Professional Documents

Culture Documents

3P 47

Uploaded by

Amber ChavezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3P 47

Uploaded by

Amber ChavezCopyright:

Available Formats

Proceedings of Symposium on Ultrasonic Electronics, Vol. 31 (2010) pp.

549-550

6-8 December, 2010

Dispersion effect of nano particle according to

ultrasound exposure by using focused ultrasonic field

Moojoon Kim

1

, Jungsoon Kim

2

, Misun Jo

1

and Kanglyeol Ha

1

(

1

Pukyong National

Univ., Korea;

2

Tongmyong Univ., Korea)

1. Introduction

Recently, since the technique of nano particle

synthesis has improved, its commercialization has

also advanced in fields such as cosmetics, medicine,

catalyst, pigments, toner, and ink in which they are

used in the state of the colloidal dispersion system

and the powder of the low concentration. When

synthesized nanosize particles are used as raw

material, however, the control of agglomeration and

dispersion behavior becomes extremely difficult for

particle diameters of 100 nm or less. In the past

several years there has been increasing interest in

dispersion methods using ultrasonic power for nano

particle

1-2

. Because the material dispersed by the

method is much purer than that produced by bead

milling. We also have already reported a high purity

dispersion method using focused ultrasonic field

3

.

The present study focuses on the effects of

ultrasonic irritation on aqueous suspension of TiO

2

nanoparticles under various exposure conditions.

2. Experimental procedure

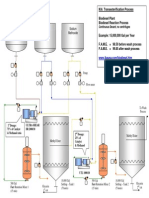

To obtain a focused ultrasonic field, an

ultrasonic dispersion system was fabricated using a

cylindrical piezoelectric vibrator as shown in Fig. 1.

A glass tube, whose thickness, diameter, and length

measured 0.3, 5.5, and 35 mm, respectively was

placed in the center an aluminum water tank.

Fig. 1 Construction of ultrasonic dispersion system

Aqueous suspension of TiO

2

(P25) was circulated

through a plastic tube connecting the glass tube to a

water pump. The aluminum water tank was then

inserted into the cylindrical vibrator of 480 kHz

resonance frequency.

------------------------------------------------------------

kimmj@pknu.ac.kr

The water tank of 36 mm inner diameter was filled

with water for transmission of ultrasonic energy to

the glass tube. The TiO

2

suspension of 0.025 % was

circulated with a flow rate of 3 mL/s to prevent

change of pH in the suspension

4

. An electric signal

from a power amplifier (NF-HSA4014) drove the

cylindrical piezoelectric vibrator. The ultrasonic

wave from the vibrator was focused on the center of

the glass tube. The ultrasonic cavitations due to the

high pressure amplitude disperse the nanoparticles

in the suspension. The particle size distribution was

measured using a particle counter (GRIMM Aerosol

Technik).

3. Results and discussion

To obtain the electro-acoustic efficiency of

the ultrasonic transducer, the admittance loci were

measured as shown in Fig. 2. The diameter of

admittance locus is reduced when an acoustic load

is loaded on the surface of the vibrator. The

electro-acoustic efficiency of the ultrasonic

transducer can be obtained by using the difference

of the diameter in admittance locus as

5

|

|

.

|

\

|

=

moo

mo

f

mo

ea

Y

Y

G

Y

1

0

q

. (1)

Here Y

mo

and Y

moo

are motional admittance with the

acoustic load and the non-acoustic load,

respectively. G

f0

is conductance at resonant

frequency with the acoustic load. From the results

of Fig. 2 and eq(1), the electro-acoustic efficiency

of the ultrasonic transducer was obtained as 48 %.

To investigate the effect of radiation power of

ultrasound, the particle size distributions were

measured for different input electric powers and

exposure time of the ultrasound as shown in Fig. 3.

These results show the tendency that the dispersion

effect become well as the power and the exposure

time of ultrasound increased. In the result of the

suspension without ultrasonic irritation, the second

peak in the range of 150~300 nm was broken after

the strong ultrasound was irritated. It causes the

increment in the range of 50~150 nm of the results

in the materials dispersed by the ultrasound. It

confirmed that the dispersion effect is best when the

exposure time is 10 min and the acoustic power is

549

3P-47

about 5.5 W.

0 100 200 300 400

-200

-100

0

100

200

G

f0

Y

mo

Y

moo

S

u

s

c

e

p

t

a

n

c

e

[

m

S

]

Conductance[mS]

Fig. 2 Admittance loci of the cylindrical transducer.

