Professional Documents

Culture Documents

Bomag Single Drum Vibratory Roller BW213-40

Uploaded by

Sam ArevaloOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bomag Single Drum Vibratory Roller BW213-40

Uploaded by

Sam ArevaloCopyright:

Available Formats

Single Drum Vibratory Rollers

BW213-40 Series

KEY FEATURES

84 inch drum width

Easy & simple operation

Cummins diesel engine

No grease points

Dual Amplitude & Dual Frequency

Dual Drum scrapers

Efcient service access

Vertically opening hood

www.bomag.com/us

The BOMAG BW213-40 series provides

features that deliver jobsite versatility and

excellent soil compaction performance.

The smooth drum BW213DH-40 model

is designed essentially for compaction of

granular and mixed soils. The padfoot

BW213PDH-40 model is best suited

for compaction of cohesive and semi-

cohesive soils. Two vibration frequencies

and two amplitudes, combined with

high optimum centrifugal forces offer

protability and superb productivity for

various jobsite applications.

n Applications:

Highway construction

and maintenance

Driveways

Parking lots

Landll

Designed specically for soil compaction.

n The high production answer to your 84compaction needs...

Two vibration frequencies and

amplitudes ensure maximum

compaction performance on a

variety of soil applications

Vibration isolated

operators platform

ROPS/FOPS with

standard steel sun canopy

Engine air intake positioned at

high level for increased lter life

Extremely low DBA

levels at operators

ears

Vertically opening hood provides

efcient access to engine,

hydraulics and all service points

Rear axle with

no-spin differential

for improved traction Bolt-on articulation joint, steering

cylinder pins, and travel bearings are

maintenance-free

ASC* for exceptional traction

and gradeability

Leveling blade

BW213-40 Series

n Operation - Comfortable,

Easier and Safer

Vibration Isolated Operators platform

Extremely low noise levels at operators ears even

with vibration

Multi-position, adjustable seat

Optional Swivel Seat

Reduced Stop to stop steering input

Operator controls are strategically and

ergonomically placed

Easy single lever control for both travel

direction, speed and vibration

n Maximum Productivity

Superb compaction performance allows

achievable density with thicker lifts or less

passes yielding better ROI

High PLI, Centrifugal Forces, and Amplitudes

Wider Clearance between frame and drum

combined with dual scrapers prevents material

build up.

ASC System* monitors slip potential between

drum and rear tires to maximize traction and

gradeability.

Low emission, Tier III Diesel engine and high

output drum drive provide improved traction

performance.

n Less Service & Maintenance:

The purchase price is important, but so are the

operating costs. Check these features:

Maintenance Free Bolt On articulation joint,

steering cylinder pins, and travel bearings

eliminates daily grease points

Quick access to all service and maintenance

points in the engine compartment.

Standard dual amplitude and frequency enhances

machines versatility

Individually changeable rubber buffers with no special tools or

disassembly of the drum required.

BTM shows the soil load bearing

results in real time.

Padfoot Shell Kit for smooth drum

equipped rollers.

Smooth Shell Kit for padfoot drum

equipped rollers.

Excellent all around visibility for maximum safety.

Ergonomic layout of instrument panel.

Featuring

Maintenance-free, rugged, oscillating-articulation joint

bolted on the outside of the front and rear frames

Optional ROPS cabin with available heating and air conditioning.

Central drain points for engine and hydraulic

oils, and for engine coolant

Spring-Applied Hydraulically-Released (SAHR)

brakes are maintenance free

Recessed frame bolts reduce bolt head shearing

and repair costs

Engine Cooling Air Flow reduces radiator

maintenance and dust creation from the jobsite

Large lters for fuel, air, and oil give better

protection to key components

Corrosion Free plastic Fuel Tank

BOMAG Hydraulic lter system extends

hydraulic oil and lter change intervals to

2000 working hours or 2 years

n Innovative Options:

Compaction Measuring and/or Control Systems

display real time soil load bearing results

avoiding over-compaction and reducing the

number of rolling passes.

