sa o Paulo (FAPESP) and the

Brazilian National Research Council (CNPq) for their

nancial assistance.

References

Baggio, S. R., & Bragagnolo, N. (2004). Validac- a o da metodologia

para a determinac- a o simulta nea, por CLAE, de colesterol e o xidos

de colesterol em produtos ca rneos processados. Ciencia e Tecno-

logia de Alimentos, 24(1), 6470.

Baggio, S. R., Vicente, E., & Bragagnolo, N. (2002). Cholesterol

oxides, cholesterol, total lipid and fatty acid composition of turkey

meat. Journal of Agricultural and Food Chemistry, 50(21),

59815986.

Baggio, S. R., Miguel, A. M. R., & Bragagnolo, N. (2005).

Simultaneous determination of cholesterol oxides, cholesterol and

fatty acids in processed turkey meat products. Food Chemistry, 89,

475484.

Bo ssinguer, S., Luf, W., & Brandl, E. (1993). Oxysterols: Their

occurrence and biological effects. International Dairy Journal, 3,

133.

Carlsen, C. U., Rasmussen, K. T., Kjeldsen, K. K., Westergaard, P., &

Skibsted, L. H. (2003). Pro and antioxidative activity of protein

fractions from pork (longissimus dorsi). European Food Research

and Technology, 217, 195200.

Chairman, L. H. K., Crummett, W., Deegan, J. J., Libby, R. O.,

Taylor, J. K., & Wentler, G. (1983). Principles of environmemtal

analysis. Journal of the American Chemical Society, 55, 22102221.

ARTICLE IN PRESS

Table 3

Fatty acid compositions (% area) of the processed meat products at zero time

Fatty acids Jerked beef Italian type salami Chicken mortadella Chester mortadella

M7SD

a

M7SD

a

M7SD

a

M7SD

a

C14:0 2.970.7 1.670.1 0.870.0 0.670.0

C15:0 2.370.2 0.370.1 0.270.0 0.270.1

C16:0 24.671.3 24.370.6 24.170.6 24.170.2

C17:0 1.370.6 0.670.1 0.370.0 0.270.1

C18:0 17.572.3 11.670.0 7.070.2 5.970.1

C20:0 nd 0.27 0.0 0.170.0 tr

C22:0 0.270.1 tr 0.170.0 tr

C24:0 tr 0.170.0 0.170.0 0.170.0

C16:1o7 4.470.2 2.770.1 4.670.1 5.270.2

C17:1o7 1.070.1 0.570.1 0.370.0 0.370.0

C18:1o9t 2.370.2 0.670.1 0.270.0 0.170.0

C18:1o9 38.474.0 41.970.8 39.370.8 37.170.4

C20:1o11 0.770.2 0.770.1 0.470.1 0.270.1

C18:2o6t

b

tr nd nd nd

C18:2o6 2.870.8 13.571.0 20.770.3 23.770.4

C18:3o6 nd 0.570.0 0.270.0 0.270.0

C18:3o3 0.470.1 0.570.0 1.170.2 1.370.0

C20:2o6 0.270.0 0.470.0 0.270.0 0.270.0

C20:4o6 0.970.3 tr 0.470.0 0.570.0

Saturated 51 39 33 31

Monounsaturated 45 46 44 43

Polyunsaturated 4 15 23 26

Total o3 0.4 0.5 1.0 1.3

Total o6 3.9 14.4 21.5 24.6

Polyunsaturated/saturated 0.1 0.4 0.7 0.8

o6/o3 10 29 22 19

tr traces (o 0.01). nd detected not.

a

Mean and standard deviation of three samples in duplicate.

b

(9c 12t+9t 12c).

S.R. Baggio, N. Bragagnolo / LWT 39 (2006) 513520 519

Chipault, J. R., Mizuno, G. R., Hawkins, J. M., & Lundberg, W. O.

(1952). The antioxidant properties of natural spices. Food Research,

17, 4655.

Finocchiaro, E. T., & Richardson, T. (1983). Sterol oxides in

foodstuffs: A rewiew. Journal of Food and Protection, 46, 917925.

Folch, J., Less, M., & Stanley, S. (1957). A simple method for the

isolation and purication of total lipids from animal tissues.

Journal of Biological and Chemistry, 226, 497509.

Food Advisory Committee. (1990). Report on review of food labelling

and advertising. London.

Guardiola, F., Codony, R., Addis, P. B., Rafecas, M., & Boatella, J.

(1996). Biological effects of oxysterols: Current status. Food

Chemistry and Toxicology, 34, 193211.

Hartman, L., & Lago, R. C. A. (1973). Rapid preparation of fatty acid

methyl esters from lipids. Laboratory Practices, 22, 475481.

