Professional Documents

Culture Documents

Fuel Cell v1

Uploaded by

Taufiq NazriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Cell v1

Uploaded by

Taufiq NazriCopyright:

Available Formats

Power regeneration

Table 1: General criteria of selecting power regeneration

Criteria Description

Reliability

When the primary electrical grid network fails, power re-generation

must be able to supply adequate power

Life expectancy Power regeneration must last beyond its expected design life cycle in

order to reduce the cost of refurbishment

Operational performance

Power regeneration could run for long term duration with low level of

discharges and with good load capability

Safety of operation Safety of the well-being personnel, equipment and environment (zero

emission of hazardous gasses) are the primary factor of the operation

Cost of operation Low cost of operation since it does not involve any moving part and

require low maintenance

1.1.1 Fuel Cell

Fuel cell is an electrochemical device that powered by combination hydrogen and oxygen to produce

electricity and leave two by-products namely water and heat (Curtin & Ghangi 2013). Fuel cell is a

promising green and clean technology that could bring good contribution towards reduction of GHGs

emission and ensuring energy security specifically in transportation and electricity power generation

sectors (Curtin & Ghangi 2013). The basic operation of fuel cell is shown as in Figure 2.7-1.

A fuel cell consist of two electrodes namely anode and cathode which is surrounded by electrolyte. Fuel

cell operate when hydrogen and oxygen is fed to anode and cathode, respectively. This will cause the

separation of hydrogen atoms into protons and electrons. Electricity is generated when electrons travel via

external circuit while protons migrate to cathode via electrolyte which then reacts with oxygen and

electrons to produce heat and water as by-products (Gielen & Simbolotti 2005).

Figure 1: The proton exchange membrane fuel cell concept (Gielen & Simbolotti 2005).

Fuel Cell Types

The types of electrolyte used in the fuel cell will differentiate the fuel cell types. Fuel cell types can be

categorized according to their operating temperatures which are high temperature fuel cells and low

temperature fuel cells. High temperature fuel cells can be operated in range of 600-1000

O

C while low

temperature fuel cells can be operated in between 60-250

O

C.

i. High Temperature Fuel Cells Types

There are two types of high temperature fuel cell namely Molten Carbonate Fuel Cells and Solid Oxide

Fuel Cells. The characteristics of these fuel cells are shown in Table 2.7.1.1-1.

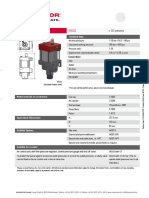

Table 2: High temperature fuel cells (Peighambardoust,et al. 2010).

Parameter Molten Carbonate Solid Oxide

Electrolyte Sodium/ Magnesium Carbonates Calcium/Zirconium Oxide

Operating

Temperature (

O

C)

600 to 7000 800 to 1000

Efficiency Range 60-65% 55-65%

Unit Power Output

(MW)

Up to 2 Up to 0.1

Power Density

(mW/cm

2

)

100 240

Electrode Catalyst Nickel Lanthanum Strontium Manganite

Best Area of

Application

Large Stationary co-generation Constant Stationary co-generation

Lifetime (hr) >40,000 >40,000

Capital Cost

(USD/kW)

1000 1500

Diagrams

Figure 1.1.1-2: Molten carbonate fuel cell.

Figure 1.1.1-3: Solid oxide fuel cell.

Advantages High effieciency High effieciency

Fuel Source Most hydrocarbons Most Hydrocarbons

i. Low Temperature Fuel Cell Types

Proton Exchange Membrane (PEM) , Alkaline and Phosphoric Acid fuel cells are the three common

types of low temperature fuel cells. The characteristic of these fuel cells are shown in Table 2.7.1.1-2.

Table 3: Low temperature fuel cells (Peighambardoust,et al. 2010).

Parameter Proton Exchange Membrane Alkaline Phosphoric Acid

Electrolyte Polymer Membrane Potassium Hydroxide Phosphoric Acid

Operating Temperature (

O

C) 50-80 60-90 160-220

Efficiency Range (%) 45-60 40-60 55

Unit Output(kW) 50-250 0.3-5 Up to 200

Power Density (mW/cm

2

) 350 100-200 200

Electrode Catalyst Platinum Platinum Platinum

Best Area of Application Stationary Power Generation / Mobile Use in Apollo spacecraft to provide

electricity and drinking water

Stationary Power Generation

Lifetime (hr) >40,000 >10,000 >40,000

Capital Cost (USD/kW) >200 >200 3000

Diagrams

Advantages Low temperature & quick start-up High performance High tolerance to impurities in hydrogen

Fuel Source Pure Hydrogen Pure Hydrogen Pure Hydrogen

Source: http://mypages.iit.edu/~smart/garrear/fuelcells.htm

Figure 1.1.1-4: PEM fuel cell. Figure 1.1.1-5: Alkaline

Figure 1.1.1-6: Phosphoric fuel

Balance of Plant of Hydrogen Fuel Cells

There are several additional equipments that are required to be integrated with fuel cell because fuel

itself cannot generate electricity. This additional equipments is known as balance of plant.

