Professional Documents

Culture Documents

Fenwal Phoenix 3-Way Directional Valve

Uploaded by

Mohan ArumugavallalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fenwal Phoenix 3-Way Directional Valve

Uploaded by

Mohan ArumugavallalCopyright:

Available Formats

R

Protection Systems

TM

A UTC Fire & Security Company

Effective: Nov. 2010

F-93-121

Fenwal Phoenix

3-Way Directional Valve

P/N: 93-2200XX-00X

DESCRIPTION

The Fenwal Phoenix Series System offers the use of

directional valves for protection of multiple hazards from

one central storage bank of agent and nitrogen driver cyl-

inders. When the same set of cylinders are used to pro-

tect different hazards, 3-Way Directional Valves may be

included in the system. Since only one system (i.e., distri-

bution piping and nozzles) can be entered and calculated

at one time, it is necessary to create separate projects

(.flc files) for each configuration. With respect to the direc-

tional valves, separate objects are used for a given valve

size depending on the orientation of the valve. An open

valve is used to allow agent to flow through the side

(branch) outlet of the valve, and a closed valve would be

used to allow agent to flow through the run outlet of the

valve. When working with multiple files, the user should

ensure that the type, diameter and length of any pipes

common to more than one project file are identical. The

pipe locking feature is useful here. In addition, the agent

quantity per cylinder and area of the nitrogen restrictor

orifice should be identical.

Note: Per NFPA 2001In sections where a valve

arrangement introduces sections of closed pip-

ing, such sections shall be equipped with pres-

sure relief devices, or the valves shall be

designed to prevent entrapment of liquid. For

pressure relief of manifold arrangements using

directional valves, use a safety outlet (P/N

844346).

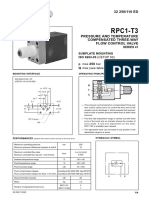

Figure 1. T Flow Position

Valve Position Closed to Hazard

Figure 2. L Flow Position

Valve Position Open to Hazard

FEATURES

For use with Fenwal Phoenix Systems

Cost-Effective Option for Protecting

Multiple Hazards

Pneumatic Operation Using

Nitrogen Pilot Cylinder

3-Way Valve Comes Pre-Assembled with Pneumatic

Actuator

Nickel Plated Carbon Steel

Low Loss Three Port Design

UL Listed

TOP VIEW

PIPING TO HAZARD

AGENT

SOURCE

PIPING TO HAZARD

TOP VIEW

AGENT

SOURCE

- 2 -

3

-

W

a

y

V

a

l

v

e

S

w

i

n

g

C

h

e

c

k

o

r

C

h

e

c

k

V

a

l

v

e

E

l

e

c

t

r

i

c

C

o

n

t

r

o

l

H

e

a

d

E

E

E

E

D

i

s

c

h

a

r

g

e

M

a

n

i

f

o

l

d

C

Y

L

.

1

-

3

3

-

W

a

y

V

A

L

V

E

1

3

-

W

a

y

V

A

L

V

E

2

P

I

P

I

N

G

T

O

H

A

Z

A

R

D

B

H

A

Z

A

R

D

A

C

Y

L

2

-

3

P

I

P

I

N

G

T

O

#

3

N

2

F

M

-

2

0

0

T

a

n

k

#

2

N

2

F

M

-

2

0

0

T

a

n

k

#

1

N

2

F

M

-

2

0

0

T

a

n

k

S

w

i

n

g

C

h

e

c

k

o

r

C

h

e

c

k

V

a

l

v

e

F

l

e

x

H

o

s

e

o

r

H

a

r

d

P

i

p

e

E

l

e

c

t

r

i

c

C

o

n

t

r

o

l

1

/

4

i

n

c

h

S

c

h

4

0

p

i

p

e

o

r

S

t

a

i

n

l

e

s

s

s

t

e

e

l

t

u

b

i

n

g

5

/

1

6

O

.

D

.

X

0

.

0

3

5

"

w

a

l

l

H

e

a

d

H

e

a

d

E

l

e

c

t

r

i

c

C

o

n

t

r

o

l

N

i

t

r

o

g

e

n

P

i

l

o

t

N

i

t

r

o

g

e

n

P

i

l

o

t

P

a

n

e

l

E

N

i

t

r

o

g

e

n

p

i

l

o

t

l

i

n

e

c

o

n

n

e

c

t

e

d

t

o

e

a

c

h

3

-

w

a

y

v

a

l

v

e

.

E

l

e

c

t

r

i

c

c

o

n

t

r

o

l

h

e

a

d

s

o

n

e

a

c

h

n

i

t

r

o

g

e

n

p

i

l

o

t

c

y

l

i

n

d

e

r

t

o

c

o

n

t

r

o

l

t

h

e

d

i

r

e

c

t

i

o

n

a

l

v

a

l

v

e

s

.

E

a

c

h

p

i

l

o

t

c

y

l

i

n

d

e

r

c

o

u

l

d

a

l

s

o

b

e

m

a

n

u

a

l

l

y

a

c

t

u

a

t

e

d

.

C

h

a

n

n

e

l

s

N

e

e

d

e

d

=

#

o

f

D

i

r

e

c

t

i

o

n

a

l

V

a

l

v

e

s

E

E

P

l

a

i

n

N

u

t

D

i

s

c

h

a

r

g

e

H

e

a

d

(

T

y

p

.

)

,

P

/

N

8

7

2

4

5

0

P

l

a

i

n

N

u

t

D

i

s

c

h

a

r

g

e

H

e

a

d

(

T

y

p

.

)

,

P

/

N

8

7

2

4

5

0

1

"

T

r

a

n

s

f

e

r

H

o

s

e

(

T

y

p

.

)

P

/

N

0

6

-

1

1

8

2

0

7

-

0

0

3

E

l

e

c

t

r

i

c

C

o

n

t

r

o

l

H

e

a

d

A

c

t

u

a

t

i

o

n

A

s

s

e

m

b

l

y

K

i

t

f

o

r

2

2

5

a

n

d

3

9

5

l

b

.

