Professional Documents

Culture Documents

Dms Go Brochure

Uploaded by

Siddiqui Abdul Khaliq0 ratings0% found this document useful (0 votes)

77 views12 pagesscan machine cat-log

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentscan machine cat-log

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

77 views12 pagesDms Go Brochure

Uploaded by

Siddiqui Abdul Khaliqscan machine cat-log

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

GE

Measurement & Control Solutions

The new ultrasonic Go platform from

GEs Inspection Technologies business

combines a thickness gauge and a aw detector

in one single lightweight instrument.

With fast eld software upgradeability, start with a DMS Go

and add USM Go aw detector capabilities as your inspections

demand, or buy both initially.

The choice is yours!

See other side of the brochure for more information about the USM Go.

DMS Go

A exible Thickness Gauge

that can be a Flaw Detector

DMS Go

The Way Forward in Thickness

Measurement Instrumentation

The DMS Go from GEs Inspection Technologies business is a high-end thickness

gauge which combines an innovative, easy-to-use user interface, powerful data

management and an ability to provide accurate, reliable and comprehensive thick-

ness inspection data. It is ideally suited for a wide range of applications including

measuring for corrosion in the oil and gas sector and in power generation.

Built-in temperature compensation

algorithm allows accurate measure-

ment up to 540C (1000F).

Multiple Calibration and Zeroing

modes for repeatable accuracy,

including:

+ 2-point calibration.

+ 1-point calibration with Manual

on-block zeroing.

+ 1-point calibration with Auto-

zeroing for every measurement

(coupled).

+ 1-point calibration with User-

zeroing in the air (uncoupled).

Multiple measurement modes for

every applications including:

+ A-Scan

+ Thickness

+ B-Scan

+ Min / Max

+ Differential

Support of several standard probes

and the capability to support

virtually any probe using the custom

probe setup feature.

Ability to operate in harsh environ-

ments with IP67 sealing.

Easy-to-Read Screen

A large display screen, which can be

adjusted to provide optimum

visibility in varying ambient light

conditions.

An 800x480 pixel display, which is

better resolution than a standard

DVD.

A screen which has been ergonomi-

cally sized to help reduce eye strain.

Choice of thickness view, which can

be either large A-scan with smaller

digits or large digits with smaller

A-Scan.

DMS Go

Operational Excellence

The DMS Go has been designed to

provide improved reliability, accuracy

and reportability of thickness readings

in a wide range of applications.

Its operational features include:

High Performance Thickness

Measurement

High measurement stability and

reliability resulting from zero cross-

ing measurement technique.

Automatic gain control for excellent

repeatability and corrosion

monitoring.

Views to suite everyone: large A-Scan, Data Recorder,

thickness, B-Scan.

Ease of Use

Pressure-sensitive joystick imported

and adapted from the successful

range of remote visual inspection

and ultrasonic equipment offered

by GE.

Can be operated with one hand,

leaving other hand free for critical

tasks, such as maintaining probe in

optimum position or holding on to

ladders.

One hand menu directed calibration

process.

All controls within fngertip reach.

A Flip function allows the instru-

ment to be used equally well by

left-handed and right-handed

operators.

Portability

Small size, lightweight, robust dust

and waterproof construction allow

the instrument to be easily operated

in conned spaces, areas of difcult

access, and in harsh environments.

Light enough to be carried through-

out a whole days shift.

Battery provides up to 10 hours

operation. Can be recharged on-

or off-board.

Several accessories to improve

mobility are available: wrist strap,

shoulder harness, belt holster.

High Capacity Data Recorder

and Compatibility with Power-

ful Data Management Systems

The DMS Go offers powerful data

recording and data management

capability to meet the most demanding

of thickness gauging and corrosion

inspections. Important features include:

Powerful on-board data recorder has

capacity of hundreds of thousands

readings and permits the storage of

A-scan, B-scan and MicroGRID

attachments to thickness readings.

Data can be organized using pre-set

(linear, grid, boiler), custom (custom

linear, custom grid) or advanced (3D

and 4D in UltraMATE) les structures.

Data transfer is via industry standard

removable SD card up to 16 GB.

A USB port is included to allow

instrument to PC connection if

preferred no driver needed, works

with all versions of Windows.

Export in different fle formats (xls,

html, dat, csv, pdf) to allow easy

integration with user data manage-

ment softwares and user quality

control systems.

Compatible with UltraMATE and

UltraMATE lite data management

programs to allow for comprehen-

sive analysis and documentation

of data.

The data recorder fles can be

interfaced with other 3rd party

software programs using a GE

software development kit, supplied

on CD.

