Professional Documents

Culture Documents

Anion Exchange Membrane AEM

Uploaded by

Elkin Yesid Valbuena0 ratings0% found this document useful (0 votes)

23 views5 pagesAnion exchange membrane fuel cells (AEMFCs) are a viable alternative to PEMFCs. Anion exchange membrane conducts hydroxide (or carbonate) anions during current flow. Oxygen reduction reaction (ORR) is much more facile in alkaline environments than in acidic.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAnion exchange membrane fuel cells (AEMFCs) are a viable alternative to PEMFCs. Anion exchange membrane conducts hydroxide (or carbonate) anions during current flow. Oxygen reduction reaction (ORR) is much more facile in alkaline environments than in acidic.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views5 pagesAnion Exchange Membrane AEM

Uploaded by

Elkin Yesid ValbuenaAnion exchange membrane fuel cells (AEMFCs) are a viable alternative to PEMFCs. Anion exchange membrane conducts hydroxide (or carbonate) anions during current flow. Oxygen reduction reaction (ORR) is much more facile in alkaline environments than in acidic.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

The Electrochemical Society Interface Summer 2010 31

Anion Exchange Membrane

P

roton exchange membrane fuel cells (PEMFCs) are

currently capable of providing power for a variety of

applications, ranging from automotive transportation

to portable electronics to military devices. The widespread

commercialization of PEMFCs, however, remains a challenge

due to cost, lifetime, and fueling issues.

1,2

The need for

precious metal catalyst electrodes in PEMFCs is of concern

because of uncertainties regarding the future availability and

price of platinum group metals (PGMs), should PEM fuel cells

see widespread use. It is not at all certain that that there is

enough Pt in the world today to sustain a sizable fraction of

autos in the U.S. being powered by PEMFCs.

Anion exchange membrane fuel cells (AEMFCs) are, in

principle, a viable alternative to PEMFCs and are currently

garnering renewed attention. In an AEMFC, an anion exchange

membrane (AEM) conducts hydroxide (or carbonate) anions

(as opposed to protons) during current ow, which results

in several advantages. (1.) The oxygen reduction reaction

(ORR) is much more facile in alkaline environments than

in acidic environments.

3

This could potentially facilitate the

use of less expensive non-PGM catalysts with high stability

in alkaline environments. (2.) The electro-oxidation kinetics

for many liquid fuels (including non-conventional choices

of importance to the military, such as sodium borohydride)

are enhanced in an alkaline environment. (3.) The electro-

osmotic drag associated with ion transport opposes the

crossover of liquid fuel in AEMFCs, thereby permitting the

use of more concentrated liquid fuels. This is an advantage

for portable applications. (4.) The exibility in terms of fuel

and ORR catalyst choice also expands the parameter space for

the discovery of highly selective catalysts that are tolerant to

crossover fuel. These potential advantages make AEMFCs an

attractive future proposition.

Alkaline fuel cells were rst developed in the 1930s by F.

T. Bacon, thus they pre-date PEM fuel cells and represent one

of the oldest fuel cell types. Early alkaline fuel cells operated

with H

2

as the fuel at a temperature between 50 and 200

o

C

and employed a liquid electrolyte (e.g., an aqueous solution of

KOH). NASA used such fuel cells in the 1960s to power Apollo

space missions. The technology, however, has suffered from

problems arising from the use of liquid (aqueous) electrolytes;

in particular the inevitable shunt currents and poisoning by

carbon dioxide which leads to the formation of carbonate

precipitates

3

in the liquid electrolyte. The chemistry behind

the carbonate precipitation problem is presented below.

CO

2

+ 2OH

-

CO

3

2-

+ H

2

O (1)

CO

2

+ OH

-

HCO

3

-

(2)

HCO

3

-

CO

3

2-

+ H

+

(3)

CO

3

2-

+ 2K

+

K

2

CO

3(s)

(4)

The strongly alkaline electrolytes absorb even the smallest

amount of CO

2

, which in turn eventually reduces the

conductivity of the electrolyte. Consequently pure hydrogen

(rather than an impure hydrogen stream containing CO

2

) and

highly puried oxygen (rather than air) must be used as the

fuel and oxidant feeds. The use of such high purity oxygen,

in particular, increases signicantly the cost of generating

electricity with a liquid electrolyte alkaline fuel cell.

