Professional Documents

Culture Documents

5-EN 4050-A (Dig) - 2F1C

Uploaded by

abuzer1981Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5-EN 4050-A (Dig) - 2F1C

Uploaded by

abuzer1981Copyright:

Available Formats

Publ. 5-EN 4050-A (dig.

), replaces 5-EN 405-A

DENISON HYDRAULICS

Variable Flow Control Valve

Series 2FC

Ordering Code Back to Content

FEATURES, SYMBOL, DESCRIPTION

2

BASIC CIRCUIT DIAGRAM

SYMBOL

I N

OUT

response time

adjustment

optional with

check valve

P

I N

A

OUT

FEATURES

x

Precise stepless adjustable flow control, without shock loading.

x

Metering spool in neutral position closed no flow peaks.

x

Independent of pressure and viscosity changes (pressure compensated).

x

Exceptionally precise control within the lower flow range can be obtained by the

soft start characteristiscs:

first revolution ... 20 % of max. flow

second revolution ... 80 % of max. flow

x

Adjustment device is lockable by key.

x

The adjustment is precisely repeatable across the full flow range.

x

Flowcontrol valves, incorporating an integral check valve, allowfluid to by-pass the

control mechanism and flow freely from outlet to inlet port (reverse flow page 6).

x

The 2FC flow control valve offers the option of an mechanically adjustable

response time.

x

World wide DENISON Service.

DESCRIPTION DENISON flow control valves provide accurate speed control of cylinders and

motors. The DENISON 2FC flow valves are pressure compensated and viscosity

independent. The valve in principal is a combination of two shifting spools, a

compensator spool and a throttle spool. The throttle spool is manually operated and

controlled by a valve control knob. The compensator spool automatically adjusts its

orifice to maintain a constant pressure difference across the throttle spool orifice.

DENISON 2FC flow control valves have a key lock in the control knob which has

three positions as follows:

Lock Holds the setting position and does not permit unauthorised re-

adjustment.

Adjust Permits full adjustment through an angle of 700 h.

Trim Permits adjustment of approximately 0 h and can be used for minor flow

corrections.

Also it is possible to adjust the response time on the front plate. 2FC flow control

valves operate without shock loading, as the metering spool with the adjustable

fine throttle is closed in a no-load condition.

The required flow is adjusted by the control knob and can be repeated by

observation on a built-in scale. An exceptionallyprecise control within the lower flow

ranges can be obtained by the soft start characteristics.

With code C an integral reverse flow check valve is available which allows flow

from outlet port to the inlet port.

Back to Content Ordering Code

APPLICATION EXAMPLES

3

METER-IN SYSTEM

A (OUT)

P (I N)

The system arrangement of flow control

valves depends on individual requirements.

If an actuator, e.g. cylinder or motor, is

under load conditions acting against the

system pressure a flow control valve can

be applied as a meter-in system thus

directing controlled flow to the actuator.

METER-OUT SYSTEM

A (OUT)

P (I N) On applications where a stiff hydraulic

control is necessary due possible to

positive and negative loads on the

actuator, a meter-out system similar to

that indicated figure can be used. In this

case the flow from the actuator is

controlled by the flow control valve.

BY-PASS SYSTEM

A

(OUT)

P

(IN)

If for particular reasons either of the

above methods of control are not

practical, e.g. flow rate in excess of valve

capacity, a by-pass system may be

applied as shown. This arrangement not

only allows valves to control high

capacity systems but also affords a

power sawing feature.

