Professional Documents

Culture Documents

2808482

Uploaded by

Lauren GarciaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2808482

Uploaded by

Lauren GarciaCopyright:

Available Formats

INEEL/CON-04-01705

PREPRINT

Effect Of Off-Normal Austenization On Creep

Strength Of Ferritic-Martensitic Steels

T. C. Totemeier

J. A. Simpson

October 26, 2004

Fourth International Conference on Advances in

Materials Technology for Fossil Power Plants

This is a preprint of a paper intended for publication in a

journal or proceedings. Since changes may be made

before publication, this preprint should not be cited or

reproduced without permission of the author.

This document was prepared as an account of work

sponsored by an agency of the United States Government.

Neither the United States Government nor any agency

thereof, or any of their employees, makes any warranty,

expressed or implied, or assumes any legal liability or

responsibility for any third party's use, or the results

of such use, of any information, apparatus, product or

process disclosed in this report, or represents that its

use by such third party would not infringe privately

owned rights. The views expressed in this paper are

not necessarily those of the U.S. Government or the

sponsoring agency.

Effect of Off-Normal Austenization on Creep Strength

of Ferritic-Martensitic Steels

T.C. Totemeier

J.A. Simpson

Idaho National Engineering and Environmental Laboratory

P.O. Box 1625, MS 2218, Idaho Falls, ID 83415

Email: totetc@inel.gov

Effect of Off-Normal Austenization on Creep Strength

of Ferritic-Martensitic Steels

T.C. Totemeier

J.A. Simpson

Idaho National Engineering and Environmental Laboratory

P.O. Box 1625, MS 2218, Idaho Falls, ID 83415

Email: totetc@inel.gov

Abstract

The effect of a reduced-temperature austenization treatment on the microstructure and

strength of two ferritic-martensitic steels was studied. Prototypic 9% and 12% Cr steels,

modified 9Cr-1Mo (ASME T/P91) and Type 422 stainless (12Cr-1Mo-W-V),

respectively, were austenized at the standard 1050C and an off-normal 925C, both

followed by tempering at 760C. The reduced austenization temperature was intended

to simulate potential inadequate austenization during field construction of large

structures. The microstructure, tensile behavior, and creep strength were characterized

for both steels treated at each condition. While little change in microstructure was

observed for the modified 9Cr-1Mo steel, the creep strength was reduced at higher

temperatures and in long duration tests. The microstructure of the Type 422 stainless in

the off-normal condition consisted of polygonized ferrite instead of tempered

martensite. In this case the creep strength was reduced for short duration tests (less

than ~1000 hr), but not for long duration tests. Slight reductions in tensile strength

were observed at room temperature and elevated temperatures of 450, 550, and 650C.

Introduction

Ferritic-martensitic (F-M) steels with Cr contents ranging from 9 to 12 wt.% (all

subsequent compositions are given in wt.%) are widely used in fossil-fueled steam

generation plants as tubing and pipework. These heat-resistant steels typically contain

0.1 to 0.2% C and additions of refractory metals such as Mo, V, and W. The steels are

used in a normalized-and-tempered condition with an initial microstructure of

tempered martensite, M23C6 carbides along prior austenite and subgrain (lath)

boundaries, and in some cases fine MX precipitates within the laths. Ferritic-martensitic

steels have been extensively developed and studied over the past thirty years due to the

need for increasingly advanced steam conditions, i.e. higher temperature and pressure,

and find common use in super- and ultrasupercritical plants with steam conditions

approaching 630C and 30 MPa (1,2).

Ferritic-martensitic steels are also being considered for application in various

Generation IV advanced nuclear power plant designs as pressure vessels, tubing and

piping, and fuel cladding (3,4). They are a particularly attractive substitute for

austenitic stainless steels due to their reduced cost, lower thermal expansion coefficient,

and better radiation stability.

Although studies on the microstructure, strength, and thermal stability of F-M steels

have been widely published in the literature, most report the results of tests performed

on laboratory specimens with well-controlled heat treatments. Less documented are the

effects of off-normal heat treatments on the properties of these steels, even though

many service failures have been attributed to improper heat treatment. Specific

examples include the premature rupture of 12Cr superheater tubing due to inadequate

austenization treatment, reported by Barraclough and Gooch (5), and the replacement

of several pipe bend segments due to improper cooling after welding and prior to post-

weld heat treatment (PWHT) in a German plant, as reported by Hald (6). Of particular

concern is the fact that these improperly treated steels typically meet the standard

certification requirements, e.g., chemistry, hardness, and room-temperature tensile

strength.