BOMAG Evib Meter (BEM) Analog gauge

display of Evib values.

BOMAG BTM Prof Measuring system

controls and documents the compaction

process. Operator can view results on LCD

Display and Document results via onboard

printer

BOMAG BCM05 Compaction management

system used in conjunction with the BTM

Prof, controls and documents the compaction

process as well as allowing intelligent

compaction data management.

Padfoot and Smooth Shell Kits allow the roller to

be quickly adapted to changing jobsite applications.

Shipping dimensions

in cubic feet (m

3

) without/with ROPS/FOPS

BW213DH-40 1053 (29.8) 1379 (39)

BW213PDH-40 1053 (29.3) 1379 (39)

B

5

3

2

H

-

3

4

0

6

2

M

1

2

1

2

T

T

P

P

G

H

H2

L

A O2 O1 W

B

D

S K

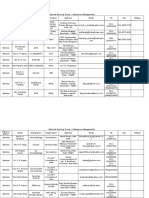

Technical data BOMAG BOMAG

BW213DH-40 BW213PDH-40

Weights

Operating Weight with ROPS/FOPS ..... lbs (kg) 26540 (12040) 27975 (12690)

Operating Weight with Blade ................. lbs (kg) 30385 (13785)

Axle load, drum ...................................... lbs (kg) 15315 (6945) 16555 (7510)

Axle load, drum with Blade ..................... lbs (kg) 19996 (9070)

Axle load, wheels ..................................... lbs (kg) 11225 (5095) 11420 (5180)

Static linear load (drum) .......................... pli (kg/cm) 182.9 (32.7)

Driving Characteristics (depending on site conditions)

Speed (1) ............................................... mph (kmph) 0-2.2 (0-3.5) 0-2.2 (0-3.5)

Speed (2) ............................................... mph (kmph) 0-3.9 (0-6.5) 0-4.0 (0-6.5)

Speed (3) ............................................... mph (kmph) 0-7.5 (0-12) 0-7.5 (0-12)

Max. gradeability without/with vibration . % 55 55

Drive

Engine manufacturer ..................................... Cummins Cummins

Type.............................................................. QSB 4.5 QSB 4.5

Tier compliance ............................................ Tier 3 Tier 3

Cooling ......................................................... water water

Number of cylinders ..................................... 4 4

Performance ISO 3046 / SAE J 1995 ...... hp (kW) 160 (119) 160 (119)

Speed .................................................... rpm 2200 2200

Fuel ............................................................... diesel diesel

Electric equipment .................................... V 12 12

Drive system ................................................. hydrostatic hydrostatic

Drum driven ................................................. standard standard

Drums and Tires

Number of pad feet ....................................... 150

Area of one pad foot ............................... in

2

(cm

2

) 21.2 (136.5)

Height of pad feet ..................................... in (mm) 3.9 (100)

Tire size ........................................................ 23.1-26/12PR 23.1-26/12PR

Tire tread ...................................................... Diamond (R-3) Tractor (R-1)

Brakes

Service brake ................................................. hydrostatic hydrostatic

Parking brake ................................................ SAHR SAHR

Steering

Steering system .............................................. oscillating, articulating oscillating, articulating

Steering method ............................................ hydrostatic hydrostatic

Steering angle +/- .............................. degrees 35 35

Oscillating angle +/- .......................... degrees 12 12

Track radius, inner .................................... in (mm) 142.3 (3615) 142.3 (3615)

Vibratory system

Drive system ................................................. hydrostatic hydrostatic

Frequency ............................................. vpm (Hz) 1800/2160 (30/36) 1800/2160 (30/36)

Amplitude ................................................. in (mm) 0.071/0.037 (1.8/0.9) 0.065/0.032 (1.64/0.82)

Centrifugal force ..................................... lbs (kN) 61825/44550 (275/198) 61825/44550 (275/198)

Capacities

Fuel ......................................................... gal (l) 66 (250) 66 (250)

Technical modications reserved. Machines may be shown with options.

