Professional Documents

Culture Documents

Sandvik Jaw Crushers - EN

Uploaded by

Alexis Iván Pérez GuerreroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sandvik Jaw Crushers - EN

Uploaded by

Alexis Iván Pérez GuerreroCopyright:

Available Formats

Sandvik

Jaw Crushers

At Sandvik we have over a century of experience of designing and

manufacturing jaw crushers. We also have a wealth of knowledge

about customers expectations and needs. This background has led to

the current range of Sandvik jaw crushers which includes models

specially suited for mobile applications. Strength has been increased

and weight has been reduced. Sandviks jaw crushers provide an

excellent choice when high production and low total cost are sought.

Robust

construction

The Sandvik jaw crusher is a single toggle jaw crusher, characterized

by attention to detail, in both design and manufacture. We have

incorporated the best of the old and applied the benefits of the latest

technology.

The frame consists of two side plates of rolled steel,

plus hollow castings at front frame end and moving jaw

which give a high rigidity/weight ratio. Large-radius

transition areas reduce stress concentrations and welds

are positioned in low-stress areas. The advantage

of a welded frame is that it is equally strong in all

directions and ensures excellent durability against

shock-loads. Thus minimizing the risk of failure on

the main-frame, as with a bolted construction.

The picture shows an FEA print-out of the predicted

stress distribution in a side plate.

Optimized

performance

High capacity

High reduction

Low jaw plate wear

Large feed acceptance capability

These four factors are closely linked and the Sandvik jaw crusher

provides a good balance.

The design of the deep symmetrical crushing chamber maxi-

mizes feed size, capacity and reduction.

An optimized nip angle ensures that the material progresses

smoothly down through the crushing chamber to enable high

reduction, productivity and superb utilization of jaw plates.

It is not just a large nominal feed opening that is necessary

the feed acceptance capability depends on a feed opening which is

effective and active (see illustration).

All crushers in the range have an almost square feed opening so

that they can accept the largest material lumps without blockages.

A thick, replaceable deflector plate protects the top of the

moving jaw from the impact of the feed material. Large material

lumps entering the crusher fall straight into the active region of the

crushing chamber, so there is no need for a stationary cross-wall in

the feed area.

22

3

Sandvik jaw crusher: A deflector

plate at the top of the moving jaw

means that no intrusive cross-wall is

required in the feed hopper. All of

the effective feed opening is active.

Material is crushed right at the top of

the crushing chamber.

Competitor: Cross-wall required

in feed hopper to protect top of

moving jaw. Stationary cross-wall

reduces effective feed opening.

Material cannot be crushed until it

has dropped a good distance into

the crushing chamber.

Active feed opening

Competitor:

Conventional crushing

chamber.

Effective feed opening <

Nominal feed opening.

Sandvik jaw crusher:

Symmetrical crushing

chamber.

Effective feed opening =

Nominal feed opening.

Real=

Nominal

Nominal >

Real

Effective feed opening

Crawler-mounted jaw crusher

3

Cross-section of drive-side main bearings.

CC:Coarse Corrugated

ST: Sharp Toothed

HD: Heavy Duty

C: Corrugated

Performance in all types

of application

Sandviks wear parts are designed to give high per-

formance and low operating costs. High quality

material and experienced design ensure quality parts.

Fine tuning in applications are ensured through the

available range of alternative jaw plate designs.

All jaw plates are reversible. The WT jaw

plate can also be used on both the stationary and

moving jaw.

Maintenance friendly

features

Thanks to carefully detailed design, Sandviks jaw

crushers secure trouble-free operation and increased

uptime.

Bearings are grease-lubricated and have grease-

filled labyrinth seals to prevent the entry of dust.

Grease lubrication hoses as standard with a cen-

tral distribution block offer safety value and

makes it easier for the operator to grease the

bearings.

Automatic lubrication system that can be con-

nected to existing control systems for remote

alarm indication. This ensures the protection of

the roller bearings.

Setting adjustment made with traditional shim

plates.

Quick and easy installation of jaw plates by using

clamping and support bars to fix the jaw plates to

the crusher.