This paper reports the results of initial work examining the effect of improper heat

treatment on two F-M steels, a modified 9Cr-1Mo steel (ASME T/P91) and a 12Cr-1Mo-

W-V steel (Type 422 stainless steel). Modified 9Cr-1Mo, a second generation F-M

steel developed in the 1970s (7,8), is widely used for tubing, headers, and piping in

current supercritical fossil plants and is a leading candidate alloy for application in

several Generation IV nuclear plants. Type 422 stainless steel finds application as steam

turbine blading and high-temperature bolting (9,10). The effect of inadequate

austenization (such as might occur in the center of a thick section) on the

microstructure, hardness, and elevated-temperature tensile and creep strength of the

two steels was determined. Specimens were austenized at the standard temperature of

1050C and an off-normal temperature of 925C, both followed by the standard 760C

tempering treatment.

Experimental Procedures

Materials and Heat Treatment

Modified 9Cr-1Mo steel (ASTM A182, F91) was obtained commercially in the form of a

hot-rolled round bar 50 mm in diameter in the normalized and tempered condition.

Type 422 stainless steel was obtained commercially in the form of a forged and

annealed plate 50 mm in thickness (the microstructure in the as-received condition

was tempered martensite). The measured chemical compositions of both steels are

listed in Table I. Both steels were sectioned into billets suitable for heat treatment, and

Table 1: Chemical Composition (wt.%)

Alloy Fe C Cr Mo V W Ni Nb N P S

Mod. 9Cr-1Mo Bal. 0.09 8.11 0.98 0.21 -- 0.17 0.08 0.049 0.014 0.003

Type 422 Bal. 0.22 11.76 0.96 0.24 1.02 0.85 0.012 0.036 0.017 0.001

were heat treated with either a standard procedure consisting of austenization at

1050C for a half-hour, air cooling to room temperature, and tempering at 760C for two

hours, or an off-normal procedure in which the austenization temperature was 925C

instead of 1050C, with the remainder the same.

The effect of heat treatment on microstructure was assessed using light microscopy

(LM), scanning electron microscopy (SEM), and transmission electron microscopy

(TEM) techniques. Mounted and polished metallographic cross-sections were prepared

using standard techniques and immersion etched with either Vilellas reagent or a

solution of 30 ml ethanol, 3 g picric acid, 0.6 ml nitric acid, and 1 ml hydrochloric acid.

A light etch with the latter was found to be effective in revealing carbide precipitates in

SEM examination. Precipitate size distributions were determined by analysis of SEM

images of etched sections taken at high magnification (20,000 to 40,000 X). TEM foils

were prepared from 3 mm discs which were mechanically thinned to 100 m and

electropolished to perforation. TEM examination was performed on a Phillips EM420

STEM operating at 120 kV.

Mechanical Testing

Tensile tests were performed at room and elevated temperatures of 25, 450, 550, and

650C on cylindrical specimens with 4.1 mm gauge diameter and 17.5 mm reduced

section. Specimen extension in room-temperature tests was measured using a standard

clip gauge. An averaging, rod-in-tube type extensometer was used for tests at elevated

temperatures; the translated displacement was measured outside the furnace using two

clip gauges. The specimens were heated with a radiant furnace and allowed to

equilibrate for 15-30 minutes prior to testing; specimen temperature was controlled

with a type K thermocouple to within 1C. The tensile tests were performed at a

constant cross-head displacement corresponding to an initial strain rate of 1 x 10

-3

sec

-1

.

Constant-load creep-rupture tests were performed at 800, 900, and 1000C on lever arm

creep machines with resistively heated furnaces. Specimens were again cylindrical with

6.3 mm gage diameter and 40 mm reduced section. Specimen temperatures were

controlled to within 5C by monitoring with two Type K thermocouples wired to the

specimen gauge length. Averaging, rod-in-tube type extensometers were used; the

displacement was measured outside the furnace by two linear variable differential

transducers (LVDTs). The temperature and LVDT readings were periodically recorded

using a computer-based data acquisition system. Most creep tests were run to failure.

Selected specimens were examined after testing. Longitudinal cross-sections of the

reduced sections were prepared, etched, and examined using SEM. General

microstructural changes were noted.

Results

Microstructure

Typical optical microstructures for the Modified 9Cr-1Mo and Type 422 steels in both

heat treatment conditions are shown in Figure 1. All show typical tempered martensite

structures at this magnification. While the lath structure in the Type 422 stainless steel

is visibly more degraded in the off-normal condition with a slight apparent coarsening

in the carbides, little difference can be distinguished between heat treatment conditions

in the modified 9Cr-1Mo steel except a slight reduction in prior austenite grain size.