Best-in-Class Ergonomics

The DMS Go portable thickness gauge

is lightweight, versatile and easy to use

in the harshest of inspection environ-

ments. Its ergonomic features include:

UltraMATE CSV File / Excel

Support of large selection of probes

DMS Go Options

DMS Go

Base

DMS Go

TC

DMS Go

DR

DMS Go

Advanced

The Instrument + Zero Block

1 Battery

Battery Charger

Mobility Kit: Handstrap + SD Card + Transportation Case

TopCoat & Auto-V option

option

Advanced Data Recorder option option

UltraMATE Lite option option

Chest Harness option option

USM Go Flaw Detector Features option option option option

The DMS Go high-end thickness gauge is suited for thickness measurement in a

wide variety of applications and especially for corrosion measurement/monitoring,

even at high temperatures and on coated parts.

Typical applications include:

Monitoring of power generation

boilers efciency by measuring

Oxide Scale in boiler tube with

special probe OSS-10.

Optional applications software

includes:

+ TopCOAT technology to allow

measurement of coating as well

as metal thickness.

+ Auto-V measurement mode to

enable thickness to be measured

on components with unknown

sound velocities without the need

for a calibration block.

Inspection for corrosion in tubes,

vessels and tanks in the oil and gas

sectors.

Inspection of complex geometry

tubes in reneries and power

generation plants.

Thickness measurement of auste-

nitic materials.

Measurement of remaining wall

thickness through thick paint coat-

ings.

Measurement of high attenuation

cast components in foundries

Maintenance checks in the aero-

space sector.

A Wide Range of Applications

The great variety of applications is

made possible by the large selection

of probes available for the DMS Go

including high temperature versions.

DMS Go

DMS Go -

Technical Specications

Display

WVGA Color LCD with adjustable LED Backlight

Active Area W: 108 mm (4.25)

H: 64.8 mm (2.55)

Screen Diagonal 5.0

Pixel Resolution W x H: 800 x 480 pixels

Environment

Languages English, German, French, Spanish, Chinese and

Japanese

Size 175 mm x 111 mm x 50 mm (6.8 x 4.3 x 1.9)

Weight 870g (1.9 lb) with the battery and stand including zero block

Temperature Shock

(Storage)

3 cycles: 4 hrs at 20C (-4F) up to 60C (140F),

4 hrs at 60C (140F),

Transitions within 5 minutes,

MIL-STD-810E Method 503.4, Procedure II

Vibration MIL-STD-810E method 514.5, Procedure I, Annex C,

Figure 6, General Exposure: 1 hr each Axis

Shock 6 cycles each Axis, 15 g, 11 ms Half Sine, MIL-STD-810E

Method 516.5, Procedure I

Loose Cargo

(In Shipping Container)

MIL-STD-810E Method 514.5, Procedure II

Transit Drop

(Packaged for Shipment)

MIL-STD-810E Method 516.5, Procedure IV, 26 drops

Operating Temperature

Range

0C to 55C (32 to 131F)

Storage Temperature Range -20C to 60C (-4 to 140 F) with battery, 24 hrs

Dustproof / Waterproof As per IEC 529 Specifcation for IP67 Classifcation

Hazardous Atmosphere

Operation

As defned by MIL-STD-810E, Method 511.3,

Procedure 1

Compliance

EMC/EMI EN 55011 & EN61000-6-2:2001

Ultrasound EN 15317, EN12668 , ASTM-E1324, ASTM-E317

I/O Connectors

Transducer Dual lemo-00 (Coax)

Mini USB

Power IN and TTL Alarm OUT

Power Supply

Battery Type Li-ion battery

Operating Time Min 8 hours in typical DMS Go continuous operation

On Board Charging

Off Board Charging with Optional Adaptor

Proportional Battery Gauge Indicating Remaining Operation Time

Charger Universal AC (100-240 V, 50-60 Hz) meets CCC, CE, UL,

CSA and PSE requirements

Measuring Range

0.40 mm to 650 mm (0.010 to 25.00) in steel, in standard operation, depending on

the probe, material and surface

Digital Display Resolution

0.01 mm or 0.1 mm (0.001 or 0.01) selectable over the entire measuring range

Material Velocity Range

250 to 16,000 m/s (0.0098 to 0.6299/s)

Units

Selectable Millimeter or Inch

Measurement Techniques

All measurments using Zero Crossing technique single element IP to 1st echo / single

element multi echo / dual-element IP to 1st echo / dual element multi echo

DMS Go TC Only TopCoat (Patent# 6,035,717) and Auto-V

Measurement Display Modes

Temperature Corrected Thickness

Thickness and large A-Scan

B-Scan

MIN / MAX Capture

Differential

Calibration

One-point, Two-point

Auto or Manual On-block and Off-block Zero

Automatic V-path Correction

Update Rate

32 Hz in MIN/MAX-capture Mode and B-Scan Display Mode

4 Hz or 8 Hz or 16 Hz (Selectable) in Standard Mode

Receiver

110 dB Dynamic Range

Automatic ain control with manual (set by user),

High, low and Auto Gain Limit

Pulser

Square Wave, Pulse-width and -voltage (120 V or 250 V) automatically matched to probe

