Professional Documents

Culture Documents

08 Energy Balance

Uploaded by

Anil TetarwalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

08 Energy Balance

Uploaded by

Anil TetarwalCopyright:

Available Formats

Energy balance for chemical reactors

Gabriele Pannocchia

First Year course, MS in Chemical Engineering, University of Pisa

Academic Year 20132014

Department of Civil and Industrial Engineering (DICI)

University of PisaItaly

Email: g.pannocchia@diccism.unipi.it

Gabriele Pannocchia Energy balance for chemical reactors 1 / 45

Outline

1

Introduction and general balance

2

Batch reactor

3

CSTR

Dynamic operation

Steady-state operation

Steady-state multiplicity and stability

4

PFR

Energy balance in transient conditions

Steady-state energy balance

PFR hot spot and runaway

5

Optimized reactor arrangements

6

Summary of balance equations

Gabriele Pannocchia Energy balance for chemical reactors 2 / 45

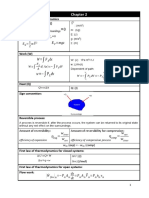

General energy balance

Q

R

j E

m

1

,

E

1

, c

j 1

m

0

,

E

0

, c

j 0

W

Arbitrary reactor volume V

Inlet: m

0

(mass rate), c

j 0

(concentration of species j ),

E

0

(per-mass energy)

Outlet: m

1

(mass rate), c

j 1

(concentration of species j ),

E

1

(per-mass energy)

Gabriele Pannocchia Energy balance for chemical reactors 3 / 45

General energy balance (continued)

Conservation of energy for system

_

rate of energy

accumulation

_

=

_

rate of energy

entering by inow

_

_

rate of energy

entering by outow

_

+

_

rate of heat

added to system

_

+

_

rate of work

added to system

_

Balance rewritten in terms of dened variables

dE

dt

=m

0

E

0

m

1

E

1

+

Q+

W

The total energy E is composed by several contributions, e.g. internal energy,

kinetic energy, potential energy, and other types of energy:

E =U +K ++

In most chemical reactors, only changes in internal energy are relevant

Gabriele Pannocchia Energy balance for chemical reactors 4 / 45

Work terms

Work terms: overview

The total work

W can be split into three parts:

W

f

: the work done by ow streams while moving material into and out of the

reactor volume

W

s

: the shaft work done by stirrers, compressors, etc.

W

b

: the work done by the reactor volume boundaries

Flow streams work term

If we assume that the ow streams enter (or leave) the reactor volume at

uniform velocity, we can express

W

f

as follows:

W

f

=v

0

A

0

p

0

v

1

A

1

p

1

where v

0

and p

0

are the inlet ow velocity and pressure, A

0

is the bounding

area; likewise for v

1

, p

1

, A

1

Let

0

and

1

be the densities of inlet and outlet ows respectively

We obtain:

W

f

=Q

0

p

0

Q

1

p

1

=m

0

p

0

0

m

1

p

1

1

Gabriele Pannocchia Energy balance for chemical reactors 5 / 45

General energy balance in nal form

Enthalpy

Recall the enthalpy denition H =U +pV or per-mass basis

H =

U +

p

Overall balance

Assume that E =U +K +, we obtain:

d

dt

(U +K +) =m

0

(

H

0

+

K

0

+

0

) m

1

(

H

1

+

K

1

+

1

) +

Q+

W

s

+

W

b

Neglecting kinetic and potential energy terms leads to

dU

dt

=m

0

H

0

m

1

H

1

+

Q+

W

s

+

W

b

Gabriele Pannocchia Energy balance for chemical reactors 6 / 45

Batch reactor: energy balance and derivations

The general balance

The energy balance for the batch reactor is obtained from the general balance

written over the entire reaction volume (V =V

R

)

Deleting the terms associated with ow streams (not present in the batch

reactor) leads to:

d

dt

(U +K +) =

Q+

W

s

+

W

b

The rate of work done by the boundaries is given by:

W

b

=p

dV

R

dt

Minor simplications

Usually kinetic and potential energy terms can be neglected

Moreover, unless the reactor is treating a highly viscous mixture the rate of

shaft work can be also neglected

Recall that H =U +pV

R

, and hence dH =dU +pdV

R

+V

R

dp, to obtain:

dU

dt

+p

dV

R

dt

=

Q

dH

dt

V

R

dp

dt

=

Q (1)

Gabriele Pannocchia Energy balance for chemical reactors 7 / 45

Manipulating the change of enthalpy

The change of enthalpy for single phase reactor

We express the change of enthalpy using (T, p, n

j

) as independent variables:

dH =

_

H

T

_

p,n

j

dT +

_

H

p

_

T,n

j

dp +

j

_

H

n

j

_

T,p,n

k=j

dn

j

(2)

The simple terms

The rst term is by denition the total heat capacity at constant pressure:

_

H

T

_

p,n

j

=C

p

=V

R

C

p

(3)

with c

P

the specic heat capacity of the mixture at constant pressure

The third term is also simple because

_

H

n

j

_

T,p,n

k=j

is the molar enthalpy of

species j , denoted by

H

j

Gabriele Pannocchia Energy balance for chemical reactors 8 / 45

Manipulating the change of enthalpy (cont.)