The large difference in prior austenite grain size between the two steels is also apparent

No clear difference in the standard and off-normal microstructures was discernable for

the modified 9Cr-1Mo steel in the TEM. Relatively coarse carbides were observed on

the prior austenite and lath boundaries, along with a high dislocation density. A similar

tempered martensite structure was observed for the Type 422 stainless steel in the

standard condition, although the carbide density was noticeably higher than in the

modified 9Cr-1Mo, commensurate with the higher C content of Type 422. Indications

of recovery and ferrite polygonization were observed in the Type 422 off-normal

condition.

Differences in the microstructures of the two heat treatment conditions were quantified

in terms of precipitate size measured using image analysis of high-magnification SEM

micrographs. Figure 2 shows typical images for the two steels; Table 2 lists precipitate

dimensions, ASTM grain size, and hardness. No difference in mean precipitate

diameter was observed for the modified 9Cr-1Mo steel, but precipitates in the Type 422

stainless steel were significantly coarser in the off-normal condition. The precipitate

size distribution for the Type 422 stainless in the off-normal condition was slightly

bimodal, with a second peak developing at 480 nm due to precipitate impingement and

agglomeration. The Rockwell C hardness levels for the two steels were consistent with

the observed microstructural differences (or lack thereof): no significant change was

observed for the modified 9Cr-1Mo steel, and the hardness of the Type 422 stainless

steel was considerably lower in the off-normal condition.

Mod. 9Cr-1Mo-V

Type 422

S

t

a

n

d

a

r

d

O

f

f

-

N

o

r

m

a

l

Figure 1: Optical Microstructure

Mod. 9Cr-1Mo Type 422

Figure 2: Typical SEM Micrographs Used for Precipitate Size Analysis

Table 2: Heat Treatment Conditions and Microstructural Characteristics

Mod. 9Cr-1Mo

Standard

Mod. 9Cr-1Mo

Off-Normal

Type 422

Standard

Type 422

Off-Normal

Normalization 1050C/0.5 h/AC 925C/0.5 h/AC 1050C/0.5 h/AC 925C/0.5 h/AC

Tempering 760C/1 h/AC 760C/1 h/AC 760C/1 h/AC 760C/1 h/AC

Prior Austenite

Grain Size

11.5 12.5 5 5

Hardness (Rc) 19.1 17.9 27.6 19.9

Mean Carbide

Diameter 95%

CI (nm)

124 8 136 8 134 6 185 12

Mean Carbide

Diameter Std.

Deviation (nm)

75 69 63 117

Elevated Temperature Strength

Figure 3 shows the elevated temperature tensile strengths of the modified 9Cr-1Mo and

Type 422 steels. Small decreases in both yield and ultimate tensile strength (UTS) were

observed for each steel; the reduction in strength was greater for Type 422 steel,

consistent with microstructure and hardness. The magnitude of reduction (roughly 50

MPa for modified 9Cr-1Mo and 100 MPa for Type 422) was relatively constant with

increasing temperature to 650C, at which temperature the strengths of the two

conditions were nearly equal. Commensurate increases in ductility were observed,

with the difference again smaller at the highest temperatures.

Figure 4 shows minimum creep rate and stress-rupture data for modified 9Cr-1Mo steel

in standard and off-normal conditions. Shown for comparison is early modified 9Cr-

1Mo data obtained at Oak Ridge National Laboratory (ORNL) (8). Data for the

standard heat treatment shows good agreement with the ORNL data, as expected. The

stress exponents, n, in the Norton creep equation (

n

min

) are relatively high and

decrease with temperature, ranging from 16 at 550C to 8.5 at 650C. The off-normal

data increasingly deviate from the standard data with increasing temperature: the two

datasets lie together at 550C, and the off-normal condition is roughly 30% weaker at

0 100 200 300 400 500 600 700

Std Yield

Std UTS

ON Yield

ON UTS

0

200

400

600

800

1000

0 100 200 300 400 500 600 700

Std Yield

Std UTS

ON Yield

ON UTS

S

t

r

e

s

s

(

M

P

a

)

Temperature (C)

Mod. 9Cr-1Mo-V

Type 422

Figure 3: Elevated Temperature Tensile Strength

650C. Data for the off-normal condition at 600C fall slightly below the standard data

for lower stresses/longer lives. The trends in minimum creep rate and rupture life are

consistent.

Creep and stress-rupture data for Type 422 stainless steel in standard and off-normal

heat treatment conditions are shown in Figure 5. Baseline data published by the

Japanese National Research Institute for Metals (NRIM) (9) are shown for comparison.

The NRIM data trends are extrapolated (gray lines) to better delineate the trends for the

present standard heat treatment data, which generally agree with the NRIM data. At

each temperature, creep rates and rupture lives for the off-normal condition agree with

those of the standard condition at the lowest stresses but are markedly poorer at higher

stresses. The magnitude of high-stress strength reduction increases with test

temperature. Although the data are limited, the creep rate or rupture life at which the

off-normal data begins to deviate from the standard data appears to change with

temperature. The minimum creep rate at which deviation occurs increases from

approximately 10

-9

sec

-1

at 550C to 10

-8

sec

-1

at 650C. Similarly, the rupture life at

which deviation occurs varies from 10,000 hr at 550C to 1,000 hr at 650C.

