Professional Documents

Culture Documents

Study of Frontal Impact of Passenger Bus

Uploaded by

tsmanjuraoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Study of Frontal Impact of Passenger Bus

Uploaded by

tsmanjuraoCopyright:

Available Formats

Final Project Presentation

Study of Frontal Impact of a Passenger Bus

Manjunath Rao T S

BBB0906034

M. Sc. (Engg.) in Automotive Engineering

Academic Guide :

Mr. Madan J

Project Manager,

SASTECH, Bangalore

M. S. Ramaiah School of Advanced Studies 1

Aim and Objectives of the Project

Aim :

To study frontal impact of a passenger bus and to

recommend methods to improve safety

Objectives :

• To review the literature on effects of impact on passenger

buses

• To study relevant analytical models that are available in

the literature

• To simulate the frontal impact behavior of the passenger

bus

• To analyze and interpret the results with the experimental

data available in literatures

• To suggest some design changes in order to improve

structure safety

M. S. Ramaiah School of Advanced Studies 2

Methodology

• Literature review on Crashworthiness of bus will be carried out

by referring reviewed journals, books and related documents

• Geometric modeling of bus structure will be carried out using

CATIA V5 R16 / Pro-E 2001

• FE model generation for all the parts will be carried out using

Hypermesh 7.0

• Input deck for simulation will be created using Hypermesh 7.0

• Frontal impact simulation will be carried out using LS-DYNA

and post processing will be carried out using LS-POST

• Investigation of the analysis results in order to improve the

crashworthiness

M. S. Ramaiah School of Advanced Studies 3

Introduction

•Among all the accidents that take place, frontal impact has got a

major share of 40%. Again in these conditions the injury caused to

drivers or the front passenger is extremely high.

•In automotive domain more emphasis has been given to the safety

of passenger cars, but seldom the importance is given to passenger

bus.

•Though the damage due to frontal impact of the bus is lesser when

compared to other vehicles, the consequences of such impact on

drivers are fatal.

•According to the study during frontal impact of bus more than

80% of drivers die than any other members of the bus.

•In frontal impact scenario more significance should be given on

structural integrity, and hence this project work is carried out in this

direction.

M. S. Ramaiah School of Advanced Studies 4

Design

Bus Specifications:

Dimension (mm) (as per IS 9435) LPO 1510/55

Wheel base 5334

Front overhang 1775

Rear overhang 3200

Overall length 10309

Max. width 2375

Track front 1930

Track rear 2050

Min. ground clearance in mm 240-275

Max. Seating capacity 53

Weights (kg.)

Bare chassis kerb weight 4010

Max. G.V.W 12500

Permissible F.A.W. 5080

Permissible R.A.W. 10160

Fuel Tank Capacity 160 litres

Engine & subsystems 500

Powertrain 400

Drivetrain 300

M. S. Ramaiah School of Advanced Studies 5

Construction

M. S. Ramaiah School of Advanced Studies 6

Design

Material : Structural steel

Std. : IS 2062

M. S. Ramaiah School of Advanced Studies 7

Design

Geometric Modeling:

Geometric modeling has been carried out using Pro-E 2001 software. All the

geometric datas were collected from “KMS Coach Builders Pvt. Ltd.”

(Official partners of KSRTC for coach building). All the structural details

were as per the 2D drawings provided.

Various views of modeled bus is shown in following sections:

M. S. Ramaiah School of Advanced Studies 8

Design

Assumptions:

• Parts which are not directly related to the frontal impact or which have

no significant effect on the final output have not been considered.

• All the sub-systems that were discarded in design process have been

considered as lumped mass at appropriate locations.

• All structural designs are as per the documents obtained from KSRTC.

M. S. Ramaiah School of Advanced Studies 9

FE Model

Meshed bus with shell elements

and 1-D Beam Elements

Total Elements 264139

Shell Elements 260779

1D Elements 2963

Total Parts 105

M. S. Ramaiah School of Advanced Studies 10

FE Model

Parts replaced with Mass Element

Mass Elements

Rigid Elements

M. S. Ramaiah School of Advanced Studies 11

Boundary Conditions

Contact interface is done by defining the box and providing

*CONTACT_AUTOMATIC_SINGLE_SURFACE

M. S. Ramaiah School of Advanced Studies 12

Boundary Conditions

Friction between tyres and rigid plane

M. S. Ramaiah School of Advanced Studies 13

Simulation Inputs

Material Properties assigned

Density Young’s modulus Poisson’s Yield Stress

Material

Kg/mm3 GPa Ration MPa

MAT_PIECEWISE_LINEAR_PLASTICITY

7.85e-6 210 0.3 350

MAT_24

MAT_RIGID 3.55e-6 210 0.3

MAT_ELASTIC 7.85e-6

210 0.3

MAT_1

Simulation Inputs

Velocity 30 km/hr

Simulation time 0.2 secs

M. S. Ramaiah School of Advanced Studies 14

Simulation & Results

M. S. Ramaiah School of Advanced Studies 15

Simulation & Results (contd.)

