Professional Documents

Culture Documents

Antilock Breaking System

Uploaded by

Sandhiya JagarnathanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Antilock Breaking System

Uploaded by

Sandhiya JagarnathanCopyright:

Available Formats

ANTILOCK-BRAKING SYSTEM USING FUZZY LOGIC

ABSTRACT

This paper deals with study and tests on

an experimental car with antilock-

braking !t"# $ABS% an& '"(icl"

)""& "ti#ation *ing +*,,! logic.

Vehicle dynamics and braking systems

are complex and behave strongly non-

linear which causes difficulties in

developing a classical controller for

ABS. u!!y logic" however facilitates

such system designs and improves

tuning abilities. The underlying control

philosophy takes into consideration

wheel acceleration as well as wheel slip

in order to recogni!e blocking

tendencies. The knowledge of the actual

vehicle velocity is necessary to calculate

wheel slips. This is done by means of a

+*,,! "ti#ator- which weighs the

inputs of a longitudinal acceleration

sensor and four wheel speed sensors. #f

lockup tendency is detected" magnetic

valves are switched to reduce brake

pressure. $erformance evaluation is

based both on computer simulations and

an experimental car. To guarantee

realtime ability %one control cycle takes

seven milliseconds& and to relieve the

electronic control unit %'()&" all fu!!y

calculations are made by the +*,,!

co)roc"or SAE ./C00A.

*easurements in the experimental car

prove the functionality of this

automotive fu!!y hardware system.

INTRO1UCTION

u!!y (ontrol" a relatively new"

intelligent" knowledge based control

techni+ue performs exceptionally well in

nonlinear" complex and even in not

mathematically describable systems.

Thus the use of fu!!y logic for an

antilock-braking system %ABS& seems to

be promising.

ANTILOCK-BRAKING

SYSTEMS

The aim of an ABS is to minimi!e brake

distance while steerability is retained

even under hard braking. To understand

the underlying physical effect which

leads to wheel-blocking during braking"

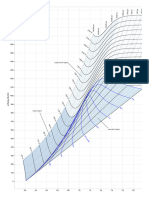

consider igure ,a- (oefficient of

friction is shown as a function of wheel

slip" relating to the terms given in igure

,b.

Figure 1: a) Friction characteristics

b)Wheelmodel

FZ: Wheel load

R: Wheel radius

w: Angular wheel frequency

v: Velocity of wheel center

F: ongitudinal force

(alculat

ing the

wheel

slip by

"

the

longitudi

nal

wheel

force

results in

.

At the beginning of an uncontrolled full

braking" the operating point starts at s .

/" then rises steeply and reaches a peak

at s . s max. After that" the wheel locks

within a few milliseconds because of the

declining friction coefficient

characteristic which acts as a positive

feedback. At this moment the wheel

force remains constant at the low level

of sliding friction. Steering is not

possible any more.

Therefore a fast and accurate control

system is re+uired to keep wheel slips

within the shaded area shown in igure

,a.

2E3ICLE S4EE1

A crucial point in the development of

wheel slip control systems is the

determination of the vehicle speed.

There are several methods possible- until

now the velocity is measured with

inductive sensors for the wheel

rotational speed. 'specially in the case

of brake slips the measured speed does

not correspond with reality. To obtain

very accurate results" optical or

microwave sensors take advantage of a

correlation method. 0owever" these

sensors are very expensive and will not

be used for ABS.

SENSORS AN1 ACTUATORS

The experimental car was fitted with

sensors and actuators shown in igure 1.

'ach wheel is connected to a metallic

gearwheel" which induces a current

within an attached sensor. The fre+uency

of the rectangular shaped current is

proportional to the angular fre+uency w i"

2 and can be evaluated by a

microcontroller. #n addition to common

ABS fitted cars" a capacitive acceleration

sensor for measuring the longitudinal

acceleration ax is implemented. urther

more igure 1 depicts the hydraulic unit

including main brake cylinder" hydraulic

lines and wheel brake cylinders. By

means of two magnetic two-way valves

each wheel" braking pressure pi" 2 is

modulated.

Three discrete conditions are possible-

decrease pressure" hold pressure firm

and increase pressure %up to main brake

pressure level only&. 'ach valve is

hydraulically connected to the main

brake cylinder" to the wheel brake

cylinders and to the recirculation.

