Professional Documents

Culture Documents

ACS 2000 ServiceMan 3BHS344169 E01 Rev

Uploaded by

adrianahouki100%(2)100% found this document useful (2 votes)

856 views78 pagesService manual Medium voltage AC drive ACS 2000, 400 - 1000 kVA, 6,0 - 6,9 kV ABB ABB ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 1 (4) Table of contents General information on manual and equipment 1 Copyright notice 1 equipment covered by the manual 1 Contact information 1 Writing conventions 2 Meaning of icons 2 Text conventions 2 Trademarks 3 Meaning of terms and abbreviations 4 tools and personal equipment 4 personal safety 4 module tray 4 personal

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentService manual Medium voltage AC drive ACS 2000, 400 - 1000 kVA, 6,0 - 6,9 kV ABB ABB ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 1 (4) Table of contents General information on manual and equipment 1 Copyright notice 1 equipment covered by the manual 1 Contact information 1 Writing conventions 2 Meaning of icons 2 Text conventions 2 Trademarks 3 Meaning of terms and abbreviations 4 tools and personal equipment 4 personal safety 4 module tray 4 personal

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

856 views78 pagesACS 2000 ServiceMan 3BHS344169 E01 Rev

Uploaded by

adrianahoukiService manual Medium voltage AC drive ACS 2000, 400 - 1000 kVA, 6,0 - 6,9 kV ABB ABB ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 1 (4) Table of contents General information on manual and equipment 1 Copyright notice 1 equipment covered by the manual 1 Contact information 1 Writing conventions 2 Meaning of icons 2 Text conventions 2 Trademarks 3 Meaning of terms and abbreviations 4 tools and personal equipment 4 personal safety 4 module tray 4 personal

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 78

Service manual

Medium voltage AC drive

ACS 2000, 400 - 1000 kVA, 6,0 - 6,9 kV

ABB

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 1 (4)

Table of contents

General information on manual and equipment 1

Copyright notice 1

Document identification 1

Equipment covered by the manual 1

Contact information 1

Target groups and required qualifications 1

Writing conventions 2

Meaning of icons 2

Text conventions 2

Trademarks 3

Meaning of terms and abbreviations 3

Related documentation 4

Tools and personal equipment 4

Personal safety 4

Module tray 4

Personal computer 5

Hand tools 5

Measuring equipment 5

Cleaning equipment 6

Chapter 1 - Safety 1-1

1.1 Classification of safety signs used in this manual 1-1

1.2 Stopping the drive 1-2

1.3 Deenergizing the drive 1-3

Chapter 2 - Grounding switch and door safety switch 2-1

2.1 Malfunctioning grounding switch 2-1

2.2 Doors and door locks 2-2

2.2.1 Door safety switch 2-3

Chapter 3 - Replacing phase modules 3-1

3.1 Overview 3-1

3.2 Dimensions and weight 3-2

3.3 Required tools and accessories 3-2

3.3.1 Procedure 3-2

Table of contents ABB

2 (4) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

Chapter 4 - Checking phase modules 4-1

4.1 Checking a phase module for short-circuit 4-1

4.1.1 Visual check of the phase module 4-1

4.1.2 Measuring the voltage across the phase module terminals 4-2

4.2 Measuring phase capacitors 4-4

4.2.1 Required tools and accessories 4-4

4.2.2 Procedure 4-4

4.3 Dismantling the phase module 4-5

4.3.1 Required tools and accessories 4-5

4.3.2 Overview 4-5

4.3.3 Procedure 4-6

4.4 Checking IGBT modules 4-9

4.4.1 Required tools and accessories 4-9

4.4.2 Procedure 4-9

4.4.3 Checking the free-wheeling diodes 4-11

4.4.4 Checking the gate unit 4-11

4.5 Replacing the IGBT heatsink assembly 4-12

4.5.1 Required tools and accessories 4-12

4.5.2 Procedure 4-12

4.6 Replacing phase capacitors 4-14

4.6.1 Required tools and accessories 4-14

4.6.2 Procedure 4-14

Chapter 5 - Removing the NP frame 5-1

5.1 Required tools and accessories 5-1

5.2 Procedure 5-1

Chapter 6 - Converter insulation test 6-1

6.1 Required tools and accessories 6-1

6.2 Procedure 6-1

Chapter 7 - Replacing circuit boards (PCBs) 7-1

7.1 Location of circuit boards 7-1

7.2 Handling instructions for PCBs and fiber-optic cables 7-2

7.2.1 PCBs 7-2

7.2.2 Fiber-optic cables 7-2

7.3 Replacing an AMC circuit board 7-2

7.3.1 Changing the AMC software flash memory 7-4

7.4 Replacing the main INT circuit board 7-6

7.5 Replacing ASE and SYN circuit boards 7-7

ABB Table of contents

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 3 (4)

7.5.1 ASE circuit board 7-8

7.5.2 SYN circuit board 7-9

7.6 Replacing the VLSCD circuit boards 7-9

7.6.1 Rear access 7-10

7.6.2 Front access 7-10

Chapter 8 - Function of LEDs 8-1

8.1 Safety 8-1

8.2 Main INT circuit board 8-2

8.3 Phase Int INT circuit board 8-3

Chapter 9 - Uploading data from the black box 9-1

Table of contents ABB

4 (4) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

ABB

ACS 2000 Service manual 3BHS210465 ZAB E01 Rev. - 1 (2)

List of figures

Figure 1-1 Connecting a grounding set 1-5

Figure 2-1 Door locks 2-2

Figure 2-2 Location of door safety switch 2-3

Figure 3-1 AFE and INU compartment 3-1

Figure 3-2 Phase module 3-2

Figure 4-1 Measuring point locations 4-1

Figure 4-2 Measuring points 4-3

Figure 4-3 Top view of a phase module 4-5

Figure 4-4 Dismantling the phase module 4-10

Figure 4-5 IGBT module 4-11

Figure 7-1 Location of circuit boards 7-1

Figure 7-2 AMC circuit board 7-2

Figure 7-3 AMC flash memory 7-4

Figure 7-4 Main INT circuit board 7-6

Figure 7-5 Location of SYN and ASE circuit board 7-7

Figure 7-6 ASE circuit board 7-8

Figure 7-7 Location of VLSCD circuit board 7-9

Figure 8-1 AMC circuit board 8-1

Figure 8-2 Main INT circuit board 8-2

Figure 8-3 Phase INT circuit board 8-3

Figure 9-1 Black box 9-1

ABB

2 (2) 3BHS210465 ZAB E01 Rev. - ACS 2000 Service manual

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 1 (2)

List of tables

Table 4-1 Readings of a healthy phase module in diode mode 4-2

Table 4-2 Readings of a healthy phase module in diode mode 4-2

Table 4-3 Readings of a healthy IGBT module in diode mode 4-11

Table 4-4 Readings of a healthy IGBT module in resistance mode 4-11

Table 8-1 Function of LEDs on the AMC circuit board 8-1

Table 8-2 LEDs on the main INT circuit board 8-2

Table 8-3 LEDs on the phase INT circuit board 8-3

ABB

2 (2) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 1 (6)

General information on manual and equipment

Copyright notice

The information in this manual is subject to change without notice.

This manual and parts thereof must not be reproduced or copied, or

disclosed to third parties, nor used for any unauthorized purpose without

written permission from ABB Switzerland Ltd, Medium Voltage Drives.

Document identification

Ownership ABB Switzerland Ltd

Medium Voltage Drives

Document number 3BHS344169 ZAB E01

Revision index -

Issue date 13.10.2010

Equipment covered by the manual

The manual does not claim to cover all variations and details of the

equipment, nor to consider all eventualities that may arise during service

of the equipment.

If information is required beyond the instructions in this manual refer the

matter to ABB. See section Contact information.

