Professional Documents

Culture Documents

Sewing Thread

Uploaded by

moorthy-sweety0 ratings0% found this document useful (0 votes)

1K views11 pagesBasics of Sewing thread

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBasics of Sewing thread

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views11 pagesSewing Thread

Uploaded by

moorthy-sweetyBasics of Sewing thread

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

BASIC REQUIREMENTS OF SEWING THREAD

Sewing threads must be designed to meet two fundamental functional requirements:

1 Sewability of the thread: It is the ability of thread to produce a seam with minimum

number of breakages and least damage to the thread and the fabric during sewing

operation

2. Thread performance in seam: It is the ability of a sewing thread to produce the desired

functional serviceability in a desired seam. Ie. The thread must ensure satisfactory

performance in the seam. It can be determined very well from the Seam efficiency

Seam efficiency in dex (SEI) = Seam tensile strength x100

Fabric tensile strength

CHARACTERISTIC OF SEWING THREAD

therefore to meet the basic requirements of sewing thread and to be able to

withstand severe working condition, it shout posses certain important characteristic.

1. Tensile Strength/Breaking Strength

2. Initial modulus

3. Abrasion resistance

4. Frictional properties

5. Resistance to higher temperature

6. Evenness with negligible fault

7. Elongation

8. Shrinkage

9. Balanced structure

10. Colour fastness

MATERIAL USED: TYPES OF SEWING THREAD

1. Spun threads

i) Cotton threads

ii) Linen threads

iii) Silk threads

iv) Spun synthetic threads

v) Spun blended sewing threads

2. Core spun threads

3. Continuous filament threads

i) Monofilament threads

ii) Multifilament threads

iii) Textured threads

4. Embroidery threads

5. Technical threads

FIBERS USED

Varity of natural fibers used in the production of sewing threads, although some

have only limited uses. Cotton, polyester and polyamide fibers are most commonly used

for the production of sewing threads. Natural fibers and manufactured fibers are also used

in different field of application, but their characteristic are closely related to those of the

fiber used. Sewing thread fibers are available in dfferent forms, short staple, long staple

and filaments.

Synthetic fiber for sewing threads must have higher strength, low elongation and

low shrinkage fro better performance. Sewing threads also produced from blends of

polyester staple fiber and cotton, however, when different fibers used for blends, the

constituent fiber should have matching bulk and physical properties.

Cotton:

Cotton fiber used in the production of sewing threads are selected primarily on the

basis of strength. Since long staple cotton are generally stronger and finer, the

sewing thread industry normally uses the longest cotton available for the better

grades of the sewing threads, especially for the finer counts.

In adition to strength, length and fineness, other criteria are used in cotton

selection for sewing threads, such as length variability, nep-forming characteristic

and colour. The main varieties of cotton for good qualities of sewing threads are:

Egyptian, American, California cottons. Egyptian, American are always used for

high quality, fine sized threads, where their extra staple length and fineness

coupled with high strength, are required.

California cottons are used in the coarser thread industry, based on the application

requirement.

Linen and silk

Linen and silk are little used in sewing thread manufacture. So the main

classification is therefore into either synthetic or cotton fibers. Owing to high

elastic and lusture, sewing thread of natural silk is still of importance.

Silk is available both in filament and broken filaments that spun in to yarn

Linen fiber is still used little, especially for making strong and rather stiff threads,

but it ghhas been largely superseded by synthetic fiber threads

Synthetic threads

Because of their strength and high durability, synthetic fiber yarns are now widely

used in the manufacture of sewing thread. The most commonly used materials are

polyester and polyamide fibers, since these fibers are thermoplastic and subjected

to considerable change in their properties when heated either in processing or in

use.

The most of the synthetic fiber for sewing threads is polyester fiber; its tensile

properties and its freedom from discoloration on exposure to heat and light are

particularly valuable in clothing industry. The different elastic properties and heat

s4etting characteristic, of polyamide fibers are suited tom other uses, including

sewing of leather.

Viscose

Viscose fibers have not yet replaced cotton to any great extent in sewing threads

because of their low strength and abrasion resistance and low elasticity when wet,

but their great advantage is their high lusture for use in embroidery.