Table 4: Balance of plant of hydrogen fuel cells

Components Description

Storage Tank Require high pressure hydrogen tanks or cryogenic hydrogen storage tanks

Pump Pump the reactant air through the stack and provide cooling system

Compressor Require high power compressor to handle high air and fuel flow rates.

Battery/DC Require battery/ additional electric supply to operate pump, compressor and

to start up the fuel cell until it reachs its operating temperature

Sensor Monitor temperature, pressure, fluid and gas flow, voltage

Filter To remove any contaminant from fuels supplies

Advantages of Hydrogen Fuel Cells over diesel generators

Hydrogen fuel cell is practically emits zero GHGs since it does not involve any combustion process. It

could generate electricity with approximately 55% efficiency with water as its by-product. Fuel cell

could be beneficial as it can be used as energy back up to supply adequate electricity power when the

grid networks fail for a certain period of time. For instant power outage has occurred in 2006 caused

by earthquake in Venezuela. Hydrogen fuel cells have been successfully operated to supply adequate

power to local resident (Jingsheng & Xingjie 2011).

Despite the fact that fuel cell is zero GHGs emission it also has several advantages over diesel power

generator in term of size, operating temperature and cost. The present of fuel cell as generator will

only leave a small foot print as it content high density power in a small size. For example, a total of

11.2MW generated by four fuel cells energy DFC3000 have been installed on one acre of land in San

Diego, USA which is equivalent to 15.51 tennis double courts size (Curtin & Ghangi 2013). In

addition, fuel cell has greater reliability than diesel power generator as it could operate at large

temperature range which is between -40

O

C and 40

O

C, hence this will make it more reliable to be used

almost everywhere in the world (Jingsheng & Xingjie 2011). Besides that, fuel cell has no moving

parts. In term of maintenance cost, this will be a great advantage of using fuel cells as power back-up

generator over diesel generator since diesel generator requires regular maintenance (Jingsheng &

Xingjie 2011). Additionally, the price of electricity generated by fuel cell is lower than the price of

utility electricity. For instant, for 1MW fuel cell installed in San Jose, California, fuel cells only

cost USD 0.11 per kilowatt-hour (kWh) as compared to utility electricity price (0.14kWh)

which saved more than USD810, 000 for the first 10 months of operation.

1.1.2 Hydrogen Powered I nternal Combustion Generator

Hydrogen has potential to be used as primary fuel in internal combustion engine generator to re-

generate electricity due its properties of high energy contents per unit mass. This principle is similar

to the internal combustion engine for vehicle except the fact that the purpose of internal combustion

engine generator is to generate electricity. Nevertheless, large quantity of hydrogen must be supplied

to the engine in order to generate adequate electricity. With minor modification to the engine of the

generator, electricity can be generated through hydrogen powered rotary generators (Woo & Lee

2009). This can be presented as in Figure

Figure 7 Hydrogen power internal combustion generator concept

Source: http://www.mpoweruk.com/hydrogen_fuel.htm

Hydrogen powered internal combustion engine is 20% more efficient than gasoline powered internal

combustion engine because of both of the compression ratio and specific heat ration of hydrogen are

larger than gasoline. This is due to ability of hydrogen to burn in lean mixtures with low self-emission

temperature (Barbir 2000). Equation below shows the ideal thermal efficiency of an internal

combustion engine:

(

Where,

compression ratio

specific heat ratio

Nevertheless, due to low energy content in the stoichiometric mixture inside the engines cylinder, the

use of hydrogen as fuel in the internal combustion engine has resulting in the loss of 15% power as

compared to gasoline. Yet, the performance of the engine can be enhanced by injecting liquid

hydrogen to the engine. This will increase the power output of the engine by nearly 33.3% (Norbeck

et al. 1996).

In 2002, Ballard Power System and Ford Power Products has introduced the worlds first hydrogen

fuelled internal combustion engine generator set which is known as Ballards Ecostar (see Figure

2.7.2-2). This gen-set runs on 6.8-litre Ford production engine that has been modified and warranted

by Ford Products to run on hydrogen that can produce approximately 114kVA power (equivalent to

114kW with power factor of 1) at certain voltage level and phase. Hence, this gen-set could be

utilized for auxiliary power generator that provides clean and green power generation (Daly 2014).