Memory

2 GB SD Card included. Up to 16 GB memory cards can be used

Data export as PDF, XML, CSV, DAT. Jpeg screen copy

Data Recorder

100,000 readings per le. Multiple les can be stored on SD card up to card capacity

File Formats

6 File Formats with DR Option (3 with Base Instrument)

Attachments

Insertion of 2x2 to 9x9 MicroGrid per Measuring Point

1 to 16 user-denable comments for each le format with up to 16 alphanumeric

characters per measuring point

A-Scan

B-Scan

Application Software

UltraMATE Lite Simple data management program for transferring

measurement data les to a PC, including integration

of the data into Windows programs

UltraMATE Extensive data management program for displaying

and printing measurement data as graphics, for

managing test data, for entering comments on les

Software Development Kit Available for integration into other software

applications

Water-, dust- and

shockproof

DMS Go

Upgrade your DMS Go to the USM Go Flaw Detector

The DMS Go uses the same operating platform as the USM Go portable aw detector.

By means of a simple software purchase your DMS Go can beneft from all the

USM Go functionalities and perform advanced aw detections.

This means that NDT personnel now need to carry only one inspection instrument

to perform accurate and dependable thickness measurement and aw detection.

A further benet of this dual modality is a signicant reduction in operator

training times.

Build your own instrument !

An extensive range of upgrade possibilities is available.

Choose any of the USM Go options and add it to your DMS Go package.

For more information contact your local GE representative or visit

www.gesensinginspection.com

GE

Measurement & Control Solutions

The new ultrasonic Go platform from

GEs Inspection Technologies business

combines a thickness gauge and a aw detector

in one single lightweight instrument.

With fast eld software upgradeability, start with a USM Go

and add DMS Go aw detector capabilities as your inspections

demand, or buy both initially.

The choice is yours!

See other side of the brochure for more information about the DMS Go.

USM Go

A exible Flaw Detector that

can be a Thickness Gauge

2010 General Electric Company. All Rights Reserved. Specications are subject to change without notice. GE is a registered

trademark of General Electric Company. Other company or product names mentioned in this document may be trademarks or

registered trademarks of their respective companies, which are not afliated with GE.

GEIT-20214EN (10/10)

USM Go -

Setting New Standards in Flaw Detection

Instrumentation

Portability

Small size, lightweight, robust,

dust- and waterproof construction

allow the instrument to be easily

operated in conned spaces, areas

of difcult access, and in harsh

environments.

Can be operated with one hand,

leaving other hand free for other

tasks, such as maintaining probe in

optimum position or holding on to

ladders.

Light enough to be carried through-

out a whole days shift.

Battery provides up to 6 hours

operation. Can be recharged on-

or off-board.

Several accessories to improve

mobility are available: wrist strap,

shoulder harness, belt holster.

Easy-to-Read Screen

A display screen that is the same size

as those in other GE aw detectors,

even though the instrument is much

smaller than other instruments in

the range.

An 800 x 480 pixel display, which

is better resolution than a

standard DVD.

A screen with an optimized aspect

ratio to ensure highly dened echo

separation.

A screen that can be easily viewed,

whether hand-held or desk-mounted.

A screen that has been ergonomi-

cally sized to help reduce eyestrain.

An integrated stand allows the user

to optimize the viewing angle, when

the instrument is desk- or bench-

mounted.

AutoGate Threshold for faster

measurement with optimum

accuracy.

USM Go

Ease of Use

Pressure-sensitive joystick imported

and adapted from the successful

range of remote visual inspection

and ultrasonic equipment offered

by GE.

All controls within fngertip reach.

User can dedicate function keys

according to preference.

A Flip function allows the instrument

to be used equally well by left-hand-

ed and right-handed people.

A standard USB connection to allow

data to be downloaded from the

aw detector for further analysis

or storage.

The instruments 2 GB memory can

be easily exchanged by SD cards up

to 16 GB.

Reports are produced in jpeg format

so there is no need for special

reading software.

Ergonomically Designed with the User in Mind

The USM Go ultrasonic portable aw detector has been ergonomically designed

to provide an instrument that is light, small and easy to use in the harshest of

inspection environments.

Its ergonomic features include:

High UT Performance

State-of-the-art electronics, includ-

ing digital amplication, for a wide

range of application benets.

A wide Pulse Repetition Frequency

range allows use at low PRF to

inspect forged parts without any

ghost echoes and to inspect welds

at high PRF when fast and regular

scanning movement is required.

Optional square wave pulser for

more demanding applications.

Increasing Productivity

The USM Go features intuitive operation

so there is virtually no time-consuming,

learning curve.

You are productive from the moment

you pick it up!

There is no need to refer to the manual,

as clear instructions are provided as

you go along. Navigation is simplied

using the proven graphical user

interface (GUI) and the innovative

joystick, allowing one-handed opera-

tion for fast and accurate adjustment.