S

y

s

t

e

m

s

,

P

/

N

0

6

-

1

2

9

8

8

2

-

0

0

1

f

o

r

6

7

5

a

n

d

1

0

1

0

l

b

.

S

y

s

t

e

m

s

,

P

/

N

0

6

-

1

2

9

9

8

5

-

0

0

1

S

o

l.

S

o

l.

S

I

D

E

V

I

E

W

T

O

P

V

I

E

W

O

p

t

i

o

n

a

l

N

o

t

e

:

T

w

o

3

-

w

a

y

v

a

l

v

e

s

a

r

e

s

h

o

w

n

f

o

r

r

e

f

e

r

e

n

c

e

.

G

e

n

e

r

a

l

u

s

a

g

e

i

s

n

o

t

l

i

m

i

t

e

d

t

o

t

w

o

3

-

w

a

y

v

a

l

v

e

s

.

P

r

e

s

s

u

r

e

R

e

g

u

l

a

t

o

r

(

P

/

N

0

6

-

1

1

8

3

3

4

-

0

0

1

)

F

a

c

t

o

r

y

S

e

t

t

o

1

1

6

P

S

I

(

8

b

a

r

)

A

l

l

c

y

l

i

n

d

e

r

s

m

u

s

t

b

e

o

f

t

h

e

s

a

m

e

s

i

z

e

a

n

d

f

i

l

l

d

e

n

s

i

t

y

.

A

l

l

n

i

t

r

o

g

e

n

d

r

i

v

e

r

s

m

u

s

t

b

e

o

f

t

h

e

s

a

m

e

s

i

z

e

a

n

d

p

r

e

s

s

u

r

e

(

1

8

0

0

P

S

I

G

)

.

N

o

t

e

:

T

h

e

a

r

r

a

n

g

e

m

e

n

t

s

s

h

o

w

n

a

b

o

v

e

u

s

e

t

h

e

l

a

r

g

e

r

c

y

l

i

n

d

e

r

s

(

6

7

5

a

n

d

1

0

1

0

l

b

.

)

f

o

r

t

h

e

p

u

r

p

o

s

e

o

f

c

l

a

r

i

t

y

.

T

h

i

s

c

o

n

c

e

p

t

c

a

n

a

l

s

o

b

e

a

c

h

i

e

v

e

d

u

s

i

n

g

t

h

e

2

2

5

a

n

d

3

9

5

l

b

.

c

y

l

i

n

d

e

r

s

.

S

O

L

E

l

e

c

t

r

i

c

S

o

l

e

n

o

i

d

(

P

/

N

0

6

-

1

1

8

3

8

4

-

0

0

1

)

S

/

O

S

a

f

e

t

y

O

u

t

l

e

t

(

P

/

N

8

4

4

3

4

6

)

S

/

O

F

i

g

u

r

e

3

.

A

r

r

a

n

g

e

m

e

n

t

1

:

3

-

W

a

y

V

a

l

v

e

w

i

t

h

P

n

e

u

m

a

t

i

c

A

c

t

u

a

t

o

r

D

e

d

i

c

a

t

e

d

f

o

r

E

a

c

h

D

i

r

e

c

t

i

o

n

a

l

V

a

l

v

e

- 3 -

3

-

W

a

y

V

a

l

v

e

S

w

i

n

g

C

h

e

c

k

o

r

C

h

e

c

k

V

a

l

v

e

E

l

e

c

t

r

i

c

C

o

n

t

r

o

l

H

e

a

d

E

E

E

E

D

i

s

c

h

a

r

g

e

M

a

n

i

f

o

l

d

C

Y

L

.

1

-

3

3

-

W

a

y

V

A

L

V

E

1

3

-

W

a

y

V

A

L

V

E

2

P

I

P

I

N

G

T

O

H

A

Z

A

R

D

B

H

A

Z

A

R

D

A

C

Y

L

2

-

3

P

I

P

I

N

G

T

O

#

3

N

2

F

M

-

2

0

0

T

a

n

k

#

2

N

2

#

1

N

2

S

w

i

n

g

C

h

e

c

k

o

r

C

h

e

c

k

V

a

l

v

e

F

l

e

x

H

o

s

e

o

r

H

a

r

d

P

i

p

e

E

l

e

c

t

r

i

c

C

o

n

t

r

o

l

H

e

a

d

1

/

4

"

S

c

h

4

0

P

i

p

e

o

r

S

t

a

i

n

l

e

s

s

s

t

e

e

l

t

u

b

i

n

g

5

/

1

6

O

.

D

.

X

0

.

0

3

5

"

w

a

l

l

N

i

t

r

o

g

e

n

P

i

l

o

t

P

a

n

e

l

N

i

t

r

o

g

e

n

p

i

l

o

t

l

i

n

e

c

o

n

n

e

c

t

e

d

t

o

e

a

c

h

3

-

w

a

y

v

a

l

v

e

.

E

l

e

c

t

r

i

c

c

o

n

t

r

o

l

h

e

a

d

a

n

d

o

n

e

p

i

l

o

t

c

y

l

i

n

d

e

r

f

e

e

d

s

a

l

l

t

h

e

v

a

l

v

e

s

.

E

a

c

h

3

-

w

a

y

v

a

l

v

e

i

s

w

i

t

h

a

s

o

l

e

n

o

i

d

p

n

e

u

m

a

t

i

c

a

c

t

u

a

t

o

r

(

r

o

t

a

t

e

s

9

0

)

.

S

o

l

.

S

o

l

.

C

h

a

n

n

e

l

s

N

e

e

d

e

d

=

#

o

f

D

i

r

e

c

t

i

o

n

a

l

V

a

l

v

e

s

+

1

1

"

T

r

a

n

s

f

e

r

H

o

s

e

(

T

y

p

.

)

,

P

/

N

0

6

-

1

1

8

2

0

7

-

0

0

3

E

E

l

e

c

t

r

i

c

C

o

n

t

r

o

l

H

e

a

d

P

l

a

i

n

N

u

t

D

i

s

c

h

a

r

g

e

H

e

a

d

(

T

y

p

.