Figure !: "ensors and actuators of the e#$erimental

car

(3- (enter of gravitiy

a

x

- 4ongitudinal acceleration

w

i"2

- Angular wheel fre+uency

0)- 0ydraulic )nit

p

i"2

- 5heel brake pressure

i- l.left" r.right

2- f.front" r.rear

ESTIMATION OF 2E3ICLE

S4EE1 USING FUZZY LOGIC

As described in the first chapter" the

knowledge of the actual vehicle speed

over ground is vital in order to calculate

wheel slips correctly. 6ai7 and 8iencke

9,: presented an estimation system based

on 8alman-ilter which performs well"

but is not suitable because of very high

performance re+uirements. #n this

approach the speed estimation uses

multisensor data fusion that means

several sensors measure vehicle speed

independently and the estimator decides

which sensor is most reliable. igure ;

represents the schematic structure of the

fu!!y estimator. The signals of the four

wheel speed sensors w i"2 are used as well

as the signal of the acceleration

sensor ax.

igure ;- 'stimation of car velocity

#n a data pre-processing block the

measured signals are filtered by a

lowpass and the inputs for the fu!!y

estimator are calculated- four wheels slip

" and an acceleration value 6 va. The

applied formulas are-

a

n

d

"

whereby a<ffset is a correction value

consisting of an offset and a road slope

part. #t is derived by comparing the

measured acceleration with the

derivative of the vehicle speed v u!"

which is calculated with the fu!!y logic

system. After this subtraction" the signal

is lowpass filtered to obtain the constant

component a<ffset

.

v u!%k-,& is the

estimated velocity of the previous cycle.

A time-delay of T is expressed by the

term ,=!.

The fu!!y estimator itself is divided into

two parts. The first %4ogic ,& determines

which wheel sensor is most reliable" and

the second %4ogic 1& decides about the

reliability of the integral of the

acceleration sensor" shown in igure >.

This cascade structure is chosen to

reduce the number of rules.

igure >-structure of the fu!!y estimator

Starting at block ?4ogic ,@ and ?4ogic

1@ the crisp inputs are fu!!ificated.

igure A shows the input-membership-

functions %#*& with four linguistic

values %%egative& Zero& 'ositive and

Very('ositive&.

igure A- input membership functions

The rule base consists of ;A rules

altogether. To classify the present

driving condition vehicle

acceleration is taken into

consideration. This should be

explained for three situations-

6 va $ositive- Braking situation"

all wheels are weighted low

because of wheel slips appearing.

6 va Bero- #f wheel speeds tend

to constant driving the

acceleration signal is low

weighted in order to ad2ust the

sensor.

6 va Cegative- The experimental

car was rearwheel driven

therefore rear wheels are less

weighted than front wheels.

igure D- output membership

functions

igure D depicts the output-membership-

functions %<*&. 0ere" three linguistic

values are sufficient. The output of the

estimation is derived as a weighted sum

of the wheel measurement plus the

integrated and corrected acceleration-

.

T3E FUZZY-ABS

ALGORIT3M

The u!!y-

(ontroller uses two

input values- the

wheel slip SB-

and

the

wheel

accele

ration

-

with wheel speed v5heel and vehicle

speed vu!" which is given by the u!!y-

'stimator.The input variables are

transformed into fu!!y variables slip and

dvwheel=dt by the fu!!ification process.

Both variables use seven linguistic

values" the slip variable is described by

the terms

sli$ . E)ero& very small& too

small& smaller than o$timum&

o$timum& too large& very largeF"

and the acceleration dvwheel*dt by

dvwheel*dt . Enegative large&

negative medium& negative small&

negative few& )ero& $ositive

small& $ositive largeF.

As a result of two fu!!y variables" each

of them having seven labels" >G different

conditions are possible. The rule base is

complete that means" all >G rules are

formulated and all >G conditions are

allowed. These rules create a nonlinear

characteristic surface as shown in igure

H.

igure H- fu!!y characteristic

surface

)sing this characteristic surface" the two

fu!!y input values sli$ and dvwheel*dt

can be mapped to the fu!!y output value

$ressure. The labels for this value are-

$ressure . E$ositive fast& $ositive

slow& )ero& negative slow&

negative fastF

The structure of the fu!!y ABS

controller is shown in igure I.

igure I- structure of fu!!y ABS

controller

The optimal breaking pressure results

from the defu!!ification of the linguistic

variable $ressure. inally a three-step

controller determines the position of the

magnetic valves" whether the pressure

should be increased" hold firm or

decreased.

igure G summari!es the total amount of

fu!!y calculations. Cumbers within a

rectangle indicate the +uantity of fu!!y

rules.

igure G- fu!!y calculations

#t should be noted that linguistic

variables and rule tables can be designed

with numerical optimi!ation methods"

for example described in 91:. #n this

work they were created using expert

knowledge and analysis of measured

data during ABS braking action.