Sacrificial parts to protect the main components

of the crusher such as frame, swing jaw and

bearings. This reduces total life-cycle costs and

increases uptime, as it is less expensive to change

the sacrificial parts than the main components.

4

WT: Wide Teeth

High strength with

low weight.

Increased uptime

thanks to operator

friendly design.

Uniform welded

construction

High capacity and

high reduction.

Effective, active

feed opening.

Jaw plates for all

types of

applications.

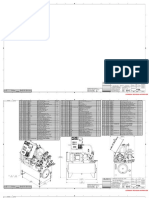

1. Deflector plate.

2. Quick and easy

installation of jaw

plates by using

clamping bars to fix

the jaw plates to

the crusher.

3. Cheek plates for

protection of side

plates.

4. Easily replaceable

support bars and

clamping bars

reduce total life-

cycle cost.

5. Wear plate

protects the front

frame end.

6. Intermediate

plate protects the

swing jaw.

7. Lubrication-free

toggle-plate.

1. 2.

3. 4. 5.

7.

5

6.

Capacity MTPH (STPH)

Product curves

The figure shows product distribution curves which are

representative for medium-hard material [Impact Work

Index (Wi = 16)], with approx. 75% of the product

smaller than the crushers Closed Side Setting (CSS).

The shape of the product curve and the proportion of

the product which will be smaller than the CSS depend on

the characteristics of the feed material. Operation with

common rock materials with different crushabilities

(Work Index between 12 and 20) normally results in a

product curve that is between 65% and 85% smaller than

the crushers CSS.

Performance

data

Closed side setting (CSS) Crusher model

mm in CJ408 CJ409 CJ411 CJ412 CJ612 CJ613 CJ615 CJ815 CJ211

50 75-110 85-115 95-135

2 (85-120) (95-125) (105-150)

75 95-150 100-160 150-200 165-220 127-192

3 (105-165) (110-175) 165-220) (180-245) (140-212)

100 115-180 125-200 200-265 220-290 160-250

4 (125-200) (140-220) (220-290) (240-320) (175-275)

125 140-210 150-235 245-325 270-355 300-395 330-430 385-495 195-310

5 (155-230) (165-260) (270-360) (300-390) (330-435) (365-475) (425-545) (215-340)

150 160-250 175-275 295-390 325-430 355-465 385-505 445-590 480-625 230-370

6 (175-275) (195-305) (325-430) (360-475) (390-515) (425-555) (490-650) (530-690) (250-410)

175 180-285 200-320 340-445 385-505 405-530 440-575 505-665 545-710 265-430

7 (200-315) (220-350) (375-490) (425-555) (445-585) (485-635) (555-735) (600-785) (290-475)

200 385-505 445-580 455-595 495-650 570-745 610-800 300-490

8 (425-555) (490-640) (500-655) (545-715) (630-820) (675-880) (330-540)

225 430-565 495-650 505-660 550-730 630-825 675-885

9 (475-625) (545-715) (555-730) (605-805) (695-910) (745-975)

250 550-720 560-735 605-810 700-920 745-975

10 605-795) (615-810) (670-895) (770-1015) (820-1075)

275 605-790 610-805 660-885 765-1000 820-1070

11 (665-870) (670-890) (730-975) (845-1100) (905-1180)

300 715-960 (825-1085) 885-1160

12 (790-1060) (910-1195) (975-1280)

The capacity figures given in the table above are approximate and are intended only to give an indication of what the crushers can be expected to produce. They apply

for the open-circuit crushing of dry blasted granite with a bulk density of 1600 kg/m

3

(100 ibs/ft

3

) and a maximum size which can be fed into the crushing chamber

without difficulty. The lower values apply for a feed from which the material finer than the crushers CSS has been removed. The higher values apply for a feed which

includes the fine material. The minimum CSS at which the crusher can be operated depends on the feed size distribution, the materials crushability (Wi), the degree of

contamination and moisture in the feed, the type of jaw plates fitted and the condition of the manganese.