M. S. Ramaiah School of Advanced Studies 16

M. S. Ramaiah School of Advanced Studies 17

Simulation & Results (contd.)

M. S. Ramaiah School of Advanced Studies 18

Simulation & Results (contd.)

M. S. Ramaiah School of Advanced Studies 19

Simulation & Results (contd.)

M. S. Ramaiah School of Advanced Studies 20

Simulation & Results (contd.)

M. S. Ramaiah School of Advanced Studies 21

Design Improvement

Comparison of various crush initiators

M. S. Ramaiah School of Advanced Studies 22

Design Improvement

Comparison of bead type crush initiators

M. S. Ramaiah School of Advanced Studies 23

Simulation & Results (contd.)

M. S. Ramaiah School of Advanced Studies 24

Simulation & Results (contd.)

M. S. Ramaiah School of Advanced Studies 25

Simulation & Results (contd.)

Comparison of Load pattern with both designs

M. S. Ramaiah School of Advanced Studies 26

Conclusion

•It has been understood that the load distribution on the structures are not uniform,

which lays down the road to improvement in buckling characteristics of the

structures.

•By having crush initiators, the peak load can be reduced. This has been achieved by

implementing such designs to some of the structural members, which is around 4%

reduction in peak load.

•The design improvement that has been achieved is just for few structural elements,

if this approach is followed for many other key structural members then the design

could be far superior.

•The floor deceleration is around 12g, which is well in agreement with ECE R80

regulation that specifies the floor deceleration to be around 8-12g at 30km/hr.

M. S. Ramaiah School of Advanced Studies 27

Future Work

•In today’s automotive body engineering advancements there are various

systems that improves the crashworthiness of the vehicle significantly. Many

such systems can be implemented in order improve the structural safety.

•Simulation of the frontal impact behavior of the passenger bus can be carried

out by considering various subsystems of the vehicle like engines, transmission,

steering system etc..

•Positioning of dummy in the driver’s seat helps in finding the injury

parameters.

•Seat belt concept in passenger bus is an alien concept in India, efforts can be

made in developing such a concept.

•More understanding is required in order to improve the structural behavior of

chassis, which can be detrimental in overall design.

M. S. Ramaiah School of Advanced Studies 28

References

[1] VINCZE-PAP Sándor, CSISZÁR András, “Real and

Simulated Crashworthiness Tests on Buses” ESV 19th

Conference, NHTSA, Paper Number 05-023, 2005

[2] Jeffrey C. Elias, Lisa K. Sullivan, Linda B. McCray, “Large

School Bus Safety Restraint Evaluation” NHTSA, Paper No.

345, 2001

[3] Yoshiriro Sukegawa, Fujio Matsukawa, Takeshi Kuboike,

Motomu Oki, “Heavy Duty Vehicle Crash Test Method in

Japan”, NHTSA, Paper number 98-S4-O-13, 1998

[4] Mátyás Matolcsy, “Technical Questions Of Bus Safety

Bumpers”, NHTSA, Paper number 05-0161, 2005

[5] Willibrordus J. Witteman “Improved Vehicle Crashworthiness

Design by Control of the Energy Absorption for Different

Collision Situations”

M. S. Ramaiah School of Advanced Studies 29

Thank You

M. S. Ramaiah School of Advanced Studies 30

You might also like

- The Multibody Systems Approach to Vehicle DynamicsFrom EverandThe Multibody Systems Approach to Vehicle DynamicsRating: 5 out of 5 stars5/5 (2)

- Nonlinear Optimization of Vehicle Safety Structures: Modeling of Structures Subjected to Large DeformationsFrom EverandNonlinear Optimization of Vehicle Safety Structures: Modeling of Structures Subjected to Large DeformationsRating: 5 out of 5 stars5/5 (1)