Ordering Code Back to Content

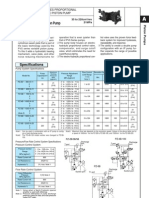

TECHNICAL DATA, ORDERING CODE

4

GENERAL

x

Type of unit 2 Port Variable Flow Control Valve

(pressure compensated)

x

Design Sharp edge orifice

x

Type of mounting Subplate mounted

x

Type of port connections Thread in subplate

x

Port sizes (subplate) 2FC02 2FC03

G

3

/8HH G

3

/4HH

x

Weight 6 kg 9 kg

x

Mounting position optional

x

Direction of flow IN f OUT

x

Ambient temperature range 20 ... +60 h C

x

Suitability for special Consult DENISON

working conditions

HYDRAULIC CHARACTERISTICS

x

Operating pressure range 2FC02 2FC03

inlet (at max. flow) 14 ... 280 bar 14 ... 350 bar

outlet (at max. flow) 0 ... 270 bar 0 ... 340 bar

x

Fluid temperature range 18 h C ... +80 h C

x

Viscosity range 10 ... 650 cSt

x

Recommended operating viscosity 30 cSt

x

Contamination level Max. permissible contamination level

according to NAS 638 Class 8

(Class 9 for 5 Micron and smaller)

or ISO 7/4

TYPE OF ADJUSTMENT

x

Manual

x

Angular movement 700 degree

ORDERING CODE Model Number: 2FC . . 01 B . . - - -

1 2 3 4 5 6 7

Series

2 Size

02 =

3

/8HH

03 =

3

/4HH

3 Adjustment

01 = Knob with key

4 Design Letter

5 Seal Class

4 = EPDM seals

5 = FPM seals (Viton

`

)

6 Reverse Flow Check

0 = without check

C = with check

7 Modification

1 2 3 4 5 6 7

Ordering Code Back to Content

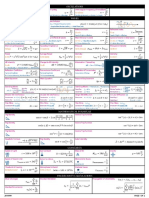

CURVES

5

Flow / Knob Adjustment Characteristics at 210 bar

Flow / Pressure Drop Characteristics

Constant Inlet Pressure Variable Outlet Pressure

F

l

o

w

l

/

m

i

n

F

l

o

w

l

/

m

i

n

F

l

o

w

l

/

m

i

n

Valve setting

1. revolution 2. revolution

Increasing flow

decreasing flow

Increasing

flow

decreasing flow

2

F

C

0

3

2

F

C

0

2

Inlet Setting

2FC02

Outlet Pressure bar

Inlet Setting

2FC03

Outlet Pressure bar

Knob

Set .96

Knob

Set .7

Knob

Set .4

Knob

Set .

Knob

Set 0.8

Knob

Set .96

Knob

Set .4

Ordering Code Back to Content

CURVES

6

Pressure Drop / Flow Characteristics

for reverse flow direction

2FC02 at 280 bar

2FC03 at 350 bar

Flow l/min

Flow / Minimum Operating Pressure Characteristics

P

r

e

s

s

u

r

e

w

p

(

b

a

r

)

r

e

v

e

r

s

e

f

l

o

w

R

a

t

e

d

f

l

o

w

R

a

t

e

d

f

l

o

w

F

l

o

w

l

/

m

i

n

F

l

o

w

l

/

m

i

n

2FC02

Pressure wp (bar)

2FC03

Pressure wp (bar)

Set .96

(max.)

Set .7

Set .5

Set .3

Set .0

Set 0.9

Set .96

(max.)

Set .6

Set .2

Set 0.8

2

F

C

0

2

.

.

.

C

2

F

C

0

3

.

.

.

C

Ordering Code Back to Content

CURVES

7

Leakage / Pressure Characteristics

Flow / Temperature Range Characteristics

at 210 bar

All curves are typical and results of tests. Operating temperature = 50

h

C, oil viscosity = 40 cSt.

Pressure bar

L

e

a

k

a

g

e

m

l

/

m

i

n

F

l

o

w

l

/

m

i

n

F

l

o

w

l

/

m

i

n

2FC02

2FC03

2FC02

Fluid temperature h C

Set .96 (max.)

Set .7

Set .3

Set 0.9

2FC03

Fluid temperature h C

Set .96 (max.)

Set .6

Set .2

Set 0.8

Ordering Code Back to Content

DIMENSIONS

8

2FC02

Response time

adjustment

Seals

IN, OUT 17.12 x 2.62 694001150 (EPDM)

695001150 (FPM)

2FC03

Response time

adjustment

Seals

IN, OUT 26.64 x 2.62 694001210 (EPDM)

695001210 (FPM)

Ordering Code Back to Content

SUBPLATES

9

For 2FC02

Weight 2.3 kg

Location hole

Port Size 4 Mounting Screws * (Torque 34 Nm)

Model No. Order No. IN, OUT Dimension Order No.