100

90

80

70

60

50

40

30

20

10

0

%

p

a

s

s

i

n

g

t

h

r

o

u

g

h

10 20 30 50 70 100 200 400

Square screen hole size, mm (in)

(

3

/8) (

3

/4) (

3

/16) (2) (2

3

/4) (2) (8) (16)

6

Crusher model

CJ408 CJ409 CJ411 CJ412 CJ612 CJ613 CJ615 CJ815 CJ211

Feed opening mm 800x550 895x660 1045x840 1200x830 1200x1100 1300x1130 1500x1070 1500x1300 1100x700

in 32x22 35x28 41x33 47x33 47x43 51x45 59x42 59x51 43x27

L = Max length m 2.37 2.55 2.99 3.23 3.61 3.76 4.11 4.50 2.39

in 93 101 118 127 142 148 161 177 94

W = Max width m 1.76 1.88 2.09 2.57 2.35 2.47 3.00 2.90 2.45

in 69 74 82 101 92 97 118 108 96

H = Max height m 2.03 2.38 2.82 2.95 3.51 3.85 3.33 4.19 2.17

in 80 94 111 116 138 152 131 165 86

D m 1.40 1.60 1.86 1.86 1.86 2.17 1.76 2.17 1.23

in 55 63 74 74 74 86 70 86 48

F m 1.33 1.58 1.88 1.93 2.50 2.68 2.39 3.05 1.54

in 53 62 74 76 98 105 94 120 61

T m 1.37 1.48 1.77 1.74 2.03 2.30 2.25 2.65 1.53

in 54 58 70 67 79 91 89 104 60

Shipping volume m

3

10 13 20 23 32 38 48 58 14.1

ft

3

343 447 704 810 1127 1329 1690 2042 498

CSS min-max mm 50-175 50-175 75-225 75-275 125-275 125-300 125-300 150-300 40-200

in 2-7 2-7 3-9 3-11 5-11 5-12 5-12 6-12 1.6-7.9

Total weight kg 9900 14100 21700 26600 36600 41500 53000 64500 14600

lbs 21800 31100 47800 58600 80700 91500 116800 142200 32200

Motor power kW 55 75 110 132 160 160 200 200 90

hp 75 100 150 200 250 250 275 275 125

Crusher speed rpm 300 270 240 240 210 225 200 200 270

Other data

D

L

W

F

H

T

7

B

2

2

2

.

1

0

0

E

N

S

a

n

d

v

i

k

S

R

P

A

B

2

0

0

7

.

S

u

b

j

e

c

t

t

o

a

l

t

e

r

a

t

i

o

n

w

i

t

h

o

u

t

p

r

i

o

r

n

o

t

i

c

e

.

S A N D V I K M I N I N G A N D C O N S T R U C T I O N. T E L. +4 6 4 0 4 0 6 8 0 0. F A X +4 6 4 0 4 0 6 8 9 8.

w w w . s a n d v i k . c o m

Sandvik is a high-technology engineering group with advanced

products and world-leading positions in selected areas tools for

metalworking, machinery and tools for rock excavation, stainless

steel, special alloys and resistance heating materials and process

systems. The Group has 39,000 employees in 130 countries, with

annual sales of approximately SEK 63,000 M.

Sandvik Mining and Construction is a business area within the Sand-

vik Group and a world-leading manufacturer of drilling and

excavation machinery, tools and service for the mining and

construction industries. Annual sales amount to SEK 20,600 M,

with about 10,600 employees.

You might also like

- Low Res PrimaryGyratory CrusherDocument8 pagesLow Res PrimaryGyratory CrusherMaikol Gonzalo Vega Blanco100% (1)

- Terex Jaques - ST JawDocument12 pagesTerex Jaques - ST Jawjonathandyson100% (2)

- 8r77r-Cybas I ConeDocument6 pages8r77r-Cybas I Coneturkishdjem100% (1)

- Nordberg Crusher Equipment SolutionsDocument84 pagesNordberg Crusher Equipment Solutionsrolandoh1100% (1)

- Sandvik Intellectual Property v. Kimball Equip. - ComplaintDocument37 pagesSandvik Intellectual Property v. Kimball Equip. - ComplaintSarah BursteinNo ratings yet

- H22-6 - Manual - S223.472.00 enDocument176 pagesH22-6 - Manual - S223.472.00 enLmf Daniel100% (3)