- Terramechanics and Off-Road Vehicle Engineering: Terrain Behaviour, Off-Road Vehicle Performance and DesignFrom EverandTerramechanics and Off-Road Vehicle Engineering: Terrain Behaviour, Off-Road Vehicle Performance and DesignRating: 5 out of 5 stars5/5 (1)

- 05 2015 04 14 Road Vehicle Aerodynamics Chapter 3 Underbody ComprDocument129 pages05 2015 04 14 Road Vehicle Aerodynamics Chapter 3 Underbody ComprpaulinoNo ratings yet

- Structural Stress Analysis of An Automotive Vehicle ChassisDocument6 pagesStructural Stress Analysis of An Automotive Vehicle ChassisMaduka SmartNo ratings yet

- Car Msc2011Document734 pagesCar Msc2011Renan AlvimNo ratings yet

- Vehicle Design For Formula SAE 2019 CompetitionDocument8 pagesVehicle Design For Formula SAE 2019 CompetitionGodwin JerryNo ratings yet

- 08a605 Vehicle Design IIDocument3 pages08a605 Vehicle Design IIdhana555No ratings yet

- Baja SAE Auburn Design Report Cleveland State University 16Document10 pagesBaja SAE Auburn Design Report Cleveland State University 16Noel Mahung Melendez100% (1)

- Baja'18 Problem Statements 1Document2 pagesBaja'18 Problem Statements 1Shubham GuptaNo ratings yet

- Vehicle Body EngineeringDocument1 pageVehicle Body Engineeringjayabalaji_7759No ratings yet

- Design and Crash Analysis of Passenger Car Frontal Bumper Beam Using Hypermesh and RadiossDocument5 pagesDesign and Crash Analysis of Passenger Car Frontal Bumper Beam Using Hypermesh and RadiossAnup M UpadhyayaNo ratings yet

- Double WishboneDocument6 pagesDouble WishboneRian SteveNo ratings yet

- Effects of Model Complexity On The Performance of Automated Vehicle Steering Controllers Model Development Validation and ComparisonDocument20 pagesEffects of Model Complexity On The Performance of Automated Vehicle Steering Controllers Model Development Validation and ComparisonAntonio NavarreteNo ratings yet

- Car Frontal ImpactDocument25 pagesCar Frontal Impactapi-3762972100% (1)

- FSAE Aero Initial Performance Predictions - MonashDocument10 pagesFSAE Aero Initial Performance Predictions - MonashPedro BarataNo ratings yet

- Ergonomic Analysis of Motor VehiclesDocument14 pagesErgonomic Analysis of Motor VehiclesdeyeNo ratings yet

- Sae Technical Paper Series: Chinar Ghike and Taehyun ShimDocument12 pagesSae Technical Paper Series: Chinar Ghike and Taehyun ShimSteven SullivanNo ratings yet

- Automotive Crashworthiness StandardsDocument3 pagesAutomotive Crashworthiness StandardssayedNo ratings yet

- Durability Analysis Vehicle Body Structure Using Modal TransientDocument8 pagesDurability Analysis Vehicle Body Structure Using Modal TransientBalaji KannaiyanNo ratings yet

- Modeling and Validation of Off-Road Vehicle Ride DynamicsDocument17 pagesModeling and Validation of Off-Road Vehicle Ride DynamicsAnderson MoribeNo ratings yet

- 13 Seat Belt Anchorage Analysis (ECER14)Document6 pages13 Seat Belt Anchorage Analysis (ECER14)JayDeep KhajureNo ratings yet

- MPC Based Yaw and Lateral Stabilisation Via Active Front Steering and Braking PDFDocument19 pagesMPC Based Yaw and Lateral Stabilisation Via Active Front Steering and Braking PDFKiran KoneNo ratings yet

- Bumper Design Enhancement Through Crash AnalysisDocument9 pagesBumper Design Enhancement Through Crash AnalysisSanthosh KumarNo ratings yet

- Sae Technical Paper Series: R. Bardini and M. HillerDocument11 pagesSae Technical Paper Series: R. Bardini and M. HillerMario BritoNo ratings yet

- Adams 2dof Car TutorialDocument19 pagesAdams 2dof Car TutorialShashank KatiyarNo ratings yet

- SAE Seat Design OverviewDocument16 pagesSAE Seat Design OverviewGuilherme PfeilstickerNo ratings yet

