Professional Documents

Culture Documents

9 - Petronas - Implementation of Electrical Energy Isolation

Uploaded by

Mohd Masri A. RazakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9 - Petronas - Implementation of Electrical Energy Isolation

Uploaded by

Mohd Masri A. RazakCopyright:

Available Formats

IMPLEMENTATION OF ELECTRICAL AND

ENERGY ISOLATION -

PETRONAS EXPERIENCE

Presented By

IR MOHD AAZMI ISMAIL

Resident Electrical Engineer, Petronas Gas

Bhd

Organized by:

21-22 July 2011

Kuala Lumpur Convention Centre (KLCC), Malaysia

21-22 July 2011, KLCC

Content

Introduction

Lessons Learnt

Type of Energy Sources

Energy Isolation Concept

Energy Isolation Procedure

Energy Isolation Simulation

Special Cases

Management of Keys

Ownership

Competency and Training

21-22 July 2011, KLCC

Introduction

21-22 July 2011, KLCC

This standard covers safe work practices and

procedures to safeguard employees, environment

and equipment in a place of work from the hazards of

energy sources including accidental release of

hazardous materials during construction, operation

and maintenance activities.

Energy Isolation Standard PTS 60.2117 Origin :

21-22 July 2011, KLCC

1.0 INTRODUCTION

2.0 SCOPE

3.0 DEFINITIONS

4.0 REFERENCES

5.0 STATUTORY REQUIREMENTS

6.0 ENERGY ISOLATION PROCEDURE

6.1 Roles & Responsibilities

6.2 Equipment Preparation

6.3 Isolation Methods

6.3.1 Positive Isolation

6.3.2 Double Block and Bleed (DBB)

6.3.3 Single Valve Isolation (SVI)

Energy Isolation Standard PTS 60.2117

21-22 July 2011, KLCC

Energy Isolation Standard PTS 60.2117

6.4 The Group LOTO System

6.4.1 Applying The Lockout Tagout Devices For The Group LOTO System

6.4.2 Removing The Lockout Tagout Devices For The Group LOTO System

6.4.3 Test Run / Troubleshooting of Equipment

6.5 Short Duration Instrument Isolation

6.6 Isolation and Lockout Tagout of Ionizing Radiation Sources

6.7 Isolation and Lockout Tagout During Plant Shutdown Periods

6.8 Training and Competencies

6.9 Special Safety Concerns

6.10 Documentation Communication & Approval

6.11 Management of Safety Infringement

6.12 Auditing and System Review

21-22 July 2011, KLCC

Energy Isolation Standard PTS 60.2117

7.0 APPENDICES

7.1 Physical Isolation Certificate Front Side

7.2 Physical Isolation Certificate Reverse Side

7.3 Isolation / Lockout Device List Example Page 1

7.4 Isolation / Lockout Device List Example Page 2

7.5 Blank Isolation / Lockout Device List Example

7.6 Spade/Blind List Alternative Example

21-22 July 2011, KLCC

Energy Isolation Standard PTS 60.2117

7.7 Tags

7.8 Isolation Methods

7.9 Lockout Box Examples

7.10 Group LOTO Flowchart

7.11 Equipment Testing Flowchart

21-22 July 2011, KLCC

Figure 1: Flash-over occurred when earth bonding clamps

was applied to 11KV cable connection bar that was still

energized.

Lesson Learnt # 1: Electrical Flash Over

21-22 July 2011, KLCC

Lesson Learnt # 2: Wrong blind installation

Correct location for blind

to be installed

Pump

l

Suction line to be modified

Wrong flange opened

for blinding

Low Pressure Alarm

signal to CCR

Correct location for blind

to be installed

Pump

l

Suction line to be modified

Wrong flange opened

for blinding

Low Pressure Alarm

signal to CCR

M2-912

N2 Tank

Under pressure

21-22 July 2011, KLCC

Lockout tagout done at the wrong breaker, LP 706B instead of LP

701B

Lesson Learnt # 3: LOTO at Wrong Breaker

21-22 July 2011, KLCC

Broken male connector

(connecting radioactive source capsule

with winding cable)

Guide Tube

Figure 1: Gamma projector with source driving and retrieval

mechanism

Lesson Learnt # 4 : Radiation Exposure

21-22 July 2011, KLCC

Type of Energy Source

21-22 July 2011, KLCC

Type of Energy

Electrical transmissions lines, transformers, circuit breakers, motors,

lighting, impressed current of cathodic protection

Hydraulic liquid under pressure e.g. pumps, hydro testing, hydraulic

system

Pneumatic air/gas systems under pressure, e.g. plant air, hydrocarbon

gas, gas cylinder

Chemical flammable, toxic, corrosive, reactive e.g. acid & caustic

(corrosive), hydrocarbons (flammable), H2S (toxic), hydrogen peroxide

& pyrophoric material (reactive)

Kinetic moving objects e.g. fan blades, fan belts, agitators, flywheels

Stored or potential springs, counter weights, raised loads

Radiation ionizing source e.g. radiography activities

Thermal extreme temperature e.g. hot surface, cryogenic materials,

steam

21-22 July 2011, KLCC

Electrical : electrocution, burn

Chemical : chemical burn, cold burn

Pneumatic : high impact injury, cut

Mechanical : cut, flying object

Radiation : burn, cell mutation

Hydraulic : injury, cut

Thermal : burn

Release of energy could result in personal injury

or damage to property and environment.