SEWING THREAD PRODUCTION METHOD

The manufacturing of sewing thread is much more complex then most clothing

technicians imagine. The thread has to be of much higher quality then a weaving or

knitting yarn and thus has to pass through more process, gradually refining the thread so

that it can be used without breakage in modern machine running at speed of up to 10000

SPI. The thread production methods vary depends upon the types of sewing thread. The

production method for cotton is longer than that for 100% synthetic staple-fiber threads.

1. Spun sewing threads

Spun sewing threads are made from staple fibers that are spun into single yarns

and then plied to make a sewing thread.

Cotton sewing thread preparation

Cotton sewing threads are manufactured in the same as the normal yarn upto

single yarn stage, where as plying, cabling onwards processes differ according to the

types of sewing thread and their end uses.

Single cotton yarns are mostly prepared on three types of spinning systems they are

1. Ring spinning

2. Rotor spinning

3. Air jet spinning

Flow chart for Cotton sewing threads production

2. Core spun synthetic threads

Core spun sewing thread is produced by spinning a cover of staple fiber around a

filament yarn and then combining these yarns into a threads construction. These threads

are offers the combination of advantages of both properties of staple sheath and filament

core. The studies show that sewability of core spun thread is comparative better. Core

spun yarn can be manufactured by different methods. In industry ring spinning and

friction spinning systems are more popular for producing core spun yarn.

Core spun sewing thread processing sequence

3. Continuous filament threads

These filaments are two types:

Monofilaments: each threads consists of only one single filament and it is produced by

usual filament spinning method.

Multifilaments: Each threads consists of many filaments.

In this method the continuous filaments are manufactured by

1. Wet spinning method

2. Dry spinning method

3. Melt spinning method

After producing the continuous mono and multi filament yarns, sewing threads are

produced in three forms depending upon their usage

1) Monofilament threads

2) Multifilament threads

3) Textured threads

Manufacturing sequence of filament sewing threads

Monofilament and multi filament sewing threads are produced from continuous

monofilament and multifilament yarns. But textured sewing thread is produced after

giving texturing treatment to the continuous filament.

Apart from the type of polymer from which it is produced and type of single yarn, the

quality of sewing thread mainly depends on the post spinning operation. Production

methods at the stage of post spinning depends on the type of single yarn and vary widely

based on the field of application.

4. Textured sewing thread

Texturising provides contionous filament yarn with textured surface which improves

cooling of the thread and subsequently reduces the risk of polymer fusing at very high

sewing speed with modern sewing machine. The rough surface of the texturised threads

restricts the movement of the seam. The process flow chart of manufacturing sewing

thread from the air jet textured yarns.

Polymer and polyamide filament air jet of false twist textured yarns are being used as

sewing threads. They are produced with low twist, so that the bulking characteristic of the

yarn are not destroyed. They are widely used in chain stitch and over lock seams for

producing action wear articles based on knitted fabrics. Twisting is done in conventional

manner same as spun yarn sewing threads for 2 or 3 fold construction. Textured sewing

threads are very soft and extensible due to crimp rigidity. Ideally suitable for knit wear

and swim wear. It gives excellent seam coverage.

PROPERTIES OF SEWING THREADS

1. Spun sewing threads

Fuzz on surface of the thread provides excellent lubricity

Able to sew on most types of equipment like lock stitch, chain stitch, over edge

etc

Least expensive

Greater seam strength and elasticity coupled with high elongation

Used for all kind of articles i.e ladies lingerie to leather garment

2. Core spun threads

Able to run in all type of sewing equipment

Able to work successfully on automatic multi directional sewing machine

Higher strength per size then spun thread

Fibrous surface due to fuzz on their surface results into soft hand, low friction

and good lubricity

Used for stitch heavy article like jeans to all verities

Commonly available as P/C and P/P blend form

P/C wrapped core spun thread provide good needle heat resistance

P/P provide good colour fastness, chemical resistance, excellent strength per

size and cheaper then P/C wrapped yarn

3. Continuous filament threads

1) Monofilament threads

Produced from a single 100% continuous filament

Cheaper in comparison to other thread types

Preferred in blind stitch operation on apparel and drapery and quilting

operation on bed spreads and quilts.

2) Multifilament threads

Provides excellent abrasion resistance

Exceptionally strong for their size resulting in excellent seam

durability

Better used for industrial sewing application like furniture, luggage,

sports goods and foot wear

Limited colour availability

Comparatively cheaper

4. Textured sewing thread

o It is an ideal thread for over edge, cover stitch and chain stitch machines

o Posses excellent seam coverage and seam elasticity due to high bulk

o High shine

o Less expensive in comparison to other threads

Applications

Sewing threads are widely used in clothing manufacture, outdoor application,

high temperature application, geo textile etc., they have several textile and non textile

application. Some 80% of all sewing threads produced are used by clothing industries.