Dimensions in inches (mm)

A B D H H2 K L O1 O2 S W

BW213DH-40 116.6 88.6 59.1 89.3 117 19.3 229.9 2.4 2.4 1.4 83.9

(2960) (2250) (1500) (2268) (2972) (490) (5840) (60) (60) (35) (2130)

BW213PDH-40 116.6 88.6 58.3 89.3 117 19.3 229.9 2.4 2.4 1.0 83.9

(2960) (2250) (1480) (2268) (2972) (490) (5840) (60) (60) (25) (2130)

Technical Specications

BW213-40 Series

Standard Equipment

Hydrostatic drum & vibration drive

Dual frequencies & amplitudes

Hydrostatic articulated steering

No spin differential with Spring

Applied Hyd. Rel. (SAHR) brakes

Anti-slip Control (ASC)

Bolt on oscillating, articulation joint

Articulation lock

Adjustable operators seat

Single lever control for travel & vibration

Drum scrapers

Emergency stop

Backup alarm & hour meter

ROPS/FOPS sun canopy with seat belt

Audible / Visual warning indicators

Engine oil pressure

Engine temperature

Hydraulic oil lter restriction

Air lter restriction

Brake control

Charge control

Optional Equipment

Leveling blade (PDH)*

Working lights front/rear

ROPS Cab with heating

Air conditioning

Padfoot drum segment kit (DH)

Smooth drum segment kit (PDH)

Swivel comfort seat

Evib Meter (BEM)

Terrameter (BTM Prof)

BCM05 Compaction Management

Front frame ballast (+ 1540lbs)

Gauges: Speedometer, voltmeter,

frequency, tachometer

CD Radio (with cab option)

Rotary beacon (permanent or portable)

* Optional leveling blade is for surface proling/contouring and

backdragging of loose ll material only. This design is not intended to

function as a device for excavation purposes.

BOMAG Americas, Inc.

2000 Kentville Rd. Kewanee, IL 61443

Tel: 309 853-3571 Fax: 309 852-0350

58256, 58257 - R1

www.bomag.com/us

You might also like

- 05-HR 40 PDFDocument8 pages05-HR 40 PDFalexjos1No ratings yet

- BW213DH-4 BVC PDFDocument2 pagesBW213DH-4 BVC PDFVlad SuteuNo ratings yet

- Cat Scaper 631G PDFDocument24 pagesCat Scaper 631G PDFTâm PhanNo ratings yet

- Operator'S Manual and Spare Parts Catalogue Schaeff ItcDocument31 pagesOperator'S Manual and Spare Parts Catalogue Schaeff ItcJesus VergaraNo ratings yet

- Vmware Validated Design 41 SDDC Architecture DesignDocument226 pagesVmware Validated Design 41 SDDC Architecture DesignmpuriceNo ratings yet

- JUNOS Cheat SheetDocument2 pagesJUNOS Cheat SheetJaeson VelascoNo ratings yet

- Course Recorder (Paperless) MDR290Document4 pagesCourse Recorder (Paperless) MDR290Jay SanchaniyaNo ratings yet

- Vibro Bomag BW226DH-4 - 226PDH-4 - Spec PDFDocument2 pagesVibro Bomag BW226DH-4 - 226PDH-4 - Spec PDFEsti NugrohadiNo ratings yet

- DUMPERDocument2 pagesDUMPERJackson PhinniNo ratings yet

- BOMAG Finisher BF 800. The Heavy Weight ChampionDocument20 pagesBOMAG Finisher BF 800. The Heavy Weight ChampionVany LunaNo ratings yet

- Sakai PM550Document8 pagesSakai PM550Laibern JppdNo ratings yet

- Road RollerDocument24 pagesRoad RollerAnita WulandariNo ratings yet

- Dynapac Large Tracked Paver Range: Dynapac SD2500C / SD2500CS SD2550C / SD2550CSDocument16 pagesDynapac Large Tracked Paver Range: Dynapac SD2500C / SD2500CS SD2550C / SD2550CSsobirin100% (1)