- David Garcia's 500mm Granite Crushing ProcessDocument1 pageDavid Garcia's 500mm Granite Crushing ProcessDavid GarciaNo ratings yet

- 7.2 Crusher Erection and Maintenance Data - FlsmidthDocument3 pages7.2 Crusher Erection and Maintenance Data - FlsmidthWILSON JUAN DE DIOS QUISPE YUPANQUINo ratings yet

- cths660 01spcr2231349 01Document36 pagescths660 01spcr2231349 01Elvis100% (1)

- Crusher Guide Ch440Document5 pagesCrusher Guide Ch440biro_4100% (1)

- Semi-Mobile Gyratory Crushing PlantsDocument23 pagesSemi-Mobile Gyratory Crushing PlantsJosé Andrés Toro BelmarNo ratings yet

- Hydraulic power unit specificationsDocument9 pagesHydraulic power unit specificationsJavier Pineda GalvisNo ratings yet

- Content Inhalt Contenido Sisällysluettelo InnehållDocument129 pagesContent Inhalt Contenido Sisällysluettelo InnehållLina JiaNo ratings yet

- SANDVIK CJ411:01: Operator's ManualDocument80 pagesSANDVIK CJ411:01: Operator's ManualECU Mod100% (2)

- Asri-Good Info PDFDocument39 pagesAsri-Good Info PDFVin100% (1)

- 05.CH660-04 Installation Instructions S223.1257-04 enDocument78 pages05.CH660-04 Installation Instructions S223.1257-04 enMichael adu-boahen100% (1)

- Sandvik Cths660: Spare Parts CatalogDocument36 pagesSandvik Cths660: Spare Parts CatalogWalter Barradas100% (1)

- The Art of Rock CrushingDocument48 pagesThe Art of Rock CrushingJesusFloresRodriguez100% (1)

- CI Manual enDocument63 pagesCI Manual enLmf DanielNo ratings yet

- Sandvik Jaw Crushers-2009 PDFDocument12 pagesSandvik Jaw Crushers-2009 PDFHamid100% (1)

- Nordberg GP300 Cone Crusher Instruction ManualDocument76 pagesNordberg GP300 Cone Crusher Instruction Manualeaglego00100% (5)

- Improper Crusher Feeding: Jaw CrushersDocument1 pageImproper Crusher Feeding: Jaw CrushersbfygNo ratings yet

- Instrucciones de Operación y Montaje SMCP 63x75Document138 pagesInstrucciones de Operación y Montaje SMCP 63x75gytomanNo ratings yet

- The MP2500: The Largest Cone Crusher Ever Built: Materials Handling and LogisticsDocument1 pageThe MP2500: The Largest Cone Crusher Ever Built: Materials Handling and LogisticsDiegoAlvarezHuguezNo ratings yet

- Chancadora TrioDocument123 pagesChancadora Triojlfy100% (1)

- Washing and Classifying Brochure EnglishDocument24 pagesWashing and Classifying Brochure EnglishMohammed Alshami GeologistNo ratings yet

- Gyratory Mill: EccentricDocument10 pagesGyratory Mill: EccentricAbhishek Kumar100% (1)

- hp300 PDFDocument2 pageshp300 PDFsam samin100% (1)

- 2007 Green Pages Catalogo de RepuestosDocument50 pages2007 Green Pages Catalogo de RepuestosEdgar VillalvaNo ratings yet

- Polycom High-Pressure Grinding Roll: Machine Manual en-PM - CPT.001.DDocument133 pagesPolycom High-Pressure Grinding Roll: Machine Manual en-PM - CPT.001.DcarlospelaezNo ratings yet

- Sandvik JM907 Crusher Parts ManualDocument1 pageSandvik JM907 Crusher Parts ManualTomas Chien100% (1)

- Manual Chancadora C-96Document14 pagesManual Chancadora C-96julioNo ratings yet

- TP401Document112 pagesTP401Daniel Tovar Romero50% (2)

