Professional Documents

Culture Documents

(2012) Complete IELTS Bands 5-6.5 Student's Book

Uploaded by

Ahmed HamdyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(2012) Complete IELTS Bands 5-6.5 Student's Book

Uploaded by

Ahmed HamdyCopyright:

Available Formats

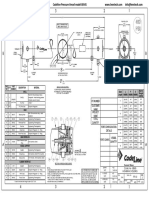

Dash

Length

L

IN(MM)

P

IN(MM)

S

IN(MM)

Approx

Weight

LB(KG)

64.15 47 10X1

190

(1629) (1194) (254) (86)

104.15 87 50X1 235

(2645) (2210) (1270) (107)

144.15 127 80X1

279

(3661) (3226) (2032) (127)

184.15 167 64X2 324

(4677) (4242) (1626) (147)

224.15 207 78X2

368

(5693) (5258) (1981) (167)

264.15 247 92X2 416

(6709) (6274) (2337) (189)

304.15 287 106X2 461

(7725) (7290) (2692) (209)

344.15 327 120X2 505

(8741) (8306) (3048) (229)

-8

-6

-7

-1

-2

-4

-5

-3

DWG

REF

QTY

PART

NUMBER

DESCRIPTION MATERIAL

1 1 SHELL

Filament Wound Epoxy/Glass

composite - Head locking grooves

integrally wound in place.

2 A/R F/C Port CD 3MWCuN *

3 A/R F/C Port Seal Ethylene Propylene

4 2 96158 Bearing Plate

6061-T6 Aluminium alloy - Hard

anodized*

5 2 96159 Sealing Plate Engineering Thermoplastic.

6 2 96161 Permeate Port Engineering Thermoplastic.

7 2 45066 Port Nut Engineering Thermoplastic.

8 2 96000 Head Seal Ethylene Propylene - O - Ring

9 2 45312 Perm Port Seal Ethylene Propylene - O - Ring

10 2 47336

Quick Release Spiral

Ring

316 Stainless Steel.

11

+

2 52169 Saddle Engineering Thermoplastic.

12

+

2 45042 Strap Assy. 304 Stainless Steel-PVC Cushion.

13 4 46265 Strap screw. 5/16-18 UNC, 18-8 Stainless Steel.

14 2 A/R Adapter Engineering Thermoplastic.

15 2 52245 Adapter seal Ethylene Propylene - O - Ring

16 4 A/R PWT Seal Ethylene Propylene - O - Ring

17 1 96163 Thrust Cone Engineering Thermoplastic.

+

3 each furnished with length code 4,5,6,7&8.

VESSEL SUPPORT

ELEMENT INTERFACE

SHELL

HEAD

ORDER

SECTION

HEAD INTERLOCK

RATING:

DESIGN PRESSURE.1200 PSIG at 150F

(8.27 MPa at 66C)

MIN. OPERATING TEMP...20F

(-7C)

FACTORY TEST PRESSURE.1800PSIG/1320 PSIG

(12.41 MPa)/(9.10 MPa)

QUALIFICATION PRESSURE ...... 7200 PSI

(49.64 MPa)

INTENDED USE:

The CodeLine 80H120 Fiberglass RO Pressure Vessel is

designed for continuous, long term use as housing for

reverse osmosis membrane elements to desalt typical

brackish waters at pressures up to 1200 psi. Any make of

eight-inch nominal diameter spiral-wound element is

easily accommodated; the appropriate interfacing

hardware for the element specified is furnished with the

vessel.

The CodeLine 80H120 is designed in accordance with the

engineering standards of the Boiler and Pressure Vessel

Code of the American Society of Mechanical Engineers

(ASME) Code. At small additional cost vessels can be

inspected during construction by an ASME Authorized

Inspector and ASME Code stamped.

The CodeLine 80H120 must be installed, operated and

maintained in accordance with the listed precautions and

good industrial practice to assure safe operation over a

long service life.

The high performance Filament wound FRP shell must be

allowed to expand under pressure; undue restraint at

support points or piping connections can cause leaks to

develop in the shell. This side-ported vessel requires

special precautions in mounting and connection to piping

so that the vessel will not be subjected to excessive stress

due to bending moments acting at the side openings in the

fiberglass shell. The end closure, incorporating close

fitting, interlocking metal components, must be kept dry

and free of corrosion; deterioration can lead to

catastrophic mechanical failure of the head.