Useful thermodynamic relations

dG =SdT +V

R

dp +

j

dn

j

(4)

dH =dG +TdS +SdT =TdS +V

R

dp +

j

dn

j

(5)

_

S

p

_

T,n

j

=

_

p

_

T,n

j

_

G

T

_

p,n

j

=

_

T

_

p,n

j

_

G

p

_

T,n

j

=

_

V

R

T

_

p,n

j

(6)

Partial derivative of enthalpy w.r.t. pressure

From (5) and (6) we can write:

_

H

p

_

T,n

j

=T

_

S

p

_

T,n

j

+V

R

=T

_

V

R

T

_

p,n

j

+V

R

=V

R

(1T) (7)

=

1

V

R

_

V

R

T

_

p,n

j

is the isobaric coefcient of expansion of the mixture

Gabriele Pannocchia Energy balance for chemical reactors 9 / 45

Manipulating the change of enthalpy (cont.)

Collecting the three terms of (2)

dH

dt

=V

R

C

p

dT

dt

+V

R

(1)

dp

dt

+

H

j

dn

j

dt

(8)

The reaction term

The reaction term appearing in (8) can be further simplied by recalling the

material balance:

dn

j

dt

=R

j

V

R

=

i j

r

i

V

R

(9)

We then can write:

H

j

dn

j

dt

=

H

j

i j

r

i

V

R

=

i j

H

j

r

i

V

R

=

i

H

Ri

r

i

V

R

(10)

with H

Ri

=

j

i j

H

j

the molar heat of reaction i

Gabriele Pannocchia Energy balance for chemical reactors 10 / 45

Final energy balances for the batch reactor

General energy balance for a batch reactor

From (1), (10) and (8) we obtain:

V

R

C

p

dT

dt

TV

R

dp

dt

=

i

(H

Ri

)r

i

V

R

+

Q (11)

Incompressible uid or constant pressure reactor

If the mixture is incompressible, i.e. =0, or the reactor operates at constant

pressure, the balance becomes:

V

R

C

p

dT

dt

=

i

(H

Ri

)r

i

V

R

+

Q (12)

Gabriele Pannocchia Energy balance for chemical reactors 11 / 45

Energy balance for compressible mixtures

Constant volume reactor with compressible mixture: introduction

For gas-phase mixtures, in constant volume batch reactors, it is possible to

relate

dp

dt

to the change of temperature and moles due to reaction

Derivation

Express the term

dp

dt

as follows (assuming constant V

R

):

dp

dt

=

_

p

T

_

V

R

,n

j

dT

dt

+

j

_

p

n

j

_

T,V

R

,n

k=j

dn

j

dt

(13)

Inserting (13) into (11), recalling the material balance (9), we obtain:

_

V

R

C

p

TV

R

_

p

T

_

V

R

,n

j

_

dT

dt

=

i

[(H

Ri

)+

T

i j

_

p

n

j

_

T,V

R

,n

k=j

_

r

i

V

R

+

Q

Gabriele Pannocchia Energy balance for chemical reactors 12 / 45

Energy balance for compressible mixtures (cont.)

Final result

Observe that

_

V

R

C

p

TV

R

_

p

T

_

V

R

,n

j

_

is the constant volume heat capacity,

which can be written as V

R

c

V

, and obtain:

V

R

C

V

dT

dt

=

i

_

(H

Ri

) +TV

R

i j

_

p

n

j

_

T,V

R

,n

k=j

_

r

i

V

R

+

Q (14)

Ideal gas mixture

Observe that

T =1,

_

p

n

j

_

T,V

R

,n

k=j

=

RT

V

R

Obtain:

V

R

C

V

dT

dt

=

i

(H

Ri

+RT

i

)r

i

V

R

+

Q (15)

Gabriele Pannocchia Energy balance for chemical reactors 13 / 45

Simple reaction in adiabatic conditions

Single reaction

Consider a single reaction:

A

k

B, with r =k(T)c

n

A

and k(T) =k

0

exp(E

a

/(RT))

Dene x

A

=

n

A0

n

A

n

A0

, and write material and energy balance (12):

_

_

n

A0

dx

A

dt

=r V

R

V

R

C

p

dT

dt

=(H

R

)r V

R

Obtain a relation between T and x

A

:

dT

dx

A

=

(H

R

)n

A0

V

R

C

p

When V

R

is constant =

(H

R

)c

A0

C

p

is the adiabatic temperature rise, to obtain:

T =x

A

T =T

0

+x

A

Gabriele Pannocchia Energy balance for chemical reactors 14 / 45

CSTR in dynamic operation: energy balance

Denitions and general balance

Q

0

,

0

,

H

0

: inlet ow rate, density and enthalpy

Q, ,

H: outlet ow rate, density and enthalpy

Q external heat ow,

W

s

rate of shaft work,

W

b

rate of boundary work

General balance applied to V =V

R

:

dU

dt

=Q

0

0

H

0

Q

H +

Q+

W

s

+

W

b

W

s

V

R

R

j

Q

Q

0

, c

j 0

,

H

0

Q, c

j

,

H

Neglect shaft work

dU

dt

+p

dV

R

dt

=Q

0

0

H

0

Q

H +

Q

dH

dt

V

R

dp

dt

=Q

0

0

H

0

Q

H +

Q (16)