Contact information

Address ABB Switzerland Ltd

Medium Voltage Drives

CH-5300 Turgi, Switzerland

Phone +41 844 845 845

Fax +41 58 589 29 84

Email mvdrives@ch.abb.com

Target groups and required qualifications

The equipment presented in this manual is part of an industrial

environment where voltages are present that contain a potential hazard of

electric shock and / or burn.

For this reason, only personnel who have a thorough knowledge of the

equipment and the industrial environment and have obtained the required

General information on manual and equipment ABB

2 (6) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

qualification may service the equipment. Personnel must know the safe

shutdown and grounding procedures for the equipment.

Writing conventions

The following icons and text conventions are used in the manual.

Meaning of icons

Illustrates an illuminated lamp or pushbutton.

Illustrates a button or key to be pressed.

Arrows indicate an alternating display message.

Refers to further information in a separate document.

Text conventions

Bulleted list

Used to list items or steps in a procedure, where the sequence does

not matter.

Bulleted list of a subsection following a main paragraph

Used to list items for procedures, where the sequence does not

matter.

1 Steps of a procedure, to be followed in the specified order (e.g. 1, 2,

3.....)

1 Figure legend, numbers identify the items referred to in the illustration

above (e.g. 1, 2, 3.....)

Arial Bold is used to highlight switches to be operated, status messages

shown in a display and special terms.

UPPERCASE letters refer to a parameter.

Italic is used for references to illustrations, chapters and supplementary

documentation.

ABB General information on manual and equipment

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 3 (6)

Trademarks

Names that are believed to be trademarks of other companies and

organizations are designated as such. The absence or presence of such

a designation should however not be regarded as an offence of the legal

status of any trademark. The following registrations and trademarks are

used in this manual:

Fluke Registered trademark of Fluke Corporation

Meaning of terms and abbreviations

Abbreviation Meaning

AFE Active Front End

The AFE, also referred to as ARU (Active Rectifier Unit), is the

line-side rectifier of the drive that enables four-quadrant operation

and reactive power compensation.

AMC Application and Motor Controller

The digital signal processor is the heart of the control system of

the drive. A separate AMC circuit board is assigned to the line-

side rectifer (AFE) and the motor inverter (INU) of the drive.

DC Direct current

Drive Short form for ACS 2000 frequency converter

EMC Electromagnetic compatibility

All measures to suppress electromagnetic disturbances caused

by different electrical equipment in the same electromagnetic

environment, and to strengthen the immunity of the equipment to

such disturbances.

Equipment Frequency converter and related equipment

Ground Earth

To ground The conducting path (e.g. conductor) between the electric

equipment (e.g. frequency converter) and the earth. The electric

equipment is connected to the earth, e.g. by a grounding set or a

grounding switch.

Drive Short form for ACS 2000 frequency converter

HVD High voltage divider

INT Interface

INU Inverter unit of the drive. The INU converts the DC voltage to the

required AC motor voltage and frequency.

IPS Isolated power supply

LED Light emitting diode

NP Neutral point

OEI Optical electrical interface

PCB Printed circuit board

General information on manual and equipment ABB

4 (6) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

Related documentation

The following documents are available for supplementary information:

Tools and personal equipment

Personal safety

Safety goggles or spectacles

Dust mask

Hearing protection earmuffs

Safety helmet

Soft leather mechanics gloves

Module tray

The module tray is delivered with each drive. The tray is used if a phase

module of the drive has to be removed from the cabinet.

SW Software

VLSCD Voltage level short circuit detection

Abbreviation Meaning

Title Document number

ACS 2000 Users manual 3BHS297030 ZAB E01

Warranty directives 3BHS404420 ZAB E01

Wiring diagrams 3BHS319007 ZAB E01

ABB General information on manual and equipment

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 5 (6)

Personal computer

Personal computer with NDPA-02 PCMCIA-card, NDPC-12 optical

transmitter / receiver, optical cables and DriveWindow or DriveDebug

Hand tools

Drive socket set with ratchets and extension bars

Spanner set

Screwdriver set

Side cutter

Hex key set

Measuring equipment

Multimeter (e.g. Fluke 87)

Test leads of sufficient length

Test probes

The test probes should have sufficient length and short uninsulated

tips (see circles).

5 kV Megger, for example AVO BM11D

Fiber-optic cable tester, e.g:

Tempo 253B Led source (set to 660nm, no modulation), 10ZP

Adapter

Tempo 557B power meter (set to 660nm, dBm), 10ZP Adapter

Photom 205A - optical power meter, Haktronics Co., Ltd

LEONI optical power meter

LEONI optical sender ZXXX-TS0

Fiber optic GmbH, 96524 Neuhaus-Schierschnitz, ZXXX-TM0

~30 cm

General information on manual and equipment ABB

6 (6) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

Cleaning equipment

Antistatic vacuum cleaner (for example SV-497 ABF - VACUUM 3M

220V from 3M) for cleaning of sensitve electronic components (e.g.

printed circuit boards)

Antistatic brush for cleaning of printed circuit boards

Cloths and brushes for general cleaning

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 1-1 (6)

Chapter 1 - Safety

1.1 Classification of safety signs used in this manual

Safety instructions are used to highlight a potential hazard when working

on the equipment. Safety instructions must be strictly followed! Non-

compliance can jeopardise the safety of personnel, the equipment and the

environment.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to personal injury.

The safety instructions are derived from the following standards:

ISO 3864-2:2004 (E)

Graphical symbols Safety colours and safety signs Part 2: Design

principles for product safety labels

ANSI Z535.6

American National Standard for Product Safety Information in

Product Manuals, Instructions, and Other Collateral Materials

Chapter 1 - Safety ABB

1-2 (6) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

1.2 Stopping the drive

Press the stop key on the CDP control panel.

The motor stops according to the preset stop function and the drive stops

modulating. While the motor stops, the status line of the display shows

ReadyRef. The run status indication blinks during the stop sequence.

As long as the stop sequence is in progress, the drive can always be

restarted by pressing the start key on the CDP control panel.

Just before the motor will come to a standstill, the CDP control panel

displays shortly the message Stopping.

When the drive has stopped modulating, the CDP control panel displays

ReadyRun:

1 L -> 600.0 rpm

StateINU ReadyRef

MOTOR SP 300.00 rpm

POWER 20.0 kW

1 L -> 600.0 rpm 0

StateINU Stopping

MOTOR SP 0.00 rpm

POWER 0.0 kW

1 L -> 600.0 rpm 0

StateINU ReadyRun

MOTOR SP 0.00 rpm

POWER 0.0 kW

ABB Chapter 1 - Safety

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 1-3 (6)

As long as the MCB has not been opened, the motor can be started

again.

1.3 Deenergizing the drive

DANGER

Hazardous voltage!

Do not try to gain access to the input transformer, the medium voltage

compartments of the drive, nor the motor, as long as the drive system is

energized and not grounded.

To disconnect the drive from the main power supply, proceed as follows:

1 Stop the motor as described in 1.2 Stopping the drive.

When the motor has reached zero speed, the display shows

ReadyRun:

2 Press the SUPPLY OFF pushbutton to disconnect the drive from the

main power supply. The following takes place:

The MCB opens.

The DC link discharges.

While the DC link discharges, the display shows OffSeqOn:

The SUPPLY OFF pushbutton flashes and changes to a perma-

nent light when the DC link is discharged completely.

1 L -> 600.0 rpm 0

StateINU ReadyRun

MOTOR SP 0.00 rpm

POWER 0.0 kW

1 L -> 600.0 rpm

StateINU OffSeqOn

MOTOR SP 0.00 rpm

POWER 0.0 kW

Chapter 1 - Safety ABB

1-4 (6) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

When the DC link is discharged, the display shows ReadyOn:

3 Rack-out, lock-out, ground and tag-out the MCB.

4 Turn the grounding switch to the grounded position when the lamp

GROUNDING SWITCH UNLOCKED is on.