Energy : Consequence Of Energy Release

21-22 July 2011, KLCC

All energy sources shall be isolated and brought down to

zero energy state before work begins.

Special cases for consideration:

electrical capacitor, energy stored shall be discharged

stored energy in spring

trapped energy in system, e.g. multiple valves isolation, clogged line

Energy : Key Principle

21-22 July 2011, KLCC

Energy Isolation Concept :

+

ISOLATION

LOTO

21-22 July 2011, KLCC

Isolation : The act of separating something (Oxford)

Type of Isolation

Physical Isolation

Electrical Isolation

21-22 July 2011, KLCC

1. Positive Isolation

Spool / valve removal

Blind / spade isolation ( Blind Type : Rated,

Correct Material & Correct Size )

If blind/spade cannot be applied, risk assessment is required

e.g. shutdown, space constraint, valve passing

2. Double Block and Bleed (DBB)

Physical Isolation :

Energy

Source

Area of

Safe isolation

Valve Closed

Valve Opened

Vent / Drain to

Safe location

21-22 July 2011, KLCC

3. Single Valve Isolation (SVI)

Energy

Source

Area of

Safe isolation

Valve Closed

Positive isolation is regarded as the most secure method

and must always be considered first when planning

modification/maintenance work.

Isolation is to be as close as possible to the inlet and

outlet of the equipment to be isolated.

21-22 July 2011, KLCC

For confined space entry.

For hot or cold work on a unit which is part of a system

containing energy source, e.g.:

high temperature (touch: 60 deg C, heat stress: 38 deg C)

high pressure (pneumatic or hydraulic)

asphyxiant

toxic

corrosive

radioactive

When positive isolation is not feasible, use of double block and bleed isolation

may be used after a specific procedure has been developed and approved.

For hot or cold work on a unit which is part of a system

containing combustible or explosive material.

Physical Isolation : Situations Requiring for

Positive Isolation

21-22 July 2011, KLCC

Electrical Isolation :

1. Local Push Button Isolation

2. MCC Isolation

Switch Off

Rack Out

21-22 July 2011, KLCC

Lockout ( LO )

The placement of a locking device on an energy

isolating device, e.g. lock & chain on an isolation valve,

electrical breaker locked & open position, etc.

Tag out ( TO )

The placement of a tag on an energy isolating or lock

out device, e.g. on the lock, at the blind or valve, lock at

the lockout box, etc.

Lock Tag Clear & Try:

After all switches, valves, and devices are locked out

and tagged, and the equipment is cleared of personnel,

attempts are then made to try starting the equipment

(push button, actuators, etc.).

LOTO : Lock Out Tag Out

21-22 July 2011, KLCC

With the Group LOTO System a series of locks with a single

common master key* with tags are used to isolate the system after

which the key is placed in a secured Lockout Box.

*Spare keys shall be available but must be under strict control by the Area

Manager or equivalent.

Different color coded tags being used:

# Blue (plastic) Operations

# Red (plastic) Electrical

# Yellow (plastic) Ionizing Radiation

# Brown (paper) Common disposable tag used at lockout box

# Green (paper) Spade/blind

LOTO : Group LOTO System

21-22 July 2011, KLCC

Operations

Permanent

type plastic tag

Chargeman

Permanent

type plastic tag

Disposable

Tag

for use with

locks on

Lockout Box

(Paper/Tyvec or similar

material)

WARNING

AMARAN

DO NOT DO NOT

OPERATE OPERATE

DILARANG DILARANG

MENGENDALI MENGENDALI

Elec. Chargeman Elec. Chargeman

No. xxxxxx No. xxxxxx

WARNING

AMARAN

DO NOT DO NOT

REMOVE REMOVE

DILARANG DILARANG

MENANGGALKAN MENANGGALKAN

Name:_____________

Dept.: _____________

Equipment:_________

Date: _____________

WARNING

AMARAN

DO NOT DO NOT

OPERATE OPERATE

DILARANG DILARANG

MENGENDALI MENGENDALI

OPU OPERATION OPU OPERATION

No. xxxxxx No. xxxxxx

RPO/RPS

Permanent

type plastic tag

WARNING

AMARAN

DO NOT DO NOT

OPERATE OPERATE

DILARANG DILARANG

MENGENDALI MENGENDALI

Ionizing Radiation Ionizing Radiation

Isolation Isolation

No. xxxxxx No. xxxxxx

Disposable

Tag with serial

number, duplicated on

perforated section.

