Professional Documents

Culture Documents

Ijset V2i2 2013 02

Uploaded by

vk100Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijset V2i2 2013 02

Uploaded by

vk100Copyright:

Available Formats

International Journal of Advanced Science, Engineering and Technology.

ISSN 2319-5924

Vol 2, Issue 2, 2013, pp 125-133

http://www.bipublication.com

REVIEW ON APPLICATIONS OF UASB TECHNOLOGY FOR

WASTEWATER TREATMENT

Mrunalini M. Powar

*

, Vijay S. Kore, Sunanda V. Kore and Girish S. Kulkarni

(Environmental Science and Technology) Department of technology,

Shivaji University, Kolhapur, India

*powar.mrunalini4@gmail.com

[Received-12/12/2012, Published-07/02/2013]

ABSTRACT:

Up-flow Anaerobic Sludge Blanket (UASB) reactor is one of the anaerobic process. In this anaerobic

treatment complex organic matter is get converted into methane gas through the stages like hydrolysis,

acidogenesis and methanogenesis. UASB is widely applicable for treating various types of wastewater.

UASB has advantages over aerobic treatment. In this present review applications of UASB are explained

for wastewater like sugar industry, distillery, dairy industry, slaughter house and high strength municipal

wastewater. Under this review removal efficiency of COD (Chemical Oxygen Demand) is studied for

various organic loading and Hydraulic Retention Time (HRT).

Keywords: UASB, Hydraulic Retention Time, Organic Loading Rate, Temperature, COD.

1. INTRODUCTION:

India facing severe problems of collection,

treatment and disposal of effluents due to

rapid industrialization and urbanization.

Two types of treatments can be done on

effluents i.e. Aerobic treatment and

Anaerobic treatment, but in aerobic

treatment external energy is required for

aeration also there is excess sludge

production in aerobic treatment. Aerobic

treatments are widely applicable for treating

high strength waste water. It does not

require external energy and it itself produces

the energy in the form of methane gas.

UASB is one of the anaerobic treatment

converts the waste water organic pollutants

into small amount of sludge and large

amount of biogas as a source of energy

(Hampannavar and Shivayogimath, 2010).

Responsible parameters for the good

performance of UASB are formation of

compact granular sludge which ensures high

Mrunalini M. Powar, et al. 126

specific methenogeric activities and superior

settling characteristics (Jinye et al., 2008).

UASB is applicable for treating variety of

industrial wastewater i.e. Sugar industry

waste water, dairy waste water, textile waste

water, slaughterhouse waste water, oil

industry waste water, potato processing

waste water, distillery waste water and

recent research indicate the feasibility of

UASB process in treatment of domestic

effluents also.

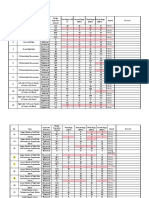

2. UASB process:

Mainly in there are four key biological and

chemical stages in UASB process i.e.

Hydrolysis, Acidogenesis, Acetogenesis and

Methanogenesis.

Fig.1 UASB process stages

Hydrolysis:

Mostly organic concentration of wastewater

is complex in nature. For the bacteria in

anaerobic digesters to access the energy

potential of the material, these complex

organic constituents should break down into

their smaller constituent parts. These

constituent parts, or monomers, such as

sugars, are readily available to other

bacteria. The process of breaking these

chains and dissolving the smaller molecules

into solution is called hydrolysis. Through

hydrolysis the complex organic

moleculesare broken down into simple

sugars, amino acids, and fatty acids. Acetate

and hydrogen produced in the first stages

can be used directly by methanogens. Other

molecules, such as volatile fatty acids with a

chain length greater than that of acetate must

first be catabolised into compounds that can

be directly used by methanogens.

Acidogenesis:

The biological process of acidogenesis

results in further breakdown of the

remaining components by acidogenic

(fermentative) bacteria. Here, vfas are

created, along with ammonia, carbon

Mrunalini M. Powar, et al. 127

dioxide, and hydrogen sulfide, as well as

other byproducts.