NOTICE

Do not turn the grounding switch to the grounded position before the

light GROUNDING SWITCH UNLOCKED is on. Otherwise, the switch will

be damaged.

The lamp is only turned on after the fan has stopped. The fan contin-

uous running for a preset time after the main power supply has been

switched off to dissipate the heat from the resistor assembly in the

back of the cabinet.

If the lamp does not light up and there is reason to believe that the

grounding circuit is malfunctioning, refer to Chapter 2 - Grounding

switch and door safety switch, 2.1 Malfunctioning grounding switch

for further information.

When the grounding switch is in the grounded position, the status

line of the display alternates between DCGnd NOpen, NotReadyOn,

AFE NotRdy:

1 L -> 600.0 rpm

StateINU ReadyOn

MOTOR SP 0.00 rpm

POWER 0.0 kW

1 L -> 600.0 rpm

StateINU DCGnd NOpen

MOTOR SP 0.00 rpm

POWER 0.0 kW

DCGnd Nopen

NotReadyOn

AFE NotRdy

ABB Chapter 1 - Safety

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 1-5 (6)

DANGER

The grounding switch connects the DC link of the drive to the PE ground

bus.

If it is planned to perform maintenance on the drive that includes the

removal of phase modules, the connection of grounding equipment at the

appropriate locations is a must. This is to ensure that hazardous voltages

cannot be fed into the drive neither from the main power supply nor the

motor.

Figure 1-1 shows an example how the terminals of the feeder cables

(1) are grounded at the PE ground bus (2) using a 4-way grounding

set (3).

Figure 1-1 Connecting a grounding set

5 Switch off all auxiliary voltages from external sources.

The drive is now dead, and safe access is possible.

3

1

2

Chapter 1 - Safety ABB

1-6 (6) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 2-1 (6)

Chapter 2 - Grounding switch and door safety switch

2.1 Malfunctioning grounding switch

When the DC link of the drive has been deenergized, the lamp

GROUNDING SWITCH UNLOCKED lights up to indicate that the

grounding switch is released and can be turned to the grounded position.

If the lamp does not light up and there is reason to assume that the

grounding circuit is malfunctioning, proceed as follows:

1 Do not try with force to turn the grounding switch in any direction.

The handle and / or the switch could be damaged if tried.

2 Verify that the MCB is in the open position.

3 Check the drive status on the CDP control panel.

The message ReadyOn is displayed when the DC link of the drive

has been discharged.

4 Verify that the DC link has been discharged.

The discharging level can be viewed in parameter 2.01 DC

VOLTAGE. The value should be below 50 V.

5 Check if there are any alarm and fault messages on the display.

If there are any, look up the messages in the Troubleshooting guide

and follow the instructions.

6 Try to rectifiy the reason for the alarms and faults, and then press the

reset key on the CDP control panel.

1 L -> 0.0 rpm

StateINU ReadyOn

MOTOR SP 0.00 rpm

POWER 0.0 kW

Chapter 2 - Grounding switch and door safety switch ABB

2-2 (6) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

2.2 Doors and door locks

To ensure safety and to prevent the doors being opened unintentionally,

all doors are lockable, and the doors of compartments where medium

voltages are present during operation are bolted or electromechanically

secured. Additionally, the doors of the medium voltage compartments

have locks with different inserts than the control compartment door. The

different lock inserts ensure that these doors can only be opened by

personnel authorized to do so.

Figure 2-1 Door locks

1 Door of terminal compartment: bolted and lockable

2 Door of control compartment: lockable

3 Door of AFE / INU compartment: electromechanically locked

Door cannot be opened when the main power has been applied.

The louvered panels can be removed during operation to replace the

filter mat.

4 Cover of input filter compartment: bolted

The louvered panel can be removed during operation to replace the

filter mat.

1 2 3

4

ABB Chapter 2 - Grounding switch and door safety switch

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 2-3 (6)

2.2.1 Door safety switch

2.2.1.1 Function

The safety switch of the AFE / INU compartment door is tied into an

interlocking mechanism that operates in conjunction with the grounding

switch and the interlocks from the main circuit breaker in the main power

supply circuit of the drive:

The interlocking system ensures that the main power cannot be

initialized to the drive unless the door is securely closed and the

grounding switch is in position not grounded.

The interlocking system also ensures that the door cannot be opened

until the main power is disconnected, the DC link capacitors are

discharged and the grounding switch is in position grounded.

The door of the control compartment is not integrated into the interlocking

mechanism and can always be opened.

The safety switch is located under the roof plate behind the door of the

AFE / INU compartment (see arrow).

Figure 2-2 Location of door safety switch

2.2.1.2 Manual release

Before the drive leaves the factory, the safety switch is put to position

unlocked. If the safety switch is in postion locked by mistake and the

auxiliary voltage is turned off, the door cannot be opened. To open the

door, the safety switch must then be unlocked manually.

Chapter 2 - Grounding switch and door safety switch ABB

2-4 (6) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

The safety switch is equipped with a mechanical release (1) that has two

adjustable positions:

Unlocked (2)

The mechanical release is put into this

position in the factory.

The auxiliary voltage can either be

switched on or off.

Locked (3)

This is the normal operating position.

To open the door, the DC link must be

discharged and the auxiliary voltage

must be switched on.

If the auxiliary voltage is switched off

and the door is locked, the safety

switch must be unlocked manually as

described in the following section.

Procedure 1 Open the control compartment door to access the release dial of the

safety switch (see arrow).

2 3 1

ABB Chapter 2 - Grounding switch and door safety switch

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 2-5 (6)

2 Using a slotted or Philips screwdriver, screw out the locking screw (1)

until the release dial (2) can be turned.

3 Using a slotted screwdriver (tip width 5 mm), turn the release dial from

the locked to the unlocked position.

4 After the door has been opened, turn the release dial to the locked

position and screw in the locking screw.

Note: After the mechanical and electrical installation has been finished, it

is the task of the commissioning personnel to check that the manual

release of the safety switch is in the locked position. Otherwise, the drive

cannot be started up.

1

2

Chapter 2 - Grounding switch and door safety switch ABB

2-6 (6) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 3-1 (10)

Chapter 3 - Replacing phase modules

3.1 Overview

Figure 3-1 AFE and INU compartment

1 Phase module 1 of INU

2 Phase module 2 of INU

3 Phase module 3 of INU

4 Phase module 1 of AFE

5 Phase module 2 of AFE

6 Phase module 3 of AFE

1

2

3

4

5

6

Chapter 3 - Replacing phase modules ABB

3-2 (10) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

3.2 Dimensions and weight

Figure 3-2 Phase module

Dimensions (L x W x H) 650 x 490 x 25 (mm)

Weight Approximately 30 kg

3.3 Required tools and accessories

Module tray

Reversible ratchet with extension

5 mm hex-head drive socket

6 mm hex-head drive socket

3.3.1 Procedure

1 Switch off the main power supply and ground the equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

2 Switch off the auxiliary power supply.

Depending on the auxiliary power supply configuration of the drive,

switch off the following miniature circuit breakers:

Drives with common auxiliary power supply (no safeline):

Miniature circuit breaker -Q1302 disconnects the complete

single-phase auxiliary voltage from the drive.

Drives with separate auxiliary power supplies (safeline):

ABB Chapter 3 - Replacing phase modules

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 3-3 (10)

Miniature circuit breaker -Q1354 disconnects the auxiliary

voltage from the phase modules.

Miniature circuit breaker -Q1352 disconnects the auxiliary

voltage from the control compartment.

