Professional Documents

Culture Documents

Uniform Force

Uploaded by

arnoldistunoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uniform Force

Uploaded by

arnoldistunoCopyright:

Available Formats

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 1

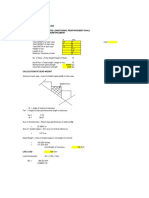

H, the horizontal component of the

brace force acting at the column and beam cen-

terlines is resisted by an axial force in the beam

and/or a transfer force acting through the

column at the beam centerline. ( not shown )

V, the vertical component of the brace

force acting at the column centerline is resisted

at the face of the column by a gusset force and a

beam force acting together such that;

V = Vc + Vb

The moment due to eccentricity ec

is resisted by an assumed couple Hc acting at

beam and gusset plate centerlines such that;

V x ec must equal Hc x (eb + )

ie Hc = V (

ec

/

eb +

)

= P cos(

ec

/

eb +

)

= P(

eb +

/

r

) (

ec

/

eb +

)

= (

ec

/

r

) P

and Hb = H-Hc = P sin (

ec

/

r

) P

= P [

( ec +

)

/

r

- (

ec

/

r

) ]

= (

/

r

) P

Engineering Instruction

Bracing Connection Design Forces

issue date 11/20/00 rev. 0

If V and Rb are distributed, considering brace T or C , so that all bolts in the column flange have equal vertical loads;

V/bolt = (V + Rb) / ( total number of bolts )

Vcx = V/bolt x ( number of bolts gusset to column )

Vbx = V/bolt x (number of bolts beam to column)

Vb = V Vcx

then from statics

Mb = Vcx (

W

/

2

+ gap )-V (

W

/

2

+ gap - ) -b(H Hc )

Notes: 1. Manipulating the gusset plate width to make Mb zero (see Uniform Force Method below ) for brace in

tension will not make it zero for brace in compression .

2. The space required for the brace to gusset connection usually dictates minimum gusset width and the gusset

should be made longer if that will make a single pass (5/16 ) fillet weld work.

3. Gusset plate thickness should be comparable to web thickness considering the grades of steel used.

4. Beam webs should be filled with bolts to make compact and economical connections.

5. Connection angle thickness will often be controlled by prying on the outstanding leg from Hc.

6. For brace connection to column web let ec and Hc equal zero.

P, ec, eb & are Given

tan = (ec + )/(eb + b)

= (eb + b) tan - ec

b= (gusset height )/2

W = width of gusset plate

r =w (ec + )

2

+ (eb + b)

2

Gap = gusset plate setback from

column flange ( in typical )

P

V=Pcos

H=Psin

Vcx

Hc

Hb

Vb

Hc

Vbx

b

eb

ec

o

A

r

Mb

gap

b

W

/

2

Rb

H

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 2

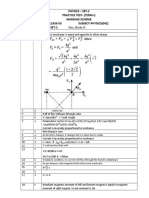

The Uniform Force Method

1. Ideal Geometry Mb = 0

Consider a FBD of the Gusset Plate

And the geometry as shown

1. Moment about o

Vc = Hb

or

Hb =

(Vc

)

/

2. H = 0

Hb + Hc = H = [

(ec +

)

/

r

] P

3. V = 0

Vb + Vc = V = [

(eb +

)

/

r

] P

Consider a FBD of the Beam

4. M

A

= 0

Vb = Hb eb

or

Vb =

(Hb eb )

/

Substituting 4 into 3:

(Hb eb )

/

+ Vc = [

(eb +

)

/

r

] P

Substituting From 1:

Vc (

/

) (

eb

/

) + Vc = ( eb + )(

P

/r )

Vc (

eb

/

+ 1 ) = ( eb + )(

P

/r )

So:

Vc = ( eb + )(

P

/r ) / (

eb

/

+ 1 ) = (

/

r

) P

Vb = [

(eb + )

/

r

] P Vc = [(eb + )/r] P = (

eb

/

r

) P

Hb = Vb / eb = (

eb

/

r

) P/eb = (

/

r

) P

Hc = [

(ec + )

/

r

] P-Hb = [

(ec + )

/

r

- /

r

]P = (

ec

/

r

) P

P

V

H

Vc

Hc

Hb

Vb

Hc

Vb

b

eb

ec

o

A

r

Mb

Note

P, ec, eb & are Given

b= ( gusset plate height) / 2

Choosing b defines for Mb = 0

= ( gusset plate width ) / 2 + gap

r =w (ec + )

2

+ (eb + b)

2

gap

Note all are functions of

geometry only

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 3

The Uniform Force Method

2. Non Ideal Geometry Mb 0

Let all remain as in case 1 except W/2

Consider a FBD of the Gusset Plate

And the geometry as shown

1. Moment about o

Vc = Hb + Vb(W/2 - ) + Mb

but from case 1

Vc = Hb

so

Mb = Vb(W/2 - )