The main classes of clothing requiring threads are

Class

Approximate percentage of all threads

produced

Dresses and blouses 13%

Shirts and nightwear 5%

Shirts, coats and other outer wears 28%

Under wears 16%

Knitwear

Work clothing

Sports wear

Other clothing accessories

21%

Household furninshing 8%

Upholstered furniture 2%

All other including luggage and leather

goods, book binding, canvas goods

7%

Staple fiber sewing threads

o Cotton General sewing, Dresses, shirts, rain wears, Jeans,

Overalls, etc.

o Linen Machine buttoning, hand buttoning, button hole gimp

o Polyester General seaming purpose, lingerie, shirts and knit wear,

decorative stitching

o Core spun threads (P/C) General stitching, lingerie, shirts, knitwear and

heavy industrial sewing

o Core spun threads (P/P)- General seaming

o Aramid fiber- flame retardant application

o Silk light seaming and decorative stitching

Continuous sewing thread

Silk Buttonholing and decorative stitching

Polyester sewing heavy stitching, general stitching, under threads, padding,

blind stitching,, quilting and fur industry.

Nylon knitwear and general sewing, leather good

Airjet textured polyester fiber - general stitching, jeans, upholstery, bedding

Monofilament suitable for blind stitching and overlocking only, general

seaming and general stitching.

You might also like

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- Sewing ThreadDocument55 pagesSewing Threadচৌদ্দগ্রাম পৌর আমজনতা0% (1)

- Featureso of Different Weaves 13.10Document28 pagesFeatureso of Different Weaves 13.10Atik U BhuiyanNo ratings yet

- Textile Yarn Manufacturing ProcessDocument21 pagesTextile Yarn Manufacturing ProcessLAXMAN SINGH SANKHLANo ratings yet

- Sewing Needles Used in Sewing MachineDocument6 pagesSewing Needles Used in Sewing MachineKhandaker Sakib Farhad100% (1)

- Seam PDFDocument15 pagesSeam PDFRakibul Hasan100% (1)

- Stitch: Methods of Stitch FormationDocument7 pagesStitch: Methods of Stitch FormationM SarfrazNo ratings yet

- Knits: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDocument23 pagesKnits: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. LakshmanakanthNo ratings yet

- Advantages of Shuttleless LoomsDocument8 pagesAdvantages of Shuttleless LoomsTanzeel Areeb0% (1)

- Apparel Manufacturing Engineering-II (TEX3205) : Lecture-2 Topic: SeamDocument21 pagesApparel Manufacturing Engineering-II (TEX3205) : Lecture-2 Topic: SeamTamanna AhmedNo ratings yet

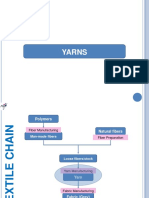

- Yarns: Types and CharacteristicsDocument32 pagesYarns: Types and Characteristicskartika ranaNo ratings yet

- SEWING MACHINE PARTS & FUNCTIONSDocument28 pagesSEWING MACHINE PARTS & FUNCTIONSRaja manimaranNo ratings yet

- Overlock Machine GuideDocument45 pagesOverlock Machine Guidevijay mahar100% (2)

- Technical Textiles IntroductionDocument17 pagesTechnical Textiles IntroductionSantiago TuestaNo ratings yet

- Stitch TypesDocument57 pagesStitch TypesOjasvi Agarwal100% (1)

- Quality Control of Knitted Garments in 38 CharactersDocument5 pagesQuality Control of Knitted Garments in 38 CharactersAnonymous zd5HPB5No ratings yet

- Study On Threading and Bobbin Winding For Single Needle Lock Stitch MachineDocument5 pagesStudy On Threading and Bobbin Winding For Single Needle Lock Stitch MachineHrithik Agarwala100% (1)

- Knitted Fabric Defects, Causes & SolutionsDocument6 pagesKnitted Fabric Defects, Causes & Solutionstexcons6771100% (2)

- Textile Yarn:: Types of Yarn - Characteristics of YarnDocument8 pagesTextile Yarn:: Types of Yarn - Characteristics of YarnHumaun Kabir100% (1)