)

P

/

N

8

7

2

4

5

0

P

l

a

i

n

N

u

t

D

i

s

c

h

a

r

g

e

H

e

a

d

(

T

y

p

.

)

,

P

/

N

8

7

2

4

5

0

E

E

S

I

D

E

V

I

E

W

T

O

P

V

I

E

W

F

M

-

2

0

0

T

a

n

k

F

M

-

2

0

0

T

a

n

k

N

o

t

e

:

T

w

o

3

-

w

a

y

v

a

l

v

e

s

a

r

e

s

h

o

w

n

f

o

r

r

e

f

e

r

e

n

c

e

.

G

e

n

e

r

a

l

u

s

a

g

e

i

s

n

o

t

l

i

m

i

t

e

d

t

o

t

w

o

3

-

w

a

y

v

a

l

v

e

s

.

A

l

l

c

y

l

i

n

d

e

r

s

m

u

s

t

b

e

o

f

t

h

e

s

a

m

e

s

i

z

e

a

n

d

f

i

l

l

d

e

n

s

i

t

y

.

A

l

l

n

i

t

r

o

g

e

n

d

r

i

v

e

r

s

m

u

s

t

b

e

o

f

t

h

e

s

a

m

e

s

i

z

e

a

n

d

p

r

e

s

s

u

r

e

(

1

8

0

0

P

S

I

G

)

.

P

r

e

s

s

u

r

e

R

e

g

u

l

a

t

o

r

(

P

/

N

0

6

-

1

1

8

3

3

4

-

0

0

1

)

F

a

c

t

o

r

y

S

e

t

t

o

1

1

6

P

S

I

(

8

b

a

r

)

S

O

L

E

l

e

c

t

r

i

c

S

o

l

e

n

o

i

d

(

P

/

N

0

6

-

1

1

8

3

8

4

-

0

0

1

)

A

c

t

u

a

t

i

o

n

A

s

s

e

m

b

l

y

K

i

t

f

o

r

2

2

5

a

n

d

3

9

5

l

b

.

S

y

s

t

e

m

s

,

P

/

N

0

6

-

1

2

9

8

8

2

-

0

0

1

f

o

r

6

7

5

a

n

d

1

0

1

0

l

b

.

S

y

s

t

e

m

s

,

P

/

N

0

6

-

1

2

9

9

8

5

-

0

0

1

N

o

t

e

:

T

h

e

a

r

r

a

n

g

e

m

e

n

t

s

s

h

o

w

n

a

b

o

v

e

u

s

e

t

h

e

l

a

r

g

e

r

c

y

l

i

n

d

e

r

s

(

6

7

5

a

n

d

1

0

1

0

l

b

.

)

f

o

r

t

h

e

p

u

r

p

o

s

e

o

f

c

l

a

r

i

t

y

.

T

h

i

s

c

o

n

c

e

p

t

c

a

n

a

l

s

o

b

e

a

c

h

i

e

v

e

d

u

s

i

n

g

t

h

e

2

2

5

a

n

d

3

9

5

l

b

.

c

y

l

i

n

d

e

r

s

.

S

/

O

S

a

f

e

t

y

O

u

t

l

e

t

(

P

/

N

8

4

4

3

4

6

)

S

/

O

F

i

g

u

r

e

4

.

A

r

r

a

n

g

e

m

e

n

t

2

:

3

-

W

a

y

V

a

l

v

e

w

i

t

h

P

n

e

u

m

a

t

i

c

A

c

t

u

a

t

o

r

C

o

n

t

r

o

l

l

e

d

b

y

a

2

4

V

d

c

S

o

l

e

n

o

i

d

- 4 -

OPERATION

Note: Figure 3 illustrates Arrangement 1 which uses

nitrogen pilot actuation for each 3-Way Direc-

tional Valve. Figure 4 illustrates Arrangement 2

which uses a single nitrogen pilot cylinder to

actuate only one of a series of 3-Way Directional

Valves.

A nitrogen pilot line is connected to each 3-Way Direc-

tional Valve. An electric control head is installed on each

nitrogen pilot cylinder to actuate and release the nitro-

gen, which, in turn, pneumatically opens the valve. The

nitrogen pilot line must be installed with a pressure regu-

lator. The nitrogen line is then installed into the pneu-

matic solenoid (P/N 06-118384-001) that is attached to

the pneumatic actuator. The pneumatic solenoid acts as

a gate valve; when the signal is received from the panel

to open the pneumatic solenoid, the pressure is then

allowed to pass through the pneumatic actuator, which

thereby turns the valve to the 90 Open orientation.

WARNING

The pneumatic actuator and pneu-

matic solenoid are rated for a pressure

of 115 to 150 PSI (6.89 to 10.34 bar

gauge). A pressure regulator must be

installed in line to reduce the nitrogen

pressure that is being released from

the pilot cylinder. Pressure regulator

P/N 06-118334-001 is factory set to 116

PSI (8 bar gauge).

Ball Valve

Size

Maximum

Number from

One Pilot

Cylinder

Maximum

Tubing 5/16" x

0.035" Weight

Maximum

1/4" Schedule

40 Pipe

4" 3 200 ft. 100 ft.

3" 5 200 ft. 100 ft.

2" 8 200 ft. 100 ft.

1" 8 200 ft. 100 ft.

1" 8 200 ft. 100 ft.

1" 8 200 ft. 100 ft.

3/4" 8 200 ft. 100 ft.

1/2" 8 200 ft. 100 ft.

Figure 5. 3-Way Directional Valves

(See Table 2 for more information.)

C

B

A

Table 1. 3-Way Directional Valve

- 5 -

Part Number

with Solenoid

Nominal

Size

Dimensions

Valve Working

Pressure

Breakaway

Torque

A* B C*

93-220030-001 1/2" 3.50 in. 0.688 11.23 in. 400 PSIG 200 in.-lb.

93-220030-002 3/4" 4.00 in. 0.824 12.13 in. 400 PSIG 250 in.-lb.

93-220030-003 1" 4.00 in. 1.000 12.13 in. 400 PSIG 250 in.-lb.