- Yamaha 25NWC 2003 Parts CatalogDocument51 pagesYamaha 25NWC 2003 Parts CatalogDaniel Barham100% (1)

- Specifications: Ibratory Oil OmpactorDocument2 pagesSpecifications: Ibratory Oil OmpactorArvind Harry100% (1)

- SM 14Document16 pagesSM 14Sanjay RajNo ratings yet

- Spare Parts Catalog: Date: 04.12.2023 Language: enDocument1,044 pagesSpare Parts Catalog: Date: 04.12.2023 Language: enezgiulusoyy07No ratings yet

- MEP - Format 12 HS - UkDocument5 pagesMEP - Format 12 HS - UkLuiz HenriqueNo ratings yet

- 1675BW Ed201408Document354 pages1675BW Ed201408PEPE100% (2)

- D85ESS-2A: Horsepower Net: 149 KW Operating Weight 20670 KGDocument8 pagesD85ESS-2A: Horsepower Net: 149 KW Operating Weight 20670 KGHeronimus RigoNo ratings yet

- 3705 Brochure Bf800 CDocument4 pages3705 Brochure Bf800 CAbdul Khaliq100% (1)

- 0409 - JCB Attachments BHL Product Guide Issue 3 30.10.14Document19 pages0409 - JCB Attachments BHL Product Guide Issue 3 30.10.14Darryl CareyNo ratings yet

- Ha90c 2 PDFDocument6 pagesHa90c 2 PDFnovian juansa100% (1)

- Hitachi ZX330 Hydraulic ExcavatorDocument2 pagesHitachi ZX330 Hydraulic ExcavatorFirstianto MnNo ratings yet

- Codigos de Falla Sd2500Document22 pagesCodigos de Falla Sd2500Pedro AvilanNo ratings yet

- Roadtec Cold Planers BrochureDocument24 pagesRoadtec Cold Planers BrochureKuntawee100% (1)

- SB Series BreakersDocument12 pagesSB Series BreakersManuel Pedro InácioNo ratings yet

- CATERPILLAR Fuel ConsumptionDocument22 pagesCATERPILLAR Fuel ConsumptionScribdTranslationsNo ratings yet

- Road Equipment Brochure 201903 High ResolutionDocument17 pagesRoad Equipment Brochure 201903 High ResolutionSabahNo ratings yet

- Earth Cutting and MovingDocument46 pagesEarth Cutting and MovingHARISH BHAT100% (1)

- DM 30 Asphalt PlantDocument4 pagesDM 30 Asphalt PlantTheodore Teddy KahiNo ratings yet

- 00 Basic Principles of Asphalt CompactionDocument59 pages00 Basic Principles of Asphalt CompactionAynup Irahtak100% (1)

- Dumper Spec FinalDocument1 pageDumper Spec FinalJackson PhinniNo ratings yet

- Cat 320 Next Gen Excavator BrochureDocument16 pagesCat 320 Next Gen Excavator BrochureKeron TrotzNo ratings yet

- SWL 55t Crane CrawlerDocument32 pagesSWL 55t Crane CrawlerHerberth SilitongaNo ratings yet

- Cat 561 N Pipe LayerDocument20 pagesCat 561 N Pipe Layercameron_froeseNo ratings yet

- pm102 PDFDocument12 pagespm102 PDFJohn MkCito KI100% (1)

- D7RDocument20 pagesD7RagegnehutamiratNo ratings yet

- Gomaco Slipform Paver NotesDocument16 pagesGomaco Slipform Paver NotesMudduKrishna shettyNo ratings yet

- Diesel Engine Shutdown Valve (Pneumatically Actuated) : Typical ApplicationsDocument5 pagesDiesel Engine Shutdown Valve (Pneumatically Actuated) : Typical ApplicationspopNo ratings yet