- Miss, Tuck & Float StitchDocument23 pagesMiss, Tuck & Float StitchKazi Sabbir AhmadNo ratings yet

- Sewing Threads From Polyester Staple FibreDocument13 pagesSewing Threads From Polyester Staple FibreganeshaniitdNo ratings yet

- Short Introduction of Sizing / Warping / WeavingDocument14 pagesShort Introduction of Sizing / Warping / WeavingAmir YasinNo ratings yet

- Basic Warp Knitting PrincipleDocument8 pagesBasic Warp Knitting PrincipleTamanna Ahmed100% (1)

- Principles of Knitting TechnologyDocument18 pagesPrinciples of Knitting TechnologysaadbinazadNo ratings yet

- Different Types of StitchDocument3 pagesDifferent Types of StitchFakrul Hasan KhanNo ratings yet

- Yarn Making ProcessDocument4 pagesYarn Making ProcessAshwani MittalNo ratings yet

- SILK: A Brief Study of the Luxurious Natural FiberDocument27 pagesSILK: A Brief Study of the Luxurious Natural FiberGuneet KaurNo ratings yet

- Woven Design FundamentalsDocument28 pagesWoven Design Fundamentalsaish aish100% (2)

- Modern Developmens in WarpingDocument30 pagesModern Developmens in Warpingsandippatil03100% (1)

- Weft Pile FabricsDocument23 pagesWeft Pile FabricsMina Samy abd el zaher100% (1)

- Weft KnittingDocument27 pagesWeft KnittingAswathy UnnikrishnanNo ratings yet

- Sewing Post Dyed GarmentsDocument4 pagesSewing Post Dyed GarmentsAshraf AliNo ratings yet

- Development of Woven FabricsDocument11 pagesDevelopment of Woven FabricsJoyDipuSahaNo ratings yet

- 3D Woven FabricDocument9 pages3D Woven FabricCrystal NewmanNo ratings yet

- Classification of FinishesDocument5 pagesClassification of FinishesOjasvee Kashyap100% (1)

- SpiralityDocument9 pagesSpiralitySenthil KumarNo ratings yet

- Elastane FabricDocument8 pagesElastane FabricMaria MirandaNo ratings yet

- Introduction To Pile FabricsDocument8 pagesIntroduction To Pile FabricsMina Samy abd el zaher100% (1)

- Smart FabricsDocument16 pagesSmart FabricsVenkatesh Malpani100% (1)

- Different Types of StitchesDocument7 pagesDifferent Types of StitchesTesfaye MuluNo ratings yet

- F Ancy Yarn Production: Chapters 2 3Document19 pagesF Ancy Yarn Production: Chapters 2 3TKK-TEXTILE PSG CT100% (1)

- Knitting ElementsDocument7 pagesKnitting ElementsTextile AcademiaNo ratings yet

- WeavingDocument49 pagesWeavingyogesh123789No ratings yet

- Protective TextilesDocument36 pagesProtective TextilesDewan Ajuad Hossain Rifat100% (1)

- Fibers Properties Textile MaterialsDocument19 pagesFibers Properties Textile MaterialsGarmentLearner100% (1)

- Tightness FactorDocument2 pagesTightness FactorAbi NikilNo ratings yet

- Weft Pile Fabrics 2Document10 pagesWeft Pile Fabrics 2Mina Samy abd el zaherNo ratings yet

- Filament Yarn Sizing Why We Need To Size Filament Yarn?Document3 pagesFilament Yarn Sizing Why We Need To Size Filament Yarn?RAHEEL JAVEDNo ratings yet

- Woven Fabric DefectsDocument28 pagesWoven Fabric DefectsGreeshma75% (4)

- Structure and Design Final AssDocument20 pagesStructure and Design Final Assmike workuNo ratings yet

- Types of Stitch Used in Garments SewingDocument10 pagesTypes of Stitch Used in Garments SewingMasudur RahmanNo ratings yet

- Wrap SpinningDocument12 pagesWrap SpinningvermadeenNo ratings yet

- Fiber PropertiesDocument24 pagesFiber Propertiessatheeshpag12367% (3)

- Study On Rapier Weaving Mechanism.Document11 pagesStudy On Rapier Weaving Mechanism.Naimul HasanNo ratings yet