Gabriele Pannocchia Energy balance for chemical reactors 15 / 45

CSTR in dynamic operation: single phase system

Expanding the enthalpy change term

As in the batch reactor we can write [see (8)]

dH

dt

=V

R

C

p

dT

dt

+V

R

(1T)

dp

dt

+

H

j

dn

j

dt

(17)

Recall the material balance:

dn

j

dt

=Q

0

c

j 0

Qc

j

+

i j

r

i

V

R

(18)

Combining (16), (17) and (18)

V

R

C

p

dT

dt

+V

R

(1T)

dp

dt

+

j

H

j

[Q

0

c

j 0

Qc

j

+

i

i j

r

i

V

R

] V

R

dp

dt

=Q

0

0

H

0

Q

H +

Q

Gabriele Pannocchia Energy balance for chemical reactors 16 / 45

CSTR in dynamic operation: single phase system (cont.)

Useful observations

Recall that:

j

i j

H

j

=

i j

H

j

=

i

H

Ri

Notice that:

Q

0

0

H

0

=

j

Q

0

c

j 0

H

j 0

j

Qc

j

H

j

=Q

H

Final balance

V

R

C

p

dT

dt

V

R

T

dp

dt

=

i

(H

Ri

)r

i

V

R

+Q

0

j

c

j 0

(

H

j 0

H

j

) +

Q (19)

Reasonable approximation for liquid mixtures

The heat capacity is reasonably constant with temperature and =0. Hence:

H

j 0

H

j

=

C

p j

(T

0

T)

j

c

j 0

(

H

j 0

H

j

) =

0

C

p

(T

0

T):

V

R

C

p

dT

dt

=

i

(H

Ri

)r

i

V

R

+Q

0

0

C

p

(T

0

T) +

Q (20)

Gabriele Pannocchia Energy balance for chemical reactors 17 / 45

Steady-state operation

General steady-state material and energy balances

The steady-state energy balance comes from (19) by setting

dT

dt

=0 and

dp

dt

=0

In general material and energy balances must be solved together:

Q

0

c

j 0

Qc

j

+

i j

r

i

V

R

=0 j =1, . . . , n

s

(21)

i

(H

Ri

)r

i

V

R

+Q

0

j

c

j 0

(

H

j 0

H

j

) +

Q =0 (22)

Steady-state material and energy balances for liquid mixtures

Q

0

(c

j 0

c

j

) +

i j

r

i

V

R

=0 j =1, . . . , n

s

(23)

i

(H

Ri

)r

i

V

R

+Q

0

0

C

p

(T

0

T) +

Q =0 (24)

Gabriele Pannocchia Energy balance for chemical reactors 18 / 45

Simple reaction in adiabatic conditions

Single reaction

Consider a single reaction:

A

k

B, with r =k(T)c

n

A

and k(T) =k

0

exp(E

a

/(RT))

Dene x

A

=

N

A0

N

A

N

A0

, and write material and energy balance (12):

_

Q

0

c

A0

x

A

=r V

R

Q

0

C

p

(T T

0

) =(H

R

)r V

R

Obtain a relation between T and x

A

:

T T

0

=

(H

R

)c

A0

C

p

x

A

Let =

(H

R

)c

A0

C

p

, observe that in general:

T =x

A

Gabriele Pannocchia Energy balance for chemical reactors 19 / 45

Steady-state multiplicity

Introduction

The coupling of energy and material balances can result in a surprisingly

complex behavior even for simple kinetic schemes

This is true even in steady-state operation, in particular because there may

exist multiple steady states

Example

Consider a rst order reaction:

A

k

B, r =k(T)c

A

, k(T) =k

0

exp(E

a

/(RT))

Adiabatic conditions in liquid phase. Recall that =V

R

/Q

0

and x

A

=

c

A0

c

A

c

A0

:

x

A

=

k

1+k

(25)

C

p

(T T

0

) =k(1x

A

)c

A0

(H

R

) (26)

Examine (x

A

, T) vs. for different H

R

Gabriele Pannocchia Energy balance for chemical reactors 20 / 45

Steady-state multiplicity: example

Temperature vs. residence time

260

280

300

320

340

360

380

400

420

440

460

1 10 100 1000 10000 100000

T

(

K

)

(min)

H

R

=300

H

R

=200

H

R

=100

H

R

=50

H

R

=0

H

R

=50

Gabriele Pannocchia Energy balance for chemical reactors 21 / 45

Steady-state multiplicity: example (cont.)

Conversion vs. residence time

0

0.2

0.4

0.6

0.8

1

1 10 100 1000 10000 100000

x

A

(min)

H

R

=300

H

R

=200

H

R

=100

H

R

=50

H

R

=0

H

R

=50

Gabriele Pannocchia Energy balance for chemical reactors 22 / 45

Steady-state multiplicity: ignition and extinction points

Temperature vs. residence time for H

R

=300kJ/mol

280

300

320

340

360

380

400

420

440

460

0 5 10 15 20 25 30 35 40

T

(

K

)

(min)

A

E

B

D

F

C

G

Gabriele Pannocchia Energy balance for chemical reactors 23 / 45

Steady-state stability: heat generation and removal

Heat generation and removal

In the energy balance (26), we replace x

A

from (25) to obtain:

C

p

(T T

0

)

. .