And as in Case 1

Vc = (

/

r

) P

Vb = (

eb

/

r

) P Note all are functions

of geometry only

Hb = (

/

r

) P

Hc = (

ec

/

r

) P

P

V

H

Vc

Hc

Hb

Vb

Hc

Vb

b

eb

ec

o

A

r

Mb

gap

W

/

2

Note

P, ec, eb & are Given

b= ( gusset plate height) / 2

Choosing b defines for Mb = 0

In this case

a ( gusset plate width ) / 2 + gap

r =w (ec + )

2

+ (eb + b)

2

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 4

The Uniform Force Method

3. Non Ideal Geometry

Mb 0 and part of Vb transferred to column

Let all else remain as in case 2

Consider a FBD of the Gusset Plate

And the geometry as shown

1. Vertical Force at center of gusset =

Vb( 1-% ) = V (Vc + %Vb )

Moment at center of gusset =

Hc + (Vc + %Vb )( W/2 + gap ) - Hb-V( W/2 + gap- )

When % = 0 and (W/2 + gap) = M = 0

ie 0 = Hc b + Vc - Hb

Subtracting

M = Vc(W/2 + gap ) + % Vb( W/2 + gap ) - V( W/2 + gap )

= % Vb( W/2 + gap) - Vb( W/2 + gap )

Vcol = (

/

r

) P + % (

eb

/

r

) P

Vb = (1 %) (

eb

/

r

) P

Hb = (

/

r

) P

Hc = (

ec

/

r

) P

P

V

H

V

c

+

%

V

b

Hc

Hb

Vb(1-%)

Hc

Vb

b

eb

ec

o

A

r

Mb

gap

W

/

2

Note

P, ec, eb & are Given

b= ( gusset plate height) / 2

Choosing b defines for Mb = 0

In this case

a ( gusset plate width ) / 2 + gap

r =w (ec + )

2

+ (eb + b)

2

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 5

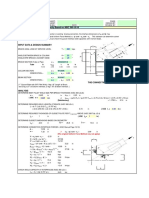

Column depth = 12.71 in. ec = column depth / 2 = 6.355 in

Web thickness = .55 in. eb = from top of flange to W.P. = 9

a = ( eb +b)tan - ec = 15.53

Beam depth = 18.11 in. b = 10.5 in. = plate height @ col. / 2

Flange width = 7.53 in. tan =H / V =168/149.7

Flange thickness = .63 in. = 48.296

Web thickness = .39 in. r = w (ec + )

2

+ (eb + b)

2

= 29.31

k = 1.3125 gap = .5 in.

k1 = .8125 W = gusset plate width = 26 in.

Connection material Fy = 36 Weld sizes shown in 16ths

Pass through load = 0 Bolted faying surfaces class A

Bracing Connection Design Forces

Hc = (

ec

/

r

) P = (6.355 / 29.31 ) ( 225) = 48.78 kips

Hb = (

/

r

) P = (15.53 /29.31 ) ( 225) = 119.21 kips

Hc + Hb = 167.99 kips = H = 168 KIPS

V/bolt = ( 149.7 - 18 ) / 22 = 5.986

kips

/

bolt

Vcx = 5.986 x 12 = 71.83 kips Vbx = 5.986 x 10 = 59.86 kips

Vb = V Vcx = (149.7 71.83 ) = 77.87 kips

Mb = Vcx (

W

/

2

+ gap)-V (

W

/

2

+ gap - ) -b(H Hc )

= 71.83(26/2 + .5 ) -149.7(26/2 + .5 - 15.53 ) - 10.5( 168 48.78 )

= 969.705 + 303.891 1251.81 = 21.79 in-kips

TS 6 x 6 x 1/2

12

10

11

/

16

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 6

Stresses along edge of gusset plate at beam flange

Gusset plate thickness = .625 inch.

Shear force = fv = Hb / width of plate = 119.21 / 26 = 4.585 kips / inch

Normal force = fn = Vb / width of plate = 77.87 / 26 = 2.995 kips / inch

and fb = Mb * 6 / (plate width)

2

= ( 21.79 x 6 ) / (26 )

2

= 0.193 kips / inch

Shear stress in gusset = fv / thickness = 4.585 / .625 = 7.336 ksi MUST BE <= .4Fy =.4 x 36 = 14.4 ksi

Normal stress in gusset = (fn + fb) / thick = (2.995 + .193 ) / .625 = 5.101 ksi MUST BE <= .6Fy = 21.6 ksi

Weld

Peak force on weld = f

peak

= w (fn + fb)

2

+ fv

2

= w (2.995 +0.193 )

2

+(4.585 )

2

=5.584 kips / inch

Average force on weld = f

avg

= w (

fn

2

+ fb

)

2

+ fv

2

= w[ (2.995 + 0.193 ) / 2]

2

+ ( 4.585)

2

= 5.530 kips / inch

Required weld size is the GREATER of f

peak

/(.928 * 2 welds) = 5.584 / ( .928 * 2 ) = 3.0/16ths

or 1.4 f

avg

/(.928 * 2 welds) = (1.4 x 5.53 ) / (.928* 2 ) = 4.2/16ths

( USE 5/16 th FILLET )

Normal stresses on beam web at end of gusset plate

Normal force at either end of gusset

= ( Vb / Length ) + or - ( Mb * 6 / Length

2

)

where Length = Width of Gusset + 2.5 x k = 26 +2.5 x 1.3125 =29.281 in.

