Professional Documents

Culture Documents

Shin-Etsu Electric and Electronic Films - R Type: Polypropylene Capacitor Film

Uploaded by

Deming0 ratings0% found this document useful (0 votes)

63 views8 pagesPP film properties.

Original Title

ppfilm_r_e.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPP film properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

63 views8 pagesShin-Etsu Electric and Electronic Films - R Type: Polypropylene Capacitor Film

Uploaded by

DemingPP film properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

Polypropylene Capacitor Film

Shin-Etsu Electric and Electronic Films R Type

Film

Polypropylene Capacitor Film

Shin-Etsu Electric and Electronic Films-R Type

Shi n-Etsus R Type fi l m was the worl ds fi rst hazy

polypropylene capacitor film successfully developed for

commercial purposes. With our unified management

system, encompassi ng al l steps from raw materi al

procurement through to production and shipping, we

offer stable supply to our customers. We use carefully

selected high-purity polypropylene resin and an inflation

process i n t he si mul t aneous bi axi al ori ent at i on

production method. It has excellent characteristics as a

dielectric film, and one major feature is the network of

evenly distributed irregularities on the film surface. This

structure facilitates oil penetration of the film surface and

improves the efficiency of insulating oil impregnation of

the capacitor elements. This network structure was

created with propri etary Shin-Etsu technol ogy that

makes use of the crystalline transformation behavior of

polypropylene, unlike products manufactured using

processing additives or secondary surface processing.

Our film offers consistent quality and the high reliability

required of capacitor materials.

Thanks to its superior oil-impregnability, Shin-Etsus R

Type electric and electronic film enabled the production

of todays all-film type capacitors that dont use capacitor

paper. Shin-Etsu has also earned high acclaim for our

contribution to greater reliability, higher capacity, and

miniaturization of power capacitors.

1

Capacitor Film

2

Features

1. Diverse variety

The physi cal and el ect r i cal pr oper t i es of

polypropylene film after impregnation with insulating

oil vary according to the type of insulating oil used

and the impregnation conditions and other conditions

of the capacitor production process. Therefore, the

required properties of PP film will differ according to

the capaci tor producti on condi ti ons and desi gn

concept.

Shin-Etsu Films product lineup includes the standard

R Type, and t he LR Type and RH Type, whose

properties differ from those of the R Type. We have a

system in place to offer the optimum product tailored

to diverse customer needs.

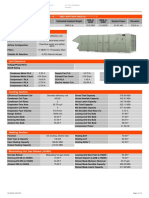

Classifications

Product Type

Thickness

Core dimensions

2. A comprehensive evaluation system

At Shi n- Et su Fi l m, we have t he equi pment f or

evaluating the various properties of polypropylene

film. For small -capacit y capacitors for consumer

appl i c at i ons, we have t he equi pment f or

manufacturing standard capacitors for evaluation

and a r ange of el ect r i cal proper t y eval uat i on

equipment. To maintain the highest standards of

quality, we evaluate the films electrical properties

as capacitors and feed this data to the production

department.

Product Type Standard Thickness (m)

R 8 9 12 13 14 15 16 18 20 22 25 30

RH 12 13 14 15 16.5 18

LR 10.1 wt

10.8 wt 12.3 wt 14.8 wt

Item Dimension

I.D. (inside diameter of core) 76.5 1.0 mm

O.D. (outside diameter of roll) up to 500 mm

Film width 30-1,500 mm

wt: thickness measured using the weight method or by micrometer.

Product Type Advantage Application

R Standard type For all-PP high-voltage and extra-high-voltage capacitors

RH Low heat-shrink type For all-PP high-voltage and microwave oven capacitors

LR Low

SF type For all-PP low- and high-voltage capacitors

SF: Space Factor

3

Properties

General properties

Mechanical properties

Capacitor Film

Item Unit Characteristic values Measurement method

Density g/cm

3

0.905 JIS K 7112

Softening point C 147 JIS K 7121

Melting point C 165 - 170 JIS K 7121

Water absorption % < 0.05 ASTM D 570

Item Unit Characteristic values Measurement method

Tensile strength

MD MPa 160

JIS C 2330

CMD MPa 200

Elongation at break

MD % 155

JIS C 2330

CMD % 80

Heat shrinkage

MD % 3 - 4

JIS C 2330

CMD % 5 - 7

20

15

10

5

0

-5

60 80 100 120 140 160

Temperature dependence of heat shrinkage

Temperature (C)

H

e

a

t

s

h

r

i

n

k

a

g

e

(%)