SSB0643135 S16246910 G

3

/8HH M8 x 100 700708428

DIN 912; 12.9

* Mounting screws are included in subplate order.

For valves ordered without subplate, mounting screws must be ordered seperately.

For 2FC03

Weight 3.2 kg

Location hole (2)

Port Size 4 Mounting Screws * (Torque 68 Nm)

Model No. Order No. IN, OUT Dimension Order No.

SSB1243136 S16246900 G

3

/4HH M10 x 100 700708438

DIN 912; 12.9

* Mounting screws are included in subplate order.

For valves ordered without subplate, mounting screws must be ordered seperately.

Ordering Code Back to Content

You might also like

- Pneumatic and Apm Liquid Level ControlDocument12 pagesPneumatic and Apm Liquid Level Controlyuri0527No ratings yet

- Proportional Pressure Relief Valve R4V DENISONDocument15 pagesProportional Pressure Relief Valve R4V DENISONBerenice Bautista BelmontesNo ratings yet

- Re29564 2007-011Document12 pagesRe29564 2007-011engineer86No ratings yet

- A6 VDocument40 pagesA6 VWesame Shnoda100% (1)

- 62 Series Servovalves Technical OverviewDocument8 pages62 Series Servovalves Technical OverviewDevendra BangarNo ratings yet

- 7-EN 520-D - D5S 2-PortDocument16 pages7-EN 520-D - D5S 2-Portabuzer1981No ratings yet

- All About HidrolicDocument7 pagesAll About Hidrolicpiteng1945100% (3)

- Components For Pneumatic Automation: Five ONEDocument26 pagesComponents For Pneumatic Automation: Five ONEamNo ratings yet

- Control Balancing ValvesDocument16 pagesControl Balancing ValvesblindjaxxNo ratings yet

- Proportional Pressure Control Valves Series P2 & 4VP01Document12 pagesProportional Pressure Control Valves Series P2 & 4VP01abuzer1981No ratings yet

- 2Fph Series Pressure Compensated Flow Regulator/Diverter: - Priority StyleDocument2 pages2Fph Series Pressure Compensated Flow Regulator/Diverter: - Priority StylemaarwaanNo ratings yet

- Re 92012Document12 pagesRe 92012Ahmed Abd Elhakeem100% (1)

- 7-En 5150-B - CarDocument15 pages7-En 5150-B - Carabuzer1981No ratings yet

- Anti Surge ControlDocument33 pagesAnti Surge Controlgopinath87100% (1)

- Bul 36115 Servo Valve OperationDocument12 pagesBul 36115 Servo Valve Operationrikkitech100% (1)

- 4WS2EM 6-2X servo directional valve technical documentationDocument12 pages4WS2EM 6-2X servo directional valve technical documentationIbrahim MoamenNo ratings yet

- Flow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3Document4 pagesFlow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3LibinNo ratings yet

- Rexroth Re29564 XN 102 b2 - 2010 05Document12 pagesRexroth Re29564 XN 102 b2 - 2010 05boilerqwerty81No ratings yet

- Hydraulic Directional Control and Check ValvesDocument28 pagesHydraulic Directional Control and Check ValvestunradotNo ratings yet

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabNo ratings yet

- Elettrovalvole Denison HydraulicsDocument62 pagesElettrovalvole Denison HydraulicsZMCONTROLNo ratings yet

- Denison Hydraulics Directional Control Valve Cetop 03: Series 4D01 Design BDocument0 pagesDenison Hydraulics Directional Control Valve Cetop 03: Series 4D01 Design BZMCONTROLNo ratings yet

- Burkert Type 8630 TopControl ContinuousDocument6 pagesBurkert Type 8630 TopControl ContinuousCarlos BernussiNo ratings yet