Used to identify

Spade/Blind location

(Paper/Tyvec or similar

material)

WARNING

AMARAN

DO NOT DO NOT

REMOVE REMOVE

DILARANG DILARANG

MENANGGALKAN MENANGGALKAN

Spade/Blind

Identification Tag

No. xxxxxx

Spade/Blind

Identification Tag

No. xxxxxx

Verified by RA/RAR

Name:________________

Dep:_____________________

Date:____________________

LOTO :Tags

21-22 July 2011, KLCC

LOTO : Tags For Physical Isolation

Operation tag at valve (Blue)

& blind (Green)

21-22 July 2011, KLCC

Electrical ACP lock & tag (red) and

Operation group lock & tag (blue)

Operation group lock & tag

(blue)

LOTO : Tags For Electrical Isolation

21-22 July 2011, KLCC

LOTO : Tags For Lockout Box

21-22 July 2011, KLCC

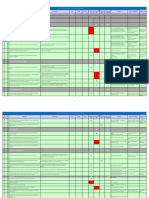

PTWNo. Work To Be Performed RA Dept. Lock No.

Section 1: To be filled out by EQUIPMENT OWNER before the job starts

Equipment Tag No:

Location or Facility : Date : Area :

NO WORK IS SO URGENT THAT WE CANNOT TAKE TIME TO DO IT SAFELY

PTWNo. NAME (Print Clearly) DEPT.

Job

Completed

Y/N

Tag & lock

Removed

Y/N

Sign Off

DEPARTMENT Number of Tags Number of Locks Removed By

OPERATIONS/EQUIPMENT OWNER

ACP/AP ( for MCC isolation)

RPO ( isolation of Ionizing Radiation)

Section 2: To be filled out by Receiving Authority(RA) after work is completed

Section 4: Close out of PIC

PHYSICAL ISOLATION CERTIFICATE

DEPARTMENT Number of Tags Number of Locks Installed By

OPERATIONS/EQUIPMENT OWNER

ACP/AP ( for MCC isolation)

RPO ( isolation of Ionizing Radiation)

No. 0000001

p

Page 1 of 2

Before any work commences on this equipment, the Equipment Owner/AA by signing on this document agrees that the equipment has been prepared in accordance

with approved procedures or instructions relating to the equipment and is safe to work on. It is also confirmation that the Approving Authority has personally

witnessed the Lock,Tag Clear and Try process which has been conducted by operating the push button, actuators, etc., to confirm that the equipment will not start.

I affirm that the above conditions have been complied with:

AA Department Lock No:_____________________________ Sign:___________________________________________Approving Authority(AA)

STOP WORK AND EVACUATE AREA ON HEARING OF EMERGENCY ALARM

NO WORK IS SO URGENT THAT WE CANNOT TAKE TIME TO DO IT SAFELY

Original PIC To Be Maintained and Displayed at the Control Room or Office Location Where the PTW is Issued

Section 3: Weekly Revalidation by Approving Authority

Week 2 3 4 5 6 7 8 9 10 11 12

Name

Signature

Date

PIC, EIC & LoEA :

Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 Page 1 of 2 of 2 of 2 of 2 of 2 of 2 of 2 of 2

in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in acco in accordance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance rdance

nally nally nally nally nally nally nally nally nally nally nally nally nally nally nally nally

will no will no will no will no will no will no will no will no will no will no will no will no will no will no will not start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start t start..........

Physical Isolation Certificate (PIC)

Electrical Isolation

Certificate (EIC)

Limit of Electrical Access

Certificate (LoEA)

21-22 July 2011, KLCC

Energy Isolation Procedure

21-22 July 2011, KLCC

Approving Authority (AA):

approving PTW for modification and/or maintenance work on equipment

or systems where energy isolation is required.

assessing the hazard associated with the work and recommend control

measures.

ensure that the Job Method Statement (JMS) and/or JSA/JHA is available.

ensure only trained and competent personnel perform the preparation

and isolation activities.

Approving Authority Representative (AAR):

Appointed by the Approving Authority to prepare and isolate the

equipment.

May also be instructed to install any lockout devices and tags under the

supervision of the Approving Authority.

Shall be competent to operate the equipment and understand the process

/ system being isolated.

EI : Roles and Responsibilities

21-22 July 2011, KLCC

Receiving Authority (RA):

Responsible for supervising the maintenance activities

Ensures that the system or equipment being worked on has been safely

isolated and disabled with proper lockout and tags.

Accepts the PTW issued for work to be carried out under his supervision.

Receiving Authority Representative (RAR):

Responsible for carrying out maintenance works

Checks and confirms that the system or equipment being worked on has

been safely isolated and disabled with proper lockout and tags.

EI : Roles and Responsibilities

21-22 July 2011, KLCC

GROUP LOTO

FLOWCHART

START

EQUIPMENT IS ISOLATED

PURGED AND FLUSHED

ISOLATION IS CONFIRMED

LOCKED & TAGGED AS PER ISOLATION /

LOCKOUT DEVICE LIST BY AAR.

