Professional Documents

Culture Documents

1 Water (Sumana)

Uploaded by

siruslara6491Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Water (Sumana)

Uploaded by

siruslara6491Copyright:

Available Formats

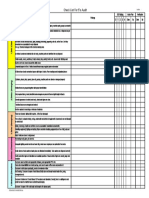

Pharmaceutical Water Systems

Pharmaceutical Water System

I Basic Regulatory Requirements

II Water Quality Requirements

III Water System Planning

IV cGMP Requirements and design

Consideration

V Microbiology of water

VI Deionization / Electro-deionization

VII Purified Water System Design

VIII Water for Injection Production

Techniques

IX Reverse Osmosis

X Storage and Distribution Installation

Considerations

XI Ozone Bio-contamination Control

XII System Materials and Finished

XIII Commissioning and Validation

XIV System Maintenance & Troubleshooting

USP Summary for Bulk Waters

USP WFI shall be produced by distillation or proven

validatable equivalent methods.

The USP requires that Purified Water and Water for

Injection meet specific conductivity <645> and

TOC<643> requirements.

USP <645> is a 3 stage conductivity test. It permits

on- line and off line testing. <645> requires the use

of non-temperature-compensated conductivity

measurement. <645> requires specific performance

requirements for the instruments.

<643> permits on-line and off-line testing.

Conductivity and TOC Requirements for USP Bulk

waters and very mature and little will change.

EP Summary for Bulk Waters

EP WFI shall be produced by distillation. Other

methods NOT accepted.

EP requires that Purified Water and water for Injection

meet specific conductivity (2.2.38) and TOC (2.2.44)

requirements. Nitrates and Heavy Metals testing still

required. EP conductivity testing has weaknesses in its

design: no on- line testing, faulty calibration, lack of

instrument QC requirements.

Conductivity requirement are changing in 2004. WFI

& WH-P conductivity to look like USP requirement.

PW conductivity to be changed to allow on-line, but

un-harmonized.

TOC testing fully harmonized with USP.

EP microbiology limits harmonized, but written as

part of monograph.

Packaged Water Summary

Packaged Water requirement need revision by

all groups.

USP has 9 chemistry tests for Sterile Water for

Injection (SWFI), after preparing WFI!

USP plans to reduce to 2 test

- Conductivity (same limits as EP?)

- Quantitative organic analysis test (TOC or

spectrophotometric)

EP has ~ 15 wet chemistry tests for SWFI,

plus conductivity

I. Basic Regulatory Requirements

Understand regulatory requirements

Pharmacopoeias

Rules and Guidance (GMP)

Regulatory Bodies

Origin and development of water

quality requirements

The Pharmacopoeia

Important statutory component of an

overall system of control of medicinal

products

Complements and assists licensing

and inspection processes

Separate for USA (USP) and Europe

(Ph. Eur., BP)

European Pharmacopoeia (Ph. Eur)

Fourth Edition (Yearly supplements)

Supported by Pharmeuropa

Used Internationally

Legally enforceable

United States Pharmacopoeia (USP)

USP 28

Supported by Pharmacopeial Forum

Sets drug standards but cannot enforce

Used Internationally

Monographs are a legal requirement

General Information Not legal

requirement

USP 28

General Information

<6D dead legs

sloped piping lines

complete drain ability

no pockets

sample valves

sanitization

installation and materials of construction

Rules and Guidance (GMP)

Rules Governing Medicinal Products in

the European Community (Commission of

the European Communities)

Code of Federal Regulations (CFR) Title

21 (Food and Drug Administration)

Regulatory Bodies

European Medicines Evaluation Agency

(EMEA)

Agencies in member nations

e.g. Medicines Control Agency (MCA)

from April 1

st

2003 Medicinal and

Healthcare products Regulatory Agency

(MHRA)

Food and Drug Administration (FDA)

Enforcement

Regulatory bodies legally enforce drug

standards

Safety

Efficacy

Strength

Purity

Enforcement (2)

Pharmacopoeias set drug standards but

cannot enforce them

MHRA/FDA enforce drug standards but

cannot set them

There are many grey areas open to

interpretation by different regulators

Good Manufacturing Practices

If the manufacture or control procedures

do not conform to cGMPs

Regulators may deem products to be

adulterated

Manufacturer may be subject to

regulatory sanctions

Regulators do not have to find products

actually contaminated before instituting

sanctions

Current Good Manufacturing

Practices (cGMPs)

Regulators enforce adherence to cGMPs

Production could be stopped

Recalls might be required

Submissions may be delayed

Importations could be stopped

Adulterated products could be seized

Common Concerns of the Regulator

poor microbial control

poor water quality test procedures

poor SOP adherence

lack of trending and validation

Drug Manufacturer Responsibilities

Define appropriate water purity

Process requirements

regulatory requirements

each process step

all critical parameters chemical,

physical and biological

Demonstrate that all waters can be

produced consistently to specification

Good Engineering Practice

Build to plans and specifications.

Inspect, test and document.

Minimum level documentation.