Type R/LR

Type RH

MD

20

15

10

5

0

-5

60 80 100 120 140 160

Temperature dependence of heat shrinkage

Temperature (C)

H

e

a

t

s

h

r

i

n

k

a

g

e

(%)

Type R/LR

Type RH

CMD

4

Surface properties

Surface roughness

Test pieces: 15R, SF 10%

Capacitor Film

a. Rough surface (Ra 0.22 m)

b. Smooth surface (Ra 0.14 m)

Item

Unit

Characteristic values

Measurement method

R RH LR

Space factor % 10 10 5 JIS C 2330

Haze % 25 - 35 25 - 35 10 - 20 JIS K 6714

Surface roughness

Face m 0.2 - 0.5 0.2 - 0.5 0.1 - 0.4

JIS B 0601

Ra

Back m 0.1 - 0.3 0.1 - 0.3 0.1 - 0.3

Surface roughness

Face m 1.5 - 4 1.5 - 4 1 - 2

JIS B 0601

Rmax

Back m 1 - 2 1 - 2 1 - 2

5

Electrical properties

Capacitor Film

650

600

550

500

450

400

350

5 10 15 20 25 30 35

Film thickness and dielectric breakdown voltage

Film thickness (m)

B

D

V

(V/m)

1

0.1

0.01

0.001

0.0001

10

-5

5 10 15 20 25 30 35

250V/m

Film thickness and Electrical defects

Film thickness (m)

D

i

e

l

e

c

t

r

i

c

d

e

f

e

c

t

s

(pcs/m

2

)

3

2.5

2

1.5

1

0.5

0

10 100 1000 10

4

10

5

10

6

10

7

at 22C

Frequency dependence of specific dielectric constant

Frequency (Hz)

S

p

e

c

i

f

i

c

d

i

e

l

e

c

t

r

i

c

c

o

n

s

t

a

n

t

1

0.1

0.01

0.001

10 100 1000 10

4

10

5

10

6

10

7

at 22C

Frequency dependence of dielectric dissipation factor

Frequency (Hz)

D

i

e

l

e

c

t

r

i

c

d

i

s

s

i

p

a

t

i

o

n

f

a

c

t

o

r

(%)

3

2.5

2

1.5

1

0.5

0

0 20 40 60 80 100 120

60 Hz

Temperature dependence of specific dielectric constant

Temperature (C)

S

p

e

c

i

f

i

c

d

i

e

l

e

c

t

r

i

c

c

o

n

s

t

a

n

t

1

0.1

0.01

0.001

0 20 40 60 80 100 120

60 Hz

Temperature dependence of dielectric dissipation factor

Temperature (C)

D

i

e

l

e

c

t

r

i

c

d

i

s

s

i

p

a

t

i

o

n

f

a

c

t

o

r

(%)

Item Unit Characteristic values Measurement method

Specific dielectric constant 2.2 JIS C 2330

Dielectric dissipation factor % 0.02 JIS C 2330

Volume resistivity cm 10

17

JIS C 2330

Dielectric breakdown voltage V/m 550 JIS C 2330

Electrical defects pcs/m

2

< 0.01 Shin-Etsu method (contact electrode method)

6

Chemical properties

Packaging

Film lengths and product roll diameters

Slit roll label

Storage and Handling Precautions

Store out of direct sunlight in a cool place with low humidity.

Do not use film more than six months past the delivery date.

The film may deteriorate, causing problems in use.

Capacitor Film

The standard outer diameters are 180 mm , 200 mm , and 250 mm . The inner diameter of the core is 76 mm .

Thickness (m) 180 mm 200 mm 250 mm

9 2,000 2,700 4,400

10 2,450 4,000

12 1,500 2,050 3,300

13 1,400 1,870 3,000

14 1,300 1,700 2,900

15 1,200 1,600 2,700

16 1,130 1,500 2,500

16.5 1,460 2,400

18 1,000 1,300 2,200

19.5 900 1,200 2,000

20 1,150 2,000

22 1,100 1,800

25 960 1,600

30 800 1,200

(unit: m)

Type R Lot No.