PIC IS FILLED IN

ACP RECEIVES EIC, ISOLATES BREAKER

& INSTALLS LOCKS & TAGS .

AAR ALSO INSTALLS LOCKS & TAGS

LOCAL CLEAR & TRY TEST

IS PERFORMED BY AAR & AA.

LOCAL SWITCH LOCKED & TAGGED

EIC & PIC ARE COMPLETED

AS PER ELECTRICAL ISOLATION

ACTION PARTY

ACTION

EQUIPMENT PREPARATION

FIELD LOCK OUT TAG OUT

IF ELECTRICAL ISOLATION

IS REQUIRED

EIC & PIC DOCUMENTATION

WORK REQUIRED

ON EQUIPMENT

AA OR RA

TO INITIATE

AA TO

INSTRUCT AAR

AAR TO ACOMPANYACP

FOR ELECTRICAL ISOLATION.

LOTO BY ACP & AAR ONLY

AA TO CONFIRM

EIC & PIC ARE CORRECT

AA TO WITNESS

AAR PERFORMING

2 AAR REQUIRED FOR THE TASK

LOTO BY OPS. ONLY.

LOCKS WITH COMMON KEY ARE USED.

ONLY TAG NUMBERS RECORDED ON PIC

CONFIRMATION OF

ELECTRICAL ENERGY ISOLATION

EI : Group LOTO Flowchart

21-22 July 2011, KLCC

KEYS FROM ELECTRICAL & ALL

OTHER LOCKOUT DEVICES ARE

PLACED IN THE LOCKOUT BOX

AA PLACES DEPARTMENT LOCK & TAG ON

LOCKOUT BOX AND RECORDS NUMBER ON PIC

LOCKOUT KEYS ARE SECURED

LOCKOUT BOX IS SECURED

RA PLACES HIS LOCK & TAG ON THE

LOCKOUT BOX AND RETAINS THE KEY

RA REQUEST FOR PTW

PTW DETAILS & RA LOCK No RECORDED

ON SECTION 1 OF PIC.

PIC No RECORDED ON PTW

PTW IS ISSUED

PTW ISSUED &

WORK BEGINS

AA TO PERFORM

AA TO PERFORM

& RETAIN KEY

AA TO WITNESS

RA INSTALLING

AA & RA TO COMPLETE

ACTION PARTY ACTION

EI : Group LOTO Flowchart (Cont)

21-22 July 2011, KLCC

ACTION PARTY

ACTION

LOCKS & TAGS IN FIELD REMOVED BY AAR

LOCKS & TAGS FOR ELECTRICAL

REMOVED BY ACP & AAR

LOCK AND TAG REMOVAL

RA TO INFORM AA

OTHER PTW

ENTERED ON

PIC & EIC

NO

YES

PIC & EIC

ARE CLOSED

END

ALL PTW ON THE

PIC & EIC ARE CLOSED

PIC & EIC

REMAIN ACTIVE UNTIL

ALL PTW ARE CLOSED

WORK IS COMPLETED

ALL WORK IS COMPLETED

ACP & AA TO COMPLETE DOCUMENTS ARE CLOSEOUT

PTW No RECORDED IN SECTION 2 OF PIC

& RA SIGNES OFF.

PTW IS CLOSED

IS ALL WORK COMPLETED?

EI : Group LOTO Flowchart (Cont)

21-22 July 2011, KLCC

Identify the energy source

Electrical

Sub

station

Field

Switch

Motor Pump

Electric

al

Hydraulic & chemical

Energy Isolation Simulation

21-22 July 2011, KLCC

Isolate the energy at substation & local switch and apply

locking & tagging (LOTO)

Open circuit

with switch

Electrical

Sub

station

Field

Switch

Motor Pump

LOTO

LOTO

Elec & Ops to apply

LOTO on switch

gear/breaker

Clear, Try, Lock and

Tag by Ops at local

switch

21-22 July 2011, KLCC

Hydraulic - valve isolation and depressurize

Open to depressurise

Electrical

Sub

station

Field

Switch

Motor Pump

LOTO

LOTO

Valve Closed

Chemical flushing & purging by

steam / nitrogen / condensate /

water

Verify whether it is safe to work on (zero energy state)

21-22 July 2011, KLCC

Locking & tagging (LOTO) at the valve

Electrical

Sub

station

Field

Switch

Motor Pump

LOTO

LOTO

Valve Closed

LOTO

LOTO

LOTO

21-22 July 2011, KLCC

Spading at confirmed location of valve flange

Electrical

Sub

station

Field

Switch

Motor Pump

LOTO

LOTO

Open

LOTO

LOTO

LOTO

Spading and tagging

Close

Close

21-22 July 2011, KLCC

Open circuit

with switch

Electrical

Sub

station

Field

Switch

Motor Pump

LOTO

LOTO

*Clear, Try, Lock and Tag

Open

LOTO

LOTO

LOTO

Spading and tagging

Close

Close

Ready for maintenance work

21-22 July 2011, KLCC

Special Case (1/3)

LOTO applies at battery limits isolation.