93-220031-001 1" 6.00 in. 1.380 13.69 in. 400 PSIG 500 in.-lb.

93-220031-002 1" 6.00 in. 1.500 13.69 in. 400 PSIG 500 in.-lb.

93-220031-003 2" 7.25 in. 2.000 15.66 in. 400 PSIG 800 in.-lb.

93-220032-001 3" 11.00 in. 3.000 21.44 in. 400 PSIG 3000 in.-lb.

93-220032-002 4" 13.38 in. 4.000 24.68 in. 400 PSIG 4300 in.-lb.

*Note: Dimensions are approximate for the entire assembly.

Part Number

with Solenoid

Nominal

Size

Material Inlets Port

T-Flow

Equivalent

Length

L-Flow

Equivalent

Length

93-220030-001 1/2" ENP Carbon Steel NPT Full 0.19 ft. 1.83 ft.

93-220030-002 3/4" ENP Carbon Steel NPT Full 0.37 ft. 3.61 ft.

93-220030-003 1" ENP Carbon Steel NPT Full 1.48 ft. 9.31 ft.

93-220031-001 1" ENP Carbon Steel NPT Full 1.19 ft. 11.65 ft.

93-220031-002 1" ENP Carbon Steel NPT Full 1.77 ft. 12.08 ft.

93-220031-003 2" ENP Carbon Steel NPT Full 1.82 ft. 13.75 ft.

93-220032-001 3" ENP Carbon Steel Victaulic Full 5.00 ft. 26.01 ft.

93-220032-002 4" ENP Carbon Steel Victaulic Full 7.73 ft. 32.42 ft.

Part Number

with Solenoid

Nominal

Size

Actuator

Mechanism

Actuator

Type

Actuator

Volume

Actuator

Torque

Working

Pressure

Maximum

Pressure

93-220030-001 1/2" Rack and Pinion Spring Return 30 cu. in. 865 in.-lb. 115 PSIG 145 PSIG

93-220030-002 3/4" Rack and Pinion Spring Return 30 cu. in. 865 in.-lb. 115 PSIG 145 PSIG

93-220030-003 1" Rack and Pinion Spring Return 30 cu. in. 865 in.-lb. 115 PSIG 145 PSIG

93-220031-001 1" Rack and Pinion Spring Return 61 cu. in. 1877 in.-lb. 115 PSIG 145 PSIG

93-220031-002 1" Rack and Pinion Spring Return 61 cu. in. 1877 in.-lb. 115 PSIG 145 PSIG

93-220031-003 2" Rack and Pinion Spring Return 61 cu. in. 1877 in.-lb. 115 PSIG 145 PSIG

93-220032-001 3" Rack and Pinion Spring Return 189 cu. in. 4887 in.-lb. 115 PSIG 145 PSIG

93-220032-002 4" Rack and Pinion Spring Return 299 cu. in. 8288 in.-lb. 115 PSIG 145 PSIG

Table 2. 3-Way Directional Valve Specifications

Table 2. 3-Way Directional Valve Specifications (cont.)

Table 3. Pneumatic Actuator Specifications

- 6 -

COMPONENTS

3-WAY DIRECTIONAL VALVES

(P/NS 93-2200XX-00X)

The 3-Way Directional Valves are used for applications

where a single bank of cylinders are used to protect mul-

tiple hazards (see the Phoenix Design, Installation, Oper-

ation and Maintenance Manual, P/N 93-FM200M-030, for

additional information). The directional valves have a fac-

tory installed pneumatic, spring loaded actuator and

range in sizes from 1/2 inch to 4 inches. The directional

valves can be installed in the network, provided that they

are accounted for in the software calculation. See Figure

5 and Table 2 for more information.

Pneumatic Solenoid (P/N 06-118384-001)

The pneumatic solenoid is a cost-effective component

that is used with the pneumatic actuators and 3-Way

Directional Valves. With the solenoid, one nitrogen pilot

cylinder can be used for multiple directional valves. The

solenoid is factory set to normally closed. A signal from

the panel opens the solenoid that is attached to the

appropriate pneumatic actuator. Pressure is then allowed

to pass through the solenoid and open the 3-Way Direc-

tional Valve (see the Phoenix Design, Installation, Opera-

tion and Maintenance Manual, P/N 93-FM200M-030, for

additional information). See Table 4 for valve operating

data.

Figure 6. Pneumatic Solenoid

Pressure Regulator (P/N 06-118334-001)

The pressure regulator is used up stream of the pneu-

matic solenoid to regulate the nitrogen pressure to 116

PSI (8 bar gauge) prior to operating the pneumatic actua-

tor on the directional valve.

Figure 7. Pressure Regulator

COMPONENT SPECIFICATIONS

INSTALLATION

All Fenwal FM-200 equipment must be installed to facili-

tate proper inspection, testing, manual operation,

recharging and any other required maintenance as may

be necessary. Equipment must not be subject to severe

weather conditions or mechanical, chemical, or other

damage that could render the equipment inoperative.

Equipment must be installed in accordance with NFPA

Standard 2001, current edition.

6.66 in.

(169 mm)

ASSEMBLY INLET,

1/4 NPT

ASSEMBLY OUTLET,

1/4 NPT

WARNING

The FM-200 cylinder/valve assemblies

must be handled, installed and ser-

viced in accordance with the instruc-

tions contained in this Section and

Compressed Gas Association (CGA)

pamphlets C-1, C-6 and P-1. CGA pam-

phlets may be obtained from: Com-

pressed Gas Association, 1235

Jefferson Davis Highway, Arlington,

VA 22202. Failure to follow these

instructions can cause FM-200 cylin-

ders to violently discharge, resulting

in severe injury, death and/or property

destruction.

Description Measurement

Pressure Range 15 to 115 PSIG

Voltage Rating 24 Vdc

Power Consumption (DC) 7W

Power Consumption (AC) 6W

Coil CG5

Weight 0.80 lb.