Today, researchers have moved to polymeric anion

exchange membranes (AEMs) as the hydroxide transport

medium in an alkaline fuel cell. In the AEM, cationic moieties

are xed to polymer chains (and are not freely mobile as in a

liquid electrolyte). This prevents the formation of carbonate

precipitates (i.e., there is no liquid-phase dissociated cation

which can react with carbonate anions to form insoluble

species like K

2

CO

3

). AEMs, however, suffer from low ionic

conductivity and poor chemical stability, especially at the

cationic site.

3,4

Additionally, most anion exchange membrane

polymers have poor solubility in low boiling, inexpensive

solvents, like the alcohol/water solvents used with proton

conducting peruorosulfonic acid polymers in PEM fuel cells.

This makes for more complicated and less environmentally

friendly membrane fabrication schemes. It also complicates

the process of incorporating an anion exchange polymer

binder into the electrode layers of an AEMFC membrane-

electrode-assembly (MEA). Thus, the preparation of catalyst

coated membranes for AEMFCs lags far behind similar work

with PEMFCs.

5

This Chalkboard article will briey outline

AEMFC operation, AEM chemistry, and key challenges to this

technology.

Overview of AEMFC Operation

For a traditional AEMFC with hydrogen fuel and air/oxygen

as the oxidant, the half cell and overall chemical reactions are

as follows:

3

H

2

+ 2OH

-

2H

2

O + 2e

-

; E

O,

anode

= 0.83 V (5)

O

2

+H

2

O + 2e

-

2OH

-

; E

O,

cathode

= 0.40 V (6)

Overall:

H

2

+ O

2

H

2

O; E

O,

cell

= 1.23 V (7)

In an AEMFC, hydroxide ions are generated during

electrochemical oxygen reduction at the cathode. They are

transported from the cathode to the anode through the anion

conducting (but electronically insulating) polymer electrolyte,

wherein they combine with hydrogen to form water. The

electrons generated during H

2

oxidation pass through the

external circuit to the cathode, where they participate in the

electrochemical reduction of oxygen to produce OH

-

. Note

that in practice, the ideal thermodynamic cell voltage of

1.23 V (at standard conditions) is not realized even at open

circuit (zero current) due to myriad irreversibilities that arise

during AEMFC operation. The phenomenological sources of

irreversibility are very similar to those in PEMFCs and include

oxygen and water activities that are less than unity, and gas

crossover at open circuit leading to mixed potentials, and

activation, ohmic, and mass transfer losses (overpotentials)

by Christopher G. Arges, Vijay Ramani, and Peter N. Pintauro

Fuel Cells

32 The Electrochemical Society Interface Summer 2010

Arges, et al.

(continued from previous page)

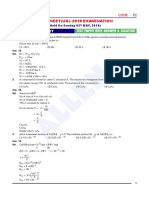

FIG. 1. Comparison of AEM and PEM fuel cell congurations for hydrogen, methanol, and sodium borohydride as fuel.

during current ow. Figure 1 contrasts AEM and PEM fuel cell

operation with different fuels (H

2

gas, liquid methanol, and

sodium borohydride). Table I presents a list of possible fuels

for AEMFCs with their standard thermodynamic cell voltages

(using an air cathode) and their energy densities.

Anion-Exchange Membrane Chemistry and

Associated Challenges

Perhaps the single greatest obstacle in developing a

commercially viable AEMFC is the anion-exchange membrane.

The method and materials used to fabricate an anion-exchange

membrane for alkaline fuel cells are intimately linked to one

another, to the properties

of the nal membrane,

and to the eventual large-

scale commercial process for

membrane manufacturing.

In general, fuel cell

membranes must meet

stringent performance,

durability, and cost targets.

More specically, as shown

in Fig. 2, the requirements for

the successful commercial

production of an alkaline

fuel cell membrane include

a robust synthetic route

with the proper selection

and positioning of cationic

ion-exchange groups on

the polymer, control of

the membrane morphology

to improve mechanical

properties, scalability, and

the use of low cost materials

and processing methods.

Membranes are typically

composed of a polymer

backbone onto which xed

cationic sites are tethered.

For example, one can

functionalize polysulfone via

chloromethylation followed

by reaction with an amine

(quaternization) or phosphine

to yield a quaternary

ammonium or phosphonium

salt. The salt form of the

membrane is readily

alkalinized by treatment

with KOH to yield a

hydroxide ion conducting

AEM. As an example, Fig. 3

shows the reaction scheme

for converting Udel

polysulfone (from Solvay

Advanced Polymers LLC)

into an anion-exchange

membrane polymer.