LOTO also applies for Electrical and ionizing radiation sources.

Tags only with the PIC (no lockout devices) will be used for other

process isolation.

The PIC, EIC and RC (Radiation Certificate) shall be used as in normal

circumstances.

Positive isolation (i.e. blinds/spades, spool removal, valve removal

etc.) requirements shall be applied for all confined space entry

activities.

1. Isolation and LOTO during plant shutdown periods (Applicable for

standalone facilities only after the area being declassified i.e.

hydrocarbon free)

EI :Special Case (1/3)

21-22 July 2011, KLCC

2. Short Duration Instrument Isolation

Short duration tasks, e.g. routine calibration of instruments, may

be done with single valve isolations, and an instrument

technician may effect the isolation.

A Permit to Work (PTW) is required and this must state that the

Equipment has been Isolated without PIC.

If the job is strictly supervised, the lockout or tagout device on

the isolation valve(s) is not required.

EI :Special Case (2/3)

21-22 July 2011, KLCC

However, single valve isolations effected by instrument technicians are NOT

allowed under the following process conditions:

*either/or If the period of isolation is to be extended, or if the isolated instrument is to be

removed, then full isolation must be implemented by a process technician. Under these

circumstances the isolation valve(s) must be locked and tagged.

EI :Special Case (2/3) cont

Process fluid Pressure* Temperature*

Flammable - Flash point below

ambient temp.

Toxic - subject to USECHH

regulations

Line Breaking containing

hazardous material

Line Breaking containing

non-hazardous material

>55Barg

-

-

>30Barg

>200C

-

-

>50C

21-22 July 2011, KLCC

3. Test run and troubleshooting

This is allowed under the following conditions:

RA requesting the test run informs the AA

AA withdraws all PTW listed on the PIC and the RAs remove the

department lock & tag from the lockout box.

AA removes his department lock & tag from the lockout box and makes

the Group Lock keys available for de-isolation. Only equipment related to

the test is de-isolated.

RA proceeds with the equipment test.

Once the test is completed, RA informs the AA.

AA will then ensures the equipment isolation returns to previous condition

and secures the Group Lock keys in the lockout box.

PTW may be revalidated after RA places the department lock and tag on

the lockout box.

EI :Special Case (3/3)

21-22 July 2011, KLCC

Field / substation

Operations key (Group lock with master key)

Electrical key (department lock with individual key)

RPO key (department lock with individual key)

Lockout Box station

AA key (department lock with individual key)

RA key (department lock with individual key)

EI : Management of Keys

21-22 July 2011, KLCC

Handover between shifts or change of AA / RA

keys shall be handed over personally and recorded in the key

handover log book by each department

handover of PTW, PIC, EIC and other certificates

Unused lock, key & tag stored at a safe place in each

department

Spare common keys shall be kept by Shift Manager or

equivalent for use during emergency

EI :Ownership

Ownership

21-22 July 2011, KLCC

Passing mark of 85% minimum out of 20 multiple choice questions (30 minutes)

Refresher training (half day) every 3 years

Awareness training for those managing isolation of energy activities (half day

every 3 years)

Energy isolation 1 day

Energy Isolation

Refresher day

Approving Authority /

Supervisor (AA)

3 3

Approving Authority

Representative (AAR)

3 3

Receiving Authority (RA)

3 3

Receiving Authority

Representative (RAR)

3 3

Work Leader (WL)

3 3

Management

Awareness Training (no

test)

3

EI :Competency & Training

21-22 July 2011, KLCC

You can Help to create An Accident

Free Workplace Through LOTO

21-22 July 2011, KLCC

Thank You

You might also like

- 9 - Petronas - Implementation of Electrical Energy Isolation PDFDocument25 pages9 - Petronas - Implementation of Electrical Energy Isolation PDFal bauerNo ratings yet

- Confined Space EntryDocument48 pagesConfined Space Entryadammzjin100% (2)

- Offshore Safety InductionDocument39 pagesOffshore Safety Inductionsrk430100% (1)

- OGP Life-Saving RulesDocument24 pagesOGP Life-Saving RulesInternational Association of Oil and Gas Producers100% (3)

- Confined Space Hazards AwarenessDocument27 pagesConfined Space Hazards AwarenessNoor Fadilah Printis100% (1)

- Learning From IncidentsDocument123 pagesLearning From Incidentsbrmamor100% (1)

- Petroleum Development Oman L.L.C.: Document Title: H Sandso Management OperationsDocument33 pagesPetroleum Development Oman L.L.C.: Document Title: H Sandso Management OperationsShambu S VtkNo ratings yet

- ZeTo RulesDocument47 pagesZeTo RulesPok Itam100% (1)

- Offshore SafetyDocument114 pagesOffshore SafetyGNo ratings yet

- Life Saving Rules Speaker Support Pack Jan 2012Document33 pagesLife Saving Rules Speaker Support Pack Jan 2012Muhammed AliNo ratings yet