100 1000

10

100

1000

d

N

[

/

c

m

3

]

Particle size [nm]

Exposure time: 1 min

1.30 W

2.11 W

5.52 W

0 W

(a)

100 1000

10

100

1000

d

N

[

/

c

m

3

]

Particle size [nm]

Exposure time: 6 min

0.26 W

1.30 W

2.21 W

5.52 W

0 W

(b)

100 1000

10

100

1000

d

N

[

/

c

m

3

]

Particle size [nm]

Exposure time: 10 min

0.26 W

1.30 W

2.21 W

5.86 W

0 W

(c)

Fig. 3 Dispersion effect according to the ultrasonic

power exposed on the suspension of the

nanoparticle.

100 1000

10

100

1000

d

N

[

/

c

m

3

]

Particle size [nm]

Exposure time

10 min (2.21 W)

6 min (2.21 W)

1 min (2.11 W)

0 min (0 W)

(a)

100 1000

10

100

1000

d

N

[

/

c

m

3

]

Particle size [nm]

Exposure time

10 min (5.86 W)

6 min (5.52 W)

1 min (5.52 W)

0 min (0 W)

(b)

Fig. 4 Dispersion effect according to the ultrasonic

exposure time.

4. Conclusion

The effects of a focused ultrasonic field on

dispersion in aqueous TiO

2

suspension was

investigated. The particle size distribution of the

suspension was measured for various exposure

conditions of ultrasonic irritation. The dispersion

effect of the nanoparticles increased as the exposure

time and the power of the ultrasound increased. It

was concluded that focused ultrasonic irratation is a

useful way of pure dispersion of nanoparticles in

aggregated aqueous suspensions.

Acknowledgment

This research was supported by Basic Science Research Program

through the National Research Foundation of Korea (NRF) funded by

the Ministry of Education, Science and Technology(2010-0002307).

References

1. C. Lee, J. Lee, S. Oh: Materials Letters 57 (2003)

2643.

2. K. Sato, J. Li, H. Kamiya and T. Ishigak: J. Am.

Ceram. Soc. 91 (2008) 2481.

3. J. Kim, M. Kim, K. Ha, and M. Chu: Jpn. J. Appl.

Phys. 49 (2010) 07HE21.

4. T. Nakamura, H. Okawa, R. Hosokawa, T. Saito,

Y. Kawamura1 and K. Sugawara: Jpn. J. Appl. Phys.

49 (2010) 07HE11.

5. M. Kim and N. Chubachi: T. IEE Japan, 114-C,

(1994) 42.

550

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- SVW 12 1000kW 41000 To 3412000 BtuhDocument2 pagesSVW 12 1000kW 41000 To 3412000 BtuhAmber ChavezNo ratings yet

- Skedule Kontruksi Mekanikal Elektrical CPO PlantbetulDocument1 pageSkedule Kontruksi Mekanikal Elektrical CPO PlantbetulAmber ChavezNo ratings yet

- PDD Asahimas Fuel Switching Ancol Draft To DOE200907Document30 pagesPDD Asahimas Fuel Switching Ancol Draft To DOE200907Amber ChavezNo ratings yet

- 50 M3/jam 960 Liter/menit 9,6 JT MCS, 8,7 JTGLP, Elektrik 18,5 KW, 25 HP 7,6 Jt. Couple 1,5 JTDocument1 page50 M3/jam 960 Liter/menit 9,6 JT MCS, 8,7 JTGLP, Elektrik 18,5 KW, 25 HP 7,6 Jt. Couple 1,5 JTAmber ChavezNo ratings yet

- Tool For Measuring Piking: R Nominal Radius of The TankDocument4 pagesTool For Measuring Piking: R Nominal Radius of The TankAmber ChavezNo ratings yet

- Laboratory 4 Two and Three Phase Separators Oct 2, 2002: Che 365 Chemical Engineering Design IDocument1 pageLaboratory 4 Two and Three Phase Separators Oct 2, 2002: Che 365 Chemical Engineering Design IAmber ChavezNo ratings yet

- Workbook: Case (Main) : Material StreamsDocument1 pageWorkbook: Case (Main) : Material StreamsAmber ChavezNo ratings yet

- Alat Panas Unit Jumlah PanasDocument14 pagesAlat Panas Unit Jumlah PanasAmber ChavezNo ratings yet

- Methanol: Sodium MethoxideDocument3 pagesMethanol: Sodium MethoxideAmber ChavezNo ratings yet

- Return Calculations Subordinated Loan With EBITDA ParticipationDocument2 pagesReturn Calculations Subordinated Loan With EBITDA ParticipationAmber ChavezNo ratings yet