Pentair Water will assist the purchaser in determining the

suitability of this standard vessel for their specific

operating conditions. The final determination however,

including evaluation of the standard material of

construction for compatibility with the specific corrosive

environment, shall be the responsibility of the purchaser.

Alternate materials with enhanced corrosion resistance are

available on special order.

Specifications are subject to change without notice.

PRECAUTIONS:

DOread, understand and follow all instructions; failure to

take every precaution will void warranty and may result in

vessel failure

DOmount the shell on horizontal members at span S

using compliant vessel supports furnished; Shim saddles if

required. Tighten hold down straps just snug

DOalign and center side ports with the manifold header.

Correct, causes of misalignment in a row of vessels

connected to the same header

DOuse flexible type IPS grooved-end pipe couplings, at

side ports; allow full, 0.125 inch gap between port and

piping, and position piping to maximize flexibility of

connection.

DOprovide flexibility in, and support for piping manifolds

so that vessel can grow in length under pressure without

undue restraint; provide additional flexible joints in large

pipes leading to manifold header.

DOprovide overpressure protection for vessel set at not

more than 105% of design pressure

DOinspect end closures regularly; replace components that

have deteriorated and correct causes of corrosion

DO Lubricate seals sparingly, using nonpetroleum

Based lubricants, i.e. Parker Super O-lube,

Glycerin or suitable silicone based lubricants.

DO NOTwork on any component until first verifying that

pressure is relieved from vessel

DO NOTmake rigid piping connections to ports or clamp

vessel in any way that resists growth of fiberglass shell

under pressure;

***DIA = 0.015 in. (0.4mm) and

***L = 0.2 in. (6mm) for a length code 8 vessel

DO NOT hang piping manifolds from ports or use vessel in

any way to support other components

DO NOTtighten Permeate Port connection more than one

turn past hand tight

DO NOT operate vessel without connecting both Permeate

Ports internally to complete set of elements or otherwise

plug ports internally so that external piping connection is

not subjected to feed pressure

DO NOTinstall Spacer on downstream end of vessel

DO NOToperate vessel without Thrust Cone installed

downstream

DO NOTpressurize vessel until double-checking to verify

that the Locking Ring is in place and fully seated.

DO NOToperate vessel at pressure and temperature in

excess of its rating.

DO NOToperate vessel with permeate pressure in excess of

125 psi at 150F (0.86 Mpa at 66PP

0

PPC).

DO NOTtolerate leaks or allow end closures to be routinely

wetted in any way

DO NOToperate outside the pH range 3-10.

DWG. NO. 99170-N. Pentair Water PAGE 2 OF 3.

ORDERING:

Using the chart below, please check the features you require

VESSEL LENGTH CODE please check one

MODEL 80H120 -1 -2 -3 -4 -5 -6 -7 -8

MEMBRANE BRAND AND MODEL

Please supply adapters for the following membrane brand and specific model

Brand_________________________ Model_______________________

CERTIFICATION REQUIRED

ASME Stamped and National Board Registered.

CE Marked Standard.

Certified by Pentair water.

In compliance with the ASME Sec X but not Code Stamped.

Hydro testing at 1.1 times the design pressure

Hydro testing at 1.5 times the design pressure

PERMEATE PORT SELECTION

Serial Number End

Size of the Permeate Port 1 1.25 1.5

Type of Connection FNPT MNPT BSPTM BSPTF IPS GROOVED

Material of Construction Noryl SS316L Zeron 100

Non Serial Number End

Size of the Permeate Port 1 1.25 1.5

Type of Connection FNPT MNPT BSPTM BSPTF IPS GROOVED

Material of Construction Noryl SS316L Zeron 100

Note:

Standard offering is 1.0 FNPT in Noryl.

1.25 & 1.5 BSPTF, 1.25 & 1.5 FNPT connections cannot be offered

STRAP ASSEMBLY

Standard SS304 Optional SS316 Optional SS316L

FEED/CONCENTRATE PORT SELECTION

Material of Construction STD Super Duplex SS (CD3MWCuN)

Optional - CE3MN

Configuration Standard CD3MWCuN 1G5G

Optional Multi port: (Refer SPEC.SHEET/PM/1.5-3 for Multi ports selection).

Ports not available in 90 configurations.

Serial number end

Opposite end

BEARING PLATE MATERIAL

Standard 6061 T6 Aluminium

Optional Stainless Steel 316L

Note: Refer page-3 for optional Part numbers.

ADAPTER KITS

UP

STREAM

DOWN

STREAM

PORT SIZE CODE

D 1 GROOVED END

E 2 GROOVED END

F 2 GROOVED END

G 3 GROOVED END

SS304 SS316 SS316L

45042 46926 94371

STRAP ASSEMBLY PART NUMBERS

1.0" / 1.25" Standard Port nut 45066

1.5" Port Retainer Ring 45247

PERM PORT RETAINER RING & PORT NUT PART

NUMBERS

PART

NUMBER DIM "A"

PART

NUMBER DIM "A"

PART

NUMBER DIM "A"

PART

NUMBER DIM "A"

PART

NUMBER DIM "A"

NORYL 96161 6.008 97378 7.008 97664 6.008 97384 7.008 97689 7.238

SS316L 97247 6.008 97379 7.008 97382 6.008 97385 7.008 97388 7.308

#

ZERON 100 97295 6.008 97380 7.008 97383 6.008 97386 7.008 97389 7.308

NORYL NA NA 97665 7.008 NA NA 97666 7.008 97667 7.238

SS316L NA NA 97390 7.008 NA NA 97392 7.008 97167 7.308

#

ZERON 100 NA NA 97391 7.008 NA NA 97393 7.008 97395 7.308

NORYL NA NA 97668 6.608 NA NA 97399 6.608 97669 7.238

SS316L NA NA 97397 6.608 NA NA 97400 6.608 97448 7.238

#

ZERON 100 NA NA 97398 6.608 NA NA 97401 6.608 97403 7.238

BSPTF BSPTM IPS GROOVED

SIZE MATERIAL

FNPT MNPT

PERMEATE PORT PART NUMBERS & PERMPORT TO F/C PORT OFFSET DISTANCE

1.0"

1.25"

1.5"

PERMEATE PORT SIZE ALUMINIUM SS316L

1.0"/1.25" 96158 96475

1.5" 96343 97370

BEARING PLATE PART NUMBERS

Standard used for Aluminium BP 96159

Optional used for SS316L BP 97404

SEALING PLATE PART NUMBERS

***CD3MWCuN **CE3MN SEAL

3" 96562 97409 96119

2.5" 96385 97377 96079

2.0" 96645 97376 96078

1.5" 96469 97375 96077

SIZE

F/C PORT & SEAL PART NUMBER

You might also like

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- Codeline Drawing 80S30 Non CodedDocument2 pagesCodeline Drawing 80S30 Non CodedDarren PonichaiNo ratings yet

- Codeline Drawing 80S45 Non CodedDocument2 pagesCodeline Drawing 80S45 Non CodedoctavioNo ratings yet

- Codeline 80S45Document3 pagesCodeline 80S45Julian Bocanegra ReyesNo ratings yet

- DWG REF QTY Number Description Material Shell: Order SectionDocument2 pagesDWG REF QTY Number Description Material Shell: Order SectionRamanNegiNo ratings yet

- Codeline Drawing 80H60Document3 pagesCodeline Drawing 80H60octavioNo ratings yet

- DWG REF QTY Number Description Material ShellDocument2 pagesDWG REF QTY Number Description Material ShellimtiyazNo ratings yet

- Codeline Drawing 80E30Document2 pagesCodeline Drawing 80E30hargote_2No ratings yet

- Steam TrapDocument2 pagesSteam TrapAmpornchai PhupolNo ratings yet

- Drawing 80AQ15-60 Non CodedDocument2 pagesDrawing 80AQ15-60 Non Codeddaus nasNo ratings yet

- Trampa Socket WeldDocument2 pagesTrampa Socket WeldOscar Nieves ZamoraNo ratings yet

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Asco S V7394R5Document16 pagesAsco S V7394R5Jorge Jarpa VNo ratings yet

- Datasheet Codeline OCTA 80S SeriesDocument4 pagesDatasheet Codeline OCTA 80S SeriesJulian Bocanegra ReyesNo ratings yet

- Series 826YD Specification SheetDocument2 pagesSeries 826YD Specification SheetFEBCONo ratings yet

- TRDP - SSSVDocument23 pagesTRDP - SSSVsambhajiNo ratings yet

- Series 825YD Specification SheetDocument2 pagesSeries 825YD Specification SheetFEBCONo ratings yet

- Actuator SpecificationDocument12 pagesActuator SpecificationFactory FactoryNo ratings yet

- Ib 10Document2 pagesIb 10dchz_62No ratings yet

- Es Lfu009Document4 pagesEs Lfu009WattsNo ratings yet

- Topworx Position SwitchDocument60 pagesTopworx Position SwitchsarkaftNo ratings yet

- 43-7500401 (Versa) PDFDocument20 pages43-7500401 (Versa) PDFAnthony WilliamsNo ratings yet

- Sree TB 0002Document12 pagesSree TB 0002Tanmoy DuttaNo ratings yet

- SPO Webversion HighDocument6 pagesSPO Webversion HighchadNo ratings yet

- Burmad 400 Series-Globe Type Deluge ValveDocument8 pagesBurmad 400 Series-Globe Type Deluge Valvenastyn-1No ratings yet

- Interruptor de Presion - AscoDocument9 pagesInterruptor de Presion - AscoJosephGutierrezNo ratings yet

- TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Document2 pagesTD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Rupesh DesaiNo ratings yet

- Neojv 0040 enDocument0 pagesNeojv 0040 enLuis GuevaraNo ratings yet

- Autoclave Subsea Ball ValvesDocument20 pagesAutoclave Subsea Ball Valvesvp989No ratings yet

- SC Fepa Sa Bârlad: Installation, Operation&Maintenance Ball Valve Type RSD-BBDocument15 pagesSC Fepa Sa Bârlad: Installation, Operation&Maintenance Ball Valve Type RSD-BBtoader56No ratings yet

- For Harsh and Hazardous Locations: Exe EnclosuresDocument79 pagesFor Harsh and Hazardous Locations: Exe EnclosuresSimon LyonNo ratings yet

- Diapham Valve PDFDocument8 pagesDiapham Valve PDFthouche007No ratings yet

- Catalogo de Presion ReotempDocument48 pagesCatalogo de Presion Reotempdiuska13No ratings yet

- Spirax Sarco PDFDocument4 pagesSpirax Sarco PDFandresaroNo ratings yet

- 1212.03 15kV Submersible Transformer SpecificationDocument8 pages1212.03 15kV Submersible Transformer SpecificationurramarianiNo ratings yet

- FMC Weco Wing Union CatalogDocument16 pagesFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- SpecDocument2 pagesSpecneversigNo ratings yet

- As 1301 en F Series Manifolds and Multi Way CocksDocument20 pagesAs 1301 en F Series Manifolds and Multi Way CocksTache MihaiNo ratings yet

- 15 Metal Seated Butterfly ValvesDocument8 pages15 Metal Seated Butterfly ValvesrajfmcNo ratings yet

- Series LF860 Specification SheetDocument2 pagesSeries LF860 Specification SheetFEBCONo ratings yet

- DPSPDFDocument6 pagesDPSPDFNavneet SinghNo ratings yet

- Lead Free Watts No. SD-3 Backflow Preventer For Carbonated Beverage Machines Specification SheetDocument2 pagesLead Free Watts No. SD-3 Backflow Preventer For Carbonated Beverage Machines Specification SheetWattsNo ratings yet

- Bombas Goulds 4NS Aguas ResidualesDocument6 pagesBombas Goulds 4NS Aguas ResidualescamatuteNo ratings yet

- Es LF919 PDFDocument4 pagesEs LF919 PDFWattsNo ratings yet

- ASCO Info Filter Canada PDFDocument8 pagesASCO Info Filter Canada PDFdicicaNo ratings yet

- s05nmdl2sm PDFDocument22 pagess05nmdl2sm PDFmn_aminNo ratings yet

- Centrifugal Pump BrochuresDocument16 pagesCentrifugal Pump BrochuresAbsar Mamun100% (3)

- 6240 SpecDocument2 pages6240 SpecCarlos Miguel Barrena TorresNo ratings yet

- Mooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & GasDocument12 pagesMooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & GasCarlos TarquinoNo ratings yet

- Index: Product List SR. NODocument40 pagesIndex: Product List SR. NOch_yustinusNo ratings yet

- SpecDocument2 pagesSpecMSNo ratings yet

- Trampa Termodinamica PDFDocument2 pagesTrampa Termodinamica PDFriquelme0788No ratings yet

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCONo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Cloud Computing: Radboud UniversityDocument123 pagesCloud Computing: Radboud UniversityNermin ImamovicNo ratings yet

- Cyber-Security-Thesis: July 2018Document8 pagesCyber-Security-Thesis: July 2018Ahmed HamdyNo ratings yet

- Robot KinematicsDocument29 pagesRobot KinematicsGuna SeelanNo ratings yet

- Analysis of Critical Speed of Shaft Using C and MATLABDocument5 pagesAnalysis of Critical Speed of Shaft Using C and MATLABAhmed HamdyNo ratings yet

- TM-IV-1,2-2 SolutionDocument1 pageTM-IV-1,2-2 SolutionAhmed HamdyNo ratings yet

- Installation ReadmeDocument12 pagesInstallation ReadmeJim BarterNo ratings yet

- Mechanical Drawings and SpecificationDocument1 pageMechanical Drawings and SpecificationAhmed HamdyNo ratings yet

- Grammar Focus - 50 Essential Grammar RulesDocument1 pageGrammar Focus - 50 Essential Grammar RulesAhmed HamdyNo ratings yet

- 09.tracheostomy Management by Speech Language Pathologists in SwedenDocument12 pages09.tracheostomy Management by Speech Language Pathologists in SwedenCarlonchaCáceresNo ratings yet

- S590 Machine SpecsDocument6 pagesS590 Machine SpecsdilanNo ratings yet

- Book BindingDocument14 pagesBook Bindingpesticu100% (2)

- Ni Elvis ManualDocument98 pagesNi Elvis ManualZhi YiNo ratings yet

- YellowstoneDocument1 pageYellowstoneOana GalbenuNo ratings yet

- THE WEATHER LISTENING - Stalin GuañunaDocument1 pageTHE WEATHER LISTENING - Stalin GuañunaSTALIN JESUS GUA�UNA CHICAIZANo ratings yet

- Igcse Revision BookDocument23 pagesIgcse Revision BookJo Patrick100% (2)

- Is 4031 Part 4 - ConsistencyDocument4 pagesIs 4031 Part 4 - ConsistencyCrypto AbhishekNo ratings yet

- Updated SAP Cards Requirement JalchdDocument51 pagesUpdated SAP Cards Requirement Jalchdapi-3804296No ratings yet

- Fama Fraternitatis Rosae Crucis PDFDocument2 pagesFama Fraternitatis Rosae Crucis PDFJudy50% (2)

- Exp6.Single Phase Bridge Inverter Using PWMDocument6 pagesExp6.Single Phase Bridge Inverter Using PWMAbdullah MohammedNo ratings yet

- The Unofficial Aterlife GuideDocument33 pagesThe Unofficial Aterlife GuideIsrael Teixeira de AndradeNo ratings yet

- GLP BmsDocument18 pagesGLP BmsDr.Subhashish TripathyNo ratings yet

- Ventricular Septal DefectDocument9 pagesVentricular Septal DefectpepotchNo ratings yet

- Antoine Constants PDFDocument3 pagesAntoine Constants PDFsofiaNo ratings yet

- Serving North Central Idaho & Southeastern WashingtonDocument12 pagesServing North Central Idaho & Southeastern WashingtonDavid Arndt100% (3)

- Guidelines For The Management of Brain InjuryDocument26 pagesGuidelines For The Management of Brain InjuryfathaNo ratings yet

- PTP S3Document8 pagesPTP S3Yongyin SHENGNo ratings yet

- Furuno CA 400Document345 pagesFuruno CA 400Димон100% (3)

- Milviz F-15e Poh V 2Document499 pagesMilviz F-15e Poh V 2Jose Ramon Martinez GutierrezNo ratings yet

- Bolt Action Italian Painting GuideDocument7 pagesBolt Action Italian Painting GuideTirmcdhol100% (2)

- Factors Affecting Physical FitnessDocument7 pagesFactors Affecting Physical FitnessMary Joy Escanillas Gallardo100% (2)

- Plato: Epistemology: Nicholas WhiteDocument2 pagesPlato: Epistemology: Nicholas WhiteAnonymous HCqIYNvNo ratings yet

- Intro Slow Keyofg: Em7 G5 A7Sus4 G C/G D/F# AmDocument2 pagesIntro Slow Keyofg: Em7 G5 A7Sus4 G C/G D/F# Ammlefev100% (1)

- Datasheet Ark XH Battery System EngDocument2 pagesDatasheet Ark XH Battery System EngLisa CowenNo ratings yet

- Lc420euf Sda1 LGDocument41 pagesLc420euf Sda1 LGjavierNo ratings yet

- Arts6,4, Week2, Module 2V4Document24 pagesArts6,4, Week2, Module 2V4Loreen Pearl MarlaNo ratings yet

- Final TestDocument10 pagesFinal TestbennyNo ratings yet

- Physics 101Document21 pagesPhysics 101Kuna KunavathiNo ratings yet

- ST 36Document4 pagesST 36ray72roNo ratings yet