Although individual data are not presented, the creep elongation to failure and

reduction in area observed in both heat treatment conditions were typical for each alloy.

Ductility in the off-normal heat treatment condition was slightly higher than in the

standard condition; all failures occurred by ductile rupture. Little change in optical

microstructure was observed for either steel after creep-rupture testing at 550 and

600C, but a degradation of the tempered martensite structure was observed for the

modified 9Cr-1Mo steel after creep testing at 650C for ~ 500 hr, as shown in Figure 6.

Spheriodization and recovery appeared to be slightly more advanced in the off-normal

condition.

10

-10

10

-9

10

-8

10

-7

10

-6

10

-5

60 80 100 300

M

i

n

i

m

u

m

C

r

e

e

p

R

a

t

e

(

s

e

c

-

1

)

Stress (MPa)

500 50

60

80

100

300

10

0

10

1

10

2

10

3

10

4

550C, Std

600C, Std

650C, Std

550C, ON

600C, ON

650C, ON

550C, ORNL

600C, ORNL

650C, ORNL

S

t

r

e

s

s

(

M

P

a

)

Time to Rupture (MPa)

500

50

Figure 4: Minimum Creep Rate and Stress Rupture Life for Modified 9Cr-1Mo Steel

60

80

100

300

10

0

10

1

10

2

10

3

10

4

550C, Std

600C, Std

650C, Std

550C, ON

600C, ON

650C, ON

550C, NRIM

600C, NRIM

650C, NRIM

S

t

r

e

s

s

(

M

P

a

)

Time to Rupture (hr)

500

50 10

-10

10

-9

10

-8

10

-7

10

-6

10

-5

60 80 100 300

M

i

n

i

m

u

m

C

r

e

e

p

R

a

t

e

(

s

e

c

-

1

)

Stress (MPa)

50 500

Figure 5: Minimum Creep Rate and Stress Rupture Life for Type 422 Stainless Steel

Standard: 462 hr at 100 MPa Off-Normal: 654 hr at 65 MPa

Figure 6: Microstructures of Modified 9Cr-1Mo Steel After Creep at 650C

Discussion

Modified 9Cr-1Mo Steel

Austenization of modified 9Cr-1Mo steel at 925C instead of the standard 1050C

resulted in little microstructural change. Off-normal and standard structures observed

using LM, SEM, and TEM were nearly identical, and no significant difference was

observed in the carbide size distribution. The only quantifiable difference was a small

but noticeable reduction in the prior austenite grain size (from ASTM ~11.5 to ~12.5) for

the off-normal condition.

The lack of microstructural difference is consistent with the fact that both temperatures

lie in the austenite phase field for this alloy (the Ac3 temperature is reported as 905C

(11)). The only difference expected is less carbide dissolution during the dwell at the

lower, off-normal temperature. However, because carbides in the quenched-and-

tempered initial condition are fine, the extent of dissolution at the off-normal

temperature appears to be not markedly different than that at the standard

temperature, and the two final microstructures are nearly indistinguishable. As

expected, austenite grain growth was restricted at the lower temperature, reflected in

the smaller prior austenite grain size. The small reductions in hardness and tensile

strength in the off-normal condition probably result from a slightly reduced extent of

carbide dissolution for the lower-temperature austenization, which will give softer

martensite and reduced dislocation density after tempering (11). The changes are

sufficient to overwhelm the increase in hardness and tensile strength resulting from the

decreased prior austenite grain size.

A significant reduction in creep strength at 650C was observed for the off-normal

condition despite the microstructural similarity. At 650C the strength reduction was

clear at all stress levels tested and was apparent at lower stresses (< 150 MPa) at 600C.

These strength reductions are also tentatively attributed to slightly reduced carbide

dissolution during austenization at the lower, off-normal temperature. Creep strength

in F-M steels at high temperatures is controlled by the subgrain size and dislocation

density, which are in turn controlled by carbide precipitatesNb- and V-containing MX

precipitates in particular for modified 9Cr-1Mo (12,13). Although TEM examination of

post-crept microstructures is needed, it is plausible that slightly less carbide dissolution

at 925C may ultimately result in fewer fine MX precipitates present to restrict recovery

and subgrain growth during creep, thereby resulting in reduced strength relative to the

standard condition. Such an effect would be expected to be particularly pronounced for

higher temperature or longer duration tests where microstructural changes during

creep are significant. The post-test optical microstructures support this hypothesis

after ~500 hr of creep at 650C the tempered martensite structure appears more

degraded in the off-normal condition than in the standard condition (Figure 6).