See the Wiring diagrams to identifiy the miniature circuit breakers and

the electric circuits.

CAUTION

After the miniature circuit breakers have been switched off, the charging

transformer and the fan unit are still connected to their power supplies.

3 Remove the acrylic panel (1).

Screw type: M10 socket-head screw

Required tool: 6 mm hex-head drive socket

When working on the AFE, first pull out the air pressure tube at the

bottom of the panel.

l

4 Remove the screws on each side of the phase module.

Screw type: M10 socket-head screw

Required tool: 6 mm hex-head drive socket

1

Chapter 3 - Replacing phase modules ABB

3-4 (10) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

5 Attach the module tray to the cabinet.

The tray is attached to two brackets, one on each side (see arrows).

.

Hold the tray at an angle (1) to slide the hook-shaped ends of the tray

behind the brackets. Lower it down (2) to engage the hooks with the

brackets.

ABB Chapter 3 - Replacing phase modules

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 3-5 (10)

.

CAUTION

Make sure the module tray is securely attached to the cabinet (see arrows)

to prevent dropping the phase module when placed on the tray.

1

2

Chapter 3 - Replacing phase modules ABB

3-6 (10) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

6 Holding the phase module at the handles, pull it out until it is flush with

the leading edge of the tray.

ABB Chapter 3 - Replacing phase modules

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 3-7 (10)

7 Disconnect all cables going into the cabinet from the phase INT circuit

board (1):

Auxiliary power supply cable (2)

Two fiber-optic cables (3)

The cables are partly concealed by the grounding strap.

Current transformer cable (4)

Note: This cable is only present in phase modules of the AFE.

.

8 Detach the cable chain on the side of the phase module (1, 2). Pull

down the end of the chain a little (3) and pull it into the direction of the

arrow (4) to disengage the chain from the mounting bracket.

.

1 2 3 4

1 2

Chapter 3 - Replacing phase modules ABB

3-8 (10) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

9 Lift the phase module off the module tray.

Owing to the weight (approximately 35 kg [77 lb]), it is recommended

that two persons, one on each side, lift the phase module off the tray.

Hold the phase module at the positions indicated by the arrows.

.

10 After the phase module has been replaced, proceed in reverse order

of removal.

3 4

ABB Chapter 3 - Replacing phase modules

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 3-9 (10)

11 When reconnecting the fiber-optic cables, pay attention to connect

them to their corresponding receptacles (see arrows).

.

12 When all cables have been reconnected, check that the drive control

system and the phase module communicate with each other.

Depending on the auxiliary power supply configuration of the drive,

switch on the following miniature circuit breakers:

Drives with common auxiliary power supply (no safeline):

Switch on miniature circuit breaker -Q1302.

Drives with separate auxiliary power supplies (safeline):

Switch on miniature circuit breaker -Q1354.

Wait a few seconds.

Check that the LEDs onthe phase INT circuit board of the phase

module are on (see rectangle).

13 Push the phase module back into the rack as far as it goes and

tighten the fastening bolt on each side.

Chapter 3 - Replacing phase modules ABB

3-10 (10) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

14 Remove the module tray and reinstall the acrylic panel.

15 Switch on all miniature circuit breakers in the control compartment.

16 Start the drive.

See the Users manual, 8.5 Starting the drive system locally if infor-

mation on the start-up procedure is required.

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 4-1 (14)

Chapter 4 - Checking phase modules

4.1 Checking a phase module for short-circuit

A faulty phase module can be detected by one of the two methods:

Visually checking the phase module

Measuring the voltage across the phase module terminals

4.1.1 Visual check of the phase module

Note: For the visual check, the phase module needs to be pulled half way

out of the cabinet. To do this, follow the instructions up to step 7 in Chapter

3 - Replacing phase modules, 3.3.1 Procedure.

Each phase module contains one phase INT circuit board (2) which

interfaces with the six gate drives (1). Each gate drive controls two IGBTs.

Figure 4-1 Measuring point locations

Visually check the six gate drives of the phase module. Possible findings:

All LEDs on the gate drives are on.

R4011

Measuring point E

PH DC- NP DC+

Measuring point C

1 1 2

Chapter 4 - Checking phase modules ABB

4-2 (14) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

This means that the phase module could be healthy or faulty. For

further investigation, proceed with section 4.1.2 Measuring the

voltage across the phase module terminals.

The LEDs on one or several gate drives are off.

This means that these gate drives are short-circuited at the output.

Either the gate drive or one the associated IGBTs cause the problem.

In this case, the phase module has to be replaced to get the drive

running again. Check the faulty phase module according to section

4.1.2 Measuring the voltage across the phase module terminals.

4.1.2 Measuring the voltage across the phase module terminals

Note: The phase module needs to be completely pulled out of the cabinet.

To do this, follow the instructions up to step 7 in Chapter 3 - Replacing

phase modules, 3.3.1 Procedure.

With the multimeter in diode test mode, measure the voltages at the

measuring points shown in Figure 4-2. The reading should be as stated

inTable 4-1 below. If the measured values are different, contact the MV

drives supportline for further advice.

Note: The threshold voltage for each IGBT is ~0.35 V; the measurement

includes two IGBTs.

Table 4-1 Readings of a healthy phase module in diode mode

Plus probe Minus probe Reading

PH C ~0.7 V

C DC+ ~0.7 V

NP C ~0.7 V

DC- E ~0.7 V

E PH ~0.7 V

E NP ~0.7 V

Table 4-2 Readings of a healthy phase module in diode mode

Minus probe Plus probe Display reading

PH C OL

C DC+ OL

NP C OL

DC- E OL

E PH OL

E NP OL

ABB Chapter 4 - Checking phase modules

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 4-3 (14)

Figure 4-2 Measuring points

Chapter 4 - Checking phase modules ABB

4-4 (14) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

4.2 Measuring phase capacitors

4.2.1 Required tools and accessories

LCR meter or multimeter with high capacitance range, e.g. Fluke 179

5 mm hex key

Module tray

4.2.2 Procedure

Note: This test does not require the complete removal of the phase

module.

1 Switch off the main and the auxiliary power supply and ground the

equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

2 Attach the module tray and place the phase module on the tray.

See Chapter 3 - Replacing phase modules, 3.3.1 Procedure. Follow

the instructions up to step 7.

3 Considering the polarity, measure directly on the terminals of the

phase capacitor.

The measurement should show the value in F as printed on the

capacitor rating plate, plus or minus the stated tolerance.

ABB Chapter 4 - Checking phase modules

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 4-5 (14)

4.3 Dismantling the phase module

IMPORTANT

The phase module must only be dismantled or repaired on site after

checking this with the MV drives supportline.

4.3.1 Required tools and accessories

Small slotted screwdriver

5 mm hex key

Side cutter

4.3.2 Overview

Figure 4-3 Top view of a phase module

1 Phase capacitor

2 Phase INT circuit board

3 Cover plate

1 2 3

6 NP DC- DC+ 4 4 5 PH 7

Chapter 4 - Checking phase modules ABB

4-6 (14) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

4 Gate drives

5 DC busbars

6 HVD circuit board

7 IGBT heatsink assembly

4.3.3 Procedure

1 Cut the cable ties which connect the ferrite rings (1) to the phase

module frame and put them aside.

2 Carefully unplug the six gate drive plugs (2) which connect the gate

units to the phase INT circuit board.

3 Unplug the DE-9 connector (3) from the phase INT circuit board . The

cable connects the HVD circuit board to the phase INT circuit board.

1 1 3 2 2

ABB Chapter 4 - Checking phase modules

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 4-7 (14)

4 Disconnect the cable between the HVD circuit board and the neutral

point plug (see arrow).

5 Remove the screw of the cable which connects the phase-input-

output bus end (see arrow) to the IGBTs (V4012 and V4013) and

push the cable out of the current transducer (1).