Q

r

=

k

1+k

c

A0

(H

R

)

. .

Q

g

Q

r

is the heat removal rate, associated to the different between output and

input stream enthalpies

Q

g

is the heat generation rate, associated with the reaction rate

Necessary condition for stability

An equilibrium is said to be stable if the system returns to that steady state

after any sufciently small perturbation

A necessary condition for stability is:

d

Q

r

dT

>

d

Q

g

dT

Gabriele Pannocchia Energy balance for chemical reactors 24 / 45

Steady-state stability: heat generation and removal (cont.)

Heat generation and removal for =1.79 min

-100

0

100

200

300

400

500

300 350 400 450 500

H

e

a

t

(

M

J

/

m

3

m

i

n

)

T (K)

A

E (extinction)

Removal

Generation

Gabriele Pannocchia Energy balance for chemical reactors 25 / 45

Steady-state stability: heat generation and removal (cont.)

Heat generation and removal for =15 min

-10

0

10

20

30

40

50

60

300 350 400 450 500

H

e

a

t

(

M

J

/

m

3

m

i

n

)

T (K)

B

D (unstable)

F

Removal

Generation

Gabriele Pannocchia Energy balance for chemical reactors 26 / 45

Steady-state stability: heat generation and removal (cont.)

Heat generation and removal for =30.9 min

-5

0

5

10

15

20

25

30

300 350 400 450 500

H

e

a

t

(

M

J

/

m

3

m

i

n

)

T (K)

C (ignition)

G

Removal

Generation

Gabriele Pannocchia Energy balance for chemical reactors 27 / 45

PFR: energy balance in transient conditions

PFR scheme and thin disk volume element

q(z)zD

Q(z +z)

c

j

(z +z)

V R

j

Q(z)

c

j

(z)

Q, c

j

,

H Q

0

, c

j 0

,

H

0

H(z) H(z +dz)

q(z)

Energy balance: transient conditions in V = A

c

z

(

UV )

t

= (m

H)

z

(m

H)

z+z

+ qDz

Gabriele Pannocchia Energy balance for chemical reactors 28 / 45

PFR: energy balance in transient and steady state

conditions

Obtaining the nal balance

Divide by V and take the limit as V 0:

(

U)

t

=

(Q

H)

V

+

4

D

q

Rewrite

H =

j

c

i

H

j

and obtain:

(

U)

t

=

(Q

j

c

j

H

j

)

V

+

4

D

q

q is the heat ux (i.e. heat ow per unit of transfer area), usually expressed as:

q =U

0

(T

a

T) where T

a

is the external temperature (e.g. jacket temperature)

Steady-state balance

d(Q

j

c

j

H

j

)

dV

=

4

D

q (27)

Gabriele Pannocchia Energy balance for chemical reactors 29 / 45

PFR: steady-state balance rearrangement

Expand the l.h.s. term

Recall the material balances:

d(Qc

j

)

dV

=

i j

r

i

Expand the

d(Q

j

c

j

H

j

)

dV

as follows:

d(Q

j

c

j

H

j

)

dV

=

j

_

Qc

j

d

H

j

dV

+

H

j

d(Qc

j

)

dV

_

d(Q

j

c

j

H

j

)

dV

=Q

j

c

j

d

H

j

dV

+

i

H

Ri

r

i

(28)

Gabriele Pannocchia Energy balance for chemical reactors 30 / 45

PFR: steady-state balance rearrangement (cont.)

Expanding the enthalpy change term

j

c

j

d

H

j

Let

H =

j

c

j

H

j

be the enthalpy per volume of reacting mixture. We have:

d

H =

j

_

H

j

dc

j

+c

j

d

H

j

_

(29)

As in previous cases, its change can be expressed as:

d

H =

_

H

T

_

p,n

j

dT +

_

H

p

_

T,n

j

dp +

j

_

H

n

j

_

T,p,n

k=j

dn

j

(30)

From previous derivations, (30) is re-written as:

d

H =

C

p

dT +(1T)dp +

H

j

dc

j

(31)

Finally, by comparison of (29) and (31) we obtain:

j

c

j

d

H

j

=

C

p

dT +(1T)dp (32)

Gabriele Pannocchia Energy balance for chemical reactors 31 / 45

PFR: steady-state nal balance

General balance

From (27), (28) and (32) we obtain:

Q

C

p

dT

dV

+Q(1T)

dp

dV

=

i

(H

Ri

)r

i

+

4

D

q (33)

Ideal gas or neglect pressure drop

Q

C

p

dT

dV

=

i

(H

Ri

)r

i

+

4

D

q (34)

Incompressible uid

Q

C

p

dT

dV

+Q

dp

dV

=

i

(H

Ri

)r

i

+

4

D

q (35)