The observation of reduced creep strength in modified 9Cr-1Mo steel with lowered

austenization temperature is consistent with previous findings. Sikka, et al. (8) noted

marked reduction in rupture life at 650C with decreasing austenization temperature,

with nearly an order of magnitude difference in life at 90 and 100 MPa stress levels; a

similar life reduction was observed in the present study. Other researchers have also

observed deleterious effects of exposure to temperatures in the 900-950C range

(11,14,15); such temperatures correspond to those experienced in the fine-grained HAZ

of weldments, which are preferential failure locations (Type IV cracking) in creep

conditions (16).

Type 422 Stainless Steel

The differences in the 12% Cr Type 422 stainless steel microstructures after

austenization at standard and off-normal temperatures were more marked than for the

modified 9Cr-1Mo steel. The structure following standard austenization at 1050C and

tempering was tempered martensite with high dislocation density, while polygonized

ferrite with low dislocation density was observed after austenization at 925C and

tempering; significant carbide coarsening was also observed.

The microstructural information indicates that austenite did not form at 925C, even

though (as with the modified 9Cr-1Mo steel) this temperature was within the austenite

phase field (the Ac3 temperature is reported as 885C(10)). The prior austenite grain size

in the off-normal condition was essentially the same as the as-received material and

after standard heat treatment (the ASTM grain size in all conditions was 4 to 5),

contrary to an expected reduction in prior austenite size for the lower austenization

temperature. The presence of polygonized and recovered ferrite rather than tempered

martensite indicates that martensite was not formed during cooling from the 925C

austenization temperature (and hence austenite was not present prior to cooling). The

structure resembled that seen in the intercritically-heated HAZ of weldments (17-19). It

is unclear why austenite was not formed at 925C; either the material did not actually

achieve this temperature or the dwell time was not sufficient. The higher alloy and

carbon content will result in slower transformation kinetics relative to the 9% Cr steel,

perhaps sufficiently slower that austenite was not formed during the half-hour

austenization period for Type 422 steel, but was for modified 9Cr-1Mo.

The reduced tensile strength and hardness clearly reflect the microstructural changes.

In contrast to the modified 9Cr-1Mo steel, however, the creep strength of Type 422

stainless in the off-normal condition was reduced at all temperatures, but only for high

stress, short duration tests. The creep strength at low stresses in the off-normal

condition was equivalent to the standard condition. This behavior can be understood in

terms of creep degradation of the standard microstructure. For Type 422 stainless the

initial microstructure in the off-normal condition (recovered ferrite) is similar to that

found after long-term creep testing of the standard microstructure (20,21). In a long-

duration creep test the standard microstructure evolves into a microstructure similar to

the off-normal microstructure at a relatively small fraction of the test duration. The

microstructure controlling the behavior of the majority of a long-term test is therefore

similar for standard and off-normal conditions, whereas in shorter tests the initial

microstructure dominates, and the standard microstructure is stronger. The rupture

time at which the lives of the off-normal and standard conditions become equivalent is

shorter at higher temperatures, consistent with thermally-activated recovery of the

standard microstructure as the cause of equivalent behavior. Note that in the case of

Type 422 stainless MX precipitates do not significantly enhance creep strength by

impeding recovery (the alloy is first generation, not containing Nb), so it occurs more

quickly and completely than in modified 9Cr-1Mo.

A similar study of the effect of off-normal austenization treatment was performed on

X20CrMoV121 steel by Barraclough and Gooch (5), in response to service failure of this

steel at very short life. X20CrMoV121 has a very similar composition to Type 422, but

for this alloy the effect of lower-temperature austenization (at 900C instead of 925C)

was very markedno sign of a lath microstructure was observed, only equiaxed ferrite.

The reduction in strength at 640C was approximately 20 MPa; nearly 50% of the

strength at that temperature. The strength reduction at 650C in the present study was

approximately 30%, but only for test durations shorter than 100 hr. It is unclear

whether the considerably greater degradation observed by Barraclough and Gooch

resulted from the small alloy composition difference or the small difference in

austenization temperature (25C).

These findings indicate an apparent increased sensitivity of the more highly alloyed

12% Cr steel to variations in heat treatment in comparison with the 9% Cr alloy, at least

on a microstructural level. The greater sensitivity to heat treatment variations of 12%

Cr steels has been noted by other researchers, particularly for welding processes

(16,22,23). It is important to note, however, that for typical service conditions (e.g.

lower stress, long duration) the modified 9Cr-1Mo steel is in fact more sensitive to the

reduced temperatures than Type 422 stainless. The creep strength reduction for

modified 9Cr-1Mo only exists at higher temperature and longer times, while the creep

strength of Type 422 is not reduced for these conditions. The creep strength advantage

of later-generation F-M steels (such as modified 9Cr-1Mo) over earlier alloys primarily

results from increased microstructural stability (resistance to recovery and subgrain

coarsening). The stability results from a fine, intra-lath dispersion of MX precipitates.