- Sewing Technology: M. S. AhmadiDocument29 pagesSewing Technology: M. S. AhmadidieselakiasNo ratings yet

- Cotton Fabric SewabilityDocument9 pagesCotton Fabric SewabilityTuan Nguyen MinhNo ratings yet

- What is a sewing thread? Factors that affect sewabilityDocument8 pagesWhat is a sewing thread? Factors that affect sewabilitytomNo ratings yet

- Cotton Spinning Lecture Notes For Students (07 Mart 2011)Document144 pagesCotton Spinning Lecture Notes For Students (07 Mart 2011)Onur ErbasNo ratings yet

- FILL IN THE GAPS - OdtDocument74 pagesFILL IN THE GAPS - OdtMateu Marimon RomanNo ratings yet

- FutsalDocument6 pagesFutsalFrinz ValdezNo ratings yet

- Elie Saab Case StudyDocument19 pagesElie Saab Case Studysitanshubindra100% (4)

- Gap FillingDocument6 pagesGap FillingKata TóthNo ratings yet

- The South Butt Answer To The North Face ClaimDocument12 pagesThe South Butt Answer To The North Face ClaimleftwallNo ratings yet

- Eco Design and Sustainable Manufacturing in Fashion JKDocument13 pagesEco Design and Sustainable Manufacturing in Fashion JKkarthiba jeganNo ratings yet

- Riga Now#45Document72 pagesRiga Now#45juta100% (1)

- Chemical Register PracticeDocument5 pagesChemical Register PracticeHafizuddin Adzhar100% (1)

- Cara Lipat NapkinDocument111 pagesCara Lipat NapkinAnonymous QvCeKkzHPPNo ratings yet

- Adapting Hamlet ScriptDocument9 pagesAdapting Hamlet ScriptQSFluffNo ratings yet

- Soalan ENGLISH BI Bahasa Inggeris Tahun 4 Paper 1Document9 pagesSoalan ENGLISH BI Bahasa Inggeris Tahun 4 Paper 1PURU100% (1)

- Cotton On Size Chart GuideDocument5 pagesCotton On Size Chart GuideChristian Menard De GuzmanNo ratings yet

- HR ProjectDocument88 pagesHR ProjectsreevinuNo ratings yet

- Soalan ENGLISH BI Bahasa Inggeris Tahun 4 Paper 1Document9 pagesSoalan ENGLISH BI Bahasa Inggeris Tahun 4 Paper 1sasauball68% (38)

- Objectives of The StudyDocument14 pagesObjectives of The StudySatyam KeshriNo ratings yet

- How To Sew An Under ScarfDocument3 pagesHow To Sew An Under Scarffazam8558No ratings yet

- Synthetic Fibres and Plastics MCQ PracticeDocument5 pagesSynthetic Fibres and Plastics MCQ Practicepk2varmaNo ratings yet

- Integration of Merchandising ManagementDocument36 pagesIntegration of Merchandising ManagementRasel94% (16)

- COSHH DrakerDocument2 pagesCOSHH DrakerzaimNo ratings yet

- Lopez - Caño Wedding Reception ProgramDocument6 pagesLopez - Caño Wedding Reception ProgramDegee O. Gonzales77% (13)

- Craftsman 4.5-In. Angle Grinder 927726 Model 900.277230 Instruction Manual (MAY95-CD8) - 1006464LDocument8 pagesCraftsman 4.5-In. Angle Grinder 927726 Model 900.277230 Instruction Manual (MAY95-CD8) - 1006464LboomissyNo ratings yet

- Drawing Fashion Accessories PDFDocument192 pagesDrawing Fashion Accessories PDFRuy Carlos Almeida Gonçalves100% (3)

- Partner Colibri II O2010 Euenapen 545196762Document13 pagesPartner Colibri II O2010 Euenapen 545196762Popescu OvidiuNo ratings yet

- Merci Suárez Can't Dance by Meg Medina Discussion GuideDocument3 pagesMerci Suárez Can't Dance by Meg Medina Discussion GuideCandlewick PressNo ratings yet

- In Partial Fulfillment of The Requirements For The Course: Construction Materials and Testing (CIVMATL)Document9 pagesIn Partial Fulfillment of The Requirements For The Course: Construction Materials and Testing (CIVMATL)Marla Felicity BalcosNo ratings yet

- Europa: Swing Parts ListDocument1 pageEuropa: Swing Parts ListIshmael WoolooNo ratings yet