6 Remove the six screws (see arrows) connecting the internal DC

busbars to the cover plate.

1

Chapter 4 - Checking phase modules ABB

4-8 (14) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

7 Remove the four socket-head fastening screws of the cover plate

(see arrows in Figure 4-3).

8 Carefully remove the cover plate.

The circuit board can break easily. Therefore, pay attention not to

touch any part of the gate drive circuit boards with the sharp edges of

the cover plate.

DC bus screws (wo)

ABB Chapter 4 - Checking phase modules

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 4-9 (14)

4.4 Checking IGBT modules

4.4.1 Required tools and accessories

Multimeter, e.g. Fluke-87

5 mm hex key

10 mm spanner

4.4.2 Procedure

1 Switch off the main and the auxiliary power supply and ground the

equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

2 Remove the phase module from the cabient as described in Chapter

3 - Replacing phase modules.

3 Place the phase module on a clean and stable working surface suit-

able for the weight of the phase module (approximately 35 kg [77 lb]).

4 Remove the phase module cover as described in section 4.3 Disman-

tling the phase module.

5 Unplug cables 1 and 2 at the position indicated in Figure 4-4.

6 Unscrew cable 3 at the position indicated in Figure 4-4.

7 Remove the link (see squares in Figure 4-4).

8 Remove the fastening screws (see circles in Figure 4-4) of the DC

busbars.

Chapter 4 - Checking phase modules ABB

4-10 (14) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

Figure 4-4 Dismantling the phase module

9 Proceed with section

4.4.3 if the free wheeling diodes have to be checked,

4.4.4 if the gate unit has to be checked.

3

1 2

ABB Chapter 4 - Checking phase modules

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 4-11 (14)

4.4.3 Checking the free-wheeling diodes

Check the free-wheeling diode with the multimeter in diode test mode.

Figure 4-5 IGBT module

4.4.4 Checking the gate unit

Check the gate units with a multimeter in resistance mode.

Table 4-3 Readings of a healthy IGBT module in diode mode

Plus probe Minus probe Display

1 2 OL

2 3 OL

2 1 ~0.35 V

3 2 ~0.35 V

Table 4-4 Readings of a healthy IGBT module in resistance mode

Plus probe Minus probe Display

5 6 OL

8 7 OL

6 2 0

7 3 0

Chapter 4 - Checking phase modules ABB

4-12 (14) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

4.5 Replacing the IGBT heatsink assembly

IMPORTANT

Any replacement work must only be carried out after checking this with the

MV drives supportline.

4.5.1 Required tools and accessories

5 mm hex key

10 mm spanner

4.5.2 Procedure

1 Switch off the main and the auxiliary power supply and ground the

equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

2 Remove the cover plate as described in section 4.3 Dismantling the

phase module.

3 Remove the DC busbars as described in section 4.4 Checking IGBT

modules.

4 Remove all connections between the gate drive and the IGBT

modules using long nose pliers.

ABB Chapter 4 - Checking phase modules

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 4-13 (14)

5 Remove the link (see arrow) at the capacitor terminals .

6 Remove the four fastening screws of the IGBT heatsink assembly.

7 Lift the IGBT heatsink assembly carefully out of the phase module.

Best is to take out the heat sink with two people. Avoid touching any

connecting part of a busbar or IGBT. Otherwise the electric contacts

might be affected. Best is to wear thin leather gloves.

Chapter 4 - Checking phase modules ABB

4-14 (14) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

4.6 Replacing phase capacitors

4.6.1 Required tools and accessories

5 mm hex key

10 mm spanner

4.6.2 Procedure

1 Remove the cover plate of the phase module as described in section

4.3 Dismantling the phase module.

2 Remove the DC busbars as described in section 4.4 Checking IGBT

modules.

3 Remove the link of the capacitor terminals and the cables connected

to the terminals of the phase capacitor as described in section 4.5

Replacing the IGBT heatsink assembly.

4 Remove the four screws fixing the capacitor using the hex key.

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 5-1 (4)

Chapter 5 - Removing the NP frame

5.1 Required tools and accessories

Side cutter

Reversible ratchet

5 mm hex key

17 mm spanner

5.2 Procedure

1 Switch off the main and the auxiliary power supply and ground the

equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

2 Remove all phase modules from the cabinet as described in Chapter

3 - Replacing phase modules.

3 Cut off all cable ties which fasten the cable chains to the side of the

NP frame (see arrows).

Chapter 5 - Removing the NP frame ABB

5-2 (4) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

4 Remove the two fastening screws of all cable chains.

Secure the cable chains so they will not be damaged when the NP

frame is removed from the cabinet.

5 Use the hex key to remove all fastening screws (see arrows) on both

side walls of the NP frame.

ABB Chapter 5 - Removing the NP frame

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 5-3 (4)

6 Remove the four fastening screws on the bottom of the frame using

the 17 mm spanner.

7 Remove the cable (1) connected to the ground switch (2).

1

2

Chapter 5 - Removing the NP frame ABB

5-4 (4) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

8 Place a metal plate in front of the NP frame.

Adjust the height of the metal plate so it is level with the bottom of the

NP frame (see arrows).

9 Hook the module tray to the NP frame. The module tray will serve as

a handle to remove the NP frame from the cabinet.

10 Pull out the NP frame and slide it on the metal plate

Note: When pulling out the NP frame, take care not to damage the

cables.

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 6-1 (4)

Chapter 6 - Converter insulation test

IMPORTANT

The insulation test must only be carried out if recommended by the MV

drives supportline. The test is not performed when the drive is commis-

sioned for the first time.

6.1 Required tools and accessories

5 mm hex-head key

Multimeter

Test leads for short-circuiting the terminals

5 kV insulation tester (megger)

6.2 Procedure

Note: The terminals and components referred to in the following section

correspond to those in the Power electronics overview on page 6-3.

1 Switch off the main and auxiliary power supply and ground the equip-

ment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

Preparation 2 Short-circuit all medium voltage input and output terminals (U1, V1,

W1, U2, V2, W2).

3 Short-circuit all symmetrical resistors (R

su

, R

sv

, R

sw

, R

sr

, R

ss

, R

st

) of

the phase modules and connect them to the neutral point (NP).

4 Short-circuit the terminals of all phase capacitors (C

fu

, C

fv

, C

fw

, C

fr

,

C

fs

, C

ft

) and connect them to NP.

5 Short-circuit the IFU capacitors (C

r

, C

s

, C

t

) and connect them to NP.

6 Short-circuit the EMC capacitors (C

u

, C

v

, C

w

) and connect them to

NP.

7 Disconnect the NP-to-ground-capacitor (C1021) and short-circuit the

terminals of capacitor C1012.

8 Short-circuit the high voltage charging relay by short-circuiting the

secondary of the charging transformer with the low voltage side of the

relay.

9 Short-circuit the terminals of the grounding switch.

10 Put the grounding switch to the position not grounded.

Chapter 6 - Converter insulation test ABB

6-2 (4) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

11 Connect the insulation tester between the main terminals (U1, V1,

W1, U2, V2, W2) and ground.

Test 12 Perform the insulation test between the main circuit and ground.

Test voltage: 5 kV for 60 seconds.

Duration: 60 seconds

The insulation test is passed if the measured insulation resistance is

100 Mohm or higher.

13 Remove the short-circuit leads.

NOTICE

A short-circuit in any part of the drive will lead to severe damage.

Therefore, check that all short-circuit leads have been removed before

energizing the drive.