Off-normal conditions which impair the formation of these precipitates have the

potential to seriously impair the creep strength of the advanced alloys.

Conclusions

The effect of a lowered austenization temperature, 925C instead of the standard

1050C, on the microstructure and elevated temperature strength of modified 9Cr-1Mo

steel and Type 422 stainless steel (12Cr-1Mo-W-V) was investigated. Although there

was little discernable change in the microstructure of the modified 9Cr-1Mo alloy in the

off-normal condition, the creep-rupture strength was significantly reduced at 650C;

slight reductions were observed for low stresses at 600 and 550C. The creep strength

reduction is attributed to decreased carbide dissolution at the lower austenization

temperature and a commensurate change in the size and distribution of MX

precipitates, which control the recovery and coarsening of subgrain structure in this

alloy. For Type 422 stainless, off-normal austenization resulted in a structure of

polygonized ferrite and coarsened carbides, indicating that transformation to austenite

did not occur even though the Ac3 temperature for this alloy was exceeded. The

recovered structure had significantly reduced hardness and short-term elevated

temperature tensile and creep strength, but the long-term creep strength was not

affected.

Acknowledgements

The authors would like to acknowledge the assistance of T.C. Morris with

metallography and R.J. Pink with creep testing. This work was supported by the U.S.

Department of Energy, Idaho Operations Office, under contract DE-AC07-99ID13727

References

1. F.B. Pickering: "Historical Development and Microstructure of High Chromium

Ferritic Steels for High Temperature Applications" in Microstructural Development

and Stability in High Chromium Ferritic Power Plant Steels, A. Strang and D.J. Gooch,

Eds. London: Institute of Materials, 1997, pp. 1-29.

2. F. Masuyama: ISIJ International, 2001, 41 (6), 612-625.

3. T.A. Allen, S. Bruemmer, J. Elmer, M. Kassner, A. Motta, G.R. Odette, R.E. Stoller,

G. Was, W. Wolfer, and S. Zinkle, Higher Temperature Reactor Materials Workshop.

2002, Argonne National Laboratory.

4. Next Generation Nuclear Plant Materials Selection and Qualification Program Plan. 2003,

Idaho National Engineering and Environmental Laboratory.

5. D.R. Barraclough and D.J. Gooch: Materials Science and Technology, 1985, 1 (11), 961-

967.

6. J. Hald: "Service Performance of a 12CrMoV Steam Pipe Steel" in Microstructural

Stability of Creep Resistant Alloys for High Temperature Plant Applications, A. Strang, J.

Cawley, and G.W. Greenwood, Eds. London: IOM Communications Ltd, 1998, pp.

173-184.

7. V.K. Sikka, C.T. Ward, and K.C. Thomas: "Modified 9 Cr - 1 Mo Steel -an Improved

Alloy for Steam Generator Application" in Ferritic Steels for High-Temperature

Applications, A.K. Khare, Ed. Metals Park, OH: ASM, 1983, pp. 65-84.

8. V.K. Sikka, M.G. Cowgill, and B.W. Roberts: "Creep Properties of Modified 9Cr-

1Mo Steel" in Ferritic Alloys for Use in Nuclear Energy Technologies, J.W. Davis and

D.J. Michel, Eds. Warrendale, PA: TMS, 1983, pp. 413-423.

9. NRIM Creep Data Sheet No. 10b. 1998, Japanese National Research Institute for

Metals: Ibaraki, Japan.

10. J.R. Kattus: "Type 422" in Aerospace Structural Materials Handbook, W.F. Brown, H.

Mindlin, and C.Y. Ho, Eds. West Lafayette, IN: CINDAS-Purdue University, 1997

11. K.S. Chandravathi, K. Laha, K. Bhanu Sankara Rao, and S.L. Mannan: Materials

Science and Technology, 2001, 17 (5), 559-565.

12. K. Maruyama, K. Sawada, and J. Koike: ISIJ International, 2001, 41 (6), 641-653.

13. J. Orr and L. Woollard: "The Development of 9% CrMo Steels from Steel 91 to E911"

in Microstructural Development and Stability in High Chromium Ferritic Power Plant

Steels, A. Strang and D.J. Gooch, Eds. London: Institute of Materials, 1997

14. T. Kojima, K. Hayashi, and Y. Kajita: ISIJ International, 1995, 35 (10), 1284-1290.

15. J.G. Zhang, F.W. Noble, and B.L. Eyre: Materials Science and Technology, 1991, 7 (4),

315-320.