- 20170905061501BH60MDocument4 pages20170905061501BH60MRajkumarNo ratings yet

- S36X Bro2013 PDFDocument4 pagesS36X Bro2013 PDFBagoes SetiawaneNo ratings yet

- 25ton Load Chart PDFDocument12 pages25ton Load Chart PDFIkhsanRizaldiNo ratings yet

- Vogele PB S1800Document9 pagesVogele PB S1800Pappa Anton Florin100% (2)

- Earth Moving Equipment Function and Standard ProductivityDocument5 pagesEarth Moving Equipment Function and Standard ProductivityMaxwell ChikasimaNo ratings yet

- W Brochure SP1200 0116 ENDocument24 pagesW Brochure SP1200 0116 ENمحمد شبانةNo ratings yet

- Uipe Graduate Membership FormDocument7 pagesUipe Graduate Membership FormJustin MugissaNo ratings yet

- OptionsCatalogue - BM 500 600 - ENDocument40 pagesOptionsCatalogue - BM 500 600 - ENseba6487100% (1)

- Rawler Ozer: With Steering Clutch/Brake SystemDocument10 pagesRawler Ozer: With Steering Clutch/Brake SystemDinh Phu LeNo ratings yet

- BW213-4 4pgDocument4 pagesBW213-4 4pgtokotani torajaNo ratings yet

- SP661E Maintenance Ver 1.0.2 GBDocument33 pagesSP661E Maintenance Ver 1.0.2 GBDrow RangerNo ratings yet

- MEP - Metronic - UkDocument9 pagesMEP - Metronic - UkLuiz HenriqueNo ratings yet

- 307D Excavator-Before PerationDocument8 pages307D Excavator-Before PerationMecatrónico100% (1)

- Telescopic Boom Lift 42 MDocument2 pagesTelescopic Boom Lift 42 Mkarthik bhatNo ratings yet

- Reclaimer/Mixer: Machine Shown May Have Optional EquipmentDocument12 pagesReclaimer/Mixer: Machine Shown May Have Optional EquipmentBakat Setiya Hadi100% (1)

- Bomag Heavy Articulated Tandem Vibratory Rollers BW 161 & BW 190 (UK WebsiteDocument2 pagesBomag Heavy Articulated Tandem Vibratory Rollers BW 161 & BW 190 (UK WebsitesandycastleNo ratings yet

- User Manual: Gasoline Power GeneratorsDocument16 pagesUser Manual: Gasoline Power GeneratorsErickaNo ratings yet

- BW211D-40 PDDocument4 pagesBW211D-40 PDdsn_sarma100% (2)

- BW177D 3Document4 pagesBW177D 3Sandra Milena Pinto0% (1)

- Bomag BW100AD-4 2pgDocument2 pagesBomag BW100AD-4 2pgFrans van der MerweNo ratings yet

- Single Drum Vibratory Rollers: B W211D-3, B W211PD-3Document4 pagesSingle Drum Vibratory Rollers: B W211D-3, B W211PD-3Sandiga75No ratings yet

- Bulldozer D85ESS-2ADocument4 pagesBulldozer D85ESS-2Adeanz_75100% (3)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- John Deere - Parts Catalog - Control Relay, 5 Pin k6Document1 pageJohn Deere - Parts Catalog - Control Relay, 5 Pin k6Sam ArevaloNo ratings yet

- John Deere - Parts Catalog - Front Housing and Torque Converter CoverDocument2 pagesJohn Deere - Parts Catalog - Front Housing and Torque Converter CoverSam Arevalo100% (1)

- John Deere - Parts Catalog - Backup Alarm (165986 - )Document1 pageJohn Deere - Parts Catalog - Backup Alarm (165986 - )Sam ArevaloNo ratings yet

- Hydraulic Activation Control ValveDocument1 pageHydraulic Activation Control ValveSam ArevaloNo ratings yet

- Mitfuso Owners Manual 2014 FefgDocument468 pagesMitfuso Owners Manual 2014 FefgSam ArevaloNo ratings yet