Other features allowing increased

productivity are:

A robust molded rubber casing to

withstand the harshest environ-

ments and signicantly reduce

downtime. The instrument is dust-

and waterproof to IP67 and is tested

to withstand shock and vibration.

A simple on-board data logger to

collect and save thickness measure-

ments or eventually attach the

corresponding A-scan image.

Versatile and Upgradeable

Customized versions of the USM Go

are also available, specially adapted

to meet specic inspection codes or

applications. For example, an optional

square wave pulser can be supplied for

applications involving the inspection of

highly attenuative material. The versions

shown in the table are currently

available. For more detailed informa-

tion, please contact your local GE

representative or visit

www.gesensinginspection.com

USM Go Options

USM Go

Base

USM Go

AWS

USM Go

DAC AWS

USM Go

Advanced

The Instrument

1 Battery

Battery Charger

Power Cable

Transportation Case

Brief Instruction Card

Operating Manual on CD

Manufacturer Certicate

Hand Strap

AWS option

DAC / TCG option option

DGS option option option

Phantom PRF option option option

Square Wave Pulser option option option

DMS Go Thickness Gauge Features option option option option

The USM Go has been designed to provide aw detection capability in inspection

situations throughout the industrial and process spectrum, from aerospace to

power generation and from the automotive sector to the oil and gas industry.

Inspection of Composites:

RF Display

2 gates with B-start triggered with

echo in gate A

TCG correction with high slope

120 dB/s

For more demanding applications:

Narrow band flters

Low noise digital amplifer

Optional square wave pulser

TCG correction with high slope

120 dB/s

These include:

Weld Inspection:

Trigonometric projections

AWS

DAC

DGS

Inspection of Forgings and Castings:

Manual PRF adjustment

Phantom echo indicator

DGS

Inspection of rails:

High PRF (up to 2000 Hz)

Lightweight: 850 g (1.87 lb)

Small size and ergonomics

A Wide Range of Applications

USM Go

USM Go - Technical Specications

Water-, dust- and

shockproof

LCD Display

Active Area W x H: 108 mm x 64.8 mm (4.25 x 2.55)

Screen Diagonal 5.0

Pixel Resolution W x H: 800 x 480 pixels

Connectors

Probe Connectors Two LEMO-00

UT Output Connector SAP output, alarm

USB Interface Micro USB connector

SD Card Connector Full size SD card slot to accommodate standard SD cards

Pulser - All pulser measurements taken according to EN12668 specifcations

Pulser Mode Simulated spike standard, uni-polar square wave optional

Pulser Voltage

(SQ Mode)

120 V to 300 V with 10 V steps

Pulser Width

(SQ Mode)

30 ns to 500 ns with 20 ns steps

Pulser Amplitude

(Spike Mode)

Low : 120 V

High: 300 V

Damping 50 or 1000 Ohms

PRF Automatically optimized between 15 Hz to 2000 Hz,

3 automatic adjustment modes : AutoLow, AutoMed,

AutoHigh - Manual Control of PRF from 15 to 2000 Hz

Receiver

Range 14016 mm at steel longitudinal wave (557)

Digital Gain Dynamic range of 110 dB, with 0.2 dB step

Analog Bandwidth 0.2 MHz - 20 MHz

Filters Broad band

Narrow band lters

1; 2; 2.25; 4.5; 10; 13; 15 MHz

Gate

Independent Gates 2 Gates (A and B), Gate B can support triggering by Gate A

Rectication Full Wave (FW) Positive (POS)

RF Negative (NEG)

Measurement Peak Flank

JFlank

Memory

Capacity 2 GB SD card. Up to 16 GB memory cards can be used

Report Jpeg and BMP reports

Data Logger Option for thickness or A-scan recording, compatible with

UltraMATE

Environmental

Battery 6 hours battery life

On board charging

Off board charging with optional adaptor

Proportional battery gauge indicating remaining operation

time

Charger Universal AC (100-240 V, 50-60 Hz)

Meets CCC, CE, UL, CSA and PSE requirements

Size 175 mm x 111 mm x 50 mm (6.8 x 4.3 x 1.9)

Weight 845 g (1.87 lb) with the battery

Languages Bulgarian, Chinese, Czech, Dutch, English, French, German,

Hungarian, Italian, Japanese, Portuguese, Polish, Russian

and Spanish

Protection as per Mil-Std-810F

Damp Heat and

Humidity (Storage)

10 cycles: 10 hrs at 60C (140F) down to 30C (86F),

10 hrs at 30C (86F) up to 60C (140F),

transition within 2 hrs, 507.4

Temperature Shock

(Storage)

3 cycles: 4 hrs at 20C (-4F) up to 60C (140F),

4 hrs at 60C (140F), transitions within 5 minutes,

503.4 Procedure II

Vibration 514.5-5 Procedure I, annex C, fgure 6,

general exposure: 1 hr each axis

Shock 6 cycles each axis, 15 g, 11 ms half sine, 516.5 Procedure I

Loose Cargo

(In Shipping Container)