- Energy Isolation Protocol R2 9-4-15Document23 pagesEnergy Isolation Protocol R2 9-4-15AjiwuriNo ratings yet

- Compressed Gas Cylinders PowerPointDocument20 pagesCompressed Gas Cylinders PowerPointInspire KharianNo ratings yet

- Confined SpacesDocument27 pagesConfined SpacesDivya RastogiNo ratings yet

- Energy Isolation ProcedureDocument33 pagesEnergy Isolation Procedure최승원No ratings yet

- BP/ISS Safety Moment - Focusing on the Golden RulesDocument7 pagesBP/ISS Safety Moment - Focusing on the Golden RulesChristine RossNo ratings yet

- Permit To Work SystemsDocument8 pagesPermit To Work Systemsbmckevitt100% (3)

- Mechanical Isolation Methods and ProceduresDocument13 pagesMechanical Isolation Methods and ProceduresHse RiyazNo ratings yet

- Welding HabitatDocument12 pagesWelding HabitatDesmond Chang100% (3)

- Hazardous Line Opening PermitDocument2 pagesHazardous Line Opening PermitBasil M. Ikhleif100% (2)

- Confined Space EntryDocument33 pagesConfined Space EntryLee Anthony ChingNo ratings yet

- Line BreakDocument30 pagesLine Breakmanoranjan singhNo ratings yet

- 1.2 Isolation, Lockout, TagoutDocument62 pages1.2 Isolation, Lockout, TagoutEkant GoyalNo ratings yet

- Positive & Safe Isolation MethodDocument118 pagesPositive & Safe Isolation MethodRahul S. Chandrawar100% (1)

- Indicators of Process Safety Through The Lens of MacondoDocument44 pagesIndicators of Process Safety Through The Lens of Macondoasya100% (1)

- Habitats Presentation New PDFDocument11 pagesHabitats Presentation New PDFIkhwan Hafiz100% (2)

- Lock Out Tag Out SWPPDocument3 pagesLock Out Tag Out SWPPsaleenasirajNo ratings yet

- JMS-STS-PIP - JMS Latest FormatDocument2 pagesJMS-STS-PIP - JMS Latest Formatmohd as shahiddin jafriNo ratings yet

- Hemp HazidDocument17 pagesHemp HazidrwerwerwNo ratings yet

- 10 Zero ToleranceDocument2 pages10 Zero Tolerancekel35350% (1)

- PSSR Checksheet - Offshore Asset - DraftDocument6 pagesPSSR Checksheet - Offshore Asset - Draftjai kumar100% (1)

- 6419RJ510-10006 Blinds Management ProcedureDocument14 pages6419RJ510-10006 Blinds Management ProcedureLuqman Osman100% (1)

- Hazardous Area ClassificationDocument2 pagesHazardous Area ClassificationRatnakar Pai100% (1)

- Hotwork Implementation Verification Checklist Rev 5Document3 pagesHotwork Implementation Verification Checklist Rev 5anjangandak2932100% (1)

- United Energy Pakistan's Energy Isolation ProcedureDocument53 pagesUnited Energy Pakistan's Energy Isolation ProcedureJamal Shah100% (1)

- Safe Tank EntryDocument4 pagesSafe Tank Entrywill_hiresNo ratings yet

- Upstream Control of Work BP Procedure June 2020 - Rev B06 - PDFDocument361 pagesUpstream Control of Work BP Procedure June 2020 - Rev B06 - PDFRio Reunarudi100% (1)

- 95-0120 Cometence Assurance For HSE Critical ActivitiesDocument48 pages95-0120 Cometence Assurance For HSE Critical ActivitiesClive Nicli100% (2)

- East Wind Simops MatrixDocument2 pagesEast Wind Simops MatrixkhaledNo ratings yet

- JOB HAZARD ANALYSIS FOR FIRST AND SECOND LINE WELLHEAD MAINTENANCEDocument8 pagesJOB HAZARD ANALYSIS FOR FIRST AND SECOND LINE WELLHEAD MAINTENANCEAnthony H TL75% (4)

- LifeSavingRules - Supplementary Rules PostersDocument11 pagesLifeSavingRules - Supplementary Rules PostersInternational Association of Oil and Gas ProducersNo ratings yet

- Pre Incident Plan Crude Oil Tank Pool Fire at TCOTDocument1 pagePre Incident Plan Crude Oil Tank Pool Fire at TCOTkamen55100% (3)

- Shell Abandonment Presentation IPark Workshop Feb'15Document13 pagesShell Abandonment Presentation IPark Workshop Feb'15CoolProphetNo ratings yet

- JO Simultaneous Operations ChecklistDocument9 pagesJO Simultaneous Operations Checklistmalimsaidi_160040895No ratings yet

- Hot WorkDocument20 pagesHot WorkmarceloNo ratings yet

- Confined Space Entry ProcedureDocument37 pagesConfined Space Entry ProcedureJamal Shah100% (1)