- Bulletin 1047Document2 pagesBulletin 1047Cesar Casachagua DavilaNo ratings yet

- Predicction of Cone Crusher Performance Considering Linear WearDocument70 pagesPredicction of Cone Crusher Performance Considering Linear WearHector100% (1)

- Sravya Infracon Supplies Crusher Spare Parts For MetsoDocument2 pagesSravya Infracon Supplies Crusher Spare Parts For MetsoajithNo ratings yet

- Sandvik HSI EN PDFDocument8 pagesSandvik HSI EN PDFkranthiNo ratings yet

- Hydrocone H3800 Crushing Chambers, Page 1Document1 pageHydrocone H3800 Crushing Chambers, Page 1Fatt100% (1)

- K 400 + Liner ConfigurationDocument1 pageK 400 + Liner ConfigurationBlake Cooley AndersonNo ratings yet

- TRIO Feeders BrochureDocument8 pagesTRIO Feeders BrochureZiggy GregoryNo ratings yet

- XL2000 Technical SpecificationDocument3 pagesXL2000 Technical SpecificationLeonardo SilvaNo ratings yet

- Msp300#0078-ConicaDocument69 pagesMsp300#0078-ConicaMartín Lescano ParedesNo ratings yet

- J11 Operator ManualDocument74 pagesJ11 Operator ManualKasix Dunda MalembekaNo ratings yet

- Hydrocone H4800 Crushing Chambers, Page 2 HC PDFDocument1 pageHydrocone H4800 Crushing Chambers, Page 2 HC PDFCESAR ANDRES MOREYRA CANTUNo ratings yet

- Catalogo Giratorio MetsoDocument5 pagesCatalogo Giratorio MetsoPaulaNo ratings yet

- Microsoft Word - Technical Paper-No.8Document5 pagesMicrosoft Word - Technical Paper-No.8Sam ShiddoNo ratings yet

- Modelling and Simulation of Dynamic Behaviour in Crushing PlantDocument66 pagesModelling and Simulation of Dynamic Behaviour in Crushing Plantmas26amin3465No ratings yet

- SANDVIK CH660:01: Spare Parts CatalogDocument34 pagesSANDVIK CH660:01: Spare Parts CatalogEduardoNo ratings yet

- Simu Presentacion Exam3Document1 pageSimu Presentacion Exam3Edwin Barboza DuranNo ratings yet

- Cone Crusher TC-36H Parts ManualDocument33 pagesCone Crusher TC-36H Parts ManualCarolina Váquiro Gamboa100% (1)

- Crusher Backing Compound EstimatorDocument1 pageCrusher Backing Compound Estimatorlandago100% (1)

- SBM Impact Crusher EngDocument12 pagesSBM Impact Crusher EngSilviu SanduNo ratings yet

- Sandvik S6800 Crusher Parts ManualDocument3 pagesSandvik S6800 Crusher Parts ManualTomas Chien100% (1)

- QMS Crusher Spare Parts & Wear SolutionsDocument6 pagesQMS Crusher Spare Parts & Wear SolutionsLo Siento de VerdadNo ratings yet

- Lista Equipos de Cono PDFDocument6 pagesLista Equipos de Cono PDFlandagoNo ratings yet

- PDF Conciliacion Materiales DLDocument96 pagesPDF Conciliacion Materiales DLCarlos Augusto100% (1)

- Nordberg C120中文手册12400Document60 pagesNordberg C120中文手册12400Hyton CastingNo ratings yet

- Sandvik Jaw Eng PDFDocument12 pagesSandvik Jaw Eng PDFgourave daipuria100% (1)

- Base Jaw BrochureDocument8 pagesBase Jaw BrochureronainteNo ratings yet

- What Is InterpolDocument5 pagesWhat Is InterpolJimmy Jr Comahig LapeNo ratings yet

- BL ListDocument8 pagesBL ListStraña Abigail Alonsabe Villacis100% (1)

- Engineering Standard for Rolling Stock Minimum In-Service ConditionsDocument19 pagesEngineering Standard for Rolling Stock Minimum In-Service Conditions4493464No ratings yet

- Mr. Frank Remedios Certified Career Counselor Authorised Franchise-Brain CheckerDocument24 pagesMr. Frank Remedios Certified Career Counselor Authorised Franchise-Brain Checkerrwf0606No ratings yet