SIMULATION OF A FULL

BRAKING

After implementation of the whole

system in S#*)4#C8" a full braking on

high-m -road was carried out" with and

without the fu!!y ABS.

5ithout fu!!y ABS the braking pressure

reaches a very high level and the wheels

block within short. This results in an

unstable behavior" the vehicle cannot be

steered any more and the stopping

distance increases.

5ith fu!!y ABS controller activated"

steerability is not only retained during

the whole braking maneuver" but the

slowing down length was considerably

shortened as well.

The following graphs show the steady

decline of the vehicle speed" the

fluctuating decline of the wheel speed of

the left front wheel as an example and

the fluctuating level of the wheel slip.

The applied braking pressure is depicted

in the last diagram. The other wheels

behave approximately similar.

igure ,/a- simulations of a braking

igure ,/b- simulations of a full

braking

igure ,/c- simulations of full

braking

IM4LEMENTATION OF T3E

FUZZY ABS CONTROLLER

The fu!!y ABS controller uses the

microprocessor SAB I/(,DD together

with the fu!!y coprocessor SA' I,(GGA

9;:. 6ue to the implementation of u!!y

algorithms into the hardware of the

coprocessor" the calculation speed of the

host processor increased significantly.

5hile the control cycle time was set to a

standard value of H msec" the

computation time was only /.A msecJ

This offers facilities for implementation

of extended vehicle dynamics control .

The flexibility of the coprocessor is

considerable" up to D> rule bases are

possible" each of them having up to 1AD

inputs and rules. urthermore an

interface to most commonly used

microprocessors is available. Arbitrary

shapes of membership functions"

different defu!!ification modes

including K(enter of 3ravity@" an

enormous rule engine with up to ,/

million rule calculations per second

makes this device a very interesting

product in the field of real time fu!!y

control.

TEST RESULTS

After the whole system was carefully

simulated" tests on an experimental car" a

B*5 ;1Ii" were carried out. igure ,,

shows a full braking with ABS on dry

asphalt.

igure ,,- Lesults of test brake

The first diagram displays the decreasing

estimated speed of the vehicle vu! and

the fluctuating decrease of the speed of

the left front wheel vl"f. 5heel

acceleration and wheel slip are shown in

the second and third graph. The slip

value is limited successfully by means of

the output of the ABS controller" which

is the driver current of the magnetic

valve" presented in the next diagram.

inally the system performance is

proved by the last graph. The

longitudinal acceleration ax is near the

physical limit.

CONCLUSION

The basis of the controlling algorithm

consists of a nonlinear characteristic

surface" which was created by fu!!y

logic. The convincing advantage of

fu!!y logic is the ability to modify and

tune certain parts of this characteristic

surface easily and carefully. Must the

linguistic rules or variables need to be

varied. This simplifies the development

and shortens the development time

considerable. #mplementation of the

fu!!y ABS leads to excellent results of

braking behavior of the test vehicle. The

deceleration level and steer ability is

comparable to commercially available

systems.

BIBLIOGRA43Y

9,: 6ai7" A. and 8iencke" ).-

+stimation of Vehicle "$eed , Fu))y,

+stimation in -om$arison with

.alman,Filtering" >

th

#''' ((A"

Cew Nork" ,GGA.

91: <stertag" *.- "tru/turierte

0$timierung technischer 'ro)esse

am 1eis$iel der .FZ

-rasher/ennung" #nstitute for

#ndustrial #nformation Systems"

)niversity of 8arlsruhe" $h. 6.

dissertation" ,GGD.

9;: 8lein" L.- Realisierung einer Fu))y,

A1",Regelung mit dem

2i/rocontroller "A1 34-155 und

dem Fu))y,-o$ro)essor "A+

31-66A" $ro2ect work at the #nstitute

for #ndustrial #nformation Systems"

)niversity of 8arlsruhe" ,GGA.