The rst and foremost

challenge for polymer chemists,

membrane scientists, and

electrochemists is to

fabricate anion-exchange

membranes with a high

OH

-

ion conductivity and

good mechanical properties.

Anion-exchange groups

do not strongly dissociate

(as do SO

3

H groups in

cation-exchange membranes like Naon

) and the inherent

electrochemical mobility of OH

-

in water is much lower than

that of a proton. Thus, it is very difcult for the ionic (hydroxide)

conductivity of AEMs to approach that of typical/commercial

PEMs. While AEM ionic conductivity can be enhanced by

increasing the number of cationic sites, i.e. by increasing the

polymers ion exchange capacity (IEC), this approach is limited

due to the concomitant deterioration in AEM mechanical

properties with increasing xed charge concentration; i.e.,

excessive swelling and the loss of mechanical properties when

the membranes are fully hydrated and brittleness when the

lms are partially hydrated or dry. Typical fuel cell conductivity

vs. ion-exchange capacity data (in water at 25

o

C) are shown

in Fig. 4 for a block copolymer anion-exchange membrane

The Electrochemical Society Interface Summer 2010 33

FIG. 2. General requirements for the successful production of alkaline fuel cell membranes.

Table I. Fuels for AEM fuel cells with standard thermodynamic voltages and energy densities.

Fuel Standard Thermodynamic Voltage, E

O, cell

, [V] Energy Density [kWh/kg] References

Hydrogen 1.23 39.0 [3]

Methanol 1.21 6.1 [3]

Ethanol 1.15 8.0 [3]

Propanol 1.07 8.6 [3]

Ethylene Glycol 1.22 5.3 [3]

Sodium Borohydride 1.24 9.3 [10]

based on xylylene ionenes.

5

The conductivities are

quite low, considering the

high polymer ion-exchange

capacity. Additionally, exces-

sive membrane swelling

for IECs > 2.2 mmol/g

causes the conductivity

to drop with increasing

xed charge concentration

(swelling reduces the

effective membrane-phase

concentration of xed

charges, leading to a drop in

conductivity).

It has been well

documented that AEMs also

suffer from poor chemical

stability (ironically in

alkaline environments).

3,4

Chemical degradation of

AEMs stems largely from

nucleophilic attack on

the cationic xed charged

sites by hydroxide ions.

Consequences of this

degradation mechanism

are a loss in the number of

ion-exchange groups, with a

subsequent decrease in OH

-

ion conductivity. A key mode

of degradation for AEMs is

the Hoffman elimination

reaction, wherein hydroxide

ions attack a hydrogen

atom on the beta carbon

relative to the cation. In this

degradation mechanism,

a double bond forms

between the alpha and

beta carbons, resulting in

the cation being released

(See Fig. 5). Another mode

of polymer degradation

is direct nucleophilic

displacement at the cation

site, which can occur by two

possible reaction pathways

in quaternary ammonium

xed-charge site membrane (see Figs. 6 and 7). Here, in the

absence of beta hydrogens, hydroxide ions attack either a

methyl group on the quaternary ammonium moieties and

form an alcohol or attack the C-C bond between the alpha

and beta carbons to cleave the cation site.

3,4

More information

on these and other degradation modes are available in the

literature.

6 (a-d)

There are on-going efforts to better understand

6

(c,d)

degradation mechanisms and either modify or re-design

the cation sites in AEMs.

7

The development of methods and materials for AEMFC

membrane-electrode-assembly (MEA) fabrication lag far

behind similar work for proton exchange membrane fuel cells.

Difculties lie in the inherently low hydroxide conductivity

and poor durability of anion-exchange polymer binders, the

absence of suitable low boiling-point, water-soluble organic

solvents for catalyst ink preparation, and the absence of

fast and efcient membrane/electrode attachment schemes

(i.e., techniques analogous to the hot-pressing and decal

methods used for proton exchange membrane fuel cell MEAs).