16. M. DeWitte and C. Coussement: Materials at High Temperatures, 1991, 9 (4), 178-184.

17. P.J. Ennis: OMMI, 2002, 1 (2)

18. N. Komai and F. Masuyama: ISIJ International, 2002, 42 (12), 1364-1370.

19. J.C. Lippold: "The Effect of Postweld Heat Treatment on the Microstructure and

Properties of the Heat-Affected Zone in 12Cr-1Mo-0.3V (HT9) Weldments" in

Ferritic Alloys for Use in Nuclear Energy Technologies, J.W. Davis and D.J. Michel, Eds.

Warrendale, PA: TMS, 1983, pp. 497-506.

20. H. Kimura, H. Kushima, F. Abe, and K. Yagi: "Evaluation of the Creep Strength

Property from a Viewpoint of Inherent Creep Strength for Ferritic Creep Resistant

Steels" in Microstructural Stability of Creep Resistant Alloys for High Temperature Plant

Applications, A. Strang, J. Cawley, and G.W. Greenwood, Eds. London: IOM

Publications, 1998, pp. 185-196.

21. P. Bianchi, P. Bontempi, A. Benvenuti, and N. Ricci: "Microstructural Evolution of

P91 Steel after Long Term Creep Tests" in Microstructural Stability of Creep Resistant

Alloys for High Temperature Plant Applications, A. Strang, J. Cawley, and G.W.

Greenwood, Eds. London: IOM Communications, 1998, pp. 107-116.

22. H.-O. Andren, G. Cai, and L.-E. Svensson: Applied Surface Science, 1995, 87/88, 200-

206.

23. Z.L. Tian, C. Coussement, M. DeWitte, and M. Steen: International Journal of Pressure

Vessels and Piping, 1991, 46, 339-348.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Pages From HRN en 12952-5Document14 pagesPages From HRN en 12952-5Lauren GarciaNo ratings yet

- Drawing1 Layout1Document1 pageDrawing1 Layout1Lauren GarciaNo ratings yet

- 20100330101400145Document35 pages20100330101400145Lauren GarciaNo ratings yet

- Sandvik Pipe - Tube - Bar - Hollow Bar: Stock Program in StainlessDocument26 pagesSandvik Pipe - Tube - Bar - Hollow Bar: Stock Program in Stainlessalbejo_r9No ratings yet

- 20100525083319116Document1 page20100525083319116Lauren GarciaNo ratings yet

- 20100326074831446Document1 page20100326074831446Lauren GarciaNo ratings yet

- 20100525083136149Document1 page20100525083136149Lauren GarciaNo ratings yet

- 20100526125044214Document1 page20100526125044214Lauren GarciaNo ratings yet

- 20100526100623668Document1 page20100526100623668Lauren GarciaNo ratings yet

- 20100330123609293Document29 pages20100330123609293Lauren GarciaNo ratings yet

- 2 2009 03 1563509Document1 page2 2009 03 1563509Lauren GarciaNo ratings yet

- 20100329112643710Document2 pages20100329112643710Lauren GarciaNo ratings yet

- 20100326085743579Document2 pages20100326085743579Lauren GarciaNo ratings yet

- 20100326085743579Document2 pages20100326085743579Lauren GarciaNo ratings yet

- BWE Brik Welding EvaluationDocument4 pagesBWE Brik Welding EvaluationLauren GarciaNo ratings yet

- CTODDocument4 pagesCTODthan79No ratings yet

- Dwg1 2825 RemarksDocument1 pageDwg1 2825 RemarksLauren GarciaNo ratings yet

- Effect of Heat Input To Weld Residual StressDocument4 pagesEffect of Heat Input To Weld Residual StressSurya DharmaNo ratings yet

- Etd1649 PDFDocument61 pagesEtd1649 PDFLauren GarciaNo ratings yet

- N 9003Document4 pagesN 9003Lauren GarciaNo ratings yet

- Influence of Heat Input On Corrosion Resistance of SAW Welded Duplex JointsDocument4 pagesInfluence of Heat Input On Corrosion Resistance of SAW Welded Duplex JointsLauren GarciaNo ratings yet