ABB Chapter 6 - Converter insulation test

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 6-3 (4)

+

+

+

C

f

u

C

f

v

C

f

w

R

v

R

w

C

v

C

w U

2

V

2

W

2

V

W

D

C

-

N

P

R

u

C

u

I

N

U

R

s

u

R

s

v

R

s

w

E

M

C

L

u

L

v

L

w

D

C

+

+

+

+

U

1

V

1

W

1

S

T

C

f

r

C

f

s

C

f

t

C

t

C

s

C

r

L

r

L

s

L

t

A

F

E

C

1

0

1

2

C

1

0

2

1

L

1

0

2

1

R

1

0

2

1

R

1

0

1

4

/

1

5

R

s

r

R

s

s

R

s

t

I

F

U

R

U

+ +

R

C

M

?

=

R

1

0

1

4

/

1

5

C

C

M

?

=

C

1

0

1

2

R

P

G

N

=

R

1

0

2

1

L

P

G

N

=

L

1

0

2

1

C

P

G

N

=

C

1

0

2

1

P

o

w

e

r

e

l

e

c

t

r

o

n

i

c

s

o

v

e

r

v

i

e

w

2

N

u

m

b

e

r

s

c

o

r

r

e

s

p

o

n

d

t

o

t

h

e

s

t

e

p

s

i

n

s

e

c

t

i

o

n

6

.

2

P

r

o

c

e

d

u

r

e

3

3

3

3

3

3

4

4

4

4

4

4

2

9

9

1

0

6

7

7

5

Chapter 6 - Converter insulation test ABB

6-4 (4) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 7-1 (10)

Chapter 7 - Replacing circuit boards (PCBs)

7.1 Location of circuit boards

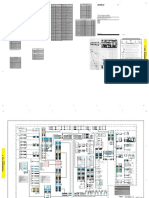

Figure 7-1 Location of circuit boards

1 AMC and main INT circuit board of INU (AMC at the front)

2 AMC and main INT circuit board of AFE (AMC at the front)

3 OEI circuit board

4 CD circuit board

5 IPS (IGBT power supply)

6 SYN circuit board

7 ASE circuit board

8 VLSCD circuit board

1

2

4

6

3

7

5

8

Chapter 7 - Replacing circuit boards (PCBs) ABB

7-2 (10) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

7.2 Handling instructions for PCBs and fiber-optic cables

7.2.1 PCBs

Do not touch circuit boards or other sensitive components without applying

static-sensitive handling precautions. Static electricity can damage circuit

boards and components.

Do not touch the components without wearing a properly grounded

wrist strap.

Put the circuit board or component on a grounded working surface

protected against electrostatic discharges.

Hold a circuit board only at the edge.

Handle a faulty circuit board as carefully as a new one.

7.2.2 Fiber-optic cables

Handle fiber-optic cables with care. Do not touch the ends of the fibers.

They are extremely sensitive to dirt. Always hold the connector when

unplugging a fiber-optic cable. Fiber-optic cables can be damaged if bent

sharply. Observe the minimum bend radius of 25 mm.

7.3 Replacing an AMC circuit board

Figure 7-2 AMC circuit board

ABB Chapter 7 - Replacing circuit boards (PCBs)

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 7-3 (10)

1 Before replacing the AMC circuit board, check that the installed soft-

ware version and the parameter settings of the new circuit board

correspond to those in the drive.

See Commissioning manual for information on loading software and

firmware to new AMC circuit board.

1 Switch off the main and the auxiliary power supply and ground the

equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

2 Ground yourself at the converter frame with a wrist strap before

touching the AMC circuit board.

3 Unplug the fiber-optic cables, the power supply connector and the

control panel connector.

4 Remove the fastening screws (7 pcs.) and the AMC circuit board.

5 Attach the new AMC board.

Use all fastening screws to ensure proper grounding of the circuit

board.

6 Reconnect the fiber-optic cables, the power supply connector and the

control panel connector.

7 Verify the connections by comparing them with the corresponding

wirIng diagram.

8 Put the defective circuit board into an antistatic bag.

9 Power up the drive and check if it is functioning properly.

10 Follow the procedures as stated in the MV Warranty Directive if a

defective circuit board has to be returned to ABB, particularly if it is

still under warranty. This procedure is also recommended even if the

warranty period has already expired.

Chapter 7 - Replacing circuit boards (PCBs) ABB

7-4 (10) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

7.3.1 Changing the AMC software flash memory

The application control software and the parameter settings are saved in

the flash memory which is on a separate flash memory PCB (see

rectangle).

Figure 7-3 AMC flash memory

When the AMC circuit board is replaced, the old flash memory can still be

used if the software has not been upgraded in the meantime.

If only the flash memory has to be replaced, the AMC circuit board can

remain in the cabinet. It is also not necessary to disconnect the fiber-optic

cables.

1 Switch off the main and the auxiliary power supply and ground the

equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

2 Ground yourself with a wrist strap before touching the circuit board.

ABB Chapter 7 - Replacing circuit boards (PCBs)

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 7-5 (10)

3 Remove the flash memory PCB by holding it with both hands and

pulling it at a 90 angle away from the AMC circuit board.

.

4 Make sure that the white dot on the flash memory PCB is on top of

that on the AMC circuit board when attaching the new PCB.

NOTICE

The correct orientation of the new PCB is important. If attached wrongly,

the new PCB will be damaged immediately when the auxiliary power is

switched on.

5 Press the PCB down firmly making sure that all pins are inserted

properly.

.

6 Mount the AMC circuit board.

Use all fastening screws to ensure proper grounding of the circuit

board.

7 Put the defective circuit board into an antistatic bag.

8 Power up the drive and check if it is functioning properly.

9 Follow the procedures as stated in the MV Warranty Directive if a

defective circuit board has to be returned to ABB, particularly if it is

still under warranty. This procedure is also recommended even if the

warranty period has already expired.

Chapter 7 - Replacing circuit boards (PCBs) ABB

7-6 (10) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

7.4 Replacing the main INT circuit board

The main INT circuit board is located behind the AMC circuit board.

Figure 7-4 Main INT circuit board

1 Switch off the main and the auxiliary power supply and ground the

equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

2 Remove the AMC circuit board as described in section 7.3 Replacing

an AMC circuit board.

Ground yourself at the drive frame with a wrist strap before touching

the main INT circuit board.

3 Unplug the fiber-optic cables and the power supply connector.

4 Remove the fastening screws (13 pcs.).

Take all necessary precautions to prevent screws and washers from

falling into other components.

AMC circuit board

Main INT circuit board

ABB Chapter 7 - Replacing circuit boards (PCBs)

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 7-7 (10)

5 Remove the main INT circuit board and place it on a grounded

working surface.

6 Install the new main INT circuit board.

Use all fastening screws to ensure proper grounding of the circuit

board.

7 Reconnect the fiber-optic cables and the power supply connector.

8 Carry out a visual check and verify the connections by comparing

them with the corresponding Wiring diagram.

9 Put the defective circuit board into an antistatic bag.

10 Power up the drive and check if it is functioning properly.

11 Follow the procedures as stated in the MV Warranty Directive if a

defective circuit board has to be returned to ABB, particularly if it is

still under warranty. This procedure is also recommended even if the

warranty period has already expired.

7.5 Replacing ASE and SYN circuit boards

Figure 7-5 Location of SYN and ASE circuit board

1

2

Chapter 7 - Replacing circuit boards (PCBs) ABB

7-8 (10) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

1 ASE circuit board (behind the cover)

2 SYN circuit board

7.5.1 ASE circuit board

Figure 7-6 ASE circuit board

1 Switch off the main and the auxiliary power supply and ground the

equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

2 Open the control section door and remove the cover of the IFU

compartment (screw type: Phillips).

3 Remove the cover of the ASE circuit board (screw type: Phillips).

4 Ground yourself at the drive frame with a wrist strap before touching

the ASE circuit board.