Ports 1/4" NPT

Includes: Locking Manual Override Button

Part Number Description

06-118334-001 Pressure Regulator

Table 4. Pneumatic Solenoid Specifications

Table 5. Pressure Regulator Specifications

- 7 -

PRESSURE ACTUATION PIPE

The pressure actuation pipe must be 1/4-inch Schedule

40 or 80 pipe or 5/16 in. O.D. x 0.035 in. wall stainless

steel tubing. Actuation lines shall be protected against

crimping and mechanical damage (per NFPA 2001, Sec-

tion 2-3.4.2). The pipe or tubing must be routed in the

most direct manner with a minimum number of fittings.

Pipe and fittings must be in accordance with the require-

ments listed in the Phoenix Design, Installation, Opera-

tion and Maintenance Manual. Fittings can be flared or

compression type. The pressure-temperature ratings of

the fitting manufacturer must not be exceeded.

DIRECTIONAL VALVES WITH PNEUMATIC

ACTUATORS AND SOLENOIDS

Note: Flanged fittings are to be installed per ANSI

B16.5.

1. Gather the required parts for the chosen directional

system based upon the number of 3-Way Direc-

tional Valves needed and the actuation scheme

desired.

Single pilot cylinder actuation requires one pilot

cylinder, actuation hoses (number of hoses

equals two times the number of directional

valves), electric control head, the directional

valves with solenoid pneumatic actuators and a

pressure regulator.

Multiple pilot actuation requires pilot cylinders

(number of pilot cylinders equals one times the

number of directional valves), actuation hoses

(number of hoses equals one times the number

of directional valves), electric control heads

(number of control heads equals one times the

number of directional valves), directional valves

with pneumatic actuators and a pressure regula-

tor.

Note: The pressure regulator must be located within

12 in. of the solenoid and pneumatic actuator.

2. Ensure that all directional valves are in the straight

through position before installation (the T-port in the

valve should be open on both ends with the side

port closed).

Figure 8. Straight Through Orientation

The directional valve must be installed so that the 90

turn of the actuator brings the T-port open on the side

branch and the end of the valve that faces the FM-200

source. The arrow on the valve must be pointed in the

direction of the flow.

Figure 9. 90 Orientation

3. Connect the actuators on the directional valves to

the pneumatic source in one of two ways:

For pilot cylinder actuation, all directional valves

must have a 24 Vdc solenoid (P/N 06-118384-001)

and a 24 Vdc connection from the control panel.

Connect the pilot cylinder to the second pressur-

ization port of the solenoid actuator using the

actuation line.

Connect each of the solenoids and the electric

control head to the control panel so that the elec-

tric control head fires and the correct directional

valve operates for the desired hazard.

Test each hazard with the control panel by listen-

ing for the solenoid click at each directional

valve.

Reconnect all electrical connections.

Attach an electric control head to the pilot cylin-

der (being sure it is set before installation).

VALVE 1

3-Way

HAZARD A

PIPING TO

VALVE 2

3-Way

PIPING TO

HAZARD B

Straight through position;

Closed to pipe network.

Nipple

Cap End

of Manifold

VALVE 1

3-Way

HAZARD A

PIPING TO

VALVE 2

3-Way

PIPING TO

HAZARD B

(In Alarm)

90 counterclockwise

turn to Hazard B.

Nipple

Cap End

of Manifold

- 8 -

4. Set the control panel to provide a 17.0 second delay

between the firing of the pilot cylinders for the direc-

tional valves and the firing of the FM-200 system

(see Table 6). This delay provides sufficient time for

the valves to fully open before the system is dis-

charged.

Note: 17.0 seconds is the maximum time needed for

the 4 in. ball valve to open under pressure.

SYSTEM RELEASE

CONTROL CONFIGURATION

IMPORTANTThe information in this paragraph refers

to circuits and wiring employed on FenwalNET 2000 pan-

els; specific Phoenix configurations and/or other pro-

grammable panels may require different wiring and/or

panel-to-panel connections.

A maximum of eight suppression hazards and a maxi-

mum of eight electrically actuated nitrogen driver cylin-

ders are allowed per system. Multiple panels may be

employed to control and release the system. The small-

est Phoenix system configuration would require a mini-

mum of four release circuits.

Figure 10. Typical Single Panel System

Release Circuit Wiring (See Notes below.)

Figure 11. Typical Multiple Panel System

Release Circuit Wiring (See Notes below.)

Notes:

1. Must use Pneumatic Solenoid (P/N 06-118384-001).

Ratings: 24 Vdc, 4.8 W; 2.0 Vdc minimum dropout.

2. Must use 24 Volt DC control head. The fire alarm

suppression panel release circuit must be capable

of supplying a minimum of 24 Vdc @ 2.8 Amps for

30 milliseconds for control head P/N 890181, and a

minimum of 24 Vdc @ 0.5 Amps continuous for con-

trol head P/N 81-100000-001.

3. Release control relays are only required if the nitro-

gen driver solenoids are released by a separate

panel. Relays employed must be electrically com-

patible with the release circuit output characteristics

for both pull-in and dropout voltages.

WARNING

Regardless of configuration, the follow-

ing sequence of activation must be

adhered to:

1. When a call for suppression is

received by the panel for a specific

suppression zone, the appropriate

selector valve solenoid and nitrogen

pilot control head must activate

within 0.5 seconds of each other.

2. Six to ten seconds after the selector

valve solenoid and nitrogen pilot

control head actuates, the appropri-

ate nitrogen driver control heads

must activate. After any hazard acti-

vates, no other activation is allowed

until the system is serviced. Failure

to follow these sequence could

result in system malfunction.

Part Number

with Solenoid

Description

Time Delays

Required to

Open

93-220030-001 1/2" NPT 17.0 sec.

93-220030-002 3/4" NPT 17.0 sec.

93-220030-003 1" NPT 17.0 sec.

93-220031-001 1" NPT 17.0 sec.

93-220031-002 1" NPT 17.0 sec.

93-220031-003 2" NPT 17.0 sec.

93-220032-001 3" Victaulic 17.0 sec.

93-220032-002 4" Victaulic 17.0 sec.