1

4510 - 85921

Thickness (m)

2

13.6 W Length (m) 1600

Width (m) 305 Mass (kg) 6.1

Shin-Etsu Polypropylene Film

1 Explanation of Lot no. (digits from left to right)

4: Final digit of 2004, the year of production of the Jumbo roll

5: Month of production (1-9, 10=X, 11=Y, 12=Z) of Jumbo roll

10: Monthly production sequence

8: Slitting machine number

5921: Slit instruction number

2 Explanation of thickness

W indicates the weight method (wt)

Item Unit Characteristic values Measurement method

Ash content ppm < 30 JIS C 2330

Chlorine content ppm < 5 Shin-Etsu method (ion chromatography)

The data presented in this catalog may not be relied upon to represent standard values.

Shin-Etsu reserves the right to change the data and information in this catalog without notice.

Shin-Etsu films are produced in plants that are registered in accordance

with international standards of quality assurance management.

Shin-Etsu Nov.2005.B.P.

Contact Shin-Etsu for more information about film

for electric and electronic applications.

Shin-Etsu Film Co., Ltd.

Stage Uchikanda, 3-8, Uchikanda 1-chome, Chiyoda-ku, Tokyo, 101-0047, Japan TEL+81-3-3259-1061

FAX+81-3-3259-1064

http://www.shinetsu-film.co.jp

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Electrical system service guideDocument301 pagesElectrical system service guideVygintas Balcius92% (12)

- Hazardous Area Chart - BartecDocument1 pageHazardous Area Chart - BartecbandianwarNo ratings yet

- Telescoping of Adhesive Coated Wound RollsDocument9 pagesTelescoping of Adhesive Coated Wound RollsDemingNo ratings yet

- Commercial Electrical Load Calculation Worksheet ExcelDocument2 pagesCommercial Electrical Load Calculation Worksheet ExcelAshish Kamboj100% (1)

- How To Measure Roll QualityDocument13 pagesHow To Measure Roll QualityDemingNo ratings yet

- BOPP Film Grade CatalogDocument32 pagesBOPP Film Grade CatalogDemingNo ratings yet

- Roll Hardness Measurements as a Tool for Quality ControlDocument49 pagesRoll Hardness Measurements as a Tool for Quality ControlDemingNo ratings yet

- Adaptive Control With Self-Tuning For Conter Driven Web WindersDocument105 pagesAdaptive Control With Self-Tuning For Conter Driven Web WindersDemingNo ratings yet

- Improving EB104 Amplifier with Transmission Line TransformerDocument20 pagesImproving EB104 Amplifier with Transmission Line Transformerpino100% (1)

- BST CLSPro 600 User ManualDocument100 pagesBST CLSPro 600 User ManualDeming56% (9)

- Rewinding QualityDocument3 pagesRewinding QualityDemingNo ratings yet

- Tubos Spirrally PDFDocument10 pagesTubos Spirrally PDFAscanio BarbosaNo ratings yet

- HPC Sprocket Wheel PDFDocument2 pagesHPC Sprocket Wheel PDFDemingNo ratings yet

- Calculation of Measuring Force PDFDocument3 pagesCalculation of Measuring Force PDFDemingNo ratings yet

- Polymer Separator FilmsDocument30 pagesPolymer Separator FilmsDemingNo ratings yet

- Electric motor driven actuator data sheetDocument2 pagesElectric motor driven actuator data sheetDemingNo ratings yet

- Release Liners - : MPI Release, Evolving Capabilities For An Evolving MarketDocument4 pagesRelease Liners - : MPI Release, Evolving Capabilities For An Evolving MarketDemingNo ratings yet

- Belt Tension and Deflection PDFDocument21 pagesBelt Tension and Deflection PDFDemingNo ratings yet

- MAM BrochureDocument4 pagesMAM BrochureDemingNo ratings yet

- Pds Targray Battery Separator pp25 PDFDocument1 pagePds Targray Battery Separator pp25 PDFDemingNo ratings yet

- Motor Modeling and Position Control Lab Week 3: Closed Loop ControlDocument14 pagesMotor Modeling and Position Control Lab Week 3: Closed Loop ControlJanett TrujilloNo ratings yet

- The Basics of Motion Control-Part 2Document3 pagesThe Basics of Motion Control-Part 2abduhalimNo ratings yet

- E&l Do2000Document32 pagesE&l Do2000Deming80% (5)

- Optimal Taper Tension ControlDocument12 pagesOptimal Taper Tension ControlDemingNo ratings yet

- E&L fx5030 ManualDocument10 pagesE&L fx5030 ManualDemingNo ratings yet

- Speed Synchronization of Web Winding Systems With Sliding Mode ControlDocument15 pagesSpeed Synchronization of Web Winding Systems With Sliding Mode ControlDemingNo ratings yet