5 Unplug the auxiliary power, fiber-optics and DC connections.

6 Remove the fastening screws of the board (screw type: Phillips).

Take all necessary precautions to prevent screws and washers falling

into other components.

7 Remove the ASE circuit board and place it on a grounded working

surface.

8 Mount the new circuit board.

Use all fastening screws to ensure proper grounding of the circuit

board.

9 Reconnect all cables.

10 Carry out a visual check and verify the connections by comparing

them with the corresponding Wiring diagram.

11 Reinstall the cover.

12 Power up the drive and check if it is functioning properly.

ABB Chapter 7 - Replacing circuit boards (PCBs)

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 7-9 (10)

13 Follow the procedures as stated in the MV Warranty Directive if a

defective circuit board has to be returned to ABB, particularly if it is

still under warranty. This procedure is also recommended even if the

warranty period has already expired.

7.5.2 SYN circuit board

The replacement procedure for the SYN circuit board is the same as for

the ASE circuit board with the exception that no circuit board cover has to

be removed.

7.6 Replacing the VLSCD circuit boards

The AFE and the INU of the drive are each equipped with two VLSCD

circuit boards (device designation: F1031, F1032, F1061and F1062).

The circuit boards can be accessed in two ways:

Through the rear of the cabinet

Rear access requires the service cover in the rear of the cabinet to be

removed.

Through the front of the cabinet

Front access requires the NP frame to be removed.

Figure 7-7 Location of VLSCD circuit board

1 INU negative VLSCD

2 INU positive VLSCD

1

2

3

4

Chapter 7 - Replacing circuit boards (PCBs) ABB

7-10 (10) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

3 AFE positive VLSCD

4 AFE negative VLSCD

7.6.1 Rear access

DANGER

Hazardous voltage!

Do not remove the service cover before the drive has been deenergized

and grounded and the fan has stopped.

1 Switch off the main and the auxiliary power supply and ground the

equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

2 Remove the service cover (screw type: Phillips).

3 Replace a circuit board following the instructions in section 7.5

Replacing ASE and SYN circuit boards, from step 9 onwards.

7.6.2 Front access

1 Switch off the main and the auxiliary power supply and ground the

equipment.

See Chapter 1 - Safety, 1.3 Deenergizing the drive if information on

deenergizing is required.

2 Remove the NP frame as described in Chapter 5 - Removing the NP

frame.

3 Proceed as described in section 7.5 Replacing ASE and SYN circuit

boards when replacing the circuit boards.

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 8-1 (4)

Chapter 8 - Function of LEDs

8.1 Safety

Figure 8-1 AMC circuit board

Fault

M

T1

S3

S2

Run

P

T2

S1

S0

Table 8-1 Function of LEDs on the AMC circuit board

LED LED color Function

R green Run indication

F red Fault indication

P green supply OK

M green not used (ON when booting)

T1 yellow ON = receiving data on DDCS channel 0

T2 yellow ON = receiving data on DDCS channel 3

S0 yellow always OFF

S1 yellow always OFF

S2 yellow always OFF

S3 yellow always OFF

Chapter 8 - Function of LEDs ABB

8-2 (4) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

8.2 Main INT circuit board

Figure 8-2 Main INT circuit board

L

E

D

_

1

L

E

D

_

2

L

E

D

_

3

L

E

D

_

4

L

E

D

_

5

L

E

D

_

6

L

E

D

_

7

L

E

D

_

8

L

E

D

_

9

Table 8-2 LEDs on the main INT circuit board

LED LED color Function

1 yellow all configured PPCS phase INT links enabled

2 yellow any latched fault (fc1/fc2)

3 yellow supply OK

4 yellow reserved for future use

5 yellow internal use

6 yellow firing-through-link faulty

7 yellow PFF link to / from AFE faulty

8 yellow PFF link to / from INU faulty

9 yellow yellow, green, FPGA successfully configured

ABB Chapter 8 - Function of LEDs

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 8-3 (4)

8.3 Phase Int INT circuit board

Figure 8-3 Phase INT circuit board

Table 8-3 LEDs on the phase INT circuit board

LED LED color Function

Done green board ready

R_OK green reset released

GDerr red any gate driver link shut down (short circuit detected)

Alarm red alarm pending

Fault red fault pending

LED1 red not used

LED2 red not used

+ 5 V green power supply on

+ 3.3 V green power supply on

- 15 V green power supply on

Chapter 8 - Function of LEDs ABB

8-4 (4) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

ABB

ACS 2000 Service manual 3BHS344169 ZAB E01 Rev. - 9-1 (2)

Chapter 9 - Uploading data from the black box

The AMC34 circuit board is equipped with an additional flash memory

PCB (see rectangle). The PCB serves as a black box which saves data

and fault loggers of the drive for a longer time even if the auxiliary power

has been switched off. When a fault occured in the drive, it is recom-

mended to send the black box data to the MV Drives Supportline of ABB

for assistance in analysing the fault.

Figure 9-1 Black box

The tools for uploading the content of the black box are part of the loading

package. The tools become only visible after the command l_acs has

been entered in a DOS window. Afterwards the folder BlackBox is created

in the loading package. The folder contains one file:

blackbox_upload.exe

1 To upload any data from the black box, open a DOS window and open

folder BlackBox. All files downloaded from the black box will be

saved in this folder.

2 After uploading move the files to another folder or rename them.

Otherwise they will be overwritten the next time a file is downloaded

from the black box.

The black box has two separate parts:

the data loggers and

the fault / parameter loggers.

Chapter 9 - Uploading data from the black box ABB

9-2 (2) 3BHS344169 ZAB E01 Rev. - ACS 2000 Service manual

Uploading

the fault logger

To upload the fault logger, enter the command:

blackbox_upload 1 /bb_upload_data /mbaud=8

1 indicates the channel 3 node number of the circuit board.

To upload data from a circuit board with node number 2, the command

would be:

blackbox_upload 2 /bb_upload_data /mbaud=8

Uploading

the data logger

To upload the dataloggers, enter the command:

blackbox_upload 1 /dl_upload_data /mbaud=8

1 indicates the channel 3 node number of the circuit board.

Each data logger is uploaded to a new file. Empty data loggers are not

uploaded.

If the black box is full, uploading the data can take up to 15 minutes. Once

started, do not interrupt the upload. If the upload is interrupted (e.g. by

closing the DOS window), some communication services will not be

closed properly and it will not be possible to start the upload again. If this

happens, do the following:

Open DriveDebug set any bit of parameter 103.01 to 1.

Uploading of data should work again.

2

ABB Switzerland Ltd

Medium Voltage Drives

CH-5300 Turgi

Phone: +41 58 589 27 95

Fax: +41 58 589 29 84

E-Mail: mvdrives@ch.abb.com

www.abb.com/drives

C

o

p

y

r

i

g

h

t

2

0

0

9

A

B

B

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

S

p

e

c

i

f

i

c

a

t

i

o

n

s

s

u

b

j

e

c

t

t

o

c

h

a

n

g

e

w

i

t

h

o

u

t

n

o

t

i

c

e

.

3

B

H

S

3

4

4

1

6

9

Z

A

B

E

0

1

R

e

v

.

-

.

