Professional Documents

Culture Documents

Help Employees Meet Great Expectations - Logistics & Supply Chain World September 2012

Uploaded by

TomisineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Help Employees Meet Great Expectations - Logistics & Supply Chain World September 2012

Uploaded by

TomisineCopyright:

Available Formats

Logistics and Supply Chain World | September 2012

1

N

e

w

s

I

n

s

i

d

e

September 2012 | R100/-

ENTREPRENEURIAL

SUPPLY CHAINS

Creating

201 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 01 012222222222222222222222222222222 Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Log Logist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist ist istics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics ics an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an an and S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d S d Supp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upp upply ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly ly Cha Cha Cha Cha Cha Cha Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor World ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ld ||||||||||||||||||||||||||||||||||| Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Se Sept pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt pt ptem em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em em ember 222222222 Cha Chain in in in in in in in in in in in in in in in in in Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor Wor

& Supply Chain World

11111111111111111111111111111111111111

Industry

Insights

Are you

overpaying for

outsourced

parts ?

Special

Feature

Rethink Social

for your Supply

Chain

Pharma SCM

Special

Cold Chain in

Emerging

Markets

Editorial Desk

Supply chain

distribution

trends in an

improving

Economy

42

Logistics and Supply Chain World | September 2012

Industry Insights

Help employees meet great

expectations

Warehouse workers dont do the same task the same way each and every

time. Observing what really happens on the floor is key to developing good

performance standards.

E

very warehouse manager has likely heard What

gets measured gets done. Measuring and

monitoring operations are key to managing an

efficient, productive facility. Therefore, developing and

implementing an employee performance expectations

program shouldnt be taken lightly.

Many warehouse managers approach labor standards

development with an assembly line mentality. They

often expect every task or warehouse function to be

repeated the same way, each and every time. Basically

Paretos Law, the 20/80 rule, does not fit into such a

simple formula. While a labor management system

(LMS) is an important component in developing

good performance standards, you must first measure

employee performance.

Three Approaches

Create a macro standard using historical records. Those

might include the number of locations visited, the

number of cartons created, and the number of units

picked to fill the average order. With that information,

the system determines the average number of picks per

hour or shift per employee. The LMS then determines

how many operators will be needed to pick orders on

the next shift.

Create master standards data using published standards.

In this approach, every task is comprised of discrete

movements, such as picking up a product and putting

it on a pallet. Over the years, industry has compiled

accepted standards for how long all of those should

take. The sum of those movements makes up the basis

by Tom Tanel

for master standards data.

Create discrete or engineered labor standards. An

engineered labor standard breaks down each process

into its component parts. Through time/motion studies

and work sampling, an industrial engineer determines

how long on average it takes workers to complete each

component of the task safely with a built-in personnel

fatigue and delay factor (PF&D).

Common Mistakes

It is impossible to create accurate expectations by making

performance fit predetermined standards without

considering the variables and their combinations. For

example, in a grocery warehouse 125 cases per hour

as a picking standard does not take into consideration

whether it is in the dry, refrigerated or frozen storage

areas. Or for that matter whether its a full pallet pick

or a mixed rainbow pallet pick. Expectations must

be based on an apples-to-apples comparison in the

warehouse.

Another mistake many managers make is using averages

to create expectations. An average is merely a statistical

aberration that does not occur in the real world.

Using averages often means

lowering standards, because just

a few poor or high performers

can skew the results

Some managers mistakenly believe that if every

employee is surpassing the standards, it is a sign that

the facility is operating at high productivity. Its actually

an indication that they need to re-evaluate their

expectations and the standard.

Finally, remember that productivity comprises two

areas: efficiency and effectiveness. Efficiency is doing

things with the least wasted effort, while effectiveness

is doing the right things or doing the things that yield

results. You cant measure productivity without looking

at both.

The Right Expectations

Which should I work on first: efficiency or effectiveness ?

In theory and practice, the best answer is to improve

your effectiveness first. Its much better to aim at the

result than to worry about the process. Too often we get

bogged down in the means and lose sight of the end.