Most studies in the literature use of Pt catalysts in AEMFC

prototypes, as opposed to non-noble metal catalysts, which

negates a prime advantage of alkaline fuel cells as compared to

PEM devices. Thus, there remains a need for further AEMFC

catalyst development and a need to show prototype operational

Alkaline Fuel Cell Membranes

Robust Synthetic Route

Highly specific chemistry

Ability to add different cationic groups

Mild reaction conditions

Selection of Fixed-Charge-Site Cation

High cation stability

High fixed-cation concentration in the membrane

Appropriate cation placement in macromolecular structure

Control of Membrane Morphology

Use of block or segmented copolymers; polymer croslinking

Controllable nano-phase separated morphology

Crystallizable non-polar segments

Scalability

Inexpensive starting materials

Simple reaction schemes

Solution casting of membranes using standard solvents/equipment

AEMFCs that are totally free of precious metals. Two recent

papers illustrate the challenges facing MEA fabrication

scientists and engineers who are searching for materials and

processing schemes that will boost AEMFC power outputs.

In one paper,

8

Y. Yan and coworkers utilize a methanol-

soluble quaternary phosphonium containing anion-exchange

polymer as the electrode binder in an AEMFC, where Pt-black

was used as the anode and cathode electrocatalysts and a

Fuma-Tech GmbH anion-exchange membrane (0.017 S/cm

conductivity in water at 20

o

C) was used to prepare MEAs.

A power density of 138 mW/cm

2

was achieved at 70

o

C with

pressurized H

2

and O

2

feed. In another paper,

9

L. Zhuang, et

al., fabricated an AEMFC membrane-electrode-assembly with

a Ag anode and a Cr-decorated Ni cathode (i.e., with no Pt),

where a quaternary ammonium polysulfone was used as the

membrane and electrode binder. For H

2

and O

2

feeds at a

pressure of 1.3 atm. and an operating temperature of 60

o

C,

a maximum power density of 50 mW/cm

2

was reported. The

power densities reported in these two articles are far below

those that are typically achieved in a PEM fuel cell with

hydrogen and air feeds at Pt/C electrodes (600-700 mW/cm

2

at 60

o

C). Also, the use of O

2

for the cathode feed is unrealistic

for consumer applications.

34 The Electrochemical Society Interface Summer 2010

Summary and Outlook

Theoretically, AEMFCs can

operate on a variety of fuels and

generate high power densities at

moderate operating temperatures.

The real advantage (albeit not

currently realized in practice) of

AEMFCs vis--vis PEM fuel cells is

the absence of expensive noble metal

catalysts in the electrodes. AEMFCs

have their own set of challenges, as

related to materials and processing

schemes, which require innovative

engineering solutions. Key among

these are the conductivity and

durability of the anion-exchange

membrane, the identication of

suitable OH

-

ion conductive polymers

for anode and cathode binders, and

the identication/optimization

of membrane-electrode-assembly

preparation methods. Recently, there

has been a surge in alkaline fuel

cell research activities and interest.

Many researchers are switching

their research outlook from an

exclusive focus on PEMs/PEMFCs

to one that includes (at a signicant

level of effort) AEM and AEMFCs.

Progress is being made, research

funding for AEMFCs is seeing an

upward trend, and more papers on

the subject are being published. The

very positive developments over the past ten years resulting

in improved PEMFC performance and durability with lower

manufacturing costs bode well for similar progress on the

AEMFC front, especially given the increasing commitment to

this technology that is emerging.

About the Authors

CHRISTOPHER ARGES is a rst year PhD student in the

Department of Chemical and Biological Engineering at Illinois

Institute of Technology, Chicago. He is conducting doctoral

research in the area of Anion Exchange Membranes for

Alkaline Fuel Cells under Prof. Vijay Ramani. Arges received

his BS from the University of Illinois (Urbana-Champaign)

and his MS from North Carolina State University, both in

Arges, et al.

(continued from previous page)

n

ION EXCHANGE

n

CHLOROMETHYLATION

(CH

3

)

3

SiCl+(CH

2

O)

n

+SnCl

4

1M KOH

O

CH

3

CH

3

S

O

O

O

n

QUATERNIZATION

n

(CH

3

)

3

N

ClH

2

C

CH

2

Cl

O

CH

3

CH

3

S

O

O

O

( H

3

C)

3

NH

2

C CH

2

N(CH

3

)

3

+

Cl

-

O

CH

3

CH

3

S

O

O

O

(H

3

C)

3

NH

2

C

CH

2

N( CH

3

)

3

+

OH

-

O

CH

3

CH

3

S

O

O

O

-

OH

+

-

Cl

+

FIG. 3. The chemical reaction steps to convert a polysulfone to an anion-exchange membrane polymer.