Health and Welfare Canada. (1990). Nutritional recommendations.

Ottawa: Canadian Government Publishing Centre.

Kunsman, J. E., Field, R. A., & Kazantzis, D. (1978). Lipid oxidation

in mechanically deboned red meat. Journal of Food Science, 43,

13751378.

Lambertson, G. (1992). Trans fatty acids topic for Lipidforum. Journal

of the American Oil Chemists Society, 3, 196197.

Larkeson, B., Dutta, P. C., & Hansson, I. (2000). Effects of frying and

storage on cholesterol oxidation in minced meat products. Journal

of the American Oil Chemists Society, 77, 675680.

Lazarus, C. R., Deng, J. C., & Watson, C. M. (1977). Changes in the

concentrations of fatty acids from the nonpolar, phospho- and

glycolipids during storage of intact lamb muscle. Journal of Food

Science, 42, 102107.

Osada, K., Hoshina, S., Nakamura, S., & Sugano, M. (2000). Cholesterol

oxidation in meat products and its regulation by supplementation of

sodium nitrite and apple polyphenol before processing. Journal of

Agricultural and Food Chemistry, 48, 38233829.

Paniangvait, P., King, A. J., Jones, A. D., & German, B. G. (1995).

Cholesterol oxides in foods of animal origin. Journal of Food

Science, 60, 11591174.

Park, S. W., & Addis, P. B. (1985). HPLC determination of C7

oxidized cholesterol derivatives in foods. Journal of Food Science,

50, 14371444.

Rodriguez-Estrada, M. T., Penazzi, G., Caboni, M. F., Bertacco, G.,

& Lercker, G. (1997). Effect of different cooking methods on some

lipid and protein components of hamburguers. Meat Science, 45,

365375.

Sander, B. D., Addis, P. B., Park, S. W., & Smith, D. E. (1989).

Quantication of cholesterol oxidation products in a variety of

foods. Journal of Food Protection, 52, 109114.

Savage, G. P., Dutta, P. C., & Rodriguez-Estrada, M. T. (2002).

Cholesterol oxides: their occurrence and methods to prevent

their generation in foods. Journal of Clinical Nutrition, 11(1),

7278.

Sevanian, A., Bittolo-Bon, G., Cazzolato, G., Hodis, H., Hwang, J.,

Zamburlini, A., Maiorino, M., & Ursini, F. (1997). LDL is a lipid

hydroperoxide-enriched circulating lipoprotein. Journal Lipid

Research, 38, 419428.

Staprans, I., Pan, X-M., Rapp, J. H., & Feingold, K. R. (1998).

Oxidized cholesterol in the diet accelerates the development of

aortic atherosclerosis in cholesterol-fed rabbits. Arteriosclerosis,

Thrombosis and Vascular Biology, 18, 977983.

Tai, C. Y., Chen, Y. C., & Chen, B. H. (1999). Analysis, formation and

inhibition of cholesterol oxidation products in foods: An overwiew

(Part I). Journal of Food and Drug Analysis, 7(4), 243258.

Torres, E., Pearson, A. M., Gray, J. L., & Ku, P. K. (1989). Lipid

oxidation in charqui (salted and dried beef). Food Chemistry, 32,

257268.

Wijendran, V., & Hayes, K. C. (2004). Dietary n-6 and n-3 fatty acid

balance and cardiovascular health. Annual Review of Nutrition, 24,

579615.

Yamauchi, K., Nagai, Y., & Ohashi, T. (1980). Quantitative relation-

ship between a-tocoferol and polyunsaturated fatty acids and

its connection to development of oxidative rancidity in

porcine skeletal muscle. Agricultural Biological Chemistry, 44,

10611071.