Design Fabrication Vendor testing

Construction Field Inspection

Commissioning

Good Engineering Practice

Documents can support commissioning

and validation

Proper planning

Proper organization

Proper authorization

Pharmaceutical Water Compendial Types

Bulk forms

Purified Water (PW)

Water Highly Purified (WHP)

Water for Injections (WFI)

II. Water Quality Requirements

Packaged Forms

Bacteriostatic WFI

Sterile Water for Inhalation

Sterile Water for Injections

Sterile Water for Irrigation

Purified Water in Containers

Pharmaceutical Uses for Water

Constituent

Production Process

Wash equipment / product

Cooling

Steam for sterilization

USP 28

Source water defined

Distillation or RO

Conductivity 3 Stages

TOC 500 ppb

BET 0.25 EU/ml

Micro count 10 cfu/100 ml

(guideline <1231>)

WFI Requirements

EP 4

th

Edition 2002

Current WFI Requirements

Source water defined

Distillation only

Conductivity (1.1 S@20

O

C)

TOC 500 ppb

Additional tests for Nitrate(max.0.2ppm), Heavy Metals

(max.0.1ppm)

BET 0.25 IU/ml

Micro count 10 cfu/100 ml (200 ml minimum)

Aluminium (max. 10 ppb,Dialysis only)

USP 28

Purified Water Requirements

Source water defined

Suitable process

Conductivity 3 Stages

TOC 500 ppb

Micro Count 100 cfu/ml

(guideline <1231>)

EP 4

th

Edition 2002

Purified Water Requirements

Source water defined

Suitable process

Conductivity (4.3S@20

O

C)

TOC 500 ppb (or Oxidisable substances)

Additional tests for Nitrate, Heavy Metals

Micro Count 100 cfu/ml (suitable sample size)

BET and Aluminium (Dialysis only)

USP/EP Differences for WFI

Distillation

Conductivity Limits

Nitrate, Heavy Metals

Aluminium

USP/EP Differences for Purified

Water

Conductivity Limits

Oxidisable Substances

Nitrate, Heavy Metals

BET and Aluminium

Conductivity Test (theory)

Conductivity increases as function of temperature

Conductivity varies as function of pH

Change in conductivity varies with different ions

Must be determined by non temperature

compensated meter

Stage 1 allows on line measurement

Stage 2 laboratory test

Stage 3 closely controlled pH and temperature

USP Conductivity Test

Stage 1 Temperature and Conductivity Requirements

(for nontemperature-compensated conductivity measurements only)

Temperature Conductivity Requirement (S/cm)

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

0.6

0.8

0.9

1.0

1.1

1.3

1.4

1.5

1.7

1.8

1.9

2.1

2.2

2.4

2.5

2.7

2.7

2.7

2.7

2.9

3.1

If the conductivity is higher than the table value, proceed with Stage 2.

Stage 2

Transfer a sufficient amount of water (100 ml

or more) to a suitable container, and stir the test

specimen. Adjust the temperature, if necessary,

and while maintaining it at 25 1

0

, begin

vigorously agitating the test specimen while

periodically observing the conductivity. When

the change in conductivity (due to uptake of

atmospheric carbon dioxide) is less than a net of

0.1 S/cm per 5 minutes, note the conductivity.

If the conductivity is greater than 2.1 S/cm,

proceed with Stage 3.

Stage 3 pH and Conductivity Requirements

(for atmosphere and temperature equilibrated samples only)

pH Conductivity Requirement (S/cm)

5.0

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

6.0

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

7..0

4.7

4.1

3.6

3.3

3.0

2.8

2.6

2.5

2.4

2.4

2.4

2.4

2.5

2.4

2.3

2.2

2.1

2.6

3.1

3.8

4.6

If either the measured conductivity is greater than this value or the pH is outside the range of

5.0 to 7.0, the water does not meet the requirements of the test for conductivity.

Conductivity

Agreed replacement for wet chemistry

Theory and model similar in US and Europe

Detailed application very different

EP differs for WFI and PW

No on-line provision in EP

Different temperatures

EP retains Nitrates

EP Conductivity

EP introduced conductivity in 1999 (2.2.38)

Difficulty complying, several anomalies

Not designed for on-line testing

States use platinum electrodes (not optimal)

Temperature compensation unclear

Lack appreciation of CO

2

equilibrium

EP update expected

Harmonization for Conductivity Limits

USP <645> has two tables of conductivity limits

- Permits on-line test from 0 - 100

o

C.

- Permits off-line tests and accounts for

innocuous CO

2

at 25

o

C.

EP 2.2.38 has two conductivity limits

- 1.1 S/cm at 20

o

C for WFI

- 4.3 S/cm at 20

o

C for Purified Water.

- Retain nitrate test.

- Retain Heavy Metals test.