FIG. 4. General chemical structure of a block copolymer based on xylylene ionenes (left) and typical variations in OH

-

ion conductivity and water uptake

with membrane ion-exchange capacity (from Ref. 5).

chemical engineering. Prior to joining IIT, he spent four years

working in industry (with Hospira and Baxter). He may be

reached at: carges@iit.edu.

VIJAY K. RAMANI is an Assistant Professor of Chemical

Engineering in the Department of Chemical and Biological

Engineering at Illinois Institute of Technology, Chicago. His

research interests lie in the broad area of electrochemical

engineering, with an emphasis on materials for electrochemical

energy conversion and storage. NSF, ONR, and DOE currently

fund his research. He is the recipient of a 2009 NSF-CAREER

award as well as a 2010 ONR-Young Investigator Award (ONR-

YIP). Ramani has a PhD from the University of Connecticut,

Storrs, and a BE from Annamalai University, India, both in

chemical engineering. He may be reached at ramani@iit.edu.

The Electrochemical Society Interface Summer 2010 35

FIG. 5. AEM degradation mechanism: the Hoffman elimination reaction.

FIG. 6. AEM degradation mechanism: direct nucleophilic substitution pathway 1.

FIG. 7. AEM degradation mechanism: direct nucleophilic substitution pathway 2.

PETER N. PINTAURO is the H. Eugene McBrayer Professor

of Chemical Engineering and Chair of the Department

of Chemical and Biomolecular Engineering at Vanderbilt

University. His research interests include new ion conducting

membranes for fuel cells, development of space-charge models

for ion uptake and transport in ion-exchange membranes, and

organic electrochemical synthesis. He has BS and MS degrees

from the University of Pennsylvania and a PhD from UCLA,

all in chemical engineering. He may be reached at peter.

pintauro@vanderbilt.edu.

References

1. F. Barbir, PEM Fuel Cells: Theory and Practice,

Elsevier Academic Press (2005).

2. H. A. Gasteiger, S. S. Kocha, B. Sompalli, and F. T.

Wagner, Appl. Catal., B., 56, 9 (2005).

3. J. R. Varcoe and R. C. T. Slade, Fuel Cells, 5, 187

(2005).

4. B. Bauer, H. Strathmann, and F. Effenberger,

Desalination, 79, 125 (1990).

5. K. M. Lee, R. Wycisk, M. Litt, P. N. Pintauro, and

J. A. Kosek, Abstract No. 344, The Electrochemical

Society Meeting Abstracts, Vol. 2009-02, Vienna,

Austria, October 4-9, 2009.

6. (a) T. Sata, M. Tsujimoto, T. Yamaguchi, and K.

Matsusaki, J. Membrane Sci., 112, 161 (1996); (b) E.

N. Komkova, D. F. Stamatialis, H. Strathmann, and

M. Wessling, J. Membrane Sci., 244, 25 (2004); (c)

S. Chempath, B. Einsla, L. Pratt, C. Macomber, J.

Boncella, J. Rau, and B. Pivovar, J. Phys. Chem. C,

112, 3179 (2008); (d) C. S. Macomber, J. M. Boncella,

and B. S. Pivovar, J. Thermal Anal. Calorimetry, 93,

225 (2008).

7. B. Pivovar and D. Thorn, U.S. Patent 7,439,275 B2

(2008).

8. S. Gu, R. Cai, T. Luo, Z. Chen, M. Sun, Y. Liu, G.

He, and Y. Yan, Angew. Chem. Int. Ed., 48, 6499

(2009).

9. S. Lu, J. Pan, A. Huang, L. Zhuang, and J. Lu, Proceed.

Natl. Acad. Sci., 105, 20611 (2008).

10. C. Ponce de Leon, F. C. Walsh, D. Pletcher, D. J.

Browning, and J. B. Lakeman, J. Power Sources, 155,

172 (2006).