Gabriele Pannocchia Energy balance for chemical reactors 32 / 45

PFR hot spot and runaway

Introduction

For exothermic (gas-phase) reactions in a PFR, the heat release can lead to the

formation of a hot spot

When reactions are highly exothermic, small changes in operating parameters

(e.g., inlet concentration, owrate, temperature) can result in very changes of

the temperature prole

This is known as the PFR parametric sensitivity, and a sudden increase in

temperature prole in known as run away

Example: exothermic reaction in a jacketed PFR

Irreversible rst order reaction in gas phase: A

k

B

Observe (N

A

, T) as function of z for different inlet stream temperatures T

0

Gabriele Pannocchia Energy balance for chemical reactors 33 / 45

PFR parametric sensitivity

Reactant molar ow

0

0.0002

0.0004

0.0006

0.0008

0.001

0.0012

0.0014

0.0016

0 0.2 0.4 0.6 0.8 1 1.2 1.4

N

A

(

k

m

o

l

/

s

)

z (m)

T

0

=615 K

T

0

=625 K

T

0

=631 K

T

0

=635 K

Gabriele Pannocchia Energy balance for chemical reactors 34 / 45

PFR parametric sensitivity

Temperature

600

620

640

660

680

700

720

740

0 0.2 0.4 0.6 0.8 1 1.2 1.4

T

(

K

)

z (m)

T

0

=615 K

T

0

=625 K

T

0

=631 K

T

0

=635 K

Gabriele Pannocchia Energy balance for chemical reactors 35 / 45

Optimized reactor arrangements: introduction

Motivations and rationale

In reactor design, it is often desirable to minimize the overall reaction volume

This goal is made possible by arranging a number of reactors (e.g. in series) to

follow a path at maximum reaction rate

To follow such optimized paths, heat transfers are required between reactors

A number of typical arrangements are described and analyzed next

A reversible reaction: kinetic data analysis

Single reversible reaction:

A

k

1

k

1

B

Kinetic data can be conveniently expressed graphically in the plane (T, x

A

)

Dene x

A

=

c

A0

c

A

c

A0

and recall:

r (T, x

A

) =k

1

(T)c

A0

(1x

A

) k

1

(T)c

A0

x

A

Gabriele Pannocchia Energy balance for chemical reactors 36 / 45

Optimized reactor arrangements: kinetic data

Kinetic data

Kinetic data report, in (T, x

A

), a number lines of constant reaction rate

Each line is dened by the implicit relation:

a =k

1

(T)c

A0

(1x

A

) k

1

(T)c

A0

x

A

where a >0 species the reaction rate

The line at a =0 denes the (implicit) equilibrium relation x

Ae

(T)

Locus of maximum rates

For each given conversion, there exists a temperature at which the reaction

rate is at maximum

This is formally dened as:

_

r (T, x

A

)

T

_

x

A

=

dk

1

dT

c

A0

(1x

A

)

dk

1

dT

c

A0

x

A

=0

Gabriele Pannocchia Energy balance for chemical reactors 37 / 45

Kinetic data for an exothermic reaction

Parametric plot of normalized reaction rate r /c

A0

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

60 80 100 120 140

x

A

T (

o

C)

0.002

0.004

0.01

0.02

0.04

0.1

0.2

0.4

1.0

Equilibrium

Isokinetic

Maximum rate

Gabriele Pannocchia Energy balance for chemical reactors 38 / 45

Kinetic data for an endothermic reaction

Parametric plot of normalized reaction rate r /c

A0

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

60 70 80 90 100 110 120 130 140

x

A

T (

o

C)

0.002

0.004

0.01

0.02

0.04

0.1

0.2

0.4

1.0

Equilibrium

Isokinetic

Gabriele Pannocchia Energy balance for chemical reactors 39 / 45

Optimized CSTR arrangements

Scheme 1: Preheating and inter-cooling

Cooler

x

A2

T

2

T

2

T

3

x

A3

T

0

T

0

T

1

T

1

x

A1

Cooler Heater

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

50 60 70 80 90 100 110 120 130 140 150

x

A

T (

o

C)

Equilibrium

Isokinetic

Maximum rate

Gabriele Pannocchia Energy balance for chemical reactors 40 / 45

Optimized CSTR arrangements (cont.)

Scheme 2: Auto-thermal preheating

x

A1

T

0

T

1

T

1

T

2

T

0

x

A2

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

50 60 70 80 90 100 110 120 130 140 150

x

A

T (

o

C)

Equilibrium

Isokinetic

Maximum rate

Gabriele Pannocchia Energy balance for chemical reactors 41 / 45

Optimized CSTR arrangements (cont.)

Scheme 3: Preheating and feed quenching

x

A3

T

3 T

0

T

0

T

1

x

A1

Heater

T

1

T

2

x

A2

T

2

x

A2

x

A1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

50 60 70 80 90 100 110 120 130 140 150

x

A

T (

o

C)

Equilibrium

Isokinetic

Maximum rate

Gabriele Pannocchia Energy balance for chemical reactors 42 / 45

Optimized reactor arrangements: auto-thermal PFR

T

r

(z)

T

0

T

0

Heater

T

a

(z)

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

50 60 70 80 90 100 110 120 130 140 150

x

A

T (

o

C)