Acetogenesis :

The third stage is acetogenesis. Here,

simple molecules created through the

acidogenesis phase are further digested by

acetogens to produce largely acetic acid, as

well as carbon dioxide and hydrogen.

Methanogenesis:

The terminal stage of anaerobic digestion is

the biological process of methanogenesis.

Here, methanogens use the intermediate

products of the preceding stages and convert

them into methane, carbon dioxide, and

water. These components make up the

majority of the biogas emitted from the

system. Methanogenesis is sensitive to both

high and low pH and occurs between pH 6.5

and pH 8. The remaining, indigestible

material the microbes cannot use and any

dead bacterial remains constitute the

digestate.

A simplified generic chemical equation for

the overall processes outlined above is as

follows:

C

6

H

12

O

6

3CO

2

+ 3CH

4

3. UASB controlling factors:

3.1 pH

The pH value is significantly affected the

UASB reactor performance and stability. pH

for this treatment is between the range of

6.3-7.8. The change in pH of influent is

mainly an important factor for system

stability. Raising the pH value by adding

NaOH is also done to increase the ph up to

7.4 to obtain increasing in the gas

production, with decreasing in CO

2

production. (Habeeb et al., 2010)

Fig.2 Schematic diagram of UASB reactor

Mrunalini M. Powar, et al. 128

3.2 Mixing

Good attachment between biomass and

substrates is mainly attributed by mixing

process. Mixing gives more opportunities of

attachment by recycling biomass as well as

activating dead zones in sludge bed which is

mainly inhibited the phenomenon of

channelling Mixing can be achieved through

biomass recirculation, mechanical mixing, or

slurry recirculation. Rapid mixing is

considered undesirable mixing indicating that

it causes a biomass. (Habeeb et al., 2010)

3.3 Temperature

The efficiency of the anaerobic process is

highly dependent on reactor temperature. The

rate of degradation of organics is enhanced at

mesophilic temperatures. The mesophilic

temperature varies between 30-40C.

However, the effect of temperature is mainly

governed by various physical, chemical, and

biological processes taking place in the

reactor. A sharp drop in methane generation

appears as the reactor temperature exceeds

45C because of bacterial decay at higher

temperatures ranging from 45 to 65C. The

effect of temperature on the efficiency of the

anaerobic process is governed by the reactor

type as well. A decline in UASB efficiency at

low temperature can be explained due to

decreases in biological activity. (Yasar and

Tabinda, 2010)

3.4 HRT

The hydraulic retention time is significantly

considered as the key operating parameter

where its effectiveness is mainly controlling

the performance of UASB reactor. The HRT

is defined as the amount of time for which

the wastewater is retained in the reactor for

digestion and is computed by dividing the

volume of the reactor by the influent flow

rate. The UASB reactor gives high COD

removal at very short HRT. However, it is a

function of effluent characteristics, which

vary from industry to industry. (Yasar and

Tabinda, 2010)

4. Applications of UASB

4.1 Sugar Industry Wastewater:

This wastewater having ph 4.6 to 7.1, reddish

yellow liquid with COD 600 to 4380 mg/L

and BOD 300 to 2000 mg/L. Sugar industry

effluent when discharged in streams, rapid

depletion of oxygen due to biological

oxidation takes place and it emits the offensive

odor and affects on fish mortality (Rao and

Dutta, 1987).

Hampannavar and Shivyogimath studied the

paper on Anaerobic treatment of Sugar

Industry Wastewater by Up flow anaerobic

sludge blanket reactor at ambient

temperature. In this study lab scale UASB is

developed of volume 7.5 litres. The ambient

room temperature during the study period is

between 29 to 37

0

C. The reactor is started with

an OLR of 0.5g COD/ L. D and loaded up to

165g COD/ L. D. HRT 48 hrs is kept constant

at an OLR 0.5 5g COD/ L. D during start up.