= 77.87 / 29.281 - (21.79 x 6 / 29.281

2

) = 2.507 kips/inch @ LEFT END

= 77.87 / 29.281 + (21.79 x 6 / 29.281

2

) = 2.811 kips/inch @ RIGHT END

Maximum normal stress is GREATER of above / web thickness

= 2.811 / .39 = 7.209 ksi MUST BE <= .66 Fy =.66 x 50 = 33 ksi

Crippling of web under compression from gusset

Localized compression load on web due to gusset forces above = 0 kips

(tension at both ends of gusset for this loading condition )

check is not applicable

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 7

Horizontal force on beam from gusset

Horizontal. shear capacity of web plus axial capacity of flange must be greater than Hb

.4Fy x ( Gusset Width + 2.5 x k ) x Web Thick + .6Fy x Area of Flange must be greater than 119.21 kips

.4 x 50 x ( 26 + 2.5 x 1.3125 ) x.39 + .6 x 50 x 7.53 x .63 =228.39 + 142.32 = 370.71 kips

which is greater than 119.21 kips

Shear in column web

Column web shear capacity must be greater than Hc

.4Fy x Column depth x column web thickness must be greater than or equal to 48.78 kips

.4 x 50 x 12.71 x .55 = 139.81 kips which is greater than 48.78 kips

IF THERE IS A BRACING CONNECTION ON THE FAR SIDE OF THE COLUMN,

Hc FROM THAT CONNECTION MAY BE ADDITIVE TO THE ABOVE.

THE TOTAL MUST BE CHECKED AGAINST THE COLUMN CAPACITY.

WEB DOUBLERS MAY BE REQUIRED

Welded TS 6 x 6 x 1/2 diagonal

Welds on longitudinal sides of slotted TS 6 x 6 x 1/2, both sides of gusset plate, 4 welds in all

Length of each fillet weld = 13 in. ( MINIMUM LENGTH = TS WIDTH = 6 in. )

Total length of fillet weld = 4 x 13 = 52 in.

Required fillet weld size = brace load / ( 0.928 x total length of weld )

= 225 / ( 0.928 x 52 ) = 4.66 16ths ( USE 5/16 TH FILLET )

Whitmore width = width of TS + 2tan30 x ( length of each weld ) = 6 + 2tan30 ( 13 ) = 21.01 in.

Tension capacity of whitmore section = whitmore width x gusset thickness x .6 Fy

= 21.01 x .625 x .6 x 36

= 283.64 kips > 225 kips OK

Block shear capacity of gusset plate around weld and end of TS 6 x 6 x 1/2 is greater of

[( Av x .4 Fy) + ( At x .5Fu)] = [ (2 x 13 x .625 x .4 x 36 ) + ( 6 x .625 x .5 x 58 )] = 234 + 108.75 = 342.75 kips

or

[( Av x .3 Fu) + ( At x .6Fy)] = [(2 x 13 x .625 x .3 x 58 ) + ( 6 x .625 x .6 x 36 )] = 282.75 + 81 = 363.75 kips

But not more than 4 x length of each weld x gusset thickness x .4Fy = 4 x 13 x .625 x .4 x 36 = 468 kips

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 8

Welds angles to gusset plate

Design is by vector analysis

Horizontal length of weld = angle leg size 1/2 in. gap = 3

1

/

2

1

/

2

= 3 in.

Vertical length of weld = angle length = 18 in.

Total weld length = 3 + 18 + 3 = 24 in.

Polar moment of inertia of weld profile = (2 x 3 + 18 )

3

/12 - ( 3

2

( 3 +18 )

2

/ ( 2 x 3 + 18 )

= 1152 165.375 = 986.625 in

3

Centroid of weld from vertical leg = 3

2

/ (2 x 3 + 18 ) = 0.375 in.

Moment on weld = Vcx x (angle leg size centroid distance ) = 71.83 x ( 3 -.375 )

= 224.77 in.-kips

Tensile force at edge of plate = Vcx / total length + moment x ( horizontal weld length centroid distance ) / Ip

fn = 71.83 / 24 + 224.77x (3 .375 ) / 986.625 = 2.99 + 0.60

= 3.59 kips / in.

Shear force at edge of plate = Hc / total weld length + moment x ( vertical length / 2 ) / Ip

fv = 48.78 / 24 + 224.77 x ( 18/2 )/ 986.625

= 2.03 + 2.05 = 4.08 kips / in.