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0

0 10 20 30 40 50 60 70 80 90 100

Temperature (

o

C)

Proposex1 EP WFI Limits

U

n

c

o

m

p

e

n

s

a

t

e

d

c

o

n

d

u

c

t

i

v

i

t

y

,

s

i

0.8

0.9

1.0

1.1

1.3

1.4

1.4

1.7

1.8

1.9

2.1

2.2

2.4

2.5

2.7 2.7 2.7 2.7

2.9

3.1

TOC

TOC = Total Organic Carbon

Non-purgeable organic carbon

Replacement for Oxidisable Substances

Introduced USP 1996

Introduced EP 1999

Previously in JP

TOC EP vs USP (1)

Common limit (500 ppb)

Methods very similar

Organics completely oxidised to CO

2

Organics compounds oxidise at different rates

Calibration uses easy to oxidise (sucrose)

and difficult (1,4-benzoquinone)

On-line or Laboratory measurements

TOC EP vs USP (2)

EP reagents cheaper (Reagent grade)

Common limit for PW and WFI

EP allows oxidisable substances for PW

EP reagent water conductivity limit 1.0Si at

25

O

C

Only minor differences, satisfactory

Microbiological Requirements

Water for Injection

USP 28 10 cfu/100 ml (<1231>)

0.25 EU/ml

Distillation or RO

EP 4

th

(2002) 10 cfu/100 ml (min 200 ml)

0.25 IU/ml

Distillation only

Method for Production

WFI only Pharmacopoeial product assigned

a specific method of production in addition

to specified quality.

Pharmaceutical only industry to use

distillation to prepare high purity water.

European regulators adamant that

distillation is only acceptable method for

WFI production.

Microbiological Requirements

Purified Water

USP 28 100 cfu/ml (<1231>)

Suitable method

preparation

EP 4

th

(2002) 100 cfu/ml (suitable

sample)

BET (dialysis) Suitable

method preparation

Water Highly Purified

Latest Grade From EP and BP

Intermediate between PW and WFI

Low Endotoxin requirement

Introduced January 2002

Ph Eur 4

th

Edition (2002)

Water, Highly Purified

Source water as for PW and WFI

For medicinal products where water of high

biological quality is needed, except where

WFI is required

Manufacture relaxed, permits RO with ultra-

filtration and deionisation (as example)

Chemical & Micro testing as for WFI with

same limits

Choice of Water Quality

Consistent with final product requirements

WFI minimum quality for parenteral drug

ingredient

Purified Water minimum quality for oral dosage

ingredient

Must establish logic for quality based upon end

product

III. Water Planning

Process Water

Manufacturing Water used for

Non Sterile Products Sterile Products

No No Yes Yes

Downstream

Processing

Parenteral

Product

WFI PW PW WFI

Cleaning Water

Cleaning Water used for

No Yes

Final

rinse

Suitable

non compendial

water

Use same water

as processing /

manufacturing

* Non compendial water comparative to potable water

(microbial)

Water Decision Considerations

Drinking Water may be used in the early stages

of chemical synthesis and in the early stages of

cleaning of pharmaceutical manufacturing

equipment USP

Water with tighter chemical and microbial

specifications should be used in later processing

steps or if the impurities are unable to be

removed in later steps FDA Guide for

Manufacturing, Processing, or Holding Active

Pharmaceutical Ingredients

Microbial Level Establishment

Alert and action levels required

Compendial and non-compendial waters

Levels for non-sterile products

product

potential harm to user

Levels based on process needs and

historical record

Microbial Level Establishment

Can microorganisms threaten product

preservation or stability?

Can product be contaminated with

pathogens or endotoxins?

Maximum action levels

WFI : 10 cfu/100 ml

PW : 100 cfu/ml

Drinking water : 500 cfu/ml

IV. cGood Manufacturing Practices

Series of rules ensuring that

pharmaceutical products are manufactured

in a CONSISTENT and CONTROLLED

manner and will be FIT for their intended

purpose

GMP maintains a Companys reputation

and product integrity.

GMP Requirements

General

Provide guidance

Need to be applied according to local conditions

Used in conjunction with pharmacopoeial

requirements and registered details as basis for

inspection

Industry norm

continuous progression

European GMP (1)

A1.31

Water treatment plants should be

designed, constructed and maintained so as

to ensure the reliable production of water

of an appropriate quality. They should not

be operated beyond their designed

capacity. Water should be produced stored

and distributed in a manner which prevents

microbial growth, for example by constant

circulation a temperature above 70C

European GMP (2)

A1.30

Water treatment systems including stills

should be subject to planned maintenance

and validation, their use following

maintenance work should be approved by

Quality Control

European GMP (3)

A1.40

Water sources, water treatment equipment

and treated water should be monitored

regularly for chemical and microbiological

contamination and, as appropriate, for

endotoxins. Records should be maintained

of the results of the monitoring and of any

action taken

European GMP (4)

3.4.3

Distilled, deionised and, where

appropriate, other water pipes should be

sanitised according to written procedures

that detail the action limits for microbial

contamination and the measures to be

taken

European GMP (5)