PEGAsys or other

FM Approved/UL Listed

fire alarm suppression

control panel

Release

Circuit

Release

Circuit

Release

Circuit

Selector Valve

Solenoid (see note 1)

Nitrogen Pilot

Control Head (see note 2)

Nitrogen Driver

Control Head (see note 2)

FenwalNET 2000 or other

programmable FM Approved

(for FM insured installations)/

UL Listed compatible fire alarm

suppression control panel

S

S

S

S

Denotes Supervised Circuit

Release

Circuit

Selector Valve

Solenoid (see note 1)

S

Nitrogen Driver

Control Head (see note 2)

S

Release

Circuit

Circuit

PEGAsys or other

FM Approved/UL Listed

fire alarm suppression

control panel

Release

Circuit

Release

Circuit

Release

Circuit

Selector Valve

Solenoid (see note 1)

Nitrogen Pilot

Control Head (see note 2)

Release

Control Relay (see note 3)

Circuit

PEGAsys or other

FM Approved/UL Listed

fire alarm suppression

control panel

Initiating

Circuit

Release

Circuit

Release

Circuit

Nitrogen Driver

Control Head (see Note 2)

Nitrogen Driver

Control Head (see Note 2)

EOLR

+

_

S

Denotes Supervised Circuit

S

S

S

S

S

S

Panel 1

Panel 2

Selector Valve

Solenoid (see note 1)

S

Circuit

Release

FenwalNET 2000 or other

programmable FM Approved

(for FM insured installations)/

UL Listed compatible fire alarm

suppression control panel

FenwalNET 2000 or other

programmable FM Approved

(for FM insured installations)/

UL Listed compatible fire alarm

suppression control panel

Table 6. Directional Valve Data

- 9 -

4. A means of manual release of the system shall be

provided. Manual release shall be accomplished by

a mechanical manual release, or by an electrical

manual release, when the control equipment moni-

tors the battery voltage level of the standby battery

supply and will provide a low battery signal. The

release shall cause simultaneous operation of auto-

matically operated valves controlling agent release

and distribution.

* Refer to the FenwalNET 2000 Installation, Operation

and Maintenance Manual (P/N 74-200016-001) for

complete details.

WARNING

The referenced control heads and

solenoids are compatible with Fenwal-

NET 2000 panels. The use of other pan-

els to operate these control heads and

solenoids has not been verified and

could result in system malfunction.

This literature is provided for informational purposes only. KIDDE-FENWAL, INC.

assumes no responsibility for the products suitability for a particular application. The

product must be properly applied to work correctly.

If you need more information on this product, or if you have a particular problem or ques-

tion, contact KIDDE-FENWAL, INC., Ashland, MA 01721. Telephone: (508) 881-2000.

F-93-121 Rev AC 2010 Kidde-Fenwal Inc. Printed in USA

R

Protection Systems

TM

A UTC Fire & Security Company

400 Main Street

Ashland, MA 01721

Ph: 508.881.2000

Fax: 508.881.8920

www.fenwalfre.com

ORDERING INFORMATION

Part Number Description

Valves

with

Solenoid

93-220030-001 3-Way Directional Valve, 1/2-inch

93-220030-002 3-Way Directional Valve, 3/4-inch

93-220030-003 3-Way Directional Valve, 1-inch

93-220031-001 3-Way Directional Valve, 1-inch

93-220031-002 3-Way Directional Valve, 1-inch

93-220031-003 3-Way Directional Valve, 2-inch

93-220032-001 3-Way Directional Valve, 3-inch

93-220032-002 3-Way Directional Valve, 4-inch

Pneumatic Solenoid

(Note: Part of Valve Assembly. Use below for spare parts only.)

06-118384-001 Pneumatic Solenoid, 24 Vdc

Pressure Regulator

06-118334-001 Pressure Regulator, 116 PSI (8 bar)

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Pressure Independent Control ValveDocument16 pagesPressure Independent Control ValverakamechNo ratings yet

- Fundamentals of Orifice Metering FMCDocument7 pagesFundamentals of Orifice Metering FMCapply19842371No ratings yet

- IEC 60751 Vs ASTM 1137Document3 pagesIEC 60751 Vs ASTM 1137Mohan ArumugavallalNo ratings yet

- Block 9 Safety ValvesDocument85 pagesBlock 9 Safety ValvesBabu AravindNo ratings yet

- 2 Way / 3 Way Valve PackagesDocument7 pages2 Way / 3 Way Valve PackagesArif MohammedNo ratings yet

- Guide To Safety Analysis For Accident PreventionDocument348 pagesGuide To Safety Analysis For Accident PreventionMohan ArumugavallalNo ratings yet

- Dry Bulk Product Safety SOPDocument14 pagesDry Bulk Product Safety SOPWan Sek ChoonNo ratings yet

- Air Release Valve E-34 Series FireDocument5 pagesAir Release Valve E-34 Series FireUghojor ElohoNo ratings yet

- Guide To Writing A NovelDocument208 pagesGuide To Writing A NovelCarles Pams100% (13)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- CO2 AnsulDocument17 pagesCO2 AnsulJorge RVNo ratings yet

- Conventional Valves GuideDocument23 pagesConventional Valves GuidePower PlantNo ratings yet

- Lego ManDocument17 pagesLego ManMohan Arumugavallal100% (3)

- Pneumatics Exercises 13Document6 pagesPneumatics Exercises 13KhamilleNo ratings yet

- Designing Steam Pressure Reducing StationsDocument7 pagesDesigning Steam Pressure Reducing StationsMohammed Hassan B KorainaNo ratings yet

- Apco Airvacuum Valves Avv Sales 601Document8 pagesApco Airvacuum Valves Avv Sales 601Jhony MedranoNo ratings yet

- Industrial Ethernet Handbook PDFDocument172 pagesIndustrial Ethernet Handbook PDFDaveNo ratings yet

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- Control Valves in Process PlantDocument8 pagesControl Valves in Process Plantmukramah.yusufNo ratings yet

- Instrument Pipe Fittings PDFDocument40 pagesInstrument Pipe Fittings PDFMohan ArumugavallalNo ratings yet