Contact us

Last page

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- DG Process Air HeatersDocument1 pageDG Process Air HeatersadrianahoukiNo ratings yet

- DG Packaged Systems Oil SystemsDocument1 pageDG Packaged Systems Oil SystemsadrianahoukiNo ratings yet

- DG Comfort Heating Sizing GuideDocument32 pagesDG Comfort Heating Sizing GuideadrianahoukiNo ratings yet

- Ecp DHS M 001Document27 pagesEcp DHS M 001adrianahoukiNo ratings yet

- DG Packaged Systems Heat Transfer SystemsDocument3 pagesDG Packaged Systems Heat Transfer SystemsadrianahoukiNo ratings yet

- KTS Magic enDocument24 pagesKTS Magic enadrianahoukiNo ratings yet

- DG Packaged Systems Steam BoilerDocument3 pagesDG Packaged Systems Steam BoileradrianahoukiNo ratings yet

- DG Packaged Systems Large Tank HeatersDocument2 pagesDG Packaged Systems Large Tank HeatersadrianahoukiNo ratings yet

- DG Immersion Heaters Over The SideDocument3 pagesDG Immersion Heaters Over The SideadrianahoukiNo ratings yet

- Reference Data Temperature Pressure Equivalents and Conversions SPDocument1 pageReference Data Temperature Pressure Equivalents and Conversions SPguadalupeocanaNo ratings yet

- Helical Catalog 2008Document28 pagesHelical Catalog 2008adrianahoukiNo ratings yet

- AL Codigos de FallaDocument3 pagesAL Codigos de Fallaadrianahouki0% (1)

- Katalog Vbs 2012 Connection and Fastening enDocument488 pagesKatalog Vbs 2012 Connection and Fastening enadrianahoukiNo ratings yet

- BSS Brandschutzleitfaden enDocument120 pagesBSS Brandschutzleitfaden enadrianahoukiNo ratings yet

- Katalog LFS 2012 enDocument476 pagesKatalog LFS 2012 enadrianahoukiNo ratings yet

- Katalog TBS 2012 enDocument420 pagesKatalog TBS 2012 enadrianahoukiNo ratings yet

- Katalog KTS 2012 enDocument500 pagesKatalog KTS 2012 enadrianahoukiNo ratings yet

- Katalog UFS 2012 enDocument494 pagesKatalog UFS 2012 enadrianahoukiNo ratings yet

- Katalog EGS 2012 enDocument235 pagesKatalog EGS 2012 enadrianahoukiNo ratings yet

- Hella LED enDocument28 pagesHella LED enadrianahoukiNo ratings yet

- Xa Se100582 5Document2 pagesXa Se100582 5adrianahoukiNo ratings yet

- Green: Green Products. Connecting and Fastening Technology From Renewable ResourcesDocument8 pagesGreen: Green Products. Connecting and Fastening Technology From Renewable ResourcesadrianahoukiNo ratings yet

- REC4281GDocument307 pagesREC4281GadrianahoukiNo ratings yet

- BSS Brandschutzleitfaden enDocument120 pagesBSS Brandschutzleitfaden enadrianahoukiNo ratings yet

- Xa Se100582a 0Document2 pagesXa Se100582a 0adrianahoukiNo ratings yet

- E - T3000 - p79 - 1047 Servo Pressure Controllers MARSH BELLOFRAMDocument26 pagesE - T3000 - p79 - 1047 Servo Pressure Controllers MARSH BELLOFRAMadrianahoukiNo ratings yet

- 928G 6XR ElectricoDocument4 pages928G 6XR ElectricoRodney Richardson100% (3)

- ProductCatalog N TRONDocument24 pagesProductCatalog N TRONadrianahoukiNo ratings yet

- 928G 6XR ElectricoDocument4 pages928G 6XR ElectricoRodney Richardson100% (3)

- Evans Carman ThorndikeanticiteraDocument39 pagesEvans Carman ThorndikeanticiteraadrianahoukiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Manual Valvula 3'' Titan RXDocument2 pagesManual Valvula 3'' Titan RXrolandNo ratings yet

- Arcing Fault: Positive-Sequence Component, in Which The Phases Are in The Same Order As The OriginalDocument3 pagesArcing Fault: Positive-Sequence Component, in Which The Phases Are in The Same Order As The Originalsandeep_chauhan3770No ratings yet

- Prospecto SPS D BH3000Document4 pagesProspecto SPS D BH3000Marcos Zimmermann100% (1)

- Test Water Pump Pressure 16H Motor GraderDocument2 pagesTest Water Pump Pressure 16H Motor GraderDouglas GomesNo ratings yet

- At Itsce Tmax Ul 2005 Kap 06 Schaltplaene enDocument18 pagesAt Itsce Tmax Ul 2005 Kap 06 Schaltplaene enisaiaspaula80No ratings yet

- Rečnik Srpsko-EngleskiDocument9 pagesRečnik Srpsko-EngleskisreckoNo ratings yet

- Ingersoll Rand Parts ListDocument42 pagesIngersoll Rand Parts ListIzabela SantanaNo ratings yet

- PRO1 10E Introduction Micromaster PDFDocument20 pagesPRO1 10E Introduction Micromaster PDFTinhNguyenNo ratings yet

- M 325 D (1) ElectDocument4 pagesM 325 D (1) ElectJesus CortesNo ratings yet

- MS 1Document6 pagesMS 1afelipef27No ratings yet

- Re 50046Document8 pagesRe 50046ShortcutterNo ratings yet

- Chapter 4 Energy ConversionDocument3 pagesChapter 4 Energy ConversionLuelsonCordovaDeclaradorNo ratings yet

- EASA AC Redesign Manual V.0214-0815 PDFDocument140 pagesEASA AC Redesign Manual V.0214-0815 PDFDon FreemanNo ratings yet

- Operator'S Manual 6544X-X 6546X-X: 4-1/4" AIR MOTORSDocument8 pagesOperator'S Manual 6544X-X 6546X-X: 4-1/4" AIR MOTORSGezzy Boys 28No ratings yet

- Cabin ModuleDocument75 pagesCabin ModuleESRANo ratings yet

- Sensor de Presion 522Document2 pagesSensor de Presion 522Israel SamaniegoNo ratings yet

- Speed Negotiation Improvement for HDD SATA InterfacesDocument99 pagesSpeed Negotiation Improvement for HDD SATA InterfacesNguyễn HạnhNo ratings yet

- 4ABB Leaflet Terra 94 - 124 - 184 - v7Document12 pages4ABB Leaflet Terra 94 - 124 - 184 - v7michael esoNo ratings yet

- Wood 159 2004 11Document76 pagesWood 159 2004 11koaa85No ratings yet

- Mech 203 Auto Differential Transmission ProjectDocument29 pagesMech 203 Auto Differential Transmission ProjectYugi SupriatnaNo ratings yet

- Tata Indigo Marina Diesel ManualDocument146 pagesTata Indigo Marina Diesel Manualxtemp100% (4)

- 1 1 1 A B SimplemachinesinclinedplanewedgescrewDocument19 pages1 1 1 A B Simplemachinesinclinedplanewedgescrewapi-366546603No ratings yet

- Product Data Sheet: Circuit Breaker Compact NS800N - Micrologic 2.0 - 800 A - 3 Poles 3tDocument3 pagesProduct Data Sheet: Circuit Breaker Compact NS800N - Micrologic 2.0 - 800 A - 3 Poles 3tArivazhagan AdhikesavanNo ratings yet

- KD 65 X 8000 CDocument98 pagesKD 65 X 8000 CkalleNo ratings yet

- Automatic H2o Pump ControllerDocument14 pagesAutomatic H2o Pump ControllerSowham ChatterjeeNo ratings yet

- Burn-In 101Document4 pagesBurn-In 101api-281858981No ratings yet

- Switch Yard REVISEDocument28 pagesSwitch Yard REVISEPratheek ReddyNo ratings yet

- Alabang MCSPDocument229 pagesAlabang MCSP[AP-STUDENT] Ina Rose LaquiNo ratings yet

- Ymz1krvasdlwd 18 30kv CableDocument2 pagesYmz1krvasdlwd 18 30kv CableJosue Crespo GonzalezNo ratings yet

- DWE4120 B3 T1 Dewalt PBDocument4 pagesDWE4120 B3 T1 Dewalt PBJose MolinaNo ratings yet