Figure 8: Ballard's Ecostar

Source: http://news.thomasnet.com/fullstory/Hydrogen-Generator-Set-provides-clean-power-for-utilities-16540

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Scroll Decent PowerDocument5 pagesScroll Decent PowerMauricioNo ratings yet

- Vragen VACBI A330-200 ATA 21Document7 pagesVragen VACBI A330-200 ATA 21Arkadiy Chernov100% (1)

- F - 155 - Esempio Di Calcolo IdraulicoDocument5 pagesF - 155 - Esempio Di Calcolo Idraulicokikohassan123No ratings yet

- Fluidised 20bed 20combustion 20boilersDocument146 pagesFluidised 20bed 20combustion 20boilersjkhan_724384No ratings yet

- AlertDocument14 pagesAlertVikrant RajputNo ratings yet

- Reflection in PrelimDocument2 pagesReflection in PrelimRichelle TanNo ratings yet

- Dokumen - Tips - Double Pipe Heat Exchanger With Matlab CDocument11 pagesDokumen - Tips - Double Pipe Heat Exchanger With Matlab CNayli AthirahNo ratings yet

- On Off Data Sheet For 9,12,18 &24KDocument2 pagesOn Off Data Sheet For 9,12,18 &24KcharbelNo ratings yet

- Pump CavitationDocument18 pagesPump CavitationEka SugiantoroNo ratings yet

- LPG Bottling Know HowDocument28 pagesLPG Bottling Know HowJosmar AnguloNo ratings yet

- Blackout RestorationDocument26 pagesBlackout RestorationSiddhant SatpathyNo ratings yet

- PC Nirvana Contact Cooled - FormDocument1 pagePC Nirvana Contact Cooled - Formjohn vickers100% (1)

- SLR Metaliks Limited: List of Lux Level in Different AreasDocument2 pagesSLR Metaliks Limited: List of Lux Level in Different AreasprasadNo ratings yet

- A Training Seminar ON 135 MW Gas Based Power Plant Utran, SuratDocument20 pagesA Training Seminar ON 135 MW Gas Based Power Plant Utran, SuratGangwal AkashNo ratings yet

- Agriculture Fuel Cells: The More Efficient, Less Expensive Alternative To Electrolysis or Delivered Industrial HydrogenDocument2 pagesAgriculture Fuel Cells: The More Efficient, Less Expensive Alternative To Electrolysis or Delivered Industrial HydrogenjuliomilitaoNo ratings yet

- RacDocument22 pagesRacFaaltu ZaanNo ratings yet

- Cooling Tower To Plant 1Document1 pageCooling Tower To Plant 1Talha BaigNo ratings yet

- Gen Set 2.5 KVA 1Document17 pagesGen Set 2.5 KVA 1Pankaj TiwariNo ratings yet

- Grundfosliterature 3980923Document2 pagesGrundfosliterature 3980923Banupriya BalasubramanianNo ratings yet

- DB-01 01 06 04-Pump-MO22Document2 pagesDB-01 01 06 04-Pump-MO22PRAMOD KUMARNo ratings yet

- Natural Gas Processing LectureDocument19 pagesNatural Gas Processing LectureManepalli Narasimha Murthy50% (2)

- Kcn411lag BXXXDocument5 pagesKcn411lag BXXXRajeesh P RaviNo ratings yet

- 158TR Chiller Selection PDFDocument2 pages158TR Chiller Selection PDFabdullah amanullahNo ratings yet

- MBA 3 20 KW 15 100 PSIG AUT013Document2 pagesMBA 3 20 KW 15 100 PSIG AUT013Wallace GualandiNo ratings yet

- Tra Loi Cau Hoi - Energy SavingDocument11 pagesTra Loi Cau Hoi - Energy Savinghung Pham ThanhNo ratings yet

- Finished Finished Finished Finished Finished Finished Finished Finished FinishedDocument1 pageFinished Finished Finished Finished Finished Finished Finished Finished FinishedR'n'R BatamNo ratings yet

- Non Mandatory: NotesDocument1 pageNon Mandatory: NotesMarko's Brazon'No ratings yet

- REEPS CH 4 Solns DGDocument7 pagesREEPS CH 4 Solns DGAnas TarikNo ratings yet

- Syllabus EgeDocument2 pagesSyllabus Egeprabhjot singhNo ratings yet

- Latvia Marine Engineering Test PaperDocument90 pagesLatvia Marine Engineering Test PaperkrishnaNo ratings yet