- Steering Guide-Based Lateral Control For Roll2roll Printed ElectronicsDocument4 pagesSteering Guide-Based Lateral Control For Roll2roll Printed ElectronicsDemingNo ratings yet

- Building A Defect Free Reel On A Paper MachineDocument7 pagesBuilding A Defect Free Reel On A Paper MachineDemingNo ratings yet

- Importants of Film SlitingDocument4 pagesImportants of Film SlitingDemingNo ratings yet

- Dsre - M 2016Document120 pagesDsre - M 2016Mohit KohliNo ratings yet

- PM-9000 Operation Manual - 5.4Document243 pagesPM-9000 Operation Manual - 5.4Jhon Alfredo Torres Cadena100% (1)

- CAD - Pic: Prof Afonso Ferreira MiguelDocument18 pagesCAD - Pic: Prof Afonso Ferreira MiguelLevi GermanoNo ratings yet

- Digital Signal Processing Lab Manual Submitted By: Farzana Latif (08 TL 04)Document35 pagesDigital Signal Processing Lab Manual Submitted By: Farzana Latif (08 TL 04)khalidNo ratings yet

- Comparison of Outer Rotor Radial Flux and Axial Flux PM Motors For CMG ApplicationDocument6 pagesComparison of Outer Rotor Radial Flux and Axial Flux PM Motors For CMG ApplicationsosiNo ratings yet

- Electrical Systems: Scope of WorksDocument4 pagesElectrical Systems: Scope of WorksSaso SaberNo ratings yet

- VOYAGER3 - TED600B4E - Consolidated Customer PackageDocument14 pagesVOYAGER3 - TED600B4E - Consolidated Customer PackageairemexNo ratings yet

- 1 1 1 Ak GeneralsafetytestDocument4 pages1 1 1 Ak Generalsafetytestapi-290804719No ratings yet

- 8-Port Antenna with Integrated RET and 4.3-10 ConnectorsDocument2 pages8-Port Antenna with Integrated RET and 4.3-10 ConnectorsYarinaNo ratings yet

- 48W-29165-0 Using An Oscillocope and Function Generator To Measure Capacitor 4-24-2013 DPDocument5 pages48W-29165-0 Using An Oscillocope and Function Generator To Measure Capacitor 4-24-2013 DPOnofre DanielNo ratings yet

- Passive filter design fundamentalsDocument9 pagesPassive filter design fundamentalsH3C2No ratings yet

- DCL ManualDocument72 pagesDCL ManualSlow GamerzNo ratings yet

- Wlan x86 812.3Document7 pagesWlan x86 812.3ReturnLab Recyclers Pvt. Ltd.No ratings yet

- v100 Ku-to-Ka Convertible: Installation and Operation ManualDocument159 pagesv100 Ku-to-Ka Convertible: Installation and Operation ManualSergeyNo ratings yet

- S1L2-J1 - Technical Data SheetDocument9 pagesS1L2-J1 - Technical Data SheetthainarimeNo ratings yet

- Multilin 269 PlusDocument214 pagesMultilin 269 Plusjoticamario123100% (1)

- 180427ze - Ds - BTR 3 GKW-ENX C-Flex 50264-3-2 600 V - 10082eDocument2 pages180427ze - Ds - BTR 3 GKW-ENX C-Flex 50264-3-2 600 V - 10082eRava SatrianiNo ratings yet

- The Art and Science of Protective RelayingDocument9 pagesThe Art and Science of Protective RelayingsouvikNo ratings yet

- AC250 Data SheetDocument5 pagesAC250 Data SheetAshutosh SinghNo ratings yet

- XLS140-2 DatasheetDocument8 pagesXLS140-2 DatasheetAdriana UstarizNo ratings yet

- DataSheet SLS510 LC en 091201Document4 pagesDataSheet SLS510 LC en 091201Nguyễn Văn SơnNo ratings yet

- Patient Monitor Maintenance CheckDocument2 pagesPatient Monitor Maintenance CheckDickyNo ratings yet

- Mitsubishi Programmable Controllers MELSEC-Q Series (QnU) PDFDocument13 pagesMitsubishi Programmable Controllers MELSEC-Q Series (QnU) PDFjaimeasisaNo ratings yet

- Thyristors & Triacs - Ten Golden RulesDocument11 pagesThyristors & Triacs - Ten Golden RulesVlad ThalheimerNo ratings yet

- Fm357 eDocument485 pagesFm357 eRafaelNo ratings yet

- IITB EE NewDocument1 pageIITB EE NewPLAY LYRICSNo ratings yet