- MF Formula Sheet - FullDocument10 pagesMF Formula Sheet - FullublehkogeniusNo ratings yet

- CamScanner Scanned PDF DocumentDocument205 pagesCamScanner Scanned PDF DocumentNabila Tsuroya BasyaNo ratings yet

- Chapter 3 Theoretical ConsiderationsDocument8 pagesChapter 3 Theoretical Considerationsapi-3696675No ratings yet

- VPN Risk Report Cybersecurity InsidersDocument20 pagesVPN Risk Report Cybersecurity InsidersMaria PerezNo ratings yet

- Form 5420 5 General Food Defense PlanDocument11 pagesForm 5420 5 General Food Defense PlanBenjamin AlecNo ratings yet

- Fundamental Powers of The State (Police Power) Ynot v. IAC Facts: Ermita Malate v. City of Manila 20 SCRA 849 (1967)Document18 pagesFundamental Powers of The State (Police Power) Ynot v. IAC Facts: Ermita Malate v. City of Manila 20 SCRA 849 (1967)Ella QuiNo ratings yet

- Non-Traditional Machining: Unit - 1Document48 pagesNon-Traditional Machining: Unit - 1bunty231No ratings yet

- Shoulder Impingement SyndromeDocument37 pagesShoulder Impingement SyndromeDADDYGUS100% (1)

- CourseLab 2 4 PDFDocument252 pagesCourseLab 2 4 PDFLiliana StanescuNo ratings yet

- Boiler Instrumentation and Control SystemsDocument68 pagesBoiler Instrumentation and Control Systemstagne simo rodrigueNo ratings yet

- 28/08/2016 1 Advanced Research Methodology... RU, Bangalore-64Document38 pages28/08/2016 1 Advanced Research Methodology... RU, Bangalore-64Ananthesh RaoNo ratings yet

- Cylinder Liner W32Document1 pageCylinder Liner W32Poma100% (1)

- Om 08.12.2022Document18 pagesOm 08.12.2022raviNo ratings yet

- Xbox - RGH E Ltu: Jogo 3.0 4.0 HD NºDocument11 pagesXbox - RGH E Ltu: Jogo 3.0 4.0 HD NºGabriel DinhaNo ratings yet

- Volume Meters Models 962 and 963 Series CDocument8 pagesVolume Meters Models 962 and 963 Series CVictor Edy Facundo DelzoNo ratings yet

- Cel2106 SCL Worksheet Week 8Document3 pagesCel2106 SCL Worksheet Week 8Hazwanee ZainalNo ratings yet

- STTH2002C: High Efficiency Ultrafast DiodeDocument16 pagesSTTH2002C: High Efficiency Ultrafast DiodeAseng saputraNo ratings yet

- Quick Healthcare Stencil: SketchDocument2 pagesQuick Healthcare Stencil: SketchNafiz Hannan NabilNo ratings yet

- I-Plan Marketing List On Installments 11-Aug-23Document10 pagesI-Plan Marketing List On Installments 11-Aug-23HuxaifaNo ratings yet

- Grand Central Terminal Mep Handbook 180323Document84 pagesGrand Central Terminal Mep Handbook 180323Pete A100% (1)

- Exhibit 1 18 116 PDFDocument27 pagesExhibit 1 18 116 PDFSimonNo ratings yet

- Lecture 8 - Life Cycle Inventory Example and SimaPro Intro - S18Document42 pagesLecture 8 - Life Cycle Inventory Example and SimaPro Intro - S18Francisco AraujoNo ratings yet

- Danfoss DatasheetDocument74 pagesDanfoss DatasheetzansNo ratings yet

- SSC CGL 13th Dec 2022 Shift-4 by CrackuDocument29 pagesSSC CGL 13th Dec 2022 Shift-4 by CrackuyuviNo ratings yet

- Role of MicrofinanceDocument1 pageRole of MicrofinanceuttamsudhirNo ratings yet

- Sample COBOL ProgramsDocument35 pagesSample COBOL Programsrahul tejNo ratings yet