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Principles and Application Lithium Secondary BatteriesDocument7 pagesPrinciples and Application Lithium Secondary BatteriesGonzalo Almeida0% (1)

- Measuring Temperature with ThermometersDocument57 pagesMeasuring Temperature with ThermometersCyril Lyn Natividad Credo91% (11)

- MBR-C3 Fouling & CleaningDocument31 pagesMBR-C3 Fouling & CleaningAlfonso José García Laguna100% (1)

- Synthesis of Ibuprofen From BenzeneDocument11 pagesSynthesis of Ibuprofen From BenzeneEriika SaucdoNo ratings yet

- Bioreactor Instrumentation MeasurementsDocument12 pagesBioreactor Instrumentation MeasurementsIrish Siaotong100% (1)

- PaperLUBMAT FinalDocument7 pagesPaperLUBMAT FinalluisA1923No ratings yet

- Water As The Universal SolventDocument2 pagesWater As The Universal Solventwsjouri2510No ratings yet

- 5.5 Limiting ReactantsDocument9 pages5.5 Limiting ReactantsMarc LoNo ratings yet

- SEO-Optimized Title for Physics Problems on Cylinder Suspended by Spring, Magnetic Field Induced EMF, and MoreDocument11 pagesSEO-Optimized Title for Physics Problems on Cylinder Suspended by Spring, Magnetic Field Induced EMF, and Moresanchit199617100% (1)

- NEET 2019 Question Paper With Answers and Solution ChemistryDocument11 pagesNEET 2019 Question Paper With Answers and Solution Chemistryashutosh singh pariharNo ratings yet

- Rikken Keiki, HW Sensor, Gas DetectorDocument1 pageRikken Keiki, HW Sensor, Gas DetectorRangga TaufiqurahmanNo ratings yet

- Five Fluid PDFDocument14 pagesFive Fluid PDFاحمد ابوبكر اشقيفهNo ratings yet

- Reaksi Alkilasi Friedel-Crafts: Kimia Organik II Jurusan Pendidikan KimiaDocument10 pagesReaksi Alkilasi Friedel-Crafts: Kimia Organik II Jurusan Pendidikan KimiaEkanisaKurniawatiNo ratings yet

- OkjhgfdsdDocument9 pagesOkjhgfdsdAntarjotNo ratings yet

- Thermodynamics SyllabusDocument1 pageThermodynamics SyllabusPrashant KashyapNo ratings yet

- Physicochemical Principles of Pharmacy, 4th Ed - Chapter4Document46 pagesPhysicochemical Principles of Pharmacy, 4th Ed - Chapter4rinNo ratings yet

- The Mass-Energy Equivalence Principle in Taheri's Theories of Consciousness by Converting Silica To Taheri's ConsciousnessDocument14 pagesThe Mass-Energy Equivalence Principle in Taheri's Theories of Consciousness by Converting Silica To Taheri's Consciousnessspring baharNo ratings yet

- Question 812038Document9 pagesQuestion 812038Rudrapalash ChakrabartiNo ratings yet

- Determination of Indiactor Constant of Bromocresol GreenDocument3 pagesDetermination of Indiactor Constant of Bromocresol GreenShouvik MitraNo ratings yet

- Experimental Investigation On Cascade Refrigeration System With and Without Phase Change MaterialDocument8 pagesExperimental Investigation On Cascade Refrigeration System With and Without Phase Change MaterialijsretNo ratings yet

- Chemical EOR S2 1Document199 pagesChemical EOR S2 1Amry Sitompul100% (1)

- ME 409 Compressible Fluid Flows ExamDocument2 pagesME 409 Compressible Fluid Flows ExamAswith R ShenoyNo ratings yet

- Numerical Modelling of A Direct Contact Condensation Experiment Using The AIAD FrameworkDocument25 pagesNumerical Modelling of A Direct Contact Condensation Experiment Using The AIAD FrameworkAmin AlAhmadyNo ratings yet

- ch19 EDDocument55 pagesch19 EDAnonymous NfxLyygnckNo ratings yet

- 0620 s14 QP 62Document12 pages0620 s14 QP 62BrianChanNo ratings yet

- Kodak Silver RecoveryDocument4 pagesKodak Silver Recovery程杰No ratings yet

- Bureau of Indian Standards - PCD12Document15 pagesBureau of Indian Standards - PCD12Divya BajpaiNo ratings yet

- Experiment 3: Organic ChemistryDocument5 pagesExperiment 3: Organic ChemistryIsuri Vidyarathne100% (1)

- Assignment Topic: HPLC M.D & ApplicationDocument7 pagesAssignment Topic: HPLC M.D & ApplicationUsman GhaniNo ratings yet

- Closed Reflux Titrimetric COD Method SummaryDocument2 pagesClosed Reflux Titrimetric COD Method SummaryAlberto VELOSA ROANo ratings yet