- English Class I CBSEDocument125 pagesEnglish Class I CBSESimrat Karamjeet0% (1)

- Efaccess Answer KeyDocument14 pagesEfaccess Answer KeyOni ZukaNo ratings yet

- Wyrd Chronicles - Ezine - Issue 18Document80 pagesWyrd Chronicles - Ezine - Issue 18Micéal Flynn100% (2)

- Weekly House Cleaning Schedule TemplateDocument2 pagesWeekly House Cleaning Schedule TemplatehnkjhijhbbhjbjkNo ratings yet

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (9)

- Sri Yantra with Golden Ratio Triangle and InscriptionsFrom EverandSri Yantra with Golden Ratio Triangle and InscriptionsRating: 5 out of 5 stars5/5 (1)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- Sew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsFrom EverandSew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsRating: 5 out of 5 stars5/5 (3)

- Knitting for Anarchists: The What, Why and How of KnittingFrom EverandKnitting for Anarchists: The What, Why and How of KnittingRating: 4 out of 5 stars4/5 (51)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesFrom Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNo ratings yet

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeFrom EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNo ratings yet

- Edward's Menagerie: The New Collection: 50 animal patterns to learn to crochetFrom EverandEdward's Menagerie: The New Collection: 50 animal patterns to learn to crochetRating: 3.5 out of 5 stars3.5/5 (4)

- Knit a Box of Socks: 24 sock knitting patterns for your dream box of socksFrom EverandKnit a Box of Socks: 24 sock knitting patterns for your dream box of socksNo ratings yet

- Irene Strange's Curious Crochet Creatures: Amazing amigurumi patterns for wonderfully weird animalsFrom EverandIrene Strange's Curious Crochet Creatures: Amazing amigurumi patterns for wonderfully weird animalsRating: 5 out of 5 stars5/5 (2)

- Crafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsFrom EverandCrafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsRating: 1.5 out of 5 stars1.5/5 (3)

- Handmade: Creative Focus in the Age of DistractionFrom EverandHandmade: Creative Focus in the Age of DistractionRating: 4.5 out of 5 stars4.5/5 (25)

- Too Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreFrom EverandToo Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreRating: 5 out of 5 stars5/5 (2)

- The Basics of Corset Building: A Handbook for BeginnersFrom EverandThe Basics of Corset Building: A Handbook for BeginnersRating: 4.5 out of 5 stars4.5/5 (17)

- Creative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsFrom EverandCreative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsRating: 4.5 out of 5 stars4.5/5 (2)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsFrom EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsRating: 5 out of 5 stars5/5 (1)

- Celestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesFrom EverandCelestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesRating: 3.5 out of 5 stars3.5/5 (6)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Crochet: Fun & Easy Patterns For BeginnersFrom EverandCrochet: Fun & Easy Patterns For BeginnersRating: 5 out of 5 stars5/5 (3)

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesFrom EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesRating: 2 out of 5 stars2/5 (12)

- Sharpie Art Workshop: Techniques & Ideas for Transforming Your WorldFrom EverandSharpie Art Workshop: Techniques & Ideas for Transforming Your WorldRating: 3 out of 5 stars3/5 (16)

- Edward's Menagerie: Dogs: 50 canine crochet patternsFrom EverandEdward's Menagerie: Dogs: 50 canine crochet patternsRating: 3 out of 5 stars3/5 (5)

- Learn to Crochet Granny Squares and Flower Motifs: 26 projects to get you startedFrom EverandLearn to Crochet Granny Squares and Flower Motifs: 26 projects to get you startedNo ratings yet

- Soap Making Guide With Recipes: DIY Homemade Soapmaking Made Easy: DIY Homemade Soapmaking Made EasyFrom EverandSoap Making Guide With Recipes: DIY Homemade Soapmaking Made Easy: DIY Homemade Soapmaking Made EasyRating: 4.5 out of 5 stars4.5/5 (17)

- Playful Petals: Learn Simple, Fusible Appliqué • 18 Quilted Projects Made From PrecutsFrom EverandPlayful Petals: Learn Simple, Fusible Appliqué • 18 Quilted Projects Made From PrecutsRating: 3.5 out of 5 stars3.5/5 (3)

- Granny Square Crochet for Beginners US VersionFrom EverandGranny Square Crochet for Beginners US VersionRating: 5 out of 5 stars5/5 (4)