- Sts ChloromaticDocument8 pagesSts Chloromaticahmsa.morsyNo ratings yet

- Bomba Hidraulica A7VODocument52 pagesBomba Hidraulica A7VOanon_491700336100% (2)

- Valvulas XT PDFDocument4 pagesValvulas XT PDFIsidro Gomez GarciaNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Axial Variable Duoble PumpDocument40 pagesAxial Variable Duoble Pumpveljeg100% (1)

- Cocon QDocument4 pagesCocon QbayunsNo ratings yet

- Dynex RP A SpecsDocument4 pagesDynex RP A SpecsAnthony DennisNo ratings yet

- D1-501en Mikro MAHDocument6 pagesD1-501en Mikro MAHocto20016962No ratings yet

- ISO 9001 Certified Digital Control Valve GuideDocument8 pagesISO 9001 Certified Digital Control Valve Guidecnrk777100% (1)

- DeaeratorDocument8 pagesDeaeratorfjoesandiNo ratings yet

- Pressure Independent Control ValveDocument16 pagesPressure Independent Control ValverakamechNo ratings yet

- Control Valve HelpDocument6 pagesControl Valve HelpHimanshu SinghNo ratings yet

- Denison Hydraulics Directional Control Valve Cetop 05: Series 4D02 Design BDocument0 pagesDenison Hydraulics Directional Control Valve Cetop 05: Series 4D02 Design BZMCONTROLNo ratings yet

- Bom A4VG - REXROTHDocument44 pagesBom A4VG - REXROTHnamduong368100% (4)

- Proportional Control Valves with Integrated 24 Volt ElectronicsDocument24 pagesProportional Control Valves with Integrated 24 Volt ElectronicsLuis Alberto RamosNo ratings yet

- 377 Series Trip ValvesDocument8 pages377 Series Trip ValvesMijin28No ratings yet

- Deltamatic Rate of Drop Linebreak Detection SystemDocument4 pagesDeltamatic Rate of Drop Linebreak Detection SystemNop PhithakthongNo ratings yet

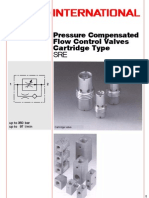

- Flow Control Valves Pressure Compensated Cartridge TypeDocument6 pagesFlow Control Valves Pressure Compensated Cartridge TypevrgohilNo ratings yet

- NIMCO CV300newDocument24 pagesNIMCO CV300newBruno SamaeianNo ratings yet

- Series RM Rate-Master Flowmeters: Specifications - Installation and Operating InstructionsDocument2 pagesSeries RM Rate-Master Flowmeters: Specifications - Installation and Operating InstructionsDJoko Trend RedsNo ratings yet

- Test Stand Technical ManualDocument51 pagesTest Stand Technical Manualewhf weGJO100% (1)

- A10VSO18 Bomba HidraulicaDocument16 pagesA10VSO18 Bomba HidraulicaGuilherme RodriguesNo ratings yet

- Om004 Om008 Integral ManualDocument9 pagesOm004 Om008 Integral ManualistopiNo ratings yet

- DRESSER Regulators FlowgridDocument12 pagesDRESSER Regulators Flowgridzalziza100% (1)

- P6..W..EV-BAC 1 0 enDocument10 pagesP6..W..EV-BAC 1 0 enZoran DanilovNo ratings yet

- AP GBDocument2 pagesAP GBTitu NicuNo ratings yet

- Bomba Hidrailica A10VSODocument44 pagesBomba Hidrailica A10VSOkiarabenitezparejaNo ratings yet

- Manual Comando Control Air Hd2Document12 pagesManual Comando Control Air Hd2Brian Schmidt100% (2)

- VMCDocument32 pagesVMCJoanaRicardo FigueiredoNo ratings yet

- Sor Adjustable Dead Band Pressure SwitchDocument16 pagesSor Adjustable Dead Band Pressure SwitchAdam SamyNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Basler Electric MVC112 Electronic Manual Voltage Control Module Datasheet1-1606813999Document4 pagesBasler Electric MVC112 Electronic Manual Voltage Control Module Datasheet1-1606813999abuzer1981No ratings yet