9>: 6ai7" A.- 1eobachtung

fahrdynamischer Zust7nde und

Verbesserung einer A1", und

Fahrdynami/regelung" #nstitute for

#ndustrial #nformation Systems"

)niversity of 8arlsruhe" $h. 6.

dissertation" ,GGD.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Design of Circular ShaftDocument7 pagesDesign of Circular Shaftจอม อรรฐาเมศร์No ratings yet

- Introduction To PIC and Embedded SystemsDocument12 pagesIntroduction To PIC and Embedded Systemsheno ahNo ratings yet

- 144S... - PCB Series: Signal Conditioned Precision Pressure TransducersDocument4 pages144S... - PCB Series: Signal Conditioned Precision Pressure TransducersAnish KumarNo ratings yet

- Magnetophoresis and Electromagnetophoresis of Microparticles in LiquidsDocument7 pagesMagnetophoresis and Electromagnetophoresis of Microparticles in Liquids3issazakaNo ratings yet

- Awards Gold Medals Grade VIDocument11 pagesAwards Gold Medals Grade VIBernadeth Escosora DolorNo ratings yet

- 3 Perform Industry CalculationsDocument90 pages3 Perform Industry CalculationsRobinson ConcordiaNo ratings yet

- Excel Formulas and Functions 2021-The Intermediate Level Step byDocument122 pagesExcel Formulas and Functions 2021-The Intermediate Level Step bymaolegu100% (3)

- ASUS U47A Repair GuideDocument5 pagesASUS U47A Repair GuideCarlos ZarateNo ratings yet

- Switching Power Supply DesignDocument21 pagesSwitching Power Supply DesignSamuel mutindaNo ratings yet

- IS4242 W3 Regression AnalysesDocument67 pagesIS4242 W3 Regression Analyseswongdeshun4No ratings yet

- Task 4 Finite Element MethodDocument7 pagesTask 4 Finite Element MethodMohd Azizee Bin SukorNo ratings yet

- Graphite PropertiesDocument42 pagesGraphite PropertiesAnnisa Puspa MustikaNo ratings yet

- 1922 A Textbook of Balochi LanguageDocument228 pages1922 A Textbook of Balochi LanguageAnonymous 0ywnNS29EGNo ratings yet

- B 1 1 4 Inplant Fluid FlowDocument5 pagesB 1 1 4 Inplant Fluid FlowBolívar AmoresNo ratings yet

- A Practical Total Synthesis of CocaineDocument13 pagesA Practical Total Synthesis of CocaineRodrigo Fernanda100% (4)

- FP 3000 PDFDocument1 pageFP 3000 PDFClaudio Godoy ZepedaNo ratings yet

- Fluid Mech. 2Document32 pagesFluid Mech. 2Leslie Owusu MensahNo ratings yet

- Final Thesis Owura Kofi AmoabengDocument84 pagesFinal Thesis Owura Kofi AmoabengKunal AgarwalNo ratings yet

- Mollier Enthalpy Entropy Chart For Steam - US UnitsDocument1 pageMollier Enthalpy Entropy Chart For Steam - US Unitslin tongNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheetbhavin24uNo ratings yet

- Strain STREMADocument6 pagesStrain STREMAChavin StormNo ratings yet

- AtomDocument15 pagesAtomdewi murtasimaNo ratings yet

- ASCE 7 ASD Basic Load CombosDocument1 pageASCE 7 ASD Basic Load CombosAamirShabbirNo ratings yet

- A Report On Traffic Volume StudyDocument33 pagesA Report On Traffic Volume StudyManoj Durairaj100% (1)

- C.KESAVAN - Diploma EEE: Phone No Mail IdDocument3 pagesC.KESAVAN - Diploma EEE: Phone No Mail IdKesavan ChinaswmiNo ratings yet

- Ace Om 230Document3 pagesAce Om 230michaelliu123456No ratings yet

- Histograms - 2Document6 pagesHistograms - 2Sonia HalepotaNo ratings yet

- Helmholtz Resonance - Wikipedia, The Free EncyclopediaDocument4 pagesHelmholtz Resonance - Wikipedia, The Free Encyclopediahamidah1963No ratings yet

- ImmunologyDocument8 pagesImmunologyማላያላም ማላያላም89% (9)

- Comptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseDocument5 pagesComptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseFcma0903100% (1)