- Petroleum Development Oman L.L.C.: H S & So Management Drilling and Well InterventionDocument67 pagesPetroleum Development Oman L.L.C.: H S & So Management Drilling and Well Interventionxu zhao0% (1)

- EP950100 HSE Management SystemDocument62 pagesEP950100 HSE Management SystemDaniel100% (1)

- User-Manual-25262Compressed Gas Cylinders PowerPointDocument20 pagesUser-Manual-25262Compressed Gas Cylinders PowerPointMohammed NaseeruddinNo ratings yet

- Conoco Phillips Specification - Surface Christmas Trees, Christmas Tree Valves and WellheadsDocument15 pagesConoco Phillips Specification - Surface Christmas Trees, Christmas Tree Valves and WellheadsJaveed A. KhanNo ratings yet

- Breaking Containment Checklist EssentialsDocument4 pagesBreaking Containment Checklist Essentialsromedic36No ratings yet

- COSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsDocument2 pagesCOSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsPaulSwinbankNo ratings yet

- Lock Out and Tag Out Standart ManualDocument25 pagesLock Out and Tag Out Standart ManualEka Candra IrawanNo ratings yet

- Claxton Wellhead Maintenance Technical PaperDocument13 pagesClaxton Wellhead Maintenance Technical Papervitali_curteanuNo ratings yet

- Confined Space Entry TrainingDocument39 pagesConfined Space Entry TrainingyounasNo ratings yet

- Petroleum Equipment Isolation ProceduresDocument56 pagesPetroleum Equipment Isolation ProceduresImmanuel100% (1)

- Safe Isolation and Reinsinment of PlantDocument85 pagesSafe Isolation and Reinsinment of PlantPradeep JoshuaNo ratings yet

- Emergency Response Planning Guidelines (ERPG)Document5 pagesEmergency Response Planning Guidelines (ERPG)btjajadiNo ratings yet

- Data logger discovery risk assessmentDocument1 pageData logger discovery risk assessmentCoin DozerNo ratings yet

- Isolation & Lock Out - Tag Out (LOTO)Document24 pagesIsolation & Lock Out - Tag Out (LOTO)Becha MouradNo ratings yet

- Effect of Temp. Rise On Prefabricated SubstationsDocument8 pagesEffect of Temp. Rise On Prefabricated SubstationsChandrakant ChandanNo ratings yet

- StyreneDocument22 pagesStyreneMohd Masri A. Razak100% (1)

- Styrene ManufactureDocument13 pagesStyrene ManufactureGunjan SolankiNo ratings yet

- Straight Pipe Flow Rate Data SheetDocument2 pagesStraight Pipe Flow Rate Data SheetMohd Masri A. RazakNo ratings yet

- Industrial Energy Audit Guidebook.Document91 pagesIndustrial Energy Audit Guidebook.Ion BlanaruNo ratings yet

- Minor LossesDocument8 pagesMinor LossesshieferNo ratings yet

- 01 Iodine ReactionDocument5 pages01 Iodine ReactionMohd Masri A. RazakNo ratings yet

- Drag Coef FrictionDocument14 pagesDrag Coef FrictionMohd Masri A. RazakNo ratings yet

- Group Assignment 1Document2 pagesGroup Assignment 1Mohd Masri A. RazakNo ratings yet

- FM 308Document6 pagesFM 308Joshua DoctorrNo ratings yet

- Liquid Gas Absorption ProcessDocument89 pagesLiquid Gas Absorption ProcessMohd Masri A. RazakNo ratings yet

- CA Kelulusan Kebenaran PtiptoDocument1 pageCA Kelulusan Kebenaran PtiptoMohd Masri A. RazakNo ratings yet

- Effect of Agitation Speed and Air Flow on KLa in BioreactorsDocument5 pagesEffect of Agitation Speed and Air Flow on KLa in BioreactorsMohd Masri A. Razak100% (1)

- Colebrook White EquationDocument1 pageColebrook White EquationRendi KurniawanNo ratings yet

- C200 ManualDocument42 pagesC200 ManualMohd Masri A. RazakNo ratings yet

- NPSH MarginDocument5 pagesNPSH MarginKCFUNGNo ratings yet

- Experiment No.1 FLOW THROUGH PIPES Background TheoryDocument8 pagesExperiment No.1 FLOW THROUGH PIPES Background TheoryMradul YadavNo ratings yet

- NPSH MarginDocument5 pagesNPSH MarginKCFUNGNo ratings yet

- 01 Operating Manual PumpDocument39 pages01 Operating Manual PumpMohd Masri A. RazakNo ratings yet

- 0 Slide AutoCad - ContentsDocument4 pages0 Slide AutoCad - ContentsMohd Masri A. RazakNo ratings yet

- Colebrook Equations Form... - Darcy Friction FactorDocument3 pagesColebrook Equations Form... - Darcy Friction FactorMohd Masri A. RazakNo ratings yet