Required fillet weld size = w ( 3.59)

2

+ ( 4.08 )

2

/ ( 0.928 x 2 ) = 5.43/ ( 0.928 x 2 )

= 2.93 16ths ( use in. minimum size for 5/8 material )

Shear stress in gusset plate @ toe of angles = Vcx / total length ( moment x centroid distance ) / Ip

fv = 71.83 /24 - (224.77 x .375 ) / 986.625

= 2.99 - 0.08 = 2.90 Kips / in.

Minimum required gusset plate thickness

fn / .6Fy = 3.59 / .6 x 36 = 0.166 in.

fv / .4Fy = 4.08 / .4 x 36 = 0.283 in.

fv / .4Fy = 2.90 / .4 x 36 = 0.201 in. ( OK 5/8 in plate used )

Bolts and angles ( gusset plate to column )

12 - dia. A325N @ 3 inches c/c, gage = 6

Tension per bolt = 48.78 / 12 = 4.06 kips

Shear per bolt = 71.83 / 12 = 5.98 kips

Check prying on column flange b = 2.725 in.

( ref. AISC 9th edition pg 4-90 ) a = 2.3125 in. < 1.25 x ( b col. flg. ) = 1.25 x (bf gage ) / 2

=1.25 x ( 12.16 6 ) /2 = 3.85 in. OK

< 1.25 x ( b angles )

= 1.25 x (2 x angle leg + plate gage ) / 2

= 1.25 x ( 2 x 5 + .625 6 ) /2

= 2.89 in. OK

p = 3 in. < 5 x bolt diameter = 3.75 in. OK

Bc = 4.06 kips; ie tension plus prying

Permissible Shear on N type bolts = 9.07 kips > 5.98 kips Ok

Permissible Shear on X type bolts = 12.96 kips > 5.98 kips Ok

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 9

Independent of prying, the permissible shear/bolt

in slip critical connections = 6.42 kips > 5.98 kips Ok

Required minimum bolt spacing in column flange = 2 x ( shear / bolt ) / ( Fu x tfcolumn ) + ( bolt dia ) / 2

= 2 x ( 5.98 ) / ( 65 x 0.900 ) + .75 / 2

= 0.204 +.375 = 0.579 in. OK

Bearing stress of bolts on column flange = ( shear / bolt ) / ( tfcolumn x bolt dia )

= 5.98 / ( 0.900 x .75 )

= 8.85 ksi < 1.2 Fu = 1.2 x 65 = 78 ksi OK

Check prying on angles b = 2.0625 inch.

a = as above

p = 3 in. < 5 x bolt diameter = 3.75 in.

Bc = 4.66 kips; ie tension plus prying

Permissible Shear on N type bolts = 9.00 kips > 5.98 kips Ok

Permissible Shear on X type bolts = 12.87 kips > 5.98 kips Ok

Independent of prying, the permissible shear/bolt

in slip critical connections = 6.42 kips > 5.98 kips Ok

Required minimum bolt spacing in angles = 2 x ( shear / bolt ) / ( Fu x tangle ) + ( bolt dia ) / 2

= 2 x ( 5.98 ) / ( 58 x 0.625 ) + .75 / 2

= 0.330 +.375 = 0.705 in. OK

Bearing stress of bolts on angles = ( shear / bolt ) / ( tangle x bolt dia )

= 5.98 / ( 0..625 x .75 )

= 12.75 ksi < 1.2 Fu = 1.2 x 58 = 69.6 ksi OK

Bolt end distance on angle = 1.5 in. > 1.5 x bolt dia. = 1.5 x .75 =1.125 in. OK

Angle shear Total shear = w Vcx

2

+ Hc

2

= w ( 71.83 )

2

+ ( 48.78 )

2

= 86.82 kips

Net area = 2 x t (angle length no. rows x ( bolt dia +1/16))

= 2 x .625 x ( 18 6 x ( 3/4 + 1/16 ))

= 16.406 in.

2

Gross area = 2 x t x angle length = 2 x .625 x 18

= 22.50 in.2

Net shear = 86.82 / 14.406

= 5.29 ksi < .3Fu = .3 x 58 = 17.4 ksi OK

Gross shear = 86.82 / 22.5

= 3.86 ksi < .4Fy = .4 x 36 = 14.4 ksi OK

Bolts and angles ( beam web to column )

10 - dia. A325N @ 3 inches c/c, gage = 6

Tension per bolt = 0 kips ( for brace in tension loading condition )

Shear per bolt = 5.98 kips ( bolt loads were made equal in gusset and beam )

No prying check required for this loading condition

Permissible Shear on N type bolts = 9.28 > 5.98 kips Ok

Permissible Shear on X type bolts = 13.26 > 5.98 kips Ok

Permissible Shear on slip critical bolts = 7.51 > 5.98 kips Ok

Bolt spacing and bearing on column flange same as at gusset plate.

Bolt spacing and bearing angle same as at gusset plate.