- Fatigue Life Prediction of Lower Suspension Arm Using Strain-Life ApproachDocument15 pagesFatigue Life Prediction of Lower Suspension Arm Using Strain-Life Approachabraham silva hernandezNo ratings yet

- Electronic Stability ProgramDocument21 pagesElectronic Stability ProgramVinay GirdharNo ratings yet

- Design Calculations On Roll-Over Protective Structures For Agricultural TractorsDocument11 pagesDesign Calculations On Roll-Over Protective Structures For Agricultural TractorsHomeNo ratings yet

- Trim SolutionDocument40 pagesTrim Solutionendoparasite100% (1)

- Aerodynamics of Road VehiclesDocument53 pagesAerodynamics of Road VehiclesandreadelftNo ratings yet

- Active Suspension Control of Ground VehicleDocument6 pagesActive Suspension Control of Ground VehicleSanjay MehrishiNo ratings yet

- Claude RouelleDocument2 pagesClaude RouelleDanielNo ratings yet

- Ergo HF 3Document14 pagesErgo HF 3Marko BrkicNo ratings yet

- Autonomous Vehicles On The Edge A Survey On Autonomous Vehicle RacingDocument31 pagesAutonomous Vehicles On The Edge A Survey On Autonomous Vehicle RacingGergely HornyakNo ratings yet

- Dynamic Analysis of A Car Chassis PDFDocument5 pagesDynamic Analysis of A Car Chassis PDFsultanu89No ratings yet

- Ergonomics of Car Packaging Part 1Document2 pagesErgonomics of Car Packaging Part 1Ejan AdinNo ratings yet

- NX General PackagingDocument4 pagesNX General PackagingRama BaruvaNo ratings yet

- Suspension Design by Ravi DeshmukhDocument11 pagesSuspension Design by Ravi DeshmukhsonirocksNo ratings yet

- Aeroelastic Tailoring f1Document10 pagesAeroelastic Tailoring f1ennegi100% (1)

- Concept Selection of Car Bumper Beam With Developed Hybrid Bio-Composite MaterialDocument9 pagesConcept Selection of Car Bumper Beam With Developed Hybrid Bio-Composite MaterialViswatej ChoudaryNo ratings yet

- Formula Student 101: A Low Inertia Goes Against Stability But It Does Help With ControlDocument12 pagesFormula Student 101: A Low Inertia Goes Against Stability But It Does Help With ControlLeonardo ColpoNo ratings yet

- Vehicle Suspension Modeling NotesDocument25 pagesVehicle Suspension Modeling Notesahmetlutfu100% (2)

- Preliminary Design ReportDocument8 pagesPreliminary Design ReportAman MaanNo ratings yet

- Getting Started Using AdamsCar Ride - Introducing AdamsCar RideDocument28 pagesGetting Started Using AdamsCar Ride - Introducing AdamsCar RidecheckblaNo ratings yet

- Tire ModelsDocument274 pagesTire Modelsdebendra128nitrNo ratings yet

- Tire-Road Friction CoefficientDocument11 pagesTire-Road Friction CoefficientAnonymous Hy5Ir9QXNo ratings yet

- Applied Vehicle Dynamics Seminar April 7-10, 2017 Sinhgad Technical Education Society - Pune, IndiaDocument2 pagesApplied Vehicle Dynamics Seminar April 7-10, 2017 Sinhgad Technical Education Society - Pune, IndiaPRAVEEN REDDY100% (1)

- At2402 NotesDocument7 pagesAt2402 NotesAnonymous ETBwIduGiNo ratings yet

- Auto ErgonomicDocument4 pagesAuto ErgonomicAnshul BediNo ratings yet

- A18 008 Parameterized FMU Using Adams CarDocument22 pagesA18 008 Parameterized FMU Using Adams Carmikael bezerra cotias dos santos100% (1)

- Aluminum Vs Steel in Passenger CarsDocument14 pagesAluminum Vs Steel in Passenger Carstoyota952No ratings yet

- Guide to Load Analysis for Durability in Vehicle EngineeringFrom EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonRating: 4 out of 5 stars4/5 (1)

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainFrom EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainNo ratings yet

- Ship UnloadersDocument2 pagesShip UnloadersNos GoteNo ratings yet

- Letter No 1497 Dated 27 07 2022 (Public Comments) KanpurDocument9 pagesLetter No 1497 Dated 27 07 2022 (Public Comments) KanpurChau Suktana EnlingNo ratings yet