ARTICLE IN PRESS

S.R. Baggio, N. Bragagnolo / LWT 39 (2006) 513520 520

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- (123757008) Guest Registration FormDocument1 page(123757008) Guest Registration FormGeorgeAzmirNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Monthly Cleaning TasksDocument1 pageMonthly Cleaning TasksGeorgeAzmirNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Guelph Transit Full System MapDocument1 pageGuelph Transit Full System MapGeorgeAzmirNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Astm A 564Document7 pagesAstm A 564GeorgeAzmirNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Cubes Aptitude QuestionsDocument5 pagesCubes Aptitude QuestionsGeorgeAzmirNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- g5 s1Document12 pagesg5 s1GeorgeAzmirNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 01 Alto 1Document4 pages01 Alto 1GeorgeAzmirNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- List of Attendees For Website 092313Document7 pagesList of Attendees For Website 092313GeorgeAzmirNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hey 4-N/i'ethylenedio Yphenyl Sopropyl E.: 4-MethylenedioxyphenylisopropylamineDocument2 pagesHey 4-N/i'ethylenedio Yphenyl Sopropyl E.: 4-MethylenedioxyphenylisopropylamineAnonymous FigYuONxuuNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- XS NanoDocument24 pagesXS NanoAnonymous GgEgellVnU100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Tuffseald 2G MSDSDocument12 pagesTuffseald 2G MSDSVijayKumarNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Lab Manual 02Document158 pagesLab Manual 02Stephen VivekNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Diffusiophoresis Migration of Colloidal Particles in Gradients of Solute ConcentrationDocument38 pagesDiffusiophoresis Migration of Colloidal Particles in Gradients of Solute ConcentrationPrateek DwivediNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- NiSlip 520ADocument8 pagesNiSlip 520ASTI InspiredNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Material Safety Data Sheet - Calcium CarbideDocument11 pagesMaterial Safety Data Sheet - Calcium Carbidegodfrey kiyinjaNo ratings yet

- Lignocellulosic Biomass A Sustainable Platform For Production of Bio-Based - Isikgor2015 PDFDocument62 pagesLignocellulosic Biomass A Sustainable Platform For Production of Bio-Based - Isikgor2015 PDFNatasha Mgt JoharNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LOVIBOND Reagents Suited For HachDocument6 pagesLOVIBOND Reagents Suited For HachKacem BenaoumeurNo ratings yet

- Pyro FormulasDocument121 pagesPyro FormulasMichael Beasley100% (4)

- Using The Logarithmic Concentration Diagram, Log C, To Teach Acid Base EquilibriumDocument5 pagesUsing The Logarithmic Concentration Diagram, Log C, To Teach Acid Base EquilibriumMario FloresNo ratings yet

- Acetone Production ReportDocument83 pagesAcetone Production Reportpravalchauha89% (9)

- UNIT VDocument23 pagesUNIT VDhilsanth SLNo ratings yet

- Course OutlineDocument2 pagesCourse Outlineijat_No ratings yet

- WSS-M21P36 10-09-2014Document4 pagesWSS-M21P36 10-09-2014Ronald AraujoNo ratings yet

- International Journal of Mining, Reclamation and EnvironmentDocument17 pagesInternational Journal of Mining, Reclamation and EnvironmentMargaritha Alexanderina FrancisNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Astm C 1202 - 2022Document8 pagesAstm C 1202 - 2022Mohammed AliNo ratings yet

- LHB Coach (Mechnical Features)Document38 pagesLHB Coach (Mechnical Features)gayathri12092002No ratings yet

- TDS Sikasil SG-18 Structural SealantDocument2 pagesTDS Sikasil SG-18 Structural SealantTuấn Anh NguyễnNo ratings yet

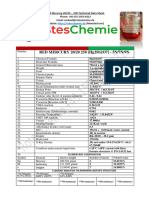

- Red Mercury 2020 Technical Data SheetDocument2 pagesRed Mercury 2020 Technical Data SheetThe UniversNo ratings yet

- 2019 Shear Strength Improvement of Lateritic Soil Stabilized by Biopolymer Based StabilizerDocument9 pages2019 Shear Strength Improvement of Lateritic Soil Stabilized by Biopolymer Based StabilizerFaklish LoufiNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Device Turns Air Pollution Into InkDocument2 pagesDevice Turns Air Pollution Into InkAnonymous izrFWiQNo ratings yet

- Radio-Analytical TechniquesDocument30 pagesRadio-Analytical TechniquesMohammad Zamir TaqwaNo ratings yet

- Production of X-RAYS Using X-RAY Tube: Journal of Physics: Conference SeriesDocument13 pagesProduction of X-RAYS Using X-RAY Tube: Journal of Physics: Conference SeriesATWIJUKIRE DICKENSNo ratings yet

- BHGFGDocument11 pagesBHGFGbsaimukeshreddy 820No ratings yet

- Phosphorus Removal On DewateringDocument39 pagesPhosphorus Removal On DewateringAlberto SemillánNo ratings yet

- M-Caps-35: Chemistry: NEET & AIIMS 2018-19Document5 pagesM-Caps-35: Chemistry: NEET & AIIMS 2018-19Vishal SinghNo ratings yet

- CSSD Central Sterile Supply DepartmentDocument35 pagesCSSD Central Sterile Supply DepartmentAnsari Shariq0% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NVT Simulation of Argon Using Lennard-Jones PotentialDocument2 pagesNVT Simulation of Argon Using Lennard-Jones Potentialt_sairamNo ratings yet

- Exergoeconomic Analysis of A Combined Heat and Power (CHP) SystemDocument17 pagesExergoeconomic Analysis of A Combined Heat and Power (CHP) Systemjhugo_mirandaNo ratings yet