- Type ConnectorDocument35 pagesType ConnectorSam ArevaloNo ratings yet

- General Information:: Description of A DepartmentDocument2 pagesGeneral Information:: Description of A DepartmentSam ArevaloNo ratings yet

- Identificación de ComponentesDocument1 pageIdentificación de Componentessiul7894No ratings yet

- HX35WDocument73 pagesHX35WSam ArevaloNo ratings yet

- Technical Data: Digital and Millivolt Gas HeatersDocument2 pagesTechnical Data: Digital and Millivolt Gas HeatersDenis CuraNo ratings yet

- Operation & Service Manual: Murzan IncDocument38 pagesOperation & Service Manual: Murzan IncgokulNo ratings yet

- cm6800 48x8 NewDocument98 pagescm6800 48x8 Newvijayakumar3661No ratings yet

- Tiger SharkDocument2 pagesTiger Sharkstefanpl94No ratings yet

- Introducing Maf and Mef Frameworks: Exploring Managed Addin FrameworkDocument9 pagesIntroducing Maf and Mef Frameworks: Exploring Managed Addin Frameworkkris2tmgNo ratings yet

- System SizingDocument50 pagesSystem SizingVictor mulotaNo ratings yet

- Subject Orientation: Empowerment TechnologiesDocument10 pagesSubject Orientation: Empowerment TechnologiesJessa GuerraNo ratings yet

- Fiesta Mk6 EnglishDocument193 pagesFiesta Mk6 EnglishStoicaAlexandru100% (2)

- RFC 5227Document21 pagesRFC 5227chetan666123No ratings yet

- Is Iec 60534 2 1 1998Document48 pagesIs Iec 60534 2 1 1998Sreeram PanigrahiNo ratings yet

- Ship-Like Target Design For Underwater Explosion Experiments PDFDocument92 pagesShip-Like Target Design For Underwater Explosion Experiments PDFFernando Raúl LADINONo ratings yet

- Electrical Machines (K-18EL101) (Mid-Term Presentation)Document11 pagesElectrical Machines (K-18EL101) (Mid-Term Presentation)Noor SabaNo ratings yet

- Arc Welding ProcessesDocument153 pagesArc Welding Processespratap biswasNo ratings yet

- Seminarski RadDocument32 pagesSeminarski RadAdmir KlinčevićNo ratings yet

- G249 MXBDocument8 pagesG249 MXBAndres SorinNo ratings yet

- Contact List For All NWGDocument22 pagesContact List For All NWGKarthickNo ratings yet

- Fuses & Circuit Breakers PDFDocument13 pagesFuses & Circuit Breakers PDFCarlos Luis Santos SomcarNo ratings yet

- Honeywell Mmi 813.1 Mod 23Document5 pagesHoneywell Mmi 813.1 Mod 23nestor_moNo ratings yet

- SV50SP2RevB Released User DocumentsDocument8 pagesSV50SP2RevB Released User DocumentsAhmed RamadanNo ratings yet

- Is Standard ListDocument11 pagesIs Standard ListSunil PulikkalNo ratings yet

- Pads Hyperlynx DDR WizardDocument3 pagesPads Hyperlynx DDR Wizardkrishna_p_n_44510456No ratings yet

- Strategic Management MBA (GTU)Document639 pagesStrategic Management MBA (GTU)keyur0% (2)

- Definition of EbookDocument14 pagesDefinition of EbookNurul IzzahNo ratings yet

- Soil-Structure Interaction Effects On The Seismic Response of Low PDFDocument106 pagesSoil-Structure Interaction Effects On The Seismic Response of Low PDFTariq MahmoodNo ratings yet

- CeldekDocument2 pagesCeldekPK SinghNo ratings yet

- Acid CleaningDocument32 pagesAcid Cleaningsekhar_ntpcNo ratings yet

- BSNL CRM FTTH User Manual - Release1.0 - ShiftDocument25 pagesBSNL CRM FTTH User Manual - Release1.0 - ShiftJTONIB AIZAWLNo ratings yet