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 10

Bolt end distance on beam web angle = 1.25 in. > 1.5 x bolt dia. = 1.5 x .75 =1.125 in. OK

Angle shear Total shear = 5.986 x 10 bolts = 59.86 kips

Net area = 2 x t (angle length no. rows x ( bolt dia +1/16))

= 2 x .625 x ( 14.5 5 x ( 3/4 + 1/16 ))

= 13.05 in.

2

Gross area = 2 x t x angle length = 2 x .625 x 14.5

= 18.125 in.2

Net shear = 59.86 / 13.05

= 4.59 ksi < .3Fu = .3 x 58 = 17.4 ksi OK

Gross shear = 59.86 / 18.125

= 3.30 ksi < .4Fy = .4 x 36 = 14.4 ksi OK

Welds angles to beam web

Design is by vector analysis

Horizontal length of weld = angle leg size 1/2 in. gap = 3

1

/

2

1

/

2

= 3 in.

Vertical length of weld = angle length = 14.5 in.

Total weld length = 3 + 14.5+ 3 = 20.5 in.

Polar moment of inertia of weld profile = (2 x 3 + 14.5 )

3

/12 - ( 3

2

( 3 +14.5 )

2

/ ( 2 x 3 + 14.5 )

= 717.92 134.45 = 583.47 in

3

Centroid of weld from vertical leg = 3

2

/ (2 x 3 + 14.5 ) = 0.439 in.

Moment on weld = Vbx x (angle leg size centroid distance ) = 59.86 x ( 3 -..439 )

= 183.23 in.-kips

Tensile force at edge of plate = Vbx / total length + moment x ( horizontal weld length centroid distance ) / Ip

fn = 59.86 / 20.5 + 183.23x (3 .439 ) / 583.47 = 2.92 + 0.804

= 3.72 kips / in.

Shear force at edge of plate = Hc / total weld length + moment x ( vertical length / 2 ) / Ip

fv = 48.78 / 20.5 + 183.23 x ( 14.5/2 )/ 583.47

= 2.38 + 2.28 = 4.66 kips / in.

Required fillet weld size = w ( 3.72)

2

+ ( 4.66 )

2

/ ( 0.928 x 2 ) = 5.96/ ( 0.928 x 2 )

= 3.21 16ths ( use in. minimum size for 5/8 material )

Shear stress in beam web @ toe of angles = Vbcx / total length ( moment x centroid distance ) / Ip

fv = 48.78 /20.5 - (183.23 x .439 ) / 583.47

= 2.38 - 0.14 = 2.24 Kips / in.

Minimum required beam web thickness

fn / .6Fy = 3.72 / .6 x 50 = 0.124 in. ( tw actual is 0.39 in. ) OK

fv / .4Fy = 4.66 / .4 x 50 = 0.233 in. OK

fv / .4Fy = 2.24 / .4 x 50 = 0.112 in. OK

v BECO Engineering Services

Engineering Instruction

Bracing Conn. Design Forces

page 11

Investigate localized beam web shear considering gusset forces acting on

beam

Consider a Free Body Diagram of the beam

and the gusset plate and column forces acting on it

The beam shear diagram for these loads is

The maximum local beam web shear is 59.86 kips as shown

Since this is a localized condition use a modified beam shear capacity including the flanges out to k1 from beam

centerline.

Modified shear capacity = (area of beam- 2 (bf - 2k1) x tf) x .4Fy

= ( 16.2- 2 (7.53 - 2 x .8125 )x 0.63 ) x .4 x 50

= ( 16.2 7.44 ) x 20

= 175.19 kips >> 59.86 kips OK

Note that for the brace in compression load condition the FBD and

shear diagram become;

Vbx = 59.86 k

Hc = 48.78 k

Vb = 77.87 k

Hb = 119.21 k

H =168 k

Rb = 18 k

Mb = 21.79 in-kips

18 k

59.86 k

Hb = 119 k

H =168 k

Vbx = 76 k

Hc = 49 k

Vb = 58 k

Rb = 18 k

Mb = 287 in-kips

18 k

76 k

NTS

NTS

You might also like

- CFD Csa A23.3 04Document82 pagesCFD Csa A23.3 04dongheep811No ratings yet

- Compression Members Problems - PDFDocument15 pagesCompression Members Problems - PDFNIKHIL BANDWALNo ratings yet

- Revit Link - ETabs & RobotDocument10 pagesRevit Link - ETabs & RobotAshish LoyaNo ratings yet

- C 5 - Shear in BeamsDocument32 pagesC 5 - Shear in BeamsRekanNo ratings yet

- Grade6 Fractions Addition and Subtraction PDFDocument12 pagesGrade6 Fractions Addition and Subtraction PDFEduGainNo ratings yet

- Reinforced Concrete Design Theory P Bhatt Thomas Joseph MacGinleyDocument1 pageReinforced Concrete Design Theory P Bhatt Thomas Joseph MacGinleyjason_gernale2011No ratings yet