Take these steps to develop performance standards and

expectations :

Determine if you can measure the task throughout

the facility. If you cant, you should not be using it as

a performance standard. Unit load degradation is a

good indicator that you cannot measure a specific task

throughout the warehouse. For example, if you receive

inventory by pallet, store it by case, but ship it by piece,

the product has to be handled in three different ways in

the facility.

Beware of technical or confusing expressions. Rather

than terms like cost ratios, use more common physical

terms such as lines, orders, SKUs, unit loads, etc. Also,

avoid mixing different businesses, such as cases and

broken case picks or LTL and FTL receipts. Once you

measure actual performance against a standard, put it

in a meaningful way.

Perform a standards study. You should clearly

communicate the purpose and methods of the study

to all employees. Implementing performance standards

and expectations without explaining the reasons for

the change can create unnecessary tension and anxiety

among those who are going to be affected. If possible,

allow employees to be involved in the process, including

work sampling and measuring.

If your workforce is unionized, you should also explain

your plans to the union. To be successful, you need the

support of everyone involved.

Seek employee involvement and gain their support.

Whether union or non-union, advise employees of the

reasons for the program, and describe what, when,

and how this will be accomplished. Ask for their

input. Discuss the results with employees, as well as

first line supervisors and verify the findings. Did your

measurements represent normal and typical activities?

A performance measurement program depends on

accurate expectations. Using abnormal conditions to

create a baseline for expectations will undermine the

entire effort.

Create a range of performance expectations, not a single

threshold. Every employee is different, and expecting

identical performance from each is unreasonable. This

only discourages those employees who cant reach

the standards, while encouraging the best performers

to underachieve. Also, employees are more likely to

support and buy into the performance expectations

if they understand that there is a range of acceptable

performance.

44

Logistics and Supply Chain World | September 2012

Set up and monitor a pilot program. Are your

expectations reasonable? If not, a pilot program should

quickly identify any errors in your original conclusions.

It is much better to discover the problem on a small

scale before you implement the expectations across the

entire warehouse.

Provide constant, positive feedback. Most employees

will not meet the new performance expectations

overnight. Look for incremental improvements, and

reward good performance. Remember, people soon

forget about monetary rewards do not undervalue

praise and recognition. It costs little, but has a much

more lasting effect.

Develop a method to monitor employee performance

graphically, instead of in spreadsheet tables. This way,

you can actually see trends and resolve issues before

they become real problems.

Communicate results of the team, not the individual.

Posting individual results can have a negative impact.

The workers on the floor can tell you who the most

productive employees are and who the least productive

are without looking at posted results. It only causes

dissension and resentment among co-workers. A

small group, through productivity gain sharing has a

better chance of achieving success as a whole than an

individual does. Only communicate individual results in

private meetings or communications.

Deal with employees who fail to meet expectations.

These employees come in two types: those who cant

and those who wont. In either case, you must identify

which type an employee is and find a way to help

him or her reach the expected level. Employees who

cant meet expectations can usually be coached. Try to

achieve improvements incrementally. People who wont

meet the expectations need to be counseled. Dont ask

what they dislike; ask them why they dislike it. This will

eliminate their opportunity to merely gripe and force

them to discuss exactly what it is about the standards

that they find unreasonable. Listen to their arguments

they may have valid points.

Use performance management appraisal and

development. Performance reviews help supervisors

feel more honest in their relationships with their

subordinates and feel better about themselves in

their supervisory roles. Subordinates are assured clear

understanding of whats expected from them, their own

personal strengths and areas for development, and a

solid sense of their relationship with their supervisor.

Avoiding performance issues ultimately decreases

morale, decreases management credibility, decreases

the organizations overall effectiveness and wastes more

of managements time to do what isnt being done

properly.

To measure your people effectively, identify metrics

that are appropriate for your organization and that will

improve the warehouses performance.

About the Author :

Tom Tanel is president and CEO of

CATTAN Services Group Inc. (www.

cattan.com), a logistics advisory,

counseling, and training firm in

College Station, Texas.