- Eagar 006Document15 pagesEagar 006Lauren GarciaNo ratings yet

- 20100716075629769Document3 pages20100716075629769Lauren GarciaNo ratings yet

- 20100618071206827Document2 pages20100618071206827Lauren GarciaNo ratings yet

- 20100709123225199Document5 pages20100709123225199Lauren GarciaNo ratings yet

- 51 4 341 346Document6 pages51 4 341 346Lauren GarciaNo ratings yet

- 20100617082758841Document1 page20100617082758841Lauren GarciaNo ratings yet

- 20100713131211561Document2 pages20100713131211561Lauren GarciaNo ratings yet

- 20100716101107497Document1 page20100716101107497Lauren GarciaNo ratings yet

- 20100716121120727Document1 page20100716121120727Lauren GarciaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Multidisciplinary Nature of Environmental StudiesDocument6 pagesMultidisciplinary Nature of Environmental StudiesWiz Calvin ManutdNo ratings yet

- Unu GTP SC 26 14Document30 pagesUnu GTP SC 26 14Ernesto RomeroNo ratings yet

- Deepwater Horizon: Lessons in ProbabilitiesDocument15 pagesDeepwater Horizon: Lessons in ProbabilitiesZaman HaiderNo ratings yet

- Damper mechanism details for Atlas Copco rock drills under 40 charactersDocument27 pagesDamper mechanism details for Atlas Copco rock drills under 40 characterssalvador341100% (2)

- RECYCLED ASPHALTDocument27 pagesRECYCLED ASPHALTwillypraviantoNo ratings yet

- Volkswagen 2.0L TDI Common Rail Engine Service TrainingDocument90 pagesVolkswagen 2.0L TDI Common Rail Engine Service TrainingАлла Харютина100% (1)

- FFRT-100: Standard SpecificationsDocument2 pagesFFRT-100: Standard SpecificationsbibhansuNo ratings yet

- Inspection, Test, Marking and RecordsDocument10 pagesInspection, Test, Marking and RecordssuryaNo ratings yet

- Cwi QuestionsDocument6 pagesCwi QuestionsGokul Thangam75% (4)

- PPTs ON BONTON CABLESDocument10 pagesPPTs ON BONTON CABLESShaishav Anand100% (1)

- Type 316 Stainless Steel Properties & ApplicationsDocument3 pagesType 316 Stainless Steel Properties & Applicationsh4josephNo ratings yet

- Wind Turbine Installation-ManualDocument23 pagesWind Turbine Installation-Manualויליאם סן מרמיגיוסNo ratings yet

- Microcontroller-Based Power Monitoring for COE RoomsDocument8 pagesMicrocontroller-Based Power Monitoring for COE Roomskenneth_molenilla1475No ratings yet

- 03 MAN D2Z2IM ACT350xx ENDocument24 pages03 MAN D2Z2IM ACT350xx ENAlfonso Lopez toroNo ratings yet

- Rectificador A Diodos Siemens-Sitras-Rec-Pi-EnDocument6 pagesRectificador A Diodos Siemens-Sitras-Rec-Pi-EnVictor Manuel BonettoNo ratings yet

- Energy Conservation Oppurtunities in Boiler SystemDocument34 pagesEnergy Conservation Oppurtunities in Boiler SystemSiddharth Jain67% (3)

- 1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshDocument65 pages1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshbenonNo ratings yet

- 11 5 Temperature and Pressure 4th EdDocument18 pages11 5 Temperature and Pressure 4th Edapi-267245178No ratings yet

- 3512TA - 1000kVA - LV - Spec Sheet PDFDocument5 pages3512TA - 1000kVA - LV - Spec Sheet PDFavinash_1229No ratings yet

- DC Components Co., LTD.: Rectifier SpecialistsDocument3 pagesDC Components Co., LTD.: Rectifier SpecialistsPICVIONo ratings yet

- Led ComponentsDocument226 pagesLed Componentselcomsrl100% (1)

- Short and Open Circuit Test On TransformerDocument1 pageShort and Open Circuit Test On TransformerRyan DagsilNo ratings yet

- GS-37 LcaDocument22 pagesGS-37 LcaGeny KucherNo ratings yet

- Apocalyptic Rhetoric KritikDocument31 pagesApocalyptic Rhetoric KritikMilkdelishNo ratings yet

- Ferhat ErdalDocument22 pagesFerhat ErdalsaifoaNo ratings yet

- Marine Chock InstallationDocument48 pagesMarine Chock InstallationSumeet SawantNo ratings yet

- Metalux Hbled Standard Efficiency Specsheet - Hbled ld5 24se W Unv l850 Ed2 UDocument5 pagesMetalux Hbled Standard Efficiency Specsheet - Hbled ld5 24se W Unv l850 Ed2 UDANIEL SALAZARNo ratings yet

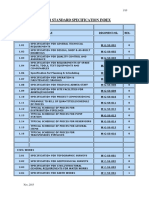

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- Introduction To The Multi MeterDocument3 pagesIntroduction To The Multi MeterFaiz FauziNo ratings yet

- Connection TableDocument10 pagesConnection TableBepdjNo ratings yet