Then OLR is increased from 0.5 to 1 within

Mrunalini M. Powar, et al. 129

decrease in HRT from 48 h to 24 h during first

35 days. Then further HRT is reduced from 24

h to 6 h with increase in OLR up to 16g

COD/L. D. Maximum COD removal

efficiency achieved is 89.5% and optimum

HRT is found 6 hrs. Maximum volumetric

biogas production is 4.66 L/L. d at OLR of 16

5 g COD/ L. d.

Nacheva et al., studied Treatment of cane

sugar mill wastewater in an up flow anaerobic

sludge bed reactor. Experimental work is

carried out in UASB reactor of volume 80 L

with effective volume of 50 L. Four organic

loadings are applied to the reactor i.e. 4, 8, 16

and 24 kg COD/m

3

.d. At OLR 4 kg

COD/m

3

.d, COD removal efficiency obtained

97% with good biogas production. As organic

loading increased further removal efficiency

initially decreased by 18% but after 10 days

period COD removal efficiency obtained 92-

96%. Organic loading up to 16 kg COD/m

3

.d

removal efficiencies obtained more than 90%.

At OLR 24 kg COD/m

3

.d COD removal

efficiency obtained is between 78-82%

because VFA concentration is increased with

high OLR.

4.2 Dairy Industry Wastewater:

Dairy waste water is generally organic in

nature. When dairy waste water discharged in

stream without any treatment a rapid

depletion of dissolved oxygen content of

stream occurs along the development of

sewage fungi at bottom of stream. Milk waste

becomes acidic due to decomposition of

lactose into lactic acid under anaerobic

condition. This results casein from waste

which further decompose highly odorous

black sludge. Gotmare et al., studied

Biomethanation of dairy wastewater through

UASB at mesophillic temperature range. In

this study UASB reactor is used with volume

of 120.12 m

3

. In this the digester efficiency

of treating dairy waste water at organic

loading rates is studying and its performance

is assessed by analyzing ph, dissolved COD,

BOD, TSS, VFA and biogas production. The

reactor achieved COD, BOD and TSS

removal efficiency obtained 87.06%, 94.50%

and 56.54%, respectively. The average gas

production and methane gas conversion at

optimum conditions is obtained 179.35 mg/l

and 125.55 mg/l respectively.

Gavala et al., studied Treatment of Dairy

wastewater Using an Up flow Anaerobic

Sludge Blanket Reactor. A 10 L UASB

reactor is developed of plexiglass for this

experimental work. Reactor is inoculated

with anaerobic mixed liquor from dairy

wastewater and glucose fed digesters. At

OLR of 6.2 g COD/ L. D and HRT of 6 d,

COD removal efficiency obtained up to 98%.

When OLR is increased to 7.5 g COD/ L. D,

the COD removal efficiency is reduced to 85-

90%. After this increase in OLR results in

decrease in COD removal efficiency and also

decrease in biogas production and ph value.

Therefore 6.2 g COD/ L. D OLR for UASB

reactor treating dairy wastewater is safe and it

Mrunalini M. Powar, et al. 130

can be increased to maximum of 7.5 g COD/

L. D.

4.2 Distillers grain Wastewater:

This waste water is acidic having ph 3 to 4.3

and high concentration of COD i.e. 90000 to

210000 mg/l, high BOD 45000 to 100000

mg/l and emits obnoxious odor when

discharged in waste streams gives immediate

discoloration and depletion of dissolved

oxygen posing serious threat to the organic

flora and fauna (Mane et al., 2006). Gao et

al., studied Performance evaluation of a

mesophilic up flow anaerobic sludge blanked

reactor in treating distillers grain waste

water. For this present study UASB reactor

of acrylic plastic is developed with working

capacity of 8.18 liters. During experimental

work temperature in the reactor was kept

37

0

C by heat exchanger. The reactor is

inoculated by seeding sludge from a

anaerobic digester in a sewage treatment

plant. OLR is increased firstly from 0.42 to

5.6 kg COD/m

3

.d at HRT of 2.5 day and

there is increase in COD removal efficiency

from 78.3 to 93.8% along with methane

production rate from 0.2 to 2.31 L CH

4

/L.d.