Equilibrium

Isokinetic

Maximum rate

Gabriele Pannocchia Energy balance for chemical reactors 43 / 45

Summary of material and energy balances

Balance equations for the batch reactor

Case Material balances Energy balance

Single phase

d(V

R

c

j

)

dt

=

i j

r

i

V

R

V

R

C

p

dT

dt

TV

R

dp

dt

=

i

(H

Ri

)r

i

V

R

+

Q

Constant pressure

d(V

R

c

j

)

dt

=

i j

r

i

V

R

V

R

C

p

dT

dt

=

i

(H

Ri

)r

i

V

R

+

Q

Constant volume

(ideal gas)

dc

j

dt

=

i j

r

i

V

R

C

v

dT

dt

=

i

(H

Ri

+RT

i

)r

i

V

R

+

Q

Liquid phase

dc

j

dt

=

i j

r

i

V

R

C

p

dT

dt

=

i

(H

Ri

)r

i

V

R

+

Q

Steady-state balance equations for the CSTR

Case Material balances Energy balance

Single phase Q

0

c

j 0

Qc

j

+

i j

r

i

V

R

=0

j

Q

0

c

j 0

(

H

j 0

H

j

) +

i

(H

Ri

)r

i

V

R

+

Q =0

Liquid phase Q

0

(c

j

c

j 0

) +

i j

r

i

V

R

=0 Q

0

0

C

p

(T

0

T) +

i

(H

Ri

)r

i

V

R

+

Q =0

Gabriele Pannocchia Energy balance for chemical reactors 44 / 45

Summary of material and energy balances (cont.)

Steady-state balance equations for the PFR

Case Material balances Energy balance

Single phase

d(Qc

j

)

dV

=

i j

r

i

Q

C

p

dT

dV

+Q(1T)

dp

dV

=

i

(H

Ri

)r

i

+

4

D

q

Constant pressure

or ideal gas

d(Qc

j

)

dV

=

i j

r

i

Q

C

p

dT

dV

=

i

(H

Ri

)r

i

+

4

D

q

Liquid phase Q

dc

j

dV

=

i j

r

i

Q

C

p

dT

dV

+Q

dp

dV

=

i

(H

Ri

)r

i

+

4

D

q

Liquid phase,

constant pressure

Q

dc

j

dV

=

i j

r

i

Q

C

p

dT

dV

=

i

(H

Ri

)r

i

+

4

D

q

Gabriele Pannocchia Energy balance for chemical reactors 45 / 45

You might also like

- Formulas For Thermo 2 QuizDocument1 pageFormulas For Thermo 2 Quizzvikush1No ratings yet

- Fe Chemical EngineeringDocument5 pagesFe Chemical EngineeringJudith LugoNo ratings yet

- Ch20 Young Freedman2Document28 pagesCh20 Young Freedman2Andrew MerrillNo ratings yet

- Chbe 346 Lecture 23 ReviewDocument72 pagesChbe 346 Lecture 23 ReviewJamie SamuelNo ratings yet

- Chemical Engineering 301 Lecture Notes: (Revised 9/04)Document9 pagesChemical Engineering 301 Lecture Notes: (Revised 9/04)shiv kr dubeyNo ratings yet

- Fe Thermodynamics Reference Handbook1Document11 pagesFe Thermodynamics Reference Handbook1Walter NelsonNo ratings yet

- Part 3 - Energy Balance Involving Gases PDFDocument15 pagesPart 3 - Energy Balance Involving Gases PDFHarold SumagaysayNo ratings yet

- Volumetric PropertiesDocument36 pagesVolumetric PropertiesRohan BhilkarNo ratings yet

- Energy Balances for Systems with Chemical Reactions: l l l l Δ = Δ = + + + − +Document4 pagesEnergy Balances for Systems with Chemical Reactions: l l l l Δ = Δ = + + + − +Wan HafiziNo ratings yet

- Teaching Materials 1 For Chemical Engineering ThermodynamicsDocument7 pagesTeaching Materials 1 For Chemical Engineering Thermodynamicsramesh pokhrelNo ratings yet

- Plant Engineering 2 - Compressors 1 The Perfect Gas ModelDocument12 pagesPlant Engineering 2 - Compressors 1 The Perfect Gas ModelDee RajanNo ratings yet

- HE3 Semi-Batch Reactor TextDocument5 pagesHE3 Semi-Batch Reactor TextMiranda Hasanah ArrasyidNo ratings yet

- FE Exam ReviewDocument7 pagesFE Exam ReviewMatt BelsonNo ratings yet

- Isothermal Reactor DesignDocument32 pagesIsothermal Reactor DesignSaswiny RitchieNo ratings yet

- Fluid 11Document210 pagesFluid 11Omolafe Olawale SamuelNo ratings yet

- Helpful Eqns ME311 F14 PJFDocument2 pagesHelpful Eqns ME311 F14 PJFtarzantrapNo ratings yet

- Slides Enbal PDFDocument139 pagesSlides Enbal PDFOmar GutierrezNo ratings yet

- Heat Engine CyclesDocument21 pagesHeat Engine CyclesMagdy RiadNo ratings yet

- Thermodynamics EquationsDocument11 pagesThermodynamics EquationsDilene DuarcadasNo ratings yet