- 01 220043enc Routine Turbine MaintenanceDocument8 pages01 220043enc Routine Turbine Maintenanceajipramudio100% (1)

- How To Read PFD and P&ID DiagramDocument60 pagesHow To Read PFD and P&ID Diagrammoh hardiusNo ratings yet

- Overview of Cp52Document0 pagesOverview of Cp52Ban NguyễnNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- GPM8-E Complete CD CompressedDocument1,417 pagesGPM8-E Complete CD CompressedDaniel Lloclla SengaNo ratings yet

- Safety devices and high pressure relief valves for CO2 systemsDocument2 pagesSafety devices and high pressure relief valves for CO2 systemsEdita SzuketiováNo ratings yet

- Cot. G 0H InverDocument487 pagesCot. G 0H InverHenry MerjeNo ratings yet

- High Pressure Carbon DioxideDocument6 pagesHigh Pressure Carbon Dioxideleunamsayan100% (1)

- XTV Trip ValvesDocument4 pagesXTV Trip ValvesBharath Nadimpalli50% (4)

- HSL 0558Document53 pagesHSL 0558Jas Philip M100% (1)

- Three Way Valve Technical OverviewDocument8 pagesThree Way Valve Technical OverviewWalter JosephNo ratings yet

- 30168700Document38 pages30168700gr8rlNo ratings yet

- Oil Pumps - Boiler Parts - Boilerparts - Co.keDocument38 pagesOil Pumps - Boiler Parts - Boilerparts - Co.keboilerpartsNo ratings yet

- Chemetron Novec Gamma Specs PDFDocument6 pagesChemetron Novec Gamma Specs PDFambition1340cnNo ratings yet

- IMO Elevator PumpDocument16 pagesIMO Elevator PumpTampaMarkNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Air Compressor C300Document39 pagesAir Compressor C300Joe Alvares75% (8)

- Hot Crude Oil StorageDocument13 pagesHot Crude Oil Storagesachinumarye100% (1)

- SMC Basic PneumaticsDocument120 pagesSMC Basic Pneumaticskellybeiss100% (1)

- FM-200 Alpha Series SystemsDocument6 pagesFM-200 Alpha Series SystemsGurusumiNo ratings yet

- Cocon QDocument4 pagesCocon QbayunsNo ratings yet

- Technical guide to pulse valves for dust collectionDocument4 pagesTechnical guide to pulse valves for dust collectionUrip S. SetyadjiNo ratings yet

- Valve Conversion To Model 210 Retro-FitDocument4 pagesValve Conversion To Model 210 Retro-FitblueagehaNo ratings yet

- cULus Listed FM Approved Pressure Maintenance DevicesDocument4 pagescULus Listed FM Approved Pressure Maintenance DevicesSavy PhanethNo ratings yet

- Flow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3Document4 pagesFlow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3LibinNo ratings yet

- Models A & B Automatic Pressure Maintenance DevicesDocument4 pagesModels A & B Automatic Pressure Maintenance DevicesHIDRUCOL SASNo ratings yet

- HPCO2Document23 pagesHPCO2Abdul RahmanNo ratings yet

- Multimatic Deluge Valve A4Document6 pagesMultimatic Deluge Valve A4Lenin Rajaah AlaganNo ratings yet

- Guidelines For Operation of Minimum Flow Control ValvesDocument10 pagesGuidelines For Operation of Minimum Flow Control ValvesDawid DobrzańskiNo ratings yet

- Pneumatic Circuit TrainerDocument5 pagesPneumatic Circuit Trainerdipsankar chatterjeeNo ratings yet

- Dry ValveDocument12 pagesDry ValveSayed MohamedNo ratings yet

- Tyco Alarm ValveDocument22 pagesTyco Alarm ValveMohammed BaquarNo ratings yet

- ManifoldDocument20 pagesManifoldNilesh MistryNo ratings yet

- Model F470 External Resetting Multimatic Deluge ValvesDocument16 pagesModel F470 External Resetting Multimatic Deluge ValveseduardoNo ratings yet

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2No ratings yet

- Potter - Purgador de Aire PAARDocument3 pagesPotter - Purgador de Aire PAARJames HansonNo ratings yet

- Ngineering ATA: Field Testing of FansDocument5 pagesNgineering ATA: Field Testing of FansMohamed TahounNo ratings yet

- MPower (Mostro) Data Sheet Gate Valve S43 NEW Edition 2009Document9 pagesMPower (Mostro) Data Sheet Gate Valve S43 NEW Edition 2009el_apache10No ratings yet

- FeDocument3 pagesFemihaidanpan791No ratings yet

- Tips For Specifying Pneumatic ValvesDocument11 pagesTips For Specifying Pneumatic ValvesLuis OrduzNo ratings yet

- Lift Check ValvesDocument4 pagesLift Check Valveslejyoner62No ratings yet

- Test Stand Technical ManualDocument51 pagesTest Stand Technical Manualewhf weGJO100% (1)

- Manual SSW10Document31 pagesManual SSW10Victor RodriguezNo ratings yet

- Williams V Series Pump IomDocument32 pagesWilliams V Series Pump IomHectorMaldonado100% (1)

- Model A Deluge Valve Features and OperationDocument4 pagesModel A Deluge Valve Features and OperationmanbkkNo ratings yet

- Chapter 1: Instrumentation Equipment MODULE 8: Control Valves and AccessoriesDocument39 pagesChapter 1: Instrumentation Equipment MODULE 8: Control Valves and AccessoriesSibabrata ChoudhuryNo ratings yet

- Application Data - Fire Pump Fittings: Minimum Fitting SystemDocument2 pagesApplication Data - Fire Pump Fittings: Minimum Fitting Systemاحمد الجزار2007No ratings yet

- Operating Manual: Altronic Gas Control Valve, 690210Document12 pagesOperating Manual: Altronic Gas Control Valve, 690210Esau Jose PabloNo ratings yet

- Reliableb1acc 1Document6 pagesReliableb1acc 1salajeanuNo ratings yet

- 189 010 - en 15.710057 V3.0Document12 pages189 010 - en 15.710057 V3.0balzac191No ratings yet