- Mercedes-Benz C63 AMG 2015Document12 pagesMercedes-Benz C63 AMG 2015Claudio RetamalNo ratings yet

- Klijn&Scholten - Delft Central - 2015Document9 pagesKlijn&Scholten - Delft Central - 2015vnchr.kNo ratings yet

- Bicycle and Motorcycle DynamicsDocument28 pagesBicycle and Motorcycle DynamicsSurya PatilNo ratings yet

- TRANSLINK - Company Profile PDFDocument39 pagesTRANSLINK - Company Profile PDFKaran DaveNo ratings yet

- Equipment Rental Rates: Description Capacity Rental RateDocument2 pagesEquipment Rental Rates: Description Capacity Rental RateasdasasdsdfsdfNo ratings yet

- Tryne Enterprise Plaza PresentationDocument50 pagesTryne Enterprise Plaza PresentationChay CruzNo ratings yet

- 2023 JMSA Fuel Consumption in Seaway Considering The Dynamic Interaction Among Environment-Hull-Propeller-EngineDocument13 pages2023 JMSA Fuel Consumption in Seaway Considering The Dynamic Interaction Among Environment-Hull-Propeller-EngineFrank LiouNo ratings yet

- Gantrail Welded Base Fixing: SpecificationsDocument2 pagesGantrail Welded Base Fixing: SpecificationstobiasNo ratings yet

- Escalator Switches AdjustmentDocument6 pagesEscalator Switches AdjustmentSANAL KUMAR SNo ratings yet

- First Voith Water JetDocument1 pageFirst Voith Water JetalimemetNo ratings yet

- Aga Khan Walk CritiqueDocument21 pagesAga Khan Walk CritiqueMaisieNo ratings yet

- Practical No.4 PDFDocument9 pagesPractical No.4 PDFSwarupa ChanchalwadNo ratings yet

- Iit BombayDocument3 pagesIit BombayAakanksha ParasharNo ratings yet

- Pavement Activity Log & Subcon Backcharge Record Excel SheetDocument85 pagesPavement Activity Log & Subcon Backcharge Record Excel SheetHorYonhuNo ratings yet

- Cpd25l2b S en Brochure 1Document5 pagesCpd25l2b S en Brochure 1Bersanz SrlNo ratings yet

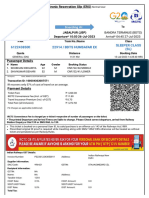

- Evidence: Planning My TripDocument14 pagesEvidence: Planning My TripRosaAnggeliicaNieto63% (24)

- Yamaha F30Document120 pagesYamaha F30Gem R100% (2)

- GL - Continuous Survey InstructionsDocument2 pagesGL - Continuous Survey Instructionshpss77No ratings yet

- Unit 1 IEN Master 2Document8 pagesUnit 1 IEN Master 2tanny nina maynictaNo ratings yet

- Test Bank For Biology The Unity and Diversity of Life 12th EditionDocument34 pagesTest Bank For Biology The Unity and Diversity of Life 12th Editionoscines.filicide.qzie100% (41)

- Clause 55 AssessmentDocument17 pagesClause 55 AssessmentJohn AlexNo ratings yet

- Apollo Experience Report Launch Escape Propulsion SubsystemDocument29 pagesApollo Experience Report Launch Escape Propulsion SubsystemBob AndrepontNo ratings yet

- Manitou MLT 735 (EN)Document20 pagesManitou MLT 735 (EN)ManitouNo ratings yet

- How To Setup gp2Document8 pagesHow To Setup gp2Aniello IaccarinoNo ratings yet

- Nissan GTR R35 by KiechDocument5 pagesNissan GTR R35 by KiechIkhtizar AbyanNo ratings yet

- 4G11T, TP, 4G11TG1,4G11TPG2 Operation and Maintenance Manual-16.03.09Document68 pages4G11T, TP, 4G11TG1,4G11TPG2 Operation and Maintenance Manual-16.03.09KiranKumarReddy67% (3)

- Rozdział 8 - Podróżowanie I Turystyka - MiniMatura (Grupa B)Document2 pagesRozdział 8 - Podróżowanie I Turystyka - MiniMatura (Grupa B)Bartek BanasiakNo ratings yet

- Euroncap Nissan Almera Tino 2001 4stars PDFDocument1 pageEuroncap Nissan Almera Tino 2001 4stars PDFCarlos MurilloNo ratings yet