- Service Manual Air Starter A17.G01Document26 pagesService Manual Air Starter A17.G01abuzer1981100% (3)

- Lal 125Document20 pagesLal 125Zvonko TrajkovNo ratings yet

- MaK VM32C Low Emission Engine 32305Document12 pagesMaK VM32C Low Emission Engine 32305abuzer1981100% (1)

- LF 120MDocument2 pagesLF 120Mabuzer1981No ratings yet

- Electr Speed Sensing eDocument12 pagesElectr Speed Sensing eabuzer1981No ratings yet

- Cms Handler Document Handler 6Document6 pagesCms Handler Document Handler 6abuzer1981No ratings yet

- Cms Handler Document Handler 6Document6 pagesCms Handler Document Handler 6abuzer1981No ratings yet

- Murphy Ems DrawingDocument1 pageMurphy Ems Drawingabuzer1981No ratings yet

- Cms Handler Document Handler 11Document12 pagesCms Handler Document Handler 11abuzer1981100% (1)

- Levelflex M FMP40: Operating InstructionsDocument92 pagesLevelflex M FMP40: Operating Instructionsabuzer1981No ratings yet

- Kwant Controls Bargraph Indicators LBM-X SeriesDocument6 pagesKwant Controls Bargraph Indicators LBM-X Seriesabuzer1981No ratings yet

- THYRISTOR POWER CONTROLLERSDocument5 pagesTHYRISTOR POWER CONTROLLERSabuzer1981No ratings yet

- Cms Handler Document Handler 1Document17 pagesCms Handler Document Handler 1abuzer1981No ratings yet

- Mas 2600Document27 pagesMas 2600abuzer1981No ratings yet

- MPCC 4 ElectricaldiagramDocument16 pagesMPCC 4 Electricaldiagramabuzer1981No ratings yet

- Hybrid Universal AVR Operation GuideDocument6 pagesHybrid Universal AVR Operation Guideabuzer1981No ratings yet

- Products 362Document2 pagesProducts 362abuzer1981No ratings yet

- t2000 User Fire Alarm SystemDocument35 pagest2000 User Fire Alarm Systemabuzer198190% (10)

- T1000 - Manual Do UsuárioDocument45 pagesT1000 - Manual Do UsuárioLee StürmNo ratings yet

- Cms Handler Document HandlerDocument14 pagesCms Handler Document Handlerabuzer1981No ratings yet

- Ea06 Manual enDocument6 pagesEa06 Manual enabuzer1981No ratings yet

- Generator AVR Manual Explains Self-Excited 5 Amp RegulatorDocument4 pagesGenerator AVR Manual Explains Self-Excited 5 Amp Regulatorabuzer1981No ratings yet

- T1200Document36 pagesT1200abuzer198150% (2)

- Products 362Document2 pagesProducts 362abuzer1981No ratings yet

- Linear Actuator: Model F-09160-A0Document4 pagesLinear Actuator: Model F-09160-A0abuzer1981No ratings yet

- THYRISTOR POWER CONTROLLERSDocument5 pagesTHYRISTOR POWER CONTROLLERSabuzer1981No ratings yet

- Ea15a3h Manual enDocument5 pagesEa15a3h Manual enabuzer1981No ratings yet

- Ea448 Manual enDocument4 pagesEa448 Manual enroozbehxoxNo ratings yet

- EA16 Generator Automatic Voltage Regulator Operation ManualDocument6 pagesEA16 Generator Automatic Voltage Regulator Operation Manualabuzer1981No ratings yet

- 2a. - Compression-Members Ce134p - Escruz - LRFDDocument19 pages2a. - Compression-Members Ce134p - Escruz - LRFDJed CernechezNo ratings yet

- Service Bulletin: - CorrectedDocument3 pagesService Bulletin: - CorrectedmichaeltibocheNo ratings yet