After OLR is increased extremely from 5.6 to

10.8 kg COD/m

3

.d there is decrease in COD

removal efficiency and methane production

rate and UFA accumulation in the effluent.

Further OLR is reduced to 1.8 kg COD/m

3

.d

after addition of sodium bicarbonate to the

influent. After successful start up 80 to 97.3

% COD removal, efficiency is achieved at

HRT 82 to 11 hrs with OLR 5 to 48.3 kg

COD/m

3

.d

4.4 High-Strength Municipal Wastewater:

Hossein et al., studied Optimizing OLR and

HRT in a UASB Reactor for pretreating High

Strength Municipal Wastewater. This

wastewater has pH between 7-8, COD in the

range 600-2400 mg/L, TSS in between 190-

250 mg/L, nitrate 4-25 mg/L. In this study a

lab scale UASB reactor is developed with

volume of 5 l. Different organic loadings are

done i.e. 3.6, 7.2, 10.8 and 14.4 kg

COD/m

3

.d. Hydraulic Retention Time (HRT)

is also varied like 3, 4, 5 and 6 hours. The

removal efficiency of COD, nitrate, sulfate

and TSS is investigated for determining the

optimum organic loading and HRT. The

removal efficiency of COD, sulfate and TSS

is obtained 80%, 80% and 70% respectively

at HRT of 4 hrs. COD removal efficiency is

maximum at organic loading range of 7.2 to

10.8 kg COD/m

3

.d. For this range COD

removal is about 85%. It represents optimum

organic loading range for the UASB reactor

is 7.2 to 10.8 kg COD/m

3

.d. Nitrate removal

efficiency is 80% at optimized organic

loading range.

Ruiz et al., studied Performance of and

biomass characterisation in a UASB Reactor

treating domestic waste water at ambient

temperature. Domestic waste water is

treated anaerobically in a laboratory-scale up

flow anaerobic sludge blanket digester, at

temperature 20C, at hydraulic retention

Mrunalini M. Powar, et al. 131

times of longer than 24 h. Active volume of

UASB reactor is 2 l and it is located in a

thermostat-controlled chamber at 20C.

Anaerobic sludge is used as seed in the

UASB reactor. At HRT 24 h the COD and SS

removal efficiencies remained practically

constant and higher than 85%. At first reactor

is operated at low organic loading and then

OLR is increased progressively up to 3 g

COD/l d, by increasing the flow rate with

decreasing the HRT down to 5 h. When HRT

reduced from 24 to 5 h, the COD removal

decreased from 85% to 53% and the SS

removal from 89% to 63%. The methane

recovered in the biogas ranged from 25% to

30% of the influent COD, increasing slightly

with the operational time. The average

methane content of the biogas obtained is

80%. The methane production recovered in

the gas phase reached 0.20 l CH4/l d at the

maximum OLR applied. The amount and the

methanogenic activity of the developed

anaerobic sludge appeared to be the main

efficiency-limiting factor of the UASB

performance.

4.5 Slaughterhouse Wastewater:

Torkian et al., studied Performance

evaluation of a UASB system for treating

slaughterhouse wastewater. In this present

study pilot scale UASB is developed of

effective volume 500 liters for the treatment

of slaughterhouse wastewater. The reactor is

inoculated with 200 liter sludge from a

municipal anaerobic digester. Removal

efficiency of COD occurred up to 80% at an

OLR 6.9 kg COD/m

3

.d. Further OLR is

increased to 14.2 kg COD/m

3

.d for 109-130

days and 25 kg COD/m

3

.d for days 131-143

did not cause any reduction in performance

and COD removal efficiency 83 and 87%

obtained respectively at temperature 31-35

0

C.

Gas production is 50 L/d in the initial phase

at temperature 15

0

C and 900 L/d at 25

0

C.