- Chapter 13Document46 pagesChapter 13Khloud MadihNo ratings yet

- First Law-RDocument28 pagesFirst Law-RHyungJun KimNo ratings yet

- Reactors1 19Document2 pagesReactors1 19Mourad kharbachNo ratings yet

- 1 Kinetika Reaksi 2018Document12 pages1 Kinetika Reaksi 2018Iqbal Al FuadyNo ratings yet

- Kinetika ReaksiDocument12 pagesKinetika ReaksiRizky RNo ratings yet

- CH 5-MassDocument37 pagesCH 5-MassIkhsan KholisNo ratings yet

- Reaction Engineering Notes IDocument15 pagesReaction Engineering Notes Isaliljain2001No ratings yet

- Chap 02Document32 pagesChap 02echelon12No ratings yet

- Volumetric Properties of Pure FluidsDocument21 pagesVolumetric Properties of Pure FluidsIR Ika EtyEtyka Dora100% (1)

- Introduction to Reactor Design ChE 3K4Document17 pagesIntroduction to Reactor Design ChE 3K4Khalil LasferNo ratings yet

- 02 Chapter 03 CompiledDocument79 pages02 Chapter 03 CompiledKamalahkar JegatheesanNo ratings yet

- 2024 Processes Involving Ideal GasesDocument17 pages2024 Processes Involving Ideal GasesncayiyanaminentleNo ratings yet

- Physical Chemistry ExamDocument5 pagesPhysical Chemistry ExamelnurorucluNo ratings yet

- CHEM F211 Physical Chemistry-I: Entropy and the Second Law of ThermodynamicsDocument28 pagesCHEM F211 Physical Chemistry-I: Entropy and the Second Law of ThermodynamicsHRIDAY MAHESHWARINo ratings yet

- ENTROPY PROBLEMSDocument5 pagesENTROPY PROBLEMSAriful RamadhanNo ratings yet

- Physics FormulasDocument6 pagesPhysics FormulasRam PrasadNo ratings yet

- J.M. Smith, Hendrick Van Ness, 2 - CompressedDocument9 pagesJ.M. Smith, Hendrick Van Ness, 2 - CompressedFelix LauwentoNo ratings yet

- Topic 7 - Flow of Compressible FluidsDocument85 pagesTopic 7 - Flow of Compressible Fluidszairulh7No ratings yet

- Thermofluids BookDocument80 pagesThermofluids BookChakravar Raja100% (2)

- Equations of Change ChE 131Document34 pagesEquations of Change ChE 131Johanna Martinne CanlasNo ratings yet

- Non-Isothermal Reactors: DN F V R DTDocument4 pagesNon-Isothermal Reactors: DN F V R DTHafid AlwanNo ratings yet

- Thermo Chemical Reaction EquilibriaDocument41 pagesThermo Chemical Reaction EquilibriaDede SyahputraNo ratings yet

- Review Basic Laws TurbomachineryDocument7 pagesReview Basic Laws TurbomachineryThosh SanNo ratings yet

- AE1104 Physics 1: List of EquationsDocument24 pagesAE1104 Physics 1: List of EquationssmithastellaNo ratings yet

- Thermodynamics and Entropy Eng ItaDocument40 pagesThermodynamics and Entropy Eng ItaLeonardo RubinoNo ratings yet

- ThermodynamicsDocument9 pagesThermodynamicssamir boseNo ratings yet

- Lesson Plan 7Document13 pagesLesson Plan 7khandaker raiyanNo ratings yet

- CRE10 Non Isothermal NonAdiabatic ReactorsDocument50 pagesCRE10 Non Isothermal NonAdiabatic ReactorsDeneshVijay100% (1)

- Chemical Reaction Engineering Energy BalanceDocument35 pagesChemical Reaction Engineering Energy BalanceSimon JusticeNo ratings yet

- Stoichiometric TableDocument22 pagesStoichiometric Table伟铭No ratings yet

- Reacting Systems NewDocument24 pagesReacting Systems NewsvkindiaNo ratings yet

- Advanced Thermodynamics: Volumetric Properties of Pure FluidsDocument36 pagesAdvanced Thermodynamics: Volumetric Properties of Pure FluidsArunodhayam NatarajanNo ratings yet

- 2 Combustion and ThermochemistryDocument111 pages2 Combustion and ThermochemistryAjin SajeevanNo ratings yet

- Chapter 2 FormulasDocument6 pagesChapter 2 FormulasShellyNo ratings yet

- Fluid Mechanics FormulaeDocument5 pagesFluid Mechanics FormulaeTom HartNo ratings yet

- Fundamentals of Fluid Mechanics Chapter 11 Analysis of Compressible FlowDocument210 pagesFundamentals of Fluid Mechanics Chapter 11 Analysis of Compressible FlowJake OkuyeNo ratings yet

- The Spectral Theory of Toeplitz Operators. (AM-99), Volume 99From EverandThe Spectral Theory of Toeplitz Operators. (AM-99), Volume 99No ratings yet

- Try AgainDocument1 pageTry AgainAnil TetarwalNo ratings yet

- ChE542 Catalyst CharacterizationDocument14 pagesChE542 Catalyst CharacterizationAnil TetarwalNo ratings yet

- Sbi Collect Steps: Step-1Document7 pagesSbi Collect Steps: Step-1Anil TetarwalNo ratings yet

- Abhishek Attal 11022Document14 pagesAbhishek Attal 11022Anil TetarwalNo ratings yet

- ABB, Gurgaon Fax: 0124-4106159Document23 pagesABB, Gurgaon Fax: 0124-4106159Anil TetarwalNo ratings yet

- Application Form For Dual Degree - Y11Document1 pageApplication Form For Dual Degree - Y11Anil TetarwalNo ratings yet

- ABB, Gurgaon Fax: 0124-4106159Document23 pagesABB, Gurgaon Fax: 0124-4106159Anil TetarwalNo ratings yet

- Che631 Assignment 1Document1 pageChe631 Assignment 1Anil TetarwalNo ratings yet

- Live With Walkman: Extended User GuideDocument0 pagesLive With Walkman: Extended User Guidepavankumar_srsNo ratings yet

- Vector SpaceDocument6 pagesVector SpaceAnil TetarwalNo ratings yet

- X RayDiffractionDocument123 pagesX RayDiffractionAnil TetarwalNo ratings yet

- Academic Calendar rgt2014 3Document1 pageAcademic Calendar rgt2014 3Pawan KumarNo ratings yet

- Lect 1Document10 pagesLect 1PVPPPNo ratings yet

- MSE 203 Lecture 1 Intro-Engg MaterDocument21 pagesMSE 203 Lecture 1 Intro-Engg MaterAnil TetarwalNo ratings yet

- MSE 203 CrystallographyDocument5 pagesMSE 203 CrystallographyAnil TetarwalNo ratings yet

- Bernolii EquationDocument5 pagesBernolii EquationEsra BelhajNo ratings yet

- Quanten PhysicsDocument218 pagesQuanten Physicsmorechicken100% (1)

- Double Well PotentialDocument6 pagesDouble Well PotentialBosonUpNo ratings yet

- 27188Document16 pages27188Łîttlë HønňëyNo ratings yet

- Diffusivity of Acetone: Mass Transfer IDocument5 pagesDiffusivity of Acetone: Mass Transfer INishant SarambaleNo ratings yet

- Phys1006 HW8Document1 pagePhys1006 HW8DanNo ratings yet

- Tight Binding ApproximationDocument20 pagesTight Binding ApproximationsayanNo ratings yet

- Termo Fermi SolDocument46 pagesTermo Fermi SolȘtefan RăzvanNo ratings yet

- EASE 4 - Physics Grade 11 - PointersDocument2 pagesEASE 4 - Physics Grade 11 - PointersDzikri R. RomadhonNo ratings yet

- Assignment FileDocument2 pagesAssignment FileMallesham DevasaneNo ratings yet

- 4 Vector Slide PDFDocument27 pages4 Vector Slide PDFNasibhaNo ratings yet

- CHEMICAL THERMODYNAMICS EXAM FOR BSC AND BED SCI DEGREESDocument3 pagesCHEMICAL THERMODYNAMICS EXAM FOR BSC AND BED SCI DEGREESjipson olooNo ratings yet

- Monatomic Crystal Entropy CalculationsDocument121 pagesMonatomic Crystal Entropy CalculationsetxepareNo ratings yet

- Propane Pressure-Enthalpy DiagramDocument1 pagePropane Pressure-Enthalpy DiagramARYAN_FATHONI_AMRINo ratings yet

- Homework 4Document2 pagesHomework 4lux0008No ratings yet

- Spontaneous Process, Entropy, and Free EnergyDocument37 pagesSpontaneous Process, Entropy, and Free EnergyRaven LampaNo ratings yet

- Lattice Boltzmann Method: Rui Liu Chengcheng Lu Junjun LiDocument60 pagesLattice Boltzmann Method: Rui Liu Chengcheng Lu Junjun LiGBE TAGONo ratings yet

- CH 6.5 NotesDocument5 pagesCH 6.5 NotesChris ChoNo ratings yet

- H.E. Puthoff - Casimir Vacuum Energy and The Semiclassical ElectronDocument4 pagesH.E. Puthoff - Casimir Vacuum Energy and The Semiclassical ElectronRtpomNo ratings yet

- I. Pengantar Perpindahan MomentumDocument33 pagesI. Pengantar Perpindahan MomentumanirahmiNo ratings yet

- MIT8 04S13 ps4Document5 pagesMIT8 04S13 ps4Yul LopeNo ratings yet

- Penrose DiagramDocument24 pagesPenrose DiagramKharanshuNo ratings yet

- ModuleDocument46 pagesModuleJOHN LENNARD DATUINNo ratings yet

- The Second Law of ThermodynamicsDocument17 pagesThe Second Law of ThermodynamicsPalash BoliaNo ratings yet

- Relativity Chap 1Document70 pagesRelativity Chap 1Daljot Singh KangNo ratings yet

- Thermo Problems (Final Exam 1)Document3 pagesThermo Problems (Final Exam 1)rii amosNo ratings yet

- CFD with OpenSource softwareDocument31 pagesCFD with OpenSource softwareAdam GordonNo ratings yet

- Set 4Document1 pageSet 4NikhilIgnatius PragadaNo ratings yet

- CALCULUSDocument5 pagesCALCULUS4gjhfv2yvfNo ratings yet