514.5 Procedure II

Transit Drop

(Packaged for Shipment)

516.5 Procedure IV, 26 drops

Operating

Temperature Range

0C to 55C (32 to 131F)

Storage

Temperature Range

-20C to 60C (-4 to 140 F) with battery, 24 hrs

Dustproof / Waterproof As per IEC 529 specifcation for IP67 classifcation

Compliance EMC/EMI EN 55011

EN61000-6-2:2001

Ultrasound EN 12668

ASTM E1324

E317

ANSI/NCSL Z 540-1-1994

MIl STD 45662A

MIL STD 2154

Options

USM Go AWS Option AWS sizing tool according to AWS D1.1 structural welding

code

USM Go DAC Option DAC sizing tool

16 points

compliant with

EN 1712- EN 1713 EN 1714

ASME & ASME III

JIS Z3060 compliant

TCG: 120 dB dynamic

TCG: 110 dB/s slope

USM Go DGS Option DGS sizing tool compliant with EN 1712

USM Go Embedded

Data Logger Option

Custom linear and grid le creation

USM Go Square Wave

Pulser Option

Allows pulser parameters ne tuning

Voltage adjustment from 120 V to 300 V per 10 V steps

Pulse width adjustment from 30 ns to 500 ns per 10 ns steps

USM Go Phantom

Indicator Option

Phantom PRF will help to identify ghost echo due to

multiple reections in low materials

USM Go

The USM Go uses the same operating and navigating platform as the DMS Go

portable thickness gauge. By means of a simple software purchase your USM Go

can benet from all the DMS Go functionalities and perform advanced thickness

measurements.

This means that NDT personnel now need to carry only one inspection instrument

to perform accurate and dependable thickness measurement and aw detection.

A further benet of this dual modality is a signicant reduction in operator

training times.

Upgrade your USM Go to the DMS Go Thickness Gauge

Build your own instrument !

An extensive range of upgrade possibilities is available.

Choose any of the DMS Go options and add it to your USM Go package.

For more information contact your local GE representative or visit

www.gesensinginspection.com

You might also like

- DMSGoDocument12 pagesDMSGojosexx311No ratings yet

- Geit-20214en Usm Go-Dms Go Single PageDocument12 pagesGeit-20214en Usm Go-Dms Go Single PageRonny AndalasNo ratings yet

- Geit-20219 Dmsgoseries enDocument4 pagesGeit-20219 Dmsgoseries ensolrac4371No ratings yet

- The DM5E Family of Corrosion Thickness Gauges: Sensing & Inspection TechnologiesDocument4 pagesThe DM5E Family of Corrosion Thickness Gauges: Sensing & Inspection TechnologiescharlitsNo ratings yet

- Dms Go Thickness Gauge Brochure English 1Document4 pagesDms Go Thickness Gauge Brochure English 1Jhonatan Lizcano ArteagaNo ratings yet

- Dektak 150 BrochureDocument4 pagesDektak 150 BrochuresinytellsNo ratings yet

- DM5E Corrosion Thickness Gauge Product BrochureDocument8 pagesDM5E Corrosion Thickness Gauge Product BrochureClaudio UNo ratings yet

- Global Brochure PDFDocument16 pagesGlobal Brochure PDFElsa VelazquezNo ratings yet

- USM Go BrochureDocument4 pagesUSM Go BrochureBranko FerenčakNo ratings yet

- Fluke Tis Building Diagnostic Thermal Imaging Scanner: Technical DataDocument3 pagesFluke Tis Building Diagnostic Thermal Imaging Scanner: Technical DataVasile SilionNo ratings yet

- Coating Thickness Gages For: ALL Metal SubstratesDocument4 pagesCoating Thickness Gages For: ALL Metal SubstratesÖzhan ÖzkanNo ratings yet

- Blastmate IIIDocument2 pagesBlastmate IIIHinawan Teguh SantosoNo ratings yet

- Leo Weighpro NewDocument47 pagesLeo Weighpro NewAman SinhaNo ratings yet

- Brochure Teledyne - Dms Motion SensorsDocument4 pagesBrochure Teledyne - Dms Motion Sensorswanderson1974No ratings yet

- Panametrics Olympus Epoch XT DatasheetDocument8 pagesPanametrics Olympus Epoch XT Datasheetcorey_resslerNo ratings yet

- Lizard® M8 Advanced NDE SystemDocument3 pagesLizard® M8 Advanced NDE Systemmelbry melNo ratings yet

- Digital Macro Vickers Hardness TesterDocument4 pagesDigital Macro Vickers Hardness Testerdinhhai1613No ratings yet

- ATOS Compact Scan en RevADocument11 pagesATOS Compact Scan en RevAkoalaboiNo ratings yet