- TFP910 09 2014Document20 pagesTFP910 09 2014goskleNo ratings yet

- Emission Control System: Parts LocationDocument24 pagesEmission Control System: Parts LocationImran Sarwar100% (1)

- 1-XI - GB Steam Conditioning ManualDocument20 pages1-XI - GB Steam Conditioning ManualtxagusNo ratings yet

- 6 4 7 Pressurizing Insulation SpacesDocument15 pages6 4 7 Pressurizing Insulation SpacesSamarinerSinghNo ratings yet

- H 07121 Choke ManifoldDocument2 pagesH 07121 Choke ManifoldmonokoeNo ratings yet

- Agilent G1160A SelValveDocument8 pagesAgilent G1160A SelValvegimfa songNo ratings yet

- 4.oil Hydraulic Circuit Trainer KitDocument13 pages4.oil Hydraulic Circuit Trainer KitAlmas 1710No ratings yet

- Safebk Rm002 en PDocument146 pagesSafebk Rm002 en PAlbertoNo ratings yet

- Hydrocom: Experience Real Capacity Control and Energy SavingsDocument8 pagesHydrocom: Experience Real Capacity Control and Energy SavingsVignesh Dheenakumar100% (1)

- Process Safety Knowledge Management in The Chemical Process IndustryDocument8 pagesProcess Safety Knowledge Management in The Chemical Process IndustryherikNo ratings yet

- TC FundamentalsDocument16 pagesTC FundamentalsMichael LewisNo ratings yet

- DS IN0017 - en - Co - 20804Document8 pagesDS IN0017 - en - Co - 20804NeoZeruelNo ratings yet

- DS IN0029 en Co 59667 PDFDocument2 pagesDS IN0029 en Co 59667 PDFGilberto Andrés JuradoNo ratings yet

- Preprint GallowayHancke IndustrialControlSurveyDocument22 pagesPreprint GallowayHancke IndustrialControlSurveyMiscAnnoyNo ratings yet

- Internetworking With TCP - IP Vol IIDocument11 pagesInternetworking With TCP - IP Vol IIMohan ArumugavallalNo ratings yet

- DS IN0029 en Co 59667 PDFDocument2 pagesDS IN0029 en Co 59667 PDFGilberto Andrés JuradoNo ratings yet

- EXT Module ManualDocument8 pagesEXT Module ManualMohan ArumugavallalNo ratings yet

- KOSO PositionersDocument34 pagesKOSO PositionersMohan Arumugavallal0% (1)

- NIST H-007 Series 3Document4 pagesNIST H-007 Series 3Satit hunsaNo ratings yet

- Manual Pressure Gauges Large PDFDocument20 pagesManual Pressure Gauges Large PDFTirtheshwar SinghNo ratings yet

- Orifice Plate Flow MetersDocument8 pagesOrifice Plate Flow MetersGaurav Dhiman100% (1)

- Heads or Tails Facilitator Guide for Coin Toss ActivityDocument14 pagesHeads or Tails Facilitator Guide for Coin Toss ActivityMohan ArumugavallalNo ratings yet

- AMG ActuatorsDocument12 pagesAMG ActuatorsMohan ArumugavallalNo ratings yet

- LOPA ArticlesDocument31 pagesLOPA ArticlesShri.krsnaNo ratings yet

- Team-building Workshop: Heads or Tails Coin Toss GameDocument8 pagesTeam-building Workshop: Heads or Tails Coin Toss GameMohan ArumugavallalNo ratings yet

- Sensors For O2 AnalysisDocument13 pagesSensors For O2 AnalysisMohan ArumugavallalNo ratings yet

- Fibre Optic TechniqueDocument4 pagesFibre Optic TechniqueMohan ArumugavallalNo ratings yet

- Fire Pump Drivers - DDFP PartsDocument4 pagesFire Pump Drivers - DDFP PartsMohan ArumugavallalNo ratings yet

- Ca 3241Document1 pageCa 3241Tien LamNo ratings yet

- Mechanical Engineer MachinaryDocument2 pagesMechanical Engineer MachinaryUpendra ChoudharyNo ratings yet

- Procedure RefillDocument2 pagesProcedure RefillSiul DasitNo ratings yet

- Hydrosatic PresentationDocument78 pagesHydrosatic PresentationZain Ali KidwaiNo ratings yet

- Exp 6Document11 pagesExp 6fu MozaNo ratings yet

- Candy Ctl128 12Document16 pagesCandy Ctl128 12Luis Alberto SchunkNo ratings yet

- Din2632 PN10 PDFDocument2 pagesDin2632 PN10 PDFPablo TututiNo ratings yet

- FMC Fluid Control Systems Ball ValvesDocument8 pagesFMC Fluid Control Systems Ball ValvesleonardoportocNo ratings yet

- Determining the Operation Point of a Centrifugal Pump Lab ReportDocument13 pagesDetermining the Operation Point of a Centrifugal Pump Lab ReportKenan GojayevNo ratings yet

- Weldolets DimensionsDocument16 pagesWeldolets Dimensionsณัฐพล ศักดิ์นภาพรเลิศNo ratings yet

- A-Series Exploded Diagrams - Spares 04-20Document6 pagesA-Series Exploded Diagrams - Spares 04-20TomNo ratings yet

- Check, Poppet Type: Common Cavity, Size 16Document2 pagesCheck, Poppet Type: Common Cavity, Size 16HIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Assignment - 2 TE-1-1Document1 pageAssignment - 2 TE-1-1Lalith SunkojuNo ratings yet

- Application of Boundary Layer TheoryDocument4 pagesApplication of Boundary Layer Theoryridzuwan rahimiNo ratings yet

- Ramjet EngineDocument3 pagesRamjet EngineMuhammad BilalNo ratings yet

- Skp-New Price ListDocument26 pagesSkp-New Price ListnuwanwimalNo ratings yet

- Single-Phase Critical FlowDocument3 pagesSingle-Phase Critical Flowsrin89No ratings yet

- Avk Ball Float ValveDocument2 pagesAvk Ball Float ValveDota NgNo ratings yet