- Ebook Staad Pro g+3 FloorDocument23 pagesEbook Staad Pro g+3 FloortoushikNo ratings yet

- 7-72-9490 - Kempinski Hotel - Muscat: Revit Working in A Worksharing Environment (Worksets)Document4 pages7-72-9490 - Kempinski Hotel - Muscat: Revit Working in A Worksharing Environment (Worksets)Voltaire MarianoNo ratings yet

- DAY - 1 Day - 5: Beams Stairs/ RampDocument2 pagesDAY - 1 Day - 5: Beams Stairs/ RampEducadd AMEERPET HyderabadNo ratings yet

- Structural Engineer SkillsDocument2 pagesStructural Engineer SkillsReceb AgaNo ratings yet

- Perform3D Getting StartedDocument49 pagesPerform3D Getting StartedJorge Güilquiruca VidalNo ratings yet

- ExcelSheetForCalculationPurposeOnly To MR Subburaman 29 04 23Document4 pagesExcelSheetForCalculationPurposeOnly To MR Subburaman 29 04 23slipformNo ratings yet

- CSI Etabs To Revit Structure Data Excahge Manual CCDocument48 pagesCSI Etabs To Revit Structure Data Excahge Manual CCkiran kumar klNo ratings yet

- Concrete Masonry Units GuideDocument8 pagesConcrete Masonry Units GuideDilxan FdoNo ratings yet

- Shrinkage and CreepDocument5 pagesShrinkage and CreepPurushotam TapariyaNo ratings yet

- Wall Bracing Handout PDFDocument45 pagesWall Bracing Handout PDFalbertNo ratings yet

- Concrete Slab Design DraftDocument13 pagesConcrete Slab Design DraftTom FallonNo ratings yet

- Heavy Duty Chain Link Fence SpecificationDocument13 pagesHeavy Duty Chain Link Fence SpecificationrobpallotNo ratings yet

- C 6 - One Way SlabsDocument25 pagesC 6 - One Way SlabsRekanNo ratings yet

- Rebar CreateFromCurves Method C SharpDocument4 pagesRebar CreateFromCurves Method C Sharpmiki1960No ratings yet

- Deep Beam Design Based On ACI 318-19: Input DataDocument1 pageDeep Beam Design Based On ACI 318-19: Input Datajorge01No ratings yet

- Structural Steel Framing SolutionsDocument17 pagesStructural Steel Framing Solutionsuhu_plus6482No ratings yet

- Comparison Between R.C.C and Steel Structures by Seismic AnalysisDocument10 pagesComparison Between R.C.C and Steel Structures by Seismic AnalysisVikramNo ratings yet

- Preliminary design Rules of thumb for reinforced concrete structuresDocument6 pagesPreliminary design Rules of thumb for reinforced concrete structuresOyens EstoyeNo ratings yet

- BEAM REBAR AREA CALCULATIONDocument8 pagesBEAM REBAR AREA CALCULATIONLenny ErastoNo ratings yet

- Steel Structure Design SoftwareDocument53 pagesSteel Structure Design Softwarehenaka ralalage rohitha pushpa kumara100% (1)

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFRhio CruzNo ratings yet

- Example On Sway and Non Sway ACI 318-08 PDFDocument11 pagesExample On Sway and Non Sway ACI 318-08 PDFAhmed RashedNo ratings yet

- Reinforced Concrete DesignDocument10 pagesReinforced Concrete Designmuhammed sabir v aNo ratings yet

- Revit Structure PackageDocument10 pagesRevit Structure PackageSony JsdNo ratings yet

- R. S. Rollings (Auth.), John W. Bull (Eds.) - Precast Concrete Raft Units-Springer US (1991)Document202 pagesR. S. Rollings (Auth.), John W. Bull (Eds.) - Precast Concrete Raft Units-Springer US (1991)Siva Rama Krishna Uppuluri100% (1)

- Design Shear Reinforcement BeamsDocument37 pagesDesign Shear Reinforcement BeamsYigezu YehombaworkNo ratings yet

- Concrete EstimateDocument20 pagesConcrete EstimateJason RoyNo ratings yet

- CIVL311 - CIVL911 - 2020 - Week 2 - Analysis and Design of Beams For Serviceability - 4 PDFDocument19 pagesCIVL311 - CIVL911 - 2020 - Week 2 - Analysis and Design of Beams For Serviceability - 4 PDFBurhan AhmadNo ratings yet

- Hambro Joist Typical DetailsDocument27 pagesHambro Joist Typical DetailsjgjgNo ratings yet

- Advanced S-FRAME Analysis Course ManualDocument142 pagesAdvanced S-FRAME Analysis Course ManualLaurence7533No ratings yet

- Bar Bending Schedule Format (BBS)Document4 pagesBar Bending Schedule Format (BBS)rommecarlolNo ratings yet