High OLR can be tolerated by the UASB

system for short period of time and for stable

operations OLR should be maintained below

20 kg COD/m

3

.d. Up flow velocity is close to

1 m/hr to improve microbial activity and

HRT is in between 6-8 hr for getting the

sufficient contact time between wastewater

and microbial population.

Nacheva et al., studied Treatment of

slaughterhouse wastewater in up flow

anaerobic sludge blanket reactor. In this

study up flow anaerobic sludge blanket

reactor is operated at ambient temperature i.

E 20.9-25.2C The experimental work is

carried out in a reactor with 15 L effective

volume. Four organic loads are applied to

reactor and the process performance is

evaluated. The COD removal rate increased

with the load rise from 4 to 15 kg COD/m

3

.d.

Removal efficiencies of 90% were obtained

with a load of 15 kg COD/m

3

.d. At first two

stages in proportion during the first two

stages due to the low up flow velocities the

entrapment of suspended solids in the sludge

Mrunalini M. Powar, et al. 132

blanket is greater. The Wastewater alkalinity

of the reactor was enough therefore the

concentrations of the volatile fatty acids is

not high. The yield coefficient of methane

production increased with the load rise,

reaching 0.266 m

3

/kg COD (removed) at 15

kg COD/m

3

.d organic load. The UASB

reactor is a good option for the biological

treatment of slaughterhouse wastewater.

5. CONCLUSION:

UASB reactor is feasible for treating variety

of wastewater. Performance of UASB reactor

is get affected by ph, HRT, OLR, temperature

and VFA to alkalinity ratio. Proper HRT

should be provided to give sufficient contact

time between wastewater and bacteria. For

avoiding VFA accumulation in UASB reactor

and for getting effective biogas production

sodium bicarbonate alkalinity should be

provided. VFA to alkalinity ratio should

maintained between 0.5 - 0.8 for good

performance of UASB reactor.

REFERENCES:

1. Agrawal Lalit K., Hideki Harada and Hiryuki

Okui (1997), Treatment of dilute wastewater

in a UASB reactor at a moderate temperature:

performance aspects, Journal of

fermentation and Bioengineering, 83(2).

2. Aiyuk sunny, Philip Odonkor, Nkoebe

Theko, Adrianus van Haandel and Willy

Verstraete (2010), Technical problems

ensuring from UASB reactor application in

domestic wastewater treatment without ore-

treatment, International Journal of

Environmental Science and Development,

1(5).

3. Banu J. R., Kaliappan S. And Yeom I. T.

(2007), Treatment of domestic wastewater

using up flow anaerobic sludge blanket

reactor, International Journal of

Environmental Science Technology, 4(3).

4. Behling E., Diaz A., Colina G., Herrera M.,

Guirrez E., Chacin E., Fernandez N. And

Forster C.F. (1997),Domestic wastewater

treatment using a UASB reactor,

Bioresource Technology, 61.

5. Elmitwalli T. A., Shalabi M., Wendland C.

And Otterpohi R. (2007), Grey water

treatment in UASB reactor at ambient

temperature, Water Science and

Technology, 55(7).

6. Gotmare Monali, Dhoble R. M. And Puttule

A. P. (2011), Biomethanation of dairy

wastewater through UASB at mesophillic

temperature range, International Journal of

Advanced Engineering Sciences and

Technologies, 8(1).

7. Gavala H. N., Kopsinis H., Skiadas V.,

Stanatelatou K. And Lyberatos G. (1998),

Treatment of dairy wastewater using up flow

anaerobic sludge blanket reactor, Journal of

Agricultural Engineering Research, 73.

8. Hampannavar U.S. and Shivayogimath C.B.

(2010), Anaerobic treatment of sugar

industry wastewater by Up flow anaerobic

sludge blanket reactor at ambient

temperature, International Journal of

Environmental Sciences, 1(4).

9. Hazrati and Hossein and shayegan Jalal

(2011), Optimizing OLR and HRT in a

UASB Reactor for pretreating High- Strength

Municipal Wastewater, Chemical

Engineering Transactions, 24.