- TW15 H - TW15 R PDFDocument2 pagesTW15 H - TW15 R PDFMohd Masri A. RazakNo ratings yet

- 0 Slide AutoCad - ContentsDocument4 pages0 Slide AutoCad - ContentsMohd Masri A. RazakNo ratings yet

- 2-TWO Phase Separator Design Guide by Manish ShahDocument62 pages2-TWO Phase Separator Design Guide by Manish Shahdennis_ugarteNo ratings yet

- Micro GC 3000 BrochureDocument8 pagesMicro GC 3000 BrochureMohd Masri A. Razak100% (1)

- Circulatory System Packet BDocument5 pagesCirculatory System Packet BLouise SalvadorNo ratings yet

- Business Startup Practical Plan PDFDocument70 pagesBusiness Startup Practical Plan PDFShaji Viswanathan. Mcom, MBA (U.K)No ratings yet

- EcoLettsandSOM, Dulvy Et Al 2004Document25 pagesEcoLettsandSOM, Dulvy Et Al 2004Nestor TorresNo ratings yet

- Pack Alimentacion Clin in Perin 14Document194 pagesPack Alimentacion Clin in Perin 14Paz BustosNo ratings yet

- Fitness WalkingDocument192 pagesFitness Walkingjha.sofcon5941100% (1)

- Benefits and Limitations of Vojta ApproachDocument50 pagesBenefits and Limitations of Vojta ApproachAlice Teodorescu100% (3)

- Nicenstripy Gardening Risk AssessmentDocument38 pagesNicenstripy Gardening Risk AssessmentVirta Nisa100% (1)

- Disinfecting Water Wells Shock ChlorinationDocument3 pagesDisinfecting Water Wells Shock ChlorinationmayaNo ratings yet

- AYUSHMAN BHARAT Operationalizing Health and Wellness CentresDocument34 pagesAYUSHMAN BHARAT Operationalizing Health and Wellness CentresDr. Sachendra Raj100% (1)

- Introduction To Animal Science For Plant ScienceDocument63 pagesIntroduction To Animal Science For Plant ScienceJack OlanoNo ratings yet

- Alok ResumeDocument3 pagesAlok Resumealok choudharyNo ratings yet

- Jounce Therapeutics Company Events and Start DatesDocument48 pagesJounce Therapeutics Company Events and Start DatesEquity NestNo ratings yet

- A&P 2 - Digestive System Flashcards - QuizletDocument1 pageA&P 2 - Digestive System Flashcards - QuizletMunachande KanondoNo ratings yet

- Cap 716 PDFDocument150 pagesCap 716 PDFjanhaviNo ratings yet

- Impact of Energy Consumption On The EnvironmentDocument9 pagesImpact of Energy Consumption On The Environmentadawiyah sofiNo ratings yet

- Proper restraint techniques for dogs and catsDocument153 pagesProper restraint techniques for dogs and catsjademattican75% (4)

- 9 To 5 Props PresetsDocument4 pages9 To 5 Props Presetsapi-300450266100% (1)

- Stress and FilipinosDocument28 pagesStress and FilipinosDaniel John Arboleda100% (2)

- MLS 321 Aubf M6u2 Other Metabolic Diseases V2122Document7 pagesMLS 321 Aubf M6u2 Other Metabolic Diseases V2122proximusNo ratings yet

- Q4 Module 8Document14 pagesQ4 Module 8DerickNo ratings yet

- Material Safety Data Sheet: WWW - Smartlab.co - IdDocument8 pagesMaterial Safety Data Sheet: WWW - Smartlab.co - Idlalan suparlanNo ratings yet

- UNICESS KR Consmetics Maeteria Nunssupjara 01apr23Document44 pagesUNICESS KR Consmetics Maeteria Nunssupjara 01apr23ZB ChuaNo ratings yet

- Goals Editable PDFDocument140 pagesGoals Editable PDFManuel Ascanio67% (3)

- Q1 Tle 4 (Ict)Document34 pagesQ1 Tle 4 (Ict)Jake Role GusiNo ratings yet

- 7 Surprising Cyberbullying StatisticsDocument4 pages7 Surprising Cyberbullying StatisticsJuby Ann Enconado100% (1)

- Week 6 Blood and Tissue FlagellatesDocument7 pagesWeek 6 Blood and Tissue FlagellatesaemancarpioNo ratings yet

- Heat Exchanger Sodium SilicateDocument2 pagesHeat Exchanger Sodium SilicateChristopher BrownNo ratings yet

- Health 6 Q 4 WK 6 Module 6 Version 4Document16 pagesHealth 6 Q 4 WK 6 Module 6 Version 4Kassandra BayogosNo ratings yet

- Laboratorio 1Document6 pagesLaboratorio 1Marlon DiazNo ratings yet

- December - Cost of Goods Sold (Journal)Document14 pagesDecember - Cost of Goods Sold (Journal)kuro hanabusaNo ratings yet