- Spec Bypass OilDocument1 pageSpec Bypass OilAmber ChavezNo ratings yet

- Define The Thesis ProblemDocument2 pagesDefine The Thesis ProblemAmber ChavezNo ratings yet

- Manuscript Info: International Journal of Advanced ResearchDocument6 pagesManuscript Info: International Journal of Advanced ResearchAmber ChavezNo ratings yet

- Rubber Statistical News: The TrendDocument4 pagesRubber Statistical News: The TrendAmber ChavezNo ratings yet

- Chemical Safety and Security Plan OutlineDocument1 pageChemical Safety and Security Plan OutlineAmber ChavezNo ratings yet

- Compressed Gas Cylinder SOPDocument4 pagesCompressed Gas Cylinder SOPAmber ChavezNo ratings yet

- Sewa TendaDocument1 pageSewa TendaAmber ChavezNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Structural Analysis Tutorial 7Document5 pagesStructural Analysis Tutorial 7pratyush mishraNo ratings yet

- Act 3 Lab EquipmentDocument2 pagesAct 3 Lab EquipmentShanna Sophia PelicanoNo ratings yet

- Type 2Document7 pagesType 2AnOnYmOuS_1995No ratings yet

- Las Piñas Science High SchoolDocument2 pagesLas Piñas Science High Schooldeviehex0% (1)

- Lecture 15Document8 pagesLecture 15Aravindan NatarajanNo ratings yet

- Semiconductor ElectronicsDocument46 pagesSemiconductor Electronicspraveen2910No ratings yet

- Design of Composite Haunch Beams and Connections For Long Span Applications PDFDocument176 pagesDesign of Composite Haunch Beams and Connections For Long Span Applications PDFVance kang100% (1)

- Safer Products and Practices For Disinfecting and Sanitizing SurfacesDocument58 pagesSafer Products and Practices For Disinfecting and Sanitizing SurfacesPariseerNo ratings yet

- Planck Constant - Wikipedia, The Free EncyclopediaDocument15 pagesPlanck Constant - Wikipedia, The Free Encyclopediad_richard_dNo ratings yet

- Crane Copper Tub Evie GaDocument22 pagesCrane Copper Tub Evie GaonspsnonsNo ratings yet

- Aluminium Sheet Grade 65032 SuppliersDocument17 pagesAluminium Sheet Grade 65032 Supplierssanghvi overseas incNo ratings yet

- Hyundai Welding Co., LTDDocument4 pagesHyundai Welding Co., LTDGerry Dan ChanliongcoNo ratings yet

- Common Causes of Battery FailuresDocument2 pagesCommon Causes of Battery Failuresavandetq15No ratings yet

- Manufacturing Technologies: Technological HistoryDocument8 pagesManufacturing Technologies: Technological HistoryKema Technowaka0% (1)

- 40 Item Test Science 6with Key To CorrectionDocument5 pages40 Item Test Science 6with Key To CorrectionvinnNo ratings yet

- Spartan 16 ManualDocument579 pagesSpartan 16 ManualwuNo ratings yet

- SSG Manual: Dow Performance SiliconesDocument59 pagesSSG Manual: Dow Performance SiliconesAditya KNo ratings yet

- Hydrcolloids 2Document24 pagesHydrcolloids 2nakshatra1714No ratings yet

- JEE Main 2023 31 January Shift 2Document13 pagesJEE Main 2023 31 January Shift 2barnwalk367No ratings yet

- Food ProcessingDocument52 pagesFood ProcessingAtanacia IlaganNo ratings yet

- 15 Esp DSTDocument10 pages15 Esp DSTام فاطمة البطاطNo ratings yet

- 60 - BS 13577 2007Document12 pages60 - BS 13577 2007mazos77No ratings yet

- INTRO To ORGANIC CHEMISTRYDocument60 pagesINTRO To ORGANIC CHEMISTRYNailah KaharNo ratings yet

- Hydrothol 191 Granular Herbicide MsdsDocument6 pagesHydrothol 191 Granular Herbicide MsdsSouth Santee AquacultureNo ratings yet

- Differential EquationDocument9 pagesDifferential EquationmCmAlNo ratings yet

- Activity Sheets For Chem With NamesDocument6 pagesActivity Sheets For Chem With Namesapi-283862617100% (1)

- DT Series Digital TachometerDocument3 pagesDT Series Digital TachometerMamani JesusNo ratings yet

- Em 1110-2-2901Document206 pagesEm 1110-2-2901Naveen RNo ratings yet

- C1604C1604MDocument5 pagesC1604C1604MJorge Luis Arevalo Lopez100% (1)

- Magic Cleaner - FroniusDocument4 pagesMagic Cleaner - FroniusKristy DavisNo ratings yet