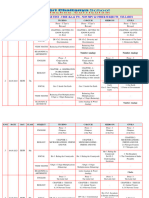

New World, New Rules, New Ideas

Day One : 27

th

September 2012

Day Two : 28

th

September 2012

27

th

- 28

th

September 2012

Taj Lands End, Mumbai

6

th

Express, Logistics &

Supply Chain Conclave

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 3dconfig Setting Di AutocadDocument4 pages3dconfig Setting Di Autocadvr_talleiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- DAAD WISE Summer Internship ReportDocument2 pagesDAAD WISE Summer Internship ReportVineet Maheshwari100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- STM ProcessDocument7 pagesSTM Processyadavpankaj1992No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hospital Information SystemDocument2 pagesHospital Information SystemManpreetaaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- "Castration", The HIV Scandal and The Japanese Bureaucracy MASAO MIYAMOTO, M.D.Document21 pages"Castration", The HIV Scandal and The Japanese Bureaucracy MASAO MIYAMOTO, M.D.WB7No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- دور معايير التقارير المالية الدولية في الحد من ممارسات ادارة الارباح في القوائم المالية للمصارفDocument18 pagesدور معايير التقارير المالية الدولية في الحد من ممارسات ادارة الارباح في القوائم المالية للمصارفWshiar Omer100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Kellogg's Case StudyDocument3 pagesKellogg's Case StudyÁkos Marian50% (2)

- Infinity Meta Weekly Ot - Ka & TN - Non MPC & Other Subjects - SyllabusDocument2 pagesInfinity Meta Weekly Ot - Ka & TN - Non MPC & Other Subjects - SyllabusR PranavNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Nhóm 1- Tấm CámDocument12 pagesNhóm 1- Tấm CámNguyễn NgọcNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Art and Design - Course ProspectusDocument20 pagesArt and Design - Course ProspectusNHCollegeNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Organisational Culture and ChangeDocument49 pagesOrganisational Culture and ChangeMahima Rojith100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Grade 5 Parallels and Meridians BLDDocument6 pagesGrade 5 Parallels and Meridians BLDAnu ReddyNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Sediment Transport Flo2DDocument22 pagesSediment Transport Flo2DJoshua Xilo MoronNo ratings yet

- PIM-NMB40103 - Course Learning Plan-Jan 2017Document5 pagesPIM-NMB40103 - Course Learning Plan-Jan 2017FirzanNo ratings yet

- Pareto DiagramDocument1 pagePareto DiagramvirtualbobNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Accelerated C++Document13 pagesAccelerated C++gokuler137No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Exercise-6 1 1 2-6 1 1 5Document7 pagesExercise-6 1 1 2-6 1 1 5Ramgie Danielle NamolNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Darwin Geologist PDFDocument3 pagesDarwin Geologist PDFKendallhernandez100% (1)

- WoodcockDocument10 pagesWoodcockPriscila Do AmaralNo ratings yet

- PB115 Connection ReferenceDocument278 pagesPB115 Connection ReferenceJose Andres LeonNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- List of Contributors: - Ukurova University, Adana, TurkeyDocument416 pagesList of Contributors: - Ukurova University, Adana, TurkeyBelhadj TarekNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Bkai3043 Topic 1Document16 pagesBkai3043 Topic 1Ros Shinie BalanNo ratings yet

- Gamification in Tourism Best PracticeDocument14 pagesGamification in Tourism Best PracticeCristina ColoteloNo ratings yet

- Using The Developer Console To Execute Apex CodeDocument5 pagesUsing The Developer Console To Execute Apex Codeksr131No ratings yet

- 1996 Umbra-One-1996Document125 pages1996 Umbra-One-1996ziggy00zaggyNo ratings yet

- Portable Centre Pivot Irrigation System With Advanced Control Through Sensors A ReviewDocument4 pagesPortable Centre Pivot Irrigation System With Advanced Control Through Sensors A ReviewEditor IJTSRDNo ratings yet

- Autonomy and Antiart - Stewart MartinDocument3 pagesAutonomy and Antiart - Stewart MartinBruna DiazNo ratings yet

- Mathematical Statistics and Data Analysis 3rd Edition - Chapter8 Solutions PDFDocument54 pagesMathematical Statistics and Data Analysis 3rd Edition - Chapter8 Solutions PDFnewpersia81% (32)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Curriculum Vitae: Basanta BhowmikDocument5 pagesCurriculum Vitae: Basanta BhowmikBasanta BhowmikNo ratings yet

- Seminar FormatDocument6 pagesSeminar Formatupasana joliaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)