- Free Vibration Analysis of A DamDocument4 pagesFree Vibration Analysis of A DamSabun-mumSanatı Nikah-bebekşekeriNo ratings yet

- BWT 7000 SCDocument1 pageBWT 7000 SCMehdi AcilNo ratings yet

- Addition - Toyota CamryDocument3 pagesAddition - Toyota CamryVivek VikramNo ratings yet

- RT-flex-Introduction May13 Rev1Document96 pagesRT-flex-Introduction May13 Rev1NAGENDRA KUMAR D100% (1)

- พอฤทัย วิริยะภาค26 3.5Document2 pagesพอฤทัย วิริยะภาค26 3.55.6 25 [พิงค์แพรว]นางสาวพอฤทัย วิริยะภาคNo ratings yet

- CMC Ready ReckonerxlsxDocument3 pagesCMC Ready ReckonerxlsxShalaniNo ratings yet

- Gear & Design Gearbox DJSDocument12 pagesGear & Design Gearbox DJSAnonymous z4Fe39jNo ratings yet

- sEW20Document78 pagessEW20Wan AzmiNo ratings yet

- NR24R Imo InformmationDocument12 pagesNR24R Imo Informmationronny ArdiansyahNo ratings yet

- FEM9.756 Engl PDFDocument57 pagesFEM9.756 Engl PDFserkanNo ratings yet

- Q4 Science 9 Week 1 8 PDFDocument33 pagesQ4 Science 9 Week 1 8 PDFJesiel MabagaNo ratings yet

- Setting Up and Adjusting a Sewing MachineDocument14 pagesSetting Up and Adjusting a Sewing MachinestansracingNo ratings yet

- PHYS 369 Formula Sheet CombinedDocument4 pagesPHYS 369 Formula Sheet Combineddarro d92No ratings yet

- Denison Hydraulics Stack Valves Cetop 03 GuideDocument13 pagesDenison Hydraulics Stack Valves Cetop 03 Guideabuzer1981100% (1)

- 1981 Garden Way Pony Manual WMDocument70 pages1981 Garden Way Pony Manual WMbfranklin2000100% (1)

- Crossrunner 250cc Service ManualDocument228 pagesCrossrunner 250cc Service ManualAnna RyanNo ratings yet

- RK-2001E2 English TraductionDocument2 pagesRK-2001E2 English TraductionwxcvbnnbvcxwNo ratings yet

- Dynamic Properties of RocksDocument5 pagesDynamic Properties of RocksArnold John Laya100% (3)

- 40-272 - Basic Vicat/HDT (Up To 3 or Up To 6 Measuring Stations)Document3 pages40-272 - Basic Vicat/HDT (Up To 3 or Up To 6 Measuring Stations)MiguelNo ratings yet

- Structural Identification of Humber Bridge For Performance Prognosis 2015Document18 pagesStructural Identification of Humber Bridge For Performance Prognosis 2015정주호No ratings yet

- TECUMSEH Model Number CodesDocument6 pagesTECUMSEH Model Number Codesd3xter0% (1)

- PETROLAND PL 2 INVENTORY RIGDocument9 pagesPETROLAND PL 2 INVENTORY RIGmantenimiento keruiNo ratings yet

- BN-G-Y017 Welding Inspection GuideDocument5 pagesBN-G-Y017 Welding Inspection GuidePugalNo ratings yet

- FMR BTS Power ConsumptionDocument3 pagesFMR BTS Power ConsumptionDeden SuredenNo ratings yet

- Morgan SiemensVAI LubricationDocument45 pagesMorgan SiemensVAI LubricationRamesh Timmanagoudar100% (2)

- Revolutionizing Underwater Travel with SupercavitationDocument20 pagesRevolutionizing Underwater Travel with SupercavitationRoshan ThimmaiahNo ratings yet

- IP Design and Installation of Inert Gas SystemDocument117 pagesIP Design and Installation of Inert Gas SystemArif Kuncoro Adi100% (1)

- Edmund Charlton Academic TranscriptDocument2 pagesEdmund Charlton Academic TranscriptCharlton EddieNo ratings yet