10. Habeeb S. A., Aziz Bin Abdul Latiff AB.

And Ahmad Zulkifli Bin (2010), Canadian

Journal on Environmental, Construction and

Civil Engineering, 1(3).

Mrunalini M. Powar, et al. 133

11. Jinye Li, Baolan Hu, Ping Zheng, Mahmood

Qaisar and Lingling Mei (2008),

Filamentous granular sludge bulking in a

laboratory scale UASB reactor, Bioresource

Technology, 99.

12. Manhokwe S., Parawira W. And Tekere M.

(2009), An evaluation of a mesophilic

reactor for treating wastewater from a

Zimbabwean potato- processing plant,

African Journal of Environmental Science

Technology, 3(4).

13. Mane J. D., Modi S., Nagawade S., Phadnis

S. P. And Bhandari V. M. (2006), Treatment

of spentwash using modified bagasse and

colour removal studies, Bioresource

Technology, 97.

14. Nacheva P. Mijaylova, Chavez G. Moeller,

Chacon J. Matias and Chul A. Canul (2009),

Treatment of cane sugar mill wastewater in

an up flow anaerobic sludge bed reactor,

Water Science and Technology.

15. Nacheva PM., Pantoja MR., and Serrano EA.

(2011), Treatment of

Slaughter house wastewater in up flow anaerobic

sludge blanket reactor, Water Science and

Technology, 63(5).

16. Neena C., Ambily P.S. and Jisha M. S.

(2007), Anaerobic degradation of coconut

husk leachate using UASB reactor, Journal

of Environmental Biology, 28(3).

17. Najafpour G. D., Hashmiyeh B.A., Asadi M.

And Ghasemi M.B. (2008), Biological

treatment of dairy wastewater in an up flow

anaerobic sludge- fixed film bioreactor,

Journal of Agricultural and Environmental

Science, 4(2).

18. Ravindranath E., Kalyanaraman Chitra,

Begum Shamshath S. And Gopalkrishnan

Navaneetha A. (2010), Effect of

recirculation rate on anaerobic treatment of

flieshing using UASB reactor with recovery

of energy, Journal of Scientific and

Industrial Research, 69.

19. Ruiz I., Soto M., Veiga MC., Ligero P., Vega

A. And Blzquez R. (1998), Performance of

and biomass characterisation in a UASB

reactor treating domestic waste water at

ambient temperature, Water Science and

Technology, 24(3).

20. Saatci Y., Arslan E. I. And Konar V. (2003),

Removal of total lipids and fatty acids from

sunflower oil effluent by UASB reactor,

Bioresource Technology, 87.

21. Soto M. (1997), Sludge granulation in

UASB digesters treating low strength

wastewaters at mesophilic and psychrophilic

temperatures, Environ Technology.

22. Torkian A., Amin M.M, Movahedian H.,

Hashmiyan S.J. and Salehi M.S. (2002),

Performance evaluation of a UASB system

for treating slaughterhouse wastewater,

Scientia Iranica, 9(2).

23. Yasar Abdullah and Tabinda Amtul Bari

(2010), Anaerobic Treatment of Industrial

Wastewater by UASB Reactor Integrated

with Chemical Oxidation Processes; an

Overview, Polish Journal of Environmental

Studies, 19(5).

24. Metcalf and Eddy, Wastewater Engineering

treatment and reuse, fourth edition, (2003).

25. Rao M.N. and Datta A.K., Wastewater

treatment, second edition, (1987).

26. American Public Health Association,

Standard Methods for the Examination of

water and Wastewater, Twenty first edition

Washington D.C., (2005).

27. Peavy H.S., Rowe D.R. and Tchobanoglous

G., Environmental Engineering, mcgraw

Hill, Singapore, (1987).