A9.4

After any chemical sanitisation of the

water systems, a validated flushing

procedure should be followed to ensure

that the sanitising agent has been

effectively removed

USA GMP

21 CFR Part 210 Interpretation

Pharmaceutical waters used in the

manufacture of drugs or drug products

are subject to the regulations of the

cGMPs whether or not the water remains

in the final product

USA GMP

21CFR Part 211.48a

Potable water shall be supplied under

continuous positive pressure in a

plumbing system free of defects that

could contribute contamination to any

drug product. Potable water shall meet

the standards prescribed in the EPAs

Primary Drinking Water Regulations

USA GMP

21CFR Part 211.48b

Drains, where connected to a sewer,

shall be provided with an air break

Of particular concern on sanitisation

or product divert lines

Air breaks preferred to check valve or

backflow preventers

Common drains should be scrutinised

to ensure there is no possibility of

back contamination

USA GMP

21CFR Part 211.65a

Surfaces that contact components, in

process materials, or drug products shall

not be reactive, additive, or absorptive so

as to alter the safety, identity, strength,

quality, or purity of the drug product

21 CFR 211.65a Interpretation

Opens all process water contact surfaces

to FDA scrutiny

Implies use of inert materials for product

water handling

Manufacturer must prove suitability of

system components and materials

USA GMP

21CFR 211.65b

Any substances required for

operation, such as lubricants or

coolants, shall not come into contact

with components so as to alter the

safety, identity, strength, quality, or

purity of the drug product beyond the

official or other established

requirement

21 CFR 211.65b Interpretation

May imply the use of :

Double containment heat exchangers

Leak detection systems

Process water pump flush seals

Atmospheric air hydrophobic vent filters

Suitable nitrogen and ozone

USA GMP

21CFR 211.67b

Equipment shall be cleaned,

maintained, and sanitised at

appropriate intervals to prevent

malfunctions or contamination that

would alter the safety, identity,

strength, quality, or purity of the drug

product beyond the official or other

established requirement

21 CFR 211.67a Interpretation

Routine maintenance plans required for

all equipment

Individual unit monitoring required

Sanitisation frequency dependent on

product water quality requirements and

system design

21 CFR 211.67a Further Interpretation

Opens equipment rinse water to review

Rinse water should be free from objectionable

contaminants

Final rinse water shall be of equal quality to

manufacturing water

Final rinse for parenteral production could be

interpreted to be :

WFI

WFI equivalent (e.g. by ultrafiltration)

USA GMP

21CFR 211.67b

Written procedures shall be

established and followed for cleaning

and maintenance of equipment

SOP required for operation and

maintenance of pharmaceutical water

systems

USA GMP

21CFR 211.67c

Records shall be kept of maintenance,

cleaning, sanitising, and inspection

Sanitisation, cleaning, and

maintenance procedures shall be

documented

Sanitisation and cleaning performance

shall be validated and records shall be

maintained

21 CFR 212 Proposals

Filters may not be used at any point in the

water for manufacturing or final rinse piping

system

No point-of-use filters

No filters present in the distribution loop

Filters cannot be the terminal process of the

generation system

Consistent with the requirements for WFI

Considered cGMP

21 CFR 212 Proposals

Pipelines for the transmission of water for

manufacturing or final rinse and other liquid

components shall be constructed of welded

stainless steel equipped for sterilisation with

steam

Assumed applicable only to product water

Some validated systems utilise plastic

piping to minimise contaminants for

product specific applications

21 CFR 212 Proposals

Pipelines for the transmission of water for

manufacturing or final rinse and other liquid

components shall be sloped to provide for

complete draining

Assumed applicable to final product water

only (sanitary piping) for steam sanitised /

sterilised systems

Complete system drainability not always

utilised for hot water and chemically

sanitised systems

21 CFR 212 Proposals

Pipelines for the transmission of water for

manufacturing or final rinse and other liquid

components shall not have unused portion

greater in length than six diameters of the

unused pipe measured from the axis o the pipe

Minimal deadleg is GMP requirement

Debate over 6D measurement

Current consensus <4D, ideally none

21 CFR 212 Proposals

The integrity of all air filters shall be verified

upon installation and maintenance throughout

use

Applicable to membrane filter elements for

storage tank vent filtration

Considered a cGMP requirement

21 CFR 212 Proposals

Heat exchangers, other than the welded

double concentric tube type or double tube

sheet, must employ a pressure differential and

a means for monitoring the differential

Applicable to sanitary heat exchangers and

condensers

Considered a cGMP requirement

21 CFR 212 Proposals

All stills and tanks holding liquid requiring

microbial control shall have air vents with

non-fiber-releasing sterilizable filters capable

of preventing microbial contamination of the

contents

Applicable to product water storage tanks

Opens nitrogen quality to scrutiny in

nitrogen blanketing system

Considered a cGMP requirement

21 CFR 212 Proposals

Pumps moving water for manufacturing or

final rinsingshall be designed to utilize

water for injection as a lubricant for the seals

Common cGMP practice for WFI

21 CFR 212 Proposals

Water used as a component of as a final rinse

for equipment or product contact surfaces

shall conform to the specifications in the USP

for Water for Injection

WFI quality water validated for final rinse

in some parenteral facilities

Allows consideration of UF as terminal

process

21 CFR 212 Proposals

Water used as a component of as a final rinse

for equipment or product contact surfaces

shall be stored in a suitable vessel or system

including a piping network for distribution to

points of use at a temperature of at least 80C

under continuous circulation or at ambient or

lower temperatures for not longer than 24

hours, after which time such water shall be

discarded to drain

21 CFR 212 Proposals

Feedwater for boilers supplying steam that

contacts components, in-process materials,

drug products, and drug product contact

surfaces shall not contain volatile additives

such as amines or hydrazines

Steam sampling program required

Pure steam generators required for steam

sanitisation of sanitary process equipment

Current cGMP requirement

Common Regulatory Concerns

Water Systems not adequately validated

Testing not representing worst case (eg.