- 45MG Ultrasonic Thickness GageDocument5 pages45MG Ultrasonic Thickness GagezulzainalNo ratings yet

- Usm Go Plus Brochure EnglishDocument4 pagesUsm Go Plus Brochure EnglishMayank Gupta100% (1)

- 100HSX Jul 2013Document2 pages100HSX Jul 2013roshanmechNo ratings yet

- Crack Measuring Devices - Electronic Crack Measuring Device, Crack Measuring MicroscopeDocument4 pagesCrack Measuring Devices - Electronic Crack Measuring Device, Crack Measuring MicroscopePrajakta RahateNo ratings yet

- GE Inspection Technologies Ultrasonics Accessories and Specifications for Krautkramer DynaMIC Rebound Hardness TesterDocument2 pagesGE Inspection Technologies Ultrasonics Accessories and Specifications for Krautkramer DynaMIC Rebound Hardness Testerm_armoutiNo ratings yet

- Olympus Epoch XTDocument8 pagesOlympus Epoch XTTimothy FieldsNo ratings yet

- Gc420 Datasheet enDocument2 pagesGc420 Datasheet enshahirnana1No ratings yet

- TRIO C8 Series CutsheetDocument2 pagesTRIO C8 Series Cutsheetcredondo1No ratings yet

- Krautkramer Usm 36 BrochureDocument4 pagesKrautkramer Usm 36 Brochuresentamil vigneshwaran100% (1)

- CL Totalgowin Tks202Document2 pagesCL Totalgowin Tks202tjNo ratings yet

- EDG SpecificationsDocument3 pagesEDG Specificationsacidrisamuel.peNo ratings yet

- Markem Imaje 9232 E DS HQ B2Document2 pagesMarkem Imaje 9232 E DS HQ B2Антон КокоринNo ratings yet

- 15 190 DJ10 Rockwell Hardness PI ENDocument4 pages15 190 DJ10 Rockwell Hardness PI ENyathee1No ratings yet

- Elsys Pro Compact, Pliant G2, enDocument4 pagesElsys Pro Compact, Pliant G2, ensergethomas2010No ratings yet

- Elcometer 224 Surface Profile GaugeDocument8 pagesElcometer 224 Surface Profile GaugeulasNo ratings yet

- UTS Digital Signage SpecDocument5 pagesUTS Digital Signage SpecMohammed JifarNo ratings yet

- 4900 DatasheetDocument2 pages4900 DatasheetMakam Raghu100% (1)

- Specification Sheet XLG3Document8 pagesSpecification Sheet XLG3danang_apriyantoNo ratings yet

- Elsys Pro Compact, Pliant G3, enDocument4 pagesElsys Pro Compact, Pliant G3, ensergethomas2010No ratings yet

- TD25ST Model 25ST Electromechanical Materials Testing MachineDocument2 pagesTD25ST Model 25ST Electromechanical Materials Testing MachineMarcelo SánchezNo ratings yet

- BROCHURE HEIMANN X RAY HI SCAN 7555iDocument2 pagesBROCHURE HEIMANN X RAY HI SCAN 7555iDian AlcatrazNo ratings yet

- TOKO Alghifarisurvey Jual Beli, Sewa, Servis Kalibrasi Total Station Sokkia Set-62 Series.Document2 pagesTOKO Alghifarisurvey Jual Beli, Sewa, Servis Kalibrasi Total Station Sokkia Set-62 Series.agusNo ratings yet

- Model 3001: Multi-Detector Survey MeterDocument1 pageModel 3001: Multi-Detector Survey MeterAlaa Al HabeesNo ratings yet

- GEIT 20056EN Usm Go Flaw DetectorDocument4 pagesGEIT 20056EN Usm Go Flaw DetectorDaniel OscarNo ratings yet

- Leica ScanStation P30-P40Document3 pagesLeica ScanStation P30-P40bbutros_317684077No ratings yet

- Dolphin 99GX: Mobile ComputerDocument2 pagesDolphin 99GX: Mobile Computerblue 1234No ratings yet

- Ludlum M3001 Datasheet PDFDocument2 pagesLudlum M3001 Datasheet PDFMike MVNo ratings yet

- Posit Ector Ut GDocument4 pagesPosit Ector Ut GMiller Alexander Mora VargasNo ratings yet

- Catalogo Colectora Carlson Mini2 ENGDocument2 pagesCatalogo Colectora Carlson Mini2 ENGChristian Camilo Gómez BautistaNo ratings yet

- Digital Macro Hardness Tester with Precise SensorDocument4 pagesDigital Macro Hardness Tester with Precise Sensordinhhai1613No ratings yet

- Automatic Water Level Data Recorder PDFDocument2 pagesAutomatic Water Level Data Recorder PDFAnonymous zpNy2bltNo ratings yet

- Dolphin 7800 For Android: Enterprise Digital Assistant (EDA)Document2 pagesDolphin 7800 For Android: Enterprise Digital Assistant (EDA)Wadh MisNo ratings yet

- Experiment No-3Date: - / / Aim: To Study About Universal Testing Machine (Utm)Document5 pagesExperiment No-3Date: - / / Aim: To Study About Universal Testing Machine (Utm)divya_91No ratings yet

- Sitrans F: Sitrans F M Magflo Electromagnetic Flowmeters Explore The Siemens SolutionDocument18 pagesSitrans F: Sitrans F M Magflo Electromagnetic Flowmeters Explore The Siemens SolutionAlonso CoradoNo ratings yet

- VJ 8510 SpecSheet2Document2 pagesVJ 8510 SpecSheet2Brajesh PandeyNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- Weekly Welder Repair Rate MonitoringDocument15 pagesWeekly Welder Repair Rate MonitoringSiddiqui Abdul Khaliq100% (1)

- Sec VIII PagesDocument3 pagesSec VIII PagesSiddiqui Abdul KhaliqNo ratings yet

- API 570 - Daily Exam 5C API-571-577 Questions - PSJDocument4 pagesAPI 570 - Daily Exam 5C API-571-577 Questions - PSJKrishna Moorthy50% (2)

- Mock-Up Block Drawings Fro AUTDocument14 pagesMock-Up Block Drawings Fro AUTSiddiqui Abdul KhaliqNo ratings yet

- Sadara MFC Inspection Checklist: Copper Pipe Installation SMIC-S-4050 PlumbingDocument1 pageSadara MFC Inspection Checklist: Copper Pipe Installation SMIC-S-4050 PlumbingSiddiqui Abdul KhaliqNo ratings yet

- Impact Testing PhotosDocument2 pagesImpact Testing PhotosSiddiqui Abdul KhaliqNo ratings yet

- Sample Welder's JCCDocument1 pageSample Welder's JCCSiddiqui Abdul KhaliqNo ratings yet

- ARCC Hydrotest Packages Summary ReportDocument4 pagesARCC Hydrotest Packages Summary ReportSiddiqui Abdul KhaliqNo ratings yet

- 1401 TamimiDocument1 page1401 TamimiSiddiqui Abdul KhaliqNo ratings yet

- Heat Treatment Requirement As Per ASME B31.3Document2 pagesHeat Treatment Requirement As Per ASME B31.3Siddiqui Abdul Khaliq67% (3)

- Figure 323.2 Asme b31.3Document1 pageFigure 323.2 Asme b31.3Siddiqui Abdul KhaliqNo ratings yet

- Sec VIII PagesDocument3 pagesSec VIII PagesSiddiqui Abdul KhaliqNo ratings yet

- SAES W 011 Cover PageDocument1 pageSAES W 011 Cover PageSiddiqui Abdul KhaliqNo ratings yet

- Page From B31.3-2012Document1 pagePage From B31.3-2012Siddiqui Abdul KhaliqNo ratings yet

- Control flow diagram for GACC's new welder qualification processDocument1 pageControl flow diagram for GACC's new welder qualification processSiddiqui Abdul KhaliqNo ratings yet

- DWG - No Revision Status Joint No. Joint Revision PJ Gen Apply Manual Joint Size Welding Type Line No. Line Class Test Package NoDocument3 pagesDWG - No Revision Status Joint No. Joint Revision PJ Gen Apply Manual Joint Size Welding Type Line No. Line Class Test Package NoSiddiqui Abdul KhaliqNo ratings yet

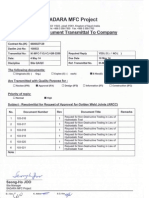

- Transmittal FormatDocument1 pageTransmittal FormatSiddiqui Abdul KhaliqNo ratings yet

- Caracteristicas Normas ASME B31Document3 pagesCaracteristicas Normas ASME B31darthneoNo ratings yet

- SS Consumable SelectionDocument1 pageSS Consumable SelectionSiddiqui Abdul KhaliqNo ratings yet

- ASME SECTION IX INTERPRETATIONSDocument77 pagesASME SECTION IX INTERPRETATIONSहेमंत कुमार मीणाNo ratings yet

- PWHT As Per Asme b31.3Document2 pagesPWHT As Per Asme b31.3Siddiqui Abdul KhaliqNo ratings yet

- Islamic Calendar 2014 1435Document12 pagesIslamic Calendar 2014 1435Anupama NagrajNo ratings yet

- ASTM Material Comparison TableDocument1 pageASTM Material Comparison Tabledhasdj100% (1)

- Engineering Procedure: SAEP-20 28 September 2005 Equipment Inspection Schedule Document Responsibility: Inspection DeptDocument25 pagesEngineering Procedure: SAEP-20 28 September 2005 Equipment Inspection Schedule Document Responsibility: Inspection DeptGritz Kay Labucay MarforiNo ratings yet

- High-Pressure Dry Abrasive Blasting Operations at Which PressureDocument2 pagesHigh-Pressure Dry Abrasive Blasting Operations at Which PressureSiddiqui Abdul Khaliq100% (1)

- Saf Rad PresentationDocument17 pagesSaf Rad PresentationSiddiqui Abdul KhaliqNo ratings yet

- Sample ResumeDocument1 pageSample ResumeSiddiqui Abdul KhaliqNo ratings yet

- Daily Welding Checklist (Sample)Document7 pagesDaily Welding Checklist (Sample)Siddiqui Abdul KhaliqNo ratings yet

- Contact Nmanpower Supply AgenciesDocument3 pagesContact Nmanpower Supply AgenciesSiddiqui Abdul KhaliqNo ratings yet

- Electrolytic CellDocument6 pagesElectrolytic CellJohn Israel R. CatedralNo ratings yet

- Fujitsu - ASIC/COT - 40nm CMOS Technology CS302 SeriesDocument2 pagesFujitsu - ASIC/COT - 40nm CMOS Technology CS302 SeriesFujitsu Semiconductor EuropeNo ratings yet

- SBHS1Document5 pagesSBHS1Rahul PancholiNo ratings yet

- CSF 110Document46 pagesCSF 110damanchurw210No ratings yet

- Edc Lab Manual Final PDFDocument81 pagesEdc Lab Manual Final PDFAchyuth NaiduNo ratings yet

- Art of Metering and ExposureDocument39 pagesArt of Metering and ExposureklladoNo ratings yet

- 1464415497007Document72 pages1464415497007romanaeva05No ratings yet

- Sequence Networks of Synchronous Generators and TransformersDocument7 pagesSequence Networks of Synchronous Generators and TransformersMadhusudhan Srinivasan0% (1)

- Magnetic Resonance Imaging: Prepared By, Anand & ShonimaDocument43 pagesMagnetic Resonance Imaging: Prepared By, Anand & ShonimaMannat BhallaNo ratings yet

- Dse402mk11 Data SheetDocument2 pagesDse402mk11 Data Sheetgigo_dreamNo ratings yet

- All-In-One Compressed Air StationDocument6 pagesAll-In-One Compressed Air StationAlexandru Bogdan FilipNo ratings yet

- Exploded View & Part ListDocument44 pagesExploded View & Part ListGardufNo ratings yet

- ANT ATD4516R5 2031 DatasheetDocument4 pagesANT ATD4516R5 2031 Datasheetangga meas100% (2)

- Nuclear Reactor InstrumentationDocument12 pagesNuclear Reactor InstrumentationRachit KanchanNo ratings yet

- Uc 3525 ADocument17 pagesUc 3525 AespaguetesNo ratings yet

- Intelligent Power Supply Design and Its DescriptionDocument45 pagesIntelligent Power Supply Design and Its Descriptionmilind kailaNo ratings yet

- Electrical Load Analysis Short Circuit Current ComputationDocument5 pagesElectrical Load Analysis Short Circuit Current ComputationNoel Joseph TobsNo ratings yet

- Ficha Técnica SUPRESOR DE PICOS 40 2 POLOSDocument2 pagesFicha Técnica SUPRESOR DE PICOS 40 2 POLOSmanuel montero guerraNo ratings yet

- 1 HPPDocument36 pages1 HPPAutomation WorksNo ratings yet

- Carvin Engineering Data: Receiving InspectionDocument4 pagesCarvin Engineering Data: Receiving InspectionBetoNo ratings yet

- Ca-Dc21e Im 96M11555 GB WW 1021-1Document2 pagesCa-Dc21e Im 96M11555 GB WW 1021-1tomy_ueziNo ratings yet

- Jason Spero: With Johanna WertherDocument41 pagesJason Spero: With Johanna WertherVasco MarquesNo ratings yet

- Marshall Class 5 Owner ManualDocument4 pagesMarshall Class 5 Owner ManualJuan Cruz LeónNo ratings yet

- Horizon Tech ManualDocument5 pagesHorizon Tech Manualwolf125No ratings yet

- Implementing Best Practices For Vlan Topologies: Defining VlansDocument66 pagesImplementing Best Practices For Vlan Topologies: Defining VlansArun JoyNo ratings yet

- LVDT Bestech PDFDocument2 pagesLVDT Bestech PDFRajitha ShehanNo ratings yet

- EW Harp ManualDocument14 pagesEW Harp ManualMatheus FrancoNo ratings yet

- Siemens RF600 Getting Started PDFDocument22 pagesSiemens RF600 Getting Started PDFazli8073No ratings yet

- Basler DECS-200 Instruction ManualDocument183 pagesBasler DECS-200 Instruction ManualFenix AutomaçãoNo ratings yet

- Chapter # 15 Electrical Measuring InstrumentsDocument5 pagesChapter # 15 Electrical Measuring InstrumentsSIR USMAN KHAN50% (2)