- ETABS ExampleDocument40 pagesETABS ExampleRaj ShahNo ratings yet

- Earthquake Resistant Design of Structurespdf PDFDocument161 pagesEarthquake Resistant Design of Structurespdf PDFVishav Kansal100% (1)

- Reinforced Concrete Structures GuideDocument7 pagesReinforced Concrete Structures GuideGandhi HammoudNo ratings yet

- Day 2 S3 BNBC 2020Document75 pagesDay 2 S3 BNBC 2020November RainNo ratings yet

- ETABS ShortcutDocument4 pagesETABS ShortcutTR PDNo ratings yet

- PEB 2D Vs 3D ModelDocument5 pagesPEB 2D Vs 3D ModelGautam PaulNo ratings yet

- Concrete Stair Design ACI318 PDFDocument4 pagesConcrete Stair Design ACI318 PDFMuhammad Dawood KhanNo ratings yet

- Factors Affecting Strength of Epoxy Repaired TimberDocument15 pagesFactors Affecting Strength of Epoxy Repaired TimberJosé PeNo ratings yet

- Day 2 S1 BNBC 2020Document64 pagesDay 2 S1 BNBC 2020November RainNo ratings yet

- Static &dynamic Analysis of Multistory Building Using Composite StructureDocument15 pagesStatic &dynamic Analysis of Multistory Building Using Composite Structureachmad yakusaNo ratings yet

- Structural Engineering SoftwareDocument2 pagesStructural Engineering SoftwareYusak Santoso UseNo ratings yet

- Engineering Economics Using ExcelDocument62 pagesEngineering Economics Using ExcelKevin ChiNo ratings yet

- LECTURE 2 RCC StairsDocument40 pagesLECTURE 2 RCC StairsArsh Chaudhary100% (1)

- Beam Shear BehaviourDocument10 pagesBeam Shear BehaviourEr Saurabh ShahNo ratings yet

- Backstay EffectDocument2 pagesBackstay EffectCHarlesghylonNo ratings yet

- Steel DetailingDocument16 pagesSteel Detailinggabox707100% (1)

- Corner Bracing Connection Capacity Based On AISC 360-10/16 Design CriteriaDocument10 pagesCorner Bracing Connection Capacity Based On AISC 360-10/16 Design CriteriaMahesh MNo ratings yet

- BraceconnectionDocument10 pagesBraceconnectionLeonardo PimentelNo ratings yet

- Physics - Set-2 Practice Test - (Term-I) Marking Scheme Class-Xii Subject-Physics (042) SET-2Document2 pagesPhysics - Set-2 Practice Test - (Term-I) Marking Scheme Class-Xii Subject-Physics (042) SET-2Jagjit MahapatraNo ratings yet

- Corner Bracing Connection Capacity AnalysisDocument2 pagesCorner Bracing Connection Capacity AnalysisKaren Esther Acuña VelasquezNo ratings yet

- Meeting 17.10.14Document25 pagesMeeting 17.10.14Ahmad mahbubul AlamNo ratings yet

- Chapter 5 Fall09 Ver2Document9 pagesChapter 5 Fall09 Ver2Jhuma DeyNo ratings yet

- Weekly Status ReportDocument1 pageWeekly Status ReportarnoldistunoNo ratings yet

- Steel Deck 101Document3 pagesSteel Deck 101arnoldistunoNo ratings yet

- Slab On Grade Reinforcing DesignDocument11 pagesSlab On Grade Reinforcing Designsantylat100% (1)

- Intro To CFS FramingDocument52 pagesIntro To CFS FramingarnoldistunoNo ratings yet

- Intro To CFS FramingDocument52 pagesIntro To CFS FramingarnoldistunoNo ratings yet

- HIT-HY 200 SupplementDocument56 pagesHIT-HY 200 SupplementarnoldistunoNo ratings yet

- Post-Tensioned Concrete Design for ACI 318-08Document43 pagesPost-Tensioned Concrete Design for ACI 318-08Duaa Makki100% (3)

- Cheat Sheet Creator (/editor/?sport NFL) : Log Out (/logout)Document11 pagesCheat Sheet Creator (/editor/?sport NFL) : Log Out (/logout)arnoldistunoNo ratings yet

- Review Vessel Drawings Foundation Loads DesignDocument5 pagesReview Vessel Drawings Foundation Loads DesignarnoldistunoNo ratings yet

- HIT-HY 200 SupplementDocument56 pagesHIT-HY 200 SupplementarnoldistunoNo ratings yet

- Hilti 2008 Product Technical Guide r021 1Document452 pagesHilti 2008 Product Technical Guide r021 1shasta963No ratings yet

- CAD Sizing ChartDocument1 pageCAD Sizing ChartEdupuganti Sujith KumarNo ratings yet

- Checklists For Structural DesignDocument5 pagesChecklists For Structural DesignarnoldistunoNo ratings yet