sampled after sanitisation)

Lack of written procedures

Failure to follow SOPs (eg. Maintenance)

Lack of adequate staff

Unapproved, unjustified changes to systems

Lack of Trending

Specific cGMP Design

Considerations

System validation

Consistent attainment of product water quality

NIST Calibratable Instruments for critical

parameters

Ability to sanitise all system components

Specific cGMP Design

Considerations

Documentation of material suitability

Accurate documentation for all assemblies,

installations, operation and maintenance

Appropriate piping joint methods

Minimal stagnant areas

Minimal deadlegs

Specific cGMP Design

Considerations

Product water storage vent filtration

Still condenser vent filtration

Double containment heat exchangers or

appropriate pressure differential

V. Microbiology Requirements

EP limits are ACTION LIMITS in Production section

- Purified Water100 cfu/ml

- WFI..10 cfu/100 ml

USP limits are recommended in <1231> general chapter

- Same limits as EP

JP limits are enforced in drinking water requirements

- Same limits as EP

In practice, this is the most widely audited and

monitored attribute of PW and WFI.

Endotoxin Requirements (WFI only)

< 0.25 EU/mL Endotoxin (USP and JP)

< 0.25 IU/mL Endotoxin (EP)

Same limits and same tests.

Alert Levels

Alert - Exceeded indicate process may be

drifting from normal operation

- Earning - not necessarily requiring

correction

- Demanding based on historic data

- Constantly reviewed

Action Levels

Action - Exceeded indicate process has

drifting from normal operation

- Corrective action requiring

- Often based on Regulatory

Guidelines but should also take

account of local situation

Typical Industry Water Testing

Approach for Bioburden

Water Method Frequency Limit

Potable

Purified

WFI

Pour Plate

Membrane

Pour Plate

Membrane

Pour Plate

Membrane

3 Months

Weekly (70%)

Daily (90%)

Absence of

specific

organisms

500 cfu/ml

100 cfu/ml

10 cfu/100ml

VI. De-ionisation/Electro de-ionization

Ion Exchange

Conversion of to acids by hydrogen

cation exchange

Removal of acids by anion exchange

Cations(+) and anions(-) in solution in

neutrality

Cation Exchange Resin

Immobile anionic radical exchange sites

(e.g. SO

3

)

Mobile cation attached (e.g. H

+

.

Na

+

,Ca

++

)

In neutrality with solution one Ca++

replaces two H

+

Cation Exchange Resin

Made of organic compound polymers (e.g.

styrene, di-vinylbenzyne)

Regenerated with acid (e.g. HCI, H

2

SO

4

)

There are Strong acid and Weak acid

types

Anion Exchange Resin

Immobile cationic radical exchange sites

(e.g. quaternary ammounium)

Mobile anions attached (e.g.

OH,CI,SO

4

=

)

Regenerated with base (NaOH)

There are Strong base and Weak

base types of resin

Separate/Single Bed Deionizer

Separate columns for cation and anion

exchange resin

Single regenerant chemical for each

column

Simple regeneration process-no resin

separation or mixing

Separate Bed Deionizer

Effluent quality normally in range of 1

to 10 ppm TDS using co-current

regeneration

Effluent quality normally in range of

0.1 to 1 ppm TDS using counter-

current regeneration

Separate Bed Deionizer

Effluent resistivity range is normally

0.05 to 0.5 megohm-cm using co-current

regeneration

Effluent resistivity range is normally

0.05 to 10 megohm-cm using counter-

current regeneration

Separate Bed Deionizer

pH difficult to predict

- wide range (3-11)

- can shift from alkaline to acidic during

run

Operation is generally simple and

reliable

Mixed Bed Deionizer

Sigle cation/anion resin column

Complex regeneration procedure

requiring resin separation and mixing

Effluent quality normally in range of 0 to

0.5 ppm TDS

Mixed Bed Deionizer

Effluent resistivity normally 1 to 18.3

megohm-cm

Product pH normally 6.8 to 7.2

Operation is generally reliable but is

morn difficult than separate bed

deionizer

Mixed Bed Regeneration Cycle

Backwash for rasin separation

Chemical introduction

Slow rinse

Fast rinse

Blow down

Air mix

Final rinse

Chemical Regeneration Requirement

Proper chemical strength

Proper chemical dosage

Proper chemical contact time

Proper chemical flow rate

Hot caustic for best silica removal

Off-Site Regenerated Deionizers

(exchange barrels)

Lower capital cost (or lease)

Higher operating costs

Easily expanded

Less control over quality

No chemical handling

Non-Regenerable New Resin

Deionizers (throw-away)

Highest operating cost

Highest quality control

Minimal TOC elution with proper resin

Resin supplier batch Q.C. documentation

should be available

Often used in small lab systems

Hot Water Sanitizable Deionizers

To help manage bio-burden

Electropolished 316 L SS vessels

Sanitary piping connections

Match loop construction quality

Sanitize at 65-80

o

C

Ion Exchange Resin Pretreatment

Multimedia Filter-Suspended Solids Removal

Cartridge Filter- Suspended Solids Removal

Activated Carboon Filter-Chlorine Removal,

Organic Reduction

Sodium Bisulfite Injection Chlorine Removal

Greensand Filter Iron Removal

Organic Scavenger Organic Reduction

Ultraviolet Steriliser Bacteria Reduction

Ion Exchange Resin Bacteria

Control Methods

Frequent chemical regeneration

Standby recirculation

Hot water sanitization

Chemical sanitization

- Peracetic acid

- Chlorine

- Formaldehyde

- Hydrogen Peroxide

Replacement

VII. Purified Water System Design

Purified Water Quality Requirements

Conductivity : e.g. USP 3 stage

measurement procedure

Total Organic Carbon: 500 ppb limit

response

Microbial Action Limit: 100 cfu/ml

maximum

- may be lower for process and product

specific applications

System Design Parameters

Meet Current Industry Standards (e.g. EP,

USP, FDA, GMP, GAMP, etc.)

Product meets USP Standards for Purified

Water at system outlet (i.e. no loop polishing

allowed)

Systems continuously recirculate in standby

mode

Some of the most common process

configurations

System Selection Considerations

Microbial Control

Capital Equipment Cost

Operating Cost

Lifecycle Cost

Chemical Handling

Reliability / Uptime

Maintenance

Water Consumption / Discharge

Footprint plantroom space

Consistent TOC Limit Attainment

Consistent Conductivity Attainment

Entrance for water system

Pump for water system

Control system for Purified water system

Reverse osmosis system for purified water

Mixed bed for residue resins

Storage for purified water with ozone

VIII. Water for Injection/s production

Techniques

Water for injection

USP-Prepared from water meeting the EPA

NPDWR or comparable regulations for Potable

water

Contains no added substance

Same chemical requirements as Purified Water

with added endotoxin specification (<0.25EU/ml)

Accepted microbial limit <10 cfu/100 ml

Water for injection

USP-Prepared by Reverse Osmosis or Distillation

(terminal process)

Japanese Pharmacopoeia allows ultra-filtration as

final process

EP, EU Pharmacopoeia allows only distillation

Distillation

Preferred method of production for WFI

Purifies water by phase change and entrapment

separation

Removes :

ionic contaminants

non-volatile organics

microorganisms

endotoxins

Distillator

Control panel for distillator

Storage with heater (>80c) for water for Injection

Other Design Considerations

Capital Equipment Cost

Operating Cost

Life cycle Cost

Chemical Handling

Reliability / Uptime

Maintenance

Water Consumption / Discharge

Utility Requirements

Space Limitations

IX. Reverse Osmosis Basics

Reverse Osmosis

Pressure driven semi-permeable membrane

process

Implemented for reduction of :

Inorganic contaminants

Organic contaminants

Colloids

Microorganisms

Endotoxins

Reverse Osmosis

Performance measurement/determination

Salt rejection

Comparative conductivity (product to

feed)

Microbial reduction

Endotoxin reduction

Cross Flow Comparison

Microfiltration

Ultrafiltration

Nanofiltration

Reverse Osmosis

10.0

Micron

1.0

Micron

0.1

Micron

0.01

Micron

0.001

Micron

0.0001

Micron

Spiral Wound RO Module

Reverse Osmosis

Microbial concerns

Most systems cannot tolerate chlorine in

feed water at it tends to hydrolyse the

membranes

Significant bio-film and planktonic counts

can occur

Frequent sanitization is often required

Pretreatment system performance is

significant factor

Preventing Biological Fouling

Utilize proper membranes

Sound sanitization plan

Minimize incoming challenge

Feed disinfectant (Cl

2

, O3, etc.)

HWS Carbon Filters

Ultraviolet Lights to reduce challenge

Lower unit recovery targets

Reverse Osmosis Sanitization

Peracetic acid

Sodium hydroxide

Formaldehyde

Hydrochloric acid

Hot water 80

0

C

RO Specification

Pretreatment and post-treatment

Feed filter housing (and elements)

Chemical tanks / pumps / controls

Cleaning skid (or sanitization skid)

RO Pretreatment Parameters

Feed water quality

Membrane type

Product water quality specifications

Two Pass Reverse Osmosis

Two RO units in series (product stream)

Known as two pass

Capable of producing USP 28/EP Purified

Water

USP 28

Generally Stage 2 or 3 conductivity

Sometimes meets Stage 1 limit

Excellent TOC reduction

Two Pass Reverse Osmosis

Excellent endotoxin reduction

Excellent microbial reduction

Can produce WFI when properly designed

and maintained

Sanitary construction

Continuous recirculation

Frequent hot water sanitization

Proper pretreatment

Typical Two-Pass RO System

Reverse Osmosis for WFI

Disadvantages :

Membrane integrity

Bacteria grow-through

Seal leakage or bypass

Chemical attack

High temperature damage

Difficult to integrity test

Reverse Osmosis for WFI

Disadvantages :

Sanitization limitations

Temperature limit

Chemical resistance

Pretreatment cost may be high

Reverse Osmosis for WFI

Advantages :

May be substantially lower in capital cost

than stills

May have substantially lower operating

costs than distillation

X. Storage and distribution

System Installation Considerations

Basic Approaches are :-

Store hot draw-off hot.

Store hot draw-off cold.

Store cold draw-off cold sanitise thermally

Store cold draw-off cold sanitise chemically

(ozone or other chemicals)

These techniques can be applied to both PW,

WHP & WFI.

Distribution General Considerations

Maintain water quality within acceptable limits

Limited water quality degradation is

acceptable degradation below quality limits

is not

Deliver water to use points at required flow,

pressure and temperature

Distribution General Considerations

Minimize capital and operating costs

Minimize time water is held at conditions

which favor microbial growth

Minimize temperature changes

Contact all areas during any sanitisation cycle

Distribution General Considerations

Batch operation

Utilizes at least two storage tanks

One is in service to users while other is

filled/tested

Filled tank enters service after successful

testing

Water usually sanitized before refill

Tank usually sanitized before refill

Batch System Operation Advantages

Water is tested before use

Each batch has QA/QC lot release

Maximum traceability and identification

Batch System Operation Disadvantages

Cumbersome to operate

Usually limited to small systems

High capital costs

High operating costs

Traditionally used to overcome unreliable

means of water production

Distribution Design Concepts

Dynamic/continuous operation

Off-sets peak demand with continuous make-

up into single tank

System supplies users continuously while

maintaining quality

Dynamic Continuous System

Advantages

Lower life cycle costs

Less complex piping at tanks

Disadvantage

No individual lot traceability for water

Distribution System Critical

Parameters

Water quality requirement

QA release required before use

Continuous recirculation requirements

Limiting hydraulics

Hot users only

Low temperature users only

Distribution System Critical

Parameters

Number of total low temperature users

Hot storage desired

Energy consumption critical

Sanitization method

Pressure requirements

Future considerations

Distribution System Critical

Parameters

Use loop filters NO ! can hide systemic

contamination problems

Use point filters NO !

Cost constraints

Available feed

Feed water quality

Feed interruptions

Reserve capacity production issues

Different Criteria Lead to Different

Designs

Batched tank recirculating system

Parallel loops, single tank

Hot storage, hot distribution

Hot storage, hot distribution, with point of use

heat exchanger

Different Criteria Lead to Different

Designs

Hot storage, cool and reheat

Hot storage, self-contained distribution

Ambient storage, ambient distribution

Ozonated storage and distribution

Pass thru system

System Comparison Parameters

Capital cost

Water consumption

Energy consumption

Ease of validation

Ease of operability

Maintenance requirements

System Comparison Measures

Tank turnover

Distribution system water content filling the

system must be considered

Line flushing requirements

Ability to respond to large peak demands

Loop balancing and control requiremetns

Microbial/endotoxin growth potential

Materials of Construction

Comparison Factors

Corrosion resistance

Availability

Extractables

Degree of Thermal expansion

External support requirements

Joining method

Storage and Distribution Sanitization

Periodic sanitization generally required

After maintenance in hot systems

Routine in ambient temperature systems

Frequency should be established through

monitoring

Response to reaching action level

Consider frequency in system annual review

Sanitization Options

Clean Steam

Extremely effective & verifiable

Requires full drainability & venting

Beat in SS

Possible in PVDF

Requires continuous support

Requires significant expansion loops

Limited to 140

0

C

Sanitization Options

Hot water

Very effective at 80

0

C

Can be done under pressure >100

0

C

Best in SS

Easily verified

Easily automated

Sanitization Options

Ozone

Best in SS and PVDF (+PP)

Very effective if frequent enough

Easily automated if already continuous in

storage tank

Easily removed with UV

Verifiable with monitors

Difficult to sanitize through use point valves

Good at biofilm removal with time

Sanitization Options - Chemical

Peracetic acid

Sodium hydroxide

Hydrogen peroxide

Quaternary ammonium compounds

Most difficult to verify

Most difficult to automate

Most difficult to rinse

Compatible with wide range of materials

XI. Ozone Biocontamination Control

Ozone

Allotrope of oxygen three atoms, 0

3

Relatively unstable

Half-life varies-10 to 120 minutes

Solubility about 13 O

2

OSHA atmosphere limit= 0.1 ppm

Potentially explosive at O

3

/O

2

mixtures>20%

- this cannot occur in water

Ozone

Microorganism kill faster than chlorine

Most bacteria killed in seconds

Lyses cell wall-not dependent on diffusion

through cell wall

8-12 minute kill for spores and Giardia

cysts

Ozone

Capable of organic oxidation including

endotoxin

Easily removed by ultraviolet light

- low pressure 254 nm or medium

pressure (multiple wavelength)

- requires about 3 the germicidal dose

Compatible with SS and PVDF

Electrolytic Ozone Generation

The preferred method for Pharma

Electrolytic generator

- Uses deionized water as feed

- Generation from water eases mixing

problem

- Electrolysis of water at anode yields

oxygen and ozone

- Lead (IV) oxide anode catalyst for O

3

- Hydrogen produced at cathode

Electrolytic Ozone Generator

Minimal ionic contamination

No danger of atmospheric O

3

release

Lower ozone levels effective (better

mixing)

Higher capital cost offsets lower O

3

level advantage

Direct current (DC), which is fed to the cell,

splits the passing de- mineralised water

into ozone, oxygen and protons on the

anode side and hydrogen gas is

produced on the cathode side.

The ozone generation takes place in a by-pass

stream off the pure water loop. The

ozone, which is dissolved in the passing

water, is distributed from the by-pass

stream back into the pure water loop

and the storage tanks.

Advantages of a ozone generator

system

No contamination by ions as the ozone is directly

produced from and dissolved in demineralised

water

Effective microbial reduction, TOC and endotoxin

decomposition at low ozone concentrations in pure

water

Continuous operation without additional

periodical disinfection with chemicals or steam

Easy installation and commissioning, low

maintenance and operating costs

Ozone Removal

Dissolved

- Ultraviolet light (3germicidal dose)

- Activated carbon

- Heat

- Time

Gas

- Manganese dioxide catalytic device

- Heat

Ozone Measurement

Chemical testing

- Indigo tri- sulfonate solution

decolorization

- absorbance change of 600 nm light

- linear with ozone level

- preferred method

- Potassium iodide color change

- interference from oxidants

- less preferred

Ozone Measurement On-line

Electrolytic membrane amperometer

- electrochemically converts ozone to

oxygen

- measures current required for

conversion- proportional to O

3

- good sensitivity

- membrane minimizes electrode

fouling and oxidant interference

Industry Views on Ozone

Many successful ozonated systems

Many FDA audits of several

systems

have been successful

Regional trends are variable about

use of ozone

Industry Views on Ozone

Not necessarily as effective as

maintaining a system at 80

o

C-but close

Much better than no heat or no Ozone

Ozone better a destroying bio- films

Some use heat sanitization for use points

Ozone Issues

Removal prior to use

Product efficacy impacted by trace

levels?

Personnel Safety monitoring required

During service periods the UV unit is in

operation, so only the storage tank and

the distribution system are Ozonated.

In most ozone applications the UV unit is

switched off during down periods. so that

the water containing ozone disinfects the

entire distribution system.

The residual ozone and proof of ozone

decomposition is monitored with

calibrated electrochemical on- line

sensors.

XII. System Materials and

Finishes Considerations

Piping Systems

Material

- Stainless Steel 316 L.

- Seemless or drawn tube may be used.

- Tube mill finished 2B internally + mechanically polished

as part of tube manufacturing process.

- Electropolish improves finish and surface corrosion

resistance.

Insulation

- Pipework insulated with chloride free materrials. In

process areas, Insulation needs to be hygienic finish

Drainability if required

- Valve configuration

- Slope

MATERIALS SELECTION S

Corrosion minimisation and resistance

Avoidance of leachates from contact

materials

Avoidance of the development and

adherennce of bio-films

Avoidance of adhesion and retention of

contaminants and cleaning/disinfecting

residues

Aesthetically appropriate appearance

Inspectability of surfaces

Ability to joint materials

Tube and Fittings Materials of

Construction

Product contact

- 300 series SS (304,304L, 316, 316L)

- Hastelloy

- AL 6XN

- Monel, titanium, Inconel etc.

AUSTENITIC STAINLESS STEEL

COMPOSITION

Composition % 304 316L

Carbon (max) 0.08 0.03

Chromium 18.5 17.0

Nickel 9.5 13.0

Molybdenum 0 2.25

Piping system

PLASTICS PIPELINE MATERIALS

PEEK Poly-ether-etherketone

PVDF Polyvinylidenedifluoride

PFA Perfluoroalkoxy

PP Polypropylene

ABS Acrylonitrile-butadiene styrene

PVC Polyvinyl chloride

- peek>20Xcost of PVC

- main value in Microelectronics

Common Specification for non-

compendial Ultra-pure Water

This specification now being demanded

for critical analytical tasks where trace

contaminants may obscure the test

targets

Inorganics 10-15 megOhm-cm

Organics < 50 ppb TOC

Particulate < 0.2

Bacteria < 10 cfu/ml

PLASTICS PIPELINE MATERIALS

for non-compendial Ultra-pure Water

PVDF Polyvinylidenedifluoride

PP Polypropylene

The following will not satisfy the

likely microbiological control limits

ABS Acrylonitrile-butadiene-

styrene

PVC Polyvinyl chloride

EXAMPLES OF APPROVED

CONTACT MATERIALS

Pure gum rubber

Black butyl rubber

Teflon PTFE

EPDM

Buna N

White butyl rubber

Silicon rubber

Surface Finishes applied to

Stainless Steel

BS Finish

reference

Typical Ra

m

General Description

0

1

n/8

5.0

Hot roll, softened, not descaled

Hot roll, soffened, descaled

2D 0.5 Cold roll, softened, descaled

2B 0.275 Cold roll, softened, descaled,+

Roll on pollshed rollers

2A 0.088 Bright annealed

3A 1.5 Ground Brush,

4 0.8 Polished with fine grit

8 - Mirror polish

SURFACE FINISH

THE EFFECT OF ELECTROPOLISHING

A highly reflective finish can be obtained with

an R

a

Value < 0.02m

Starting surface is critical to quality achieved be

electropolishing. 2A or 2B cold rolled is

appropriate.

Used to be an essential specification in the dairