Professional Documents

Culture Documents

Non Destructive Testing in Welder Qualification

Uploaded by

sulemankhan0 ratings0% found this document useful (0 votes)

59 views3 pagesNDT Codes

Original Title

Codes

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentNDT Codes

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

59 views3 pagesNon Destructive Testing in Welder Qualification

Uploaded by

sulemankhanNDT Codes

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

Non Destructive Testing in Welder Qualifcation

Reference: ASME Sec IX

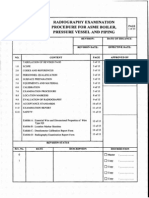

QW-! Radiogra"#ic E$a%ination

QW-!& Met#od& The radiographic examination in QW-142 for welders and in QW-143 for

welding operators

shall meet the requirements of Article 2, ection !, except as follows"

(a) A written radiographic examination procedure is not required# $emonstration of densit%

and penetrameter

image requirements on production or technique radiographs shall &e considered satisfactor%

e'idence of compliance

with Article 2 of ection !#

(b) The requirements of T-2() of Article 2 of ection ! are to &e used onl% as a guide# *inal

acceptance of

radiographs shall &e &ased on the a&ilit% to see the prescri&ed penetrameter image and the

speci+ed hole or the

designated wire or a wire penetrameter# The acceptance standards of QW-1,1#2 shall &e

met#

QW-!&' Radiogra"#ic Acce"tance (riteria

QW-!&'& Ter%inolog)

(a) Linear Indications. -rac.s, incomplete fusion, inadequate penetration, and slag are

represented on the

radiograph as linear indications in which the length is more than three times the width#

(b) Rounded Indications. /orosit% and inclusions such as slag or tungsten are represented on

the radiograph

as rounded indications with a length three times the width or less# These indications ma% &e

circular, elliptical, or

irregular in shape0 ma% ha'e tails0 and ma% 'ar% in densit%#

QW-!&'&' Acce"tance Standards& Welder and welding operator performance tests &%

radiograph% of

welds in test assem&lies shall &e 1udged unaccepta&le when the radiograph exhi&its an%

imperfections in excess

of the limits speci+ed &elow#

(a) Linear Indications

(1) an% t%pe of crac. or 2one of incomplete fusion or penetration

(2) an% elongated slag inclusion which has a length greater than

(a) 13( in# 43 mm5 for t up to 33( in# 416 mm5, inclusi'e

(b) 133t for t o'er 33( in# 416 mm5 to 2134 in# 4)7 mm5, inclusi'e

(c) 334 in# 41, mm5 for t o'er 2134 in# 4)7 mm5

(3) an% group of slag inclusions in line that ha'e an aggregate length greater than t in a

length of 12t, except

when the distance &etween the successi'e imperfections exceeds 8L where L is the length of

the longest imperfection in the group

(b) Rounded Indications

(1) The maximum permissi&le dimension for rounded indications shall &e 269 of t or 13( in# 43

mm5,

whiche'er is smaller#

(2) *or welds in material less than 13( in# 43 mm5 in thic.ness, the maximum num&er of

accepta&le rounded

indications shall not exceed 12 in a 8 in# 41)6 mm5 length of weld# A proportionatel% fewer

num&er of rounded

indications shall &e permitted in welds less than 8 in# 41)6 mm5 in length#

(3) *or welds in material 13( in# 43 mm5 or greater in thic.ness, the charts in Appendix :

represent the maximum

accepta&le t%pes of rounded indications illustrated in t%picall% clustered, assorted, and

randoml% dispersed

con+gurations# ;ounded indications less than 1332 in# 46#( mm5 in maximum diameter shall

not &e considered in the radiographic acceptance tests of welders and welding operators in

these ranges of material thic.nesses#

QW-!&'&* +roduction Welds& The acceptance standard for welding operators who

qualif% on production

welds shall &e that speci+ed in the referencing -ode ection# The acceptance standard for

welders who qualif%

on production welds as permitted &% QW-364#1 shall &e per QW-1,1#2#2#

QW-!&* Record of Tests& The results of welder and welding operator performance tests

&% radiograph%

shall &e recorded in accordance with QW-361#4#

QW-,, -isual E$a%ination

!isual examination as descri&ed in QW-1,4 is used to determine that the +nal weld surfaces

meet speci+ed

qualit% conditions#

QW-!, -isual E$a%ination . +erfor%ance

/erformance test coupons shall show complete 1oint penetration with complete fusion of

weld metal and &ase

metal#

QW-!/ 0i1uid +enetrant E$a%ination

QW-!/& The liquid penetrant examination in QW- 214 for corrosion-resistant weld metal

o'erla% shall meet

the requirements of ection !, Article 8# The acceptance standards of QW-1,)#2 shall &e

met#

QW-!/&' 0i1uid +enetrant Acce"tance (riteria

QW-!/&'& Ter%inolog)

relevant indications" indications with ma1or dimensions greater than 1318 in# 41#) mm5#

linear indications" an indication ha'ing a length greater than three times the width#

rounded indications" an indication of circular or elliptical shape with the length equal to or

less than three times

the width#

QW-!/&'&' Acce"tance Standards& /rocedure and performance tests examined &%

liquid penetrant techniques

shall &e 1udged unaccepta&le when the examination exhi&its an% indication in excess of the

limits

speci+ed &elow"

(a) rele'ant linear indications

(b) rele'ant rounded indications greater than 3318 in# 4) mm5

(c) four or more rele'ant rounded indications in a line separated &% 1318 in# 41#) mm5 or less

4edge-to-edge5

QW-*2'&' Radiogra"#ic E$a%ination& When the welder or welding operator is quali+ed

&% radiographic

examination, as permitted in QW-364 for welders and QW-36) for welding operators, the

minimum length of

coupon4s5 to &e examined shall &e 8 in# 41)6 mm5 and shall include the entire weld

circumference for pipe4s5,

except that for small diameter pipe, multiple coupons ma% &e required, &ut the num&er

need not exceed four

consecuti'el% made test coupons# The radiographic technique and acceptance criteria shall

&e in accordance with

QW-1,1#

QW-*2/&' 3ailure to Meet Radiogra"#ic Standards&

:f a portion of a production weld is selected for welding operator performance quali+cation,

and it does not meet the radiographic standards, the welding operator has failed the test# :n

this e'ent, the entire production weld made &% this welding operator shall &e radiographed

completel% and repaired &% a quali+ed welder or welding operator# Alternati'el%, retests ma%

&e made as permitted in QW-326#

QW-*2'&, -isual E$a%ination&

*or plate coupons all surfaces 4except areas designated <discard=5 shall &e examined

'isuall% per QW-1,4 &efore cutting of &end specimens# /ipe coupons shall &e 'isuall%

examined per QW-1,4 o'er the entire circumference, inside and outside#

QW-*'2 RETESTS AND RENEWA0 43 Q5A0I3I(ATI4N

QW-*' Retests

A welder or welding operator who fails one or more of the tests prescri&ed in QW-364 or QW-

36), as applica&le,

ma% &e retested under the following conditions#

QW-*'& I%%ediate Retest 5sing -isual E$a%ination&

When the quali+cation coupon has failed the 'isual examination of QW-362#4, retesting shall

&e &% 'isual examination &efore conducting the mechanical testing# When an immediate

retest is made, the welder or welding operator shall ma.e two consecuti'e test coupons for

each position which he has failed, all of which shall pass the 'isual examination

requirements# The examiner ma% select one of the successful test coupons from each set of

retest coupons which pass the 'isual examination for conducting the mechanical testing#

You might also like

- RT Asme IxDocument3 pagesRT Asme Ixhernando gelves100% (1)

- Welder Qualification Radiography Acceptance CriteriaDocument2 pagesWelder Qualification Radiography Acceptance CriteriaKamalnath KpNo ratings yet

- ASME Section IX Welding Qualification RequirementsDocument5 pagesASME Section IX Welding Qualification Requirementskirubha_karan2000No ratings yet

- Note 7 - Welder Test - Mechanical Test and X-RayDocument29 pagesNote 7 - Welder Test - Mechanical Test and X-RayMohamad Yusuf HelmiNo ratings yet

- Asme Sec IxDocument3 pagesAsme Sec IxMd Ashikur RahmanNo ratings yet

- 2-Asme BPVC Section Ix-2013Document2 pages2-Asme BPVC Section Ix-2013Reda ElsawyNo ratings yet

- Asme Section IxDocument71 pagesAsme Section Ixranjitkumar1977100% (1)

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarNo ratings yet

- Interview ASME SEC IX & General QUESTIONSDocument45 pagesInterview ASME SEC IX & General QUESTIONSabdo50% (2)

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 pagesEnbridge Pipeline Repair Workplan Welding PDFquiron2014No ratings yet

- 5welding BasicsDocument70 pages5welding BasicssreeNo ratings yet

- Asme-Ix PDFDocument9 pagesAsme-Ix PDFMuhammad ThohirNo ratings yet

- Acceptance CriteriaDocument11 pagesAcceptance Criteriarajali798890% (10)

- Asme Sec Ix-WpqDocument47 pagesAsme Sec Ix-WpqKaushal Sojitra100% (1)

- Enbridge Pipeline Repair Workplan WeldingDocument23 pagesEnbridge Pipeline Repair Workplan WeldingJesus MaestreNo ratings yet

- SECTION 20710 Flash Butt Rail Welding: Caltrain Standard SpecificationsDocument8 pagesSECTION 20710 Flash Butt Rail Welding: Caltrain Standard SpecificationsminchanmonNo ratings yet

- 6-15-0003 Rev 4Document9 pages6-15-0003 Rev 4cynideNo ratings yet

- Irst 19 2012Document65 pagesIrst 19 2012krischaever100% (1)

- 8 WeldingDocument43 pages8 WeldingLopez BetoNo ratings yet

- Wps PQR GuideDocument40 pagesWps PQR GuideBalakumar100% (10)

- Manual For Fusion Welding of Rails by The Alumino-Thermic ProcessDocument49 pagesManual For Fusion Welding of Rails by The Alumino-Thermic ProcesskrischaeverNo ratings yet

- Welding Specification for Carbon and Alloy Steel PipingDocument82 pagesWelding Specification for Carbon and Alloy Steel PipingsendelkrNo ratings yet

- Pipeline welding practices guideDocument14 pagesPipeline welding practices guideYersin Hernandez AldanNo ratings yet

- WELDINGDocument4 pagesWELDINGArputharaj Maria LouisNo ratings yet

- Module 1: Code Basics: Part QW WeldingDocument12 pagesModule 1: Code Basics: Part QW WeldingaliNo ratings yet

- 01-Visual Inspection & Welding InspectorsDocument7 pages01-Visual Inspection & Welding InspectorsSaif UllahNo ratings yet

- SB 1377Document9 pagesSB 1377Andrew KvasihinNo ratings yet

- MSEDCL technical specs for AA ACSR conductorsDocument7 pagesMSEDCL technical specs for AA ACSR conductorskamarajinNo ratings yet

- WPQTDocument10 pagesWPQTnike_y2kNo ratings yet

- Rediographic Examination ProcedureDocument6 pagesRediographic Examination ProcedureAbank RoonyNo ratings yet

- Fab & Erection Pro 20000klR1Document17 pagesFab & Erection Pro 20000klR1Gandhi OnoNo ratings yet

- Asme Sec Ix WPS PQRDocument41 pagesAsme Sec Ix WPS PQRwentroprem100% (1)

- Welder Performance Qualification WPQDocument3 pagesWelder Performance Qualification WPQramzi5ben5ahmed100% (1)

- 2 Welding Procedure 2 PDFDocument6 pages2 Welding Procedure 2 PDFMustafa MubderNo ratings yet

- Ix+ 3. (WPQ) Welding Performance QualificationsDocument7 pagesIx+ 3. (WPQ) Welding Performance QualificationsAMAL VISHNUNo ratings yet

- Welding Procedures and Welding Qualiy Control For PipingDocument17 pagesWelding Procedures and Welding Qualiy Control For PipingImam BuchairiNo ratings yet

- ASME Sec IX flashcards welding procedure and operator qualificationsDocument10 pagesASME Sec IX flashcards welding procedure and operator qualificationsqazi12No ratings yet

- Piping Shop Fabrication SpecificationDocument20 pagesPiping Shop Fabrication SpecificationAnonymous NIICRJNo ratings yet

- Receipt Inspection NS2A4Document11 pagesReceipt Inspection NS2A4islam atifNo ratings yet

- PW3Document49 pagesPW3Mujaffar ShaikhNo ratings yet

- NDT ProceduresDocument7 pagesNDT ProceduresDavid DaemmejNo ratings yet

- Radiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingDocument15 pagesRadiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingEko Kurniawan100% (1)

- Method Statement Pipe WeldingDocument14 pagesMethod Statement Pipe Weldingjayasjb90% (10)

- Article 4 Metodo UltrasonidoDocument24 pagesArticle 4 Metodo UltrasonidoLessly Lorena Apala RamirezNo ratings yet

- National Certified Pipe Welding Bureau Testing Event Policy and Procedure Training ProgramDocument52 pagesNational Certified Pipe Welding Bureau Testing Event Policy and Procedure Training ProgramPablo SkrocheNo ratings yet

- Piping Codes PDFDocument47 pagesPiping Codes PDFsosatlantiqueNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsFrom EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsRating: 5 out of 5 stars5/5 (1)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri9Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri9wibowo wibowoNo ratings yet

- Passive Block Foundation DrawingDocument1 pagePassive Block Foundation Drawingapi-426990805100% (1)

- Marshall Stability Test ProcedureDocument9 pagesMarshall Stability Test ProcedurePurshottam SharmaNo ratings yet

- Flare Joints in RacDocument7 pagesFlare Joints in RacRay NamuNo ratings yet

- Preparation of Steel Substrates Before PaintingDocument34 pagesPreparation of Steel Substrates Before PaintingHassan Feki100% (1)

- Utilization of Coconut Shell As Greener ConcreteDocument9 pagesUtilization of Coconut Shell As Greener ConcreteIJRASETPublicationsNo ratings yet

- Aluminium WeldingDocument2 pagesAluminium WeldingARYANo ratings yet

- L80 - Continental AlloysDocument1 pageL80 - Continental AlloysHans CohnNo ratings yet

- FRDLDocument3 pagesFRDLrameshNo ratings yet

- FD-1600 1.5 Hour Dynamic Rated Multi-Blade Fire DamperDocument6 pagesFD-1600 1.5 Hour Dynamic Rated Multi-Blade Fire DampernuqNo ratings yet

- Cost Index For ManufacturingDocument6 pagesCost Index For ManufacturingSari OctavianiNo ratings yet

- PPG AtlanticaDocument2 pagesPPG AtlanticaVincent BrassierNo ratings yet

- Katalog KarbosanDocument224 pagesKatalog KarbosanTonggo R ManikNo ratings yet

- Plug Socket Price-List 170121Document3 pagesPlug Socket Price-List 170121tesemaNo ratings yet

- Gliss Master Product SheetDocument58 pagesGliss Master Product SheetDiana JitariuNo ratings yet

- Untitled 1Document20 pagesUntitled 1Rabi Sankar MohantyNo ratings yet

- LVR-Part E Contents BWDocument220 pagesLVR-Part E Contents BWMintesnot BogaleNo ratings yet

- Sika PDS - E - Plastiment TM - 21Document2 pagesSika PDS - E - Plastiment TM - 21lwin_oo2435No ratings yet

- JURNAL PERKUATAN-CRBJulAug13 - WhiteSantosaHioe PDFDocument4 pagesJURNAL PERKUATAN-CRBJulAug13 - WhiteSantosaHioe PDFDenny Dwiputra NotoprasetioNo ratings yet

- F607OTSFP Válvula de Compuerta NibcoDocument1 pageF607OTSFP Válvula de Compuerta NibcoAlberth Rojas CastellanosNo ratings yet

- Planning, Analyzing and Designing of Staff Quaters Building by Using STAAD ProDocument12 pagesPlanning, Analyzing and Designing of Staff Quaters Building by Using STAAD ProInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Welding Consumable Control ProcedureDocument15 pagesWelding Consumable Control ProcedureJoni Carino Suni89% (9)

- Chemical Composition AluminiumDocument3 pagesChemical Composition AluminiumEmreNo ratings yet

- PCCP Pipe SpecificationsDocument22 pagesPCCP Pipe SpecificationsChief Engineer Hydro Project & Quality ControlNo ratings yet

- DKS Commercial Door Construction - 1800 SeriesDocument1 pageDKS Commercial Door Construction - 1800 SeriesFrank AllanNo ratings yet

- "Tech Notes": Stone Matrix Asphalt (SMA)Document4 pages"Tech Notes": Stone Matrix Asphalt (SMA)abdikarim_omarNo ratings yet

- PolyethyleneDocument31 pagesPolyethyleneHesham chemecology100% (1)

- BTM Catalog Tog L Loc Tooling (Non 940)Document36 pagesBTM Catalog Tog L Loc Tooling (Non 940)Abrão GarciaNo ratings yet

- WELDING PROCEDURE QUALIFICATION TRAVELERDocument8 pagesWELDING PROCEDURE QUALIFICATION TRAVELERHoangNo ratings yet

- PavementDocument11 pagesPavementJoji Ann UayanNo ratings yet