28. Maithi S.K., Handbook of Methods in

Environmental Studies, Second edition,

(2004).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- New Microsoft Office Excel 2007 WorkbookDocument1 pageNew Microsoft Office Excel 2007 WorkbookRahul BagraitNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Follow The Schedule As Per Given Guideline Without Fail. Prof. V.R. Kasar Subject Teacher/GuideDocument2 pagesFollow The Schedule As Per Given Guideline Without Fail. Prof. V.R. Kasar Subject Teacher/Guidevk100No ratings yet

- Muncipal Paper 2018Document39 pagesMuncipal Paper 2018vk100No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- RAT SpecimenTestPaperDocument6 pagesRAT SpecimenTestPaperPrasad KrishnamurthyNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- JSA PlansheetDocument4 pagesJSA Plansheetvk100No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- TRTI Notification PDFDocument1 pageTRTI Notification PDFvk100No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 2017 Monthly CalendarDocument12 pages2017 Monthly CalendarMuhamad AsriNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Civil Event Details-Shodh2018Document4 pagesCivil Event Details-Shodh2018vk100No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Sr. No. Item/Particulars Material Required Qty Actual QtyDocument11 pagesSr. No. Item/Particulars Material Required Qty Actual Qtyvk100No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- External Optical Level (2-Peg Test) SurveyDocument7 pagesExternal Optical Level (2-Peg Test) Surveyvk100No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Se-Civil Sem3 BMC Dec17Document1 pageSe-Civil Sem3 BMC Dec17vk100No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Paper191257 1263Document7 pagesPaper191257 1263vk100No ratings yet

- Planning of CityDocument41 pagesPlanning of CityMd.imthiyaz93% (14)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Naac 17 IndexDocument2 pagesNaac 17 Indexvk100No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Upflow Anaerobic Sludge Blanket - UASB - Reactor in Wastewater TreatmentDocument8 pagesUpflow Anaerobic Sludge Blanket - UASB - Reactor in Wastewater TreatmentMarllon LobatoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- CE ESE Objective Volume-1 (2017)Document12 pagesCE ESE Objective Volume-1 (2017)vk100No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 2017 Monthly CalendarDocument12 pages2017 Monthly CalendarMuhamad AsriNo ratings yet

- Laboratory Manual For The Microbiological Analyses of Public Drinking Water 2001Document74 pagesLaboratory Manual For The Microbiological Analyses of Public Drinking Water 2001vk100No ratings yet

- Capr I En6273Document45 pagesCapr I En6273vk100No ratings yet

- CESA LetterDocument1 pageCESA Lettervk100No ratings yet

- M21L35Document14 pagesM21L35vk100No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Studies On Treatment of Low-Strength Effluents by UASB Reactor and Its ApplicationDocument5 pagesStudies On Treatment of Low-Strength Effluents by UASB Reactor and Its Applicationadaneshi0% (1)

- Ijens 1117 HatwarDocument4 pagesIjens 1117 Hatwarvk100100% (1)

- Auto Cad ListDocument6 pagesAuto Cad Listvk100No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Laboratory Procedures For Analysis of Exploration & Production WasteDocument39 pagesLaboratory Procedures For Analysis of Exploration & Production Wastevk100No ratings yet

- 101007Document9 pages101007vk100No ratings yet

- 21 Anaerobic ProcessesDocument34 pages21 Anaerobic Processesvk100No ratings yet

- CertificateDocument1 pageCertificatevk100No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Chem E11 M3Document32 pagesChem E11 M3vk100No ratings yet

- American JournoulDocument1 pageAmerican Journoulvk100No ratings yet

- Oracle Fusion Financials Set Up Journal ApprovalsDocument64 pagesOracle Fusion Financials Set Up Journal Approvalssohaibmuzaffar0070% (3)

- Material Submittal R0-BMS - 10 Schools PDFDocument216 pagesMaterial Submittal R0-BMS - 10 Schools PDFElektrikal InhinyeroNo ratings yet

- Expansion Indicator Boiler #1Document6 pagesExpansion Indicator Boiler #1Muhammad AbyNo ratings yet

- SolarDocument4 pagesSolarShweta RawatNo ratings yet

- Thermal Modeling and Design Considerations of Lithium-Ion BatteriesDocument8 pagesThermal Modeling and Design Considerations of Lithium-Ion BatteriesVarun Gupta100% (1)

- Terms Def en It IonDocument29 pagesTerms Def en It IonVichu Kumar KumarNo ratings yet

- Working of Fingerprint ScannerDocument5 pagesWorking of Fingerprint ScannerSahana BalasubramanianNo ratings yet

- How To Get A Non-Professional Driver's License in The Philippines 2014Document7 pagesHow To Get A Non-Professional Driver's License in The Philippines 2014rkris88No ratings yet

- Hotel Cleaning Equipment Used byDocument9 pagesHotel Cleaning Equipment Used byLeonardo ViridisNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 6090 Uv Printer Operation Manual - BlackDocument26 pages6090 Uv Printer Operation Manual - BlackSonia NaickerNo ratings yet

- Gujarat Technological University: SUBJECT NAME: Computer Aided Manufacturing SUBJECT CODE: 2171903 BE Semester VIIDocument4 pagesGujarat Technological University: SUBJECT NAME: Computer Aided Manufacturing SUBJECT CODE: 2171903 BE Semester VIIKrupal VithlaniNo ratings yet

- Production and Active Pharmaceutical Ingredients 5EEC Group 1Document10 pagesProduction and Active Pharmaceutical Ingredients 5EEC Group 1Derrick RamosNo ratings yet

- 3CP.1.3 PaperDocument4 pages3CP.1.3 PaperAlexander ChekalinNo ratings yet

- 108 Names English Ucchista Ganapati SanskritDocument5 pages108 Names English Ucchista Ganapati Sanskritakshay patriNo ratings yet

- GSECL - Daily Progress Report 11.9.21Document2 pagesGSECL - Daily Progress Report 11.9.21krishna mohanNo ratings yet

- Degassed Cation Conductivity MeasurementDocument11 pagesDegassed Cation Conductivity MeasurementPhạm Nhật MinhNo ratings yet

- CIS Kubernetes Benchmark v1.4.1Document254 pagesCIS Kubernetes Benchmark v1.4.1Anonymous 4uxmV5Z4oNo ratings yet

- Aa1a32 02Document3 pagesAa1a32 02MramirezNo ratings yet

- Polymer and Web ComponentsDocument26 pagesPolymer and Web ComponentsAdjetey Adjei-laryeaNo ratings yet

- Serdes HandbookDocument98 pagesSerdes HandbookRamesh YadavNo ratings yet

- Plastic, Rubber & Recycling IndustryDocument7 pagesPlastic, Rubber & Recycling IndustryPassionate_to_LearnNo ratings yet

- Electrical Equipment in Hazardous LocationsDocument41 pagesElectrical Equipment in Hazardous LocationsSAYEDNo ratings yet

- Guide To Port Entry CD: Frequently Asked Questions (FAQ)Document6 pagesGuide To Port Entry CD: Frequently Asked Questions (FAQ)Gonçalo CruzeiroNo ratings yet

- Best Practices Nightlife 2d Ed 2011Document30 pagesBest Practices Nightlife 2d Ed 2011johnd7463No ratings yet

- Introduction To Weapon & AmmunitionDocument141 pagesIntroduction To Weapon & Ammunitionk2kkhanna105100% (1)

- Astm f1554Document3 pagesAstm f1554ingsabrinaNo ratings yet

- RC4 Vector Key Based Conditional Access System in Pay-TV Broadcasting SystemDocument5 pagesRC4 Vector Key Based Conditional Access System in Pay-TV Broadcasting SystemAlad Manoj PeterNo ratings yet

- Hemi Spherical Vs Ellipsoidal Vs Tori SphericalDocument5 pagesHemi Spherical Vs Ellipsoidal Vs Tori SphericalkingstonNo ratings yet

- Drishtee DevelopmentDocument34 pagesDrishtee Developmenttannu_11No ratings yet

- GrabBee HD ManualDocument9 pagesGrabBee HD ManualAndrea Lissette Perez FuentesNo ratings yet

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)