- AIAA-90-2375 Numerical Investigation The Thermal Stratification in Cryogenic Tanks Subjected Wall Heat FluxDocument21 pagesAIAA-90-2375 Numerical Investigation The Thermal Stratification in Cryogenic Tanks Subjected Wall Heat FluxSasank KomarlaNo ratings yet

- Convective Heat Transfer and Flow Friction For Ref (2)Document10 pagesConvective Heat Transfer and Flow Friction For Ref (2)Redwan ShaikatNo ratings yet

- 7-Practice Problem I - SolutionsDocument41 pages7-Practice Problem I - SolutionsNina Ysabelle RamosNo ratings yet

- Aircraft Structures-II - U1 - L1 - T9 - Analysis of Unsymmetrical Bending of Beams - Principal Axis MethodDocument11 pagesAircraft Structures-II - U1 - L1 - T9 - Analysis of Unsymmetrical Bending of Beams - Principal Axis Methodsarathkumar sebastinNo ratings yet

- Dispersion Relation and Cutoff Frequency For A SlinkyDocument7 pagesDispersion Relation and Cutoff Frequency For A Slinkycheatham6191No ratings yet

- Mechanics of Solids: Bela I. Sandor Ryan Roloff Stephen M. Birn Maan H. Jawad Michael L. BrownDocument1 pageMechanics of Solids: Bela I. Sandor Ryan Roloff Stephen M. Birn Maan H. Jawad Michael L. BrownkprasannanNo ratings yet

- St. Francis National High School SF I, Limay, Bataan Third Periodical Test in Science 7 NAME: - YR/SECTIONDocument2 pagesSt. Francis National High School SF I, Limay, Bataan Third Periodical Test in Science 7 NAME: - YR/SECTIONArvin Arne RodrigoNo ratings yet

- Fluid Mechanics White 7th SOL Part1 Part1Document5 pagesFluid Mechanics White 7th SOL Part1 Part1Jose EscobarNo ratings yet

- Stiffnes and Damping in Mechanical DesignDocument514 pagesStiffnes and Damping in Mechanical Designczoobs100% (6)

- Fluid - Mechanics 04bDocument54 pagesFluid - Mechanics 04bjavi checaNo ratings yet

- Abaqus 6.12: Abaqus User Subroutines Reference ManualDocument591 pagesAbaqus 6.12: Abaqus User Subroutines Reference ManualalperenacarNo ratings yet

- Ch12 - Peter NolanDocument22 pagesCh12 - Peter Nolanjohnb2bNo ratings yet

- Projectile motion worksheet case 1Document2 pagesProjectile motion worksheet case 1leah ruales100% (1)

- Thick Walled Cylinder - FeaDocument22 pagesThick Walled Cylinder - Feagpro123No ratings yet

- Shear Transfer in Concrete Having Reinforcement at An Angle To Shear PlaneDocument26 pagesShear Transfer in Concrete Having Reinforcement at An Angle To Shear PlanePremasiri Karunarathna100% (1)

- Disc Spring CatalogueDocument16 pagesDisc Spring Cataloguejharsh87No ratings yet

- Cur-037-2 Summative Assessment #1 - Week 1Document3 pagesCur-037-2 Summative Assessment #1 - Week 1Dame YooheeNo ratings yet

- Chapter V Beam Deflections 5.3Document8 pagesChapter V Beam Deflections 5.3Joshua John JulioNo ratings yet

- Force Systems & ResultantsDocument55 pagesForce Systems & ResultantsJanina Christelle OrmitaNo ratings yet

- 7408-1 Specimen Question Paper (Set 2) - Paper 1Document32 pages7408-1 Specimen Question Paper (Set 2) - Paper 1Madan KumarNo ratings yet

- Reviewer in PhysicsDocument90 pagesReviewer in PhysicsLouise RonquilloNo ratings yet

- Physical Science Week 10 Module 3Document6 pagesPhysical Science Week 10 Module 3RODJHEN ANNE P. BARQUILLA0% (1)

- 3.2 - Analysis of Singly Reinforced Beams 2Document27 pages3.2 - Analysis of Singly Reinforced Beams 2Marcelo AbreraNo ratings yet

- E.Mech Tutorials Mod 1Document8 pagesE.Mech Tutorials Mod 1rajee101No ratings yet

- As Level Physics Key WordsDocument6 pagesAs Level Physics Key Words林仁超No ratings yet

- Delta Connection in A 3 Phase SystemDocument5 pagesDelta Connection in A 3 Phase SystemnpavankNo ratings yet

- Columns and Struts: Strength of MaterialsDocument9 pagesColumns and Struts: Strength of MaterialsParth MehraNo ratings yet

- Thermodynamics MsDocument14 pagesThermodynamics MsLaila HassanNo ratings yet

- Heat Energy WorksheetDocument3 pagesHeat Energy Worksheetfakhar.0917No ratings yet

- Solid Mechanics Lab Quiz Question ME 2211Document2 pagesSolid Mechanics Lab Quiz Question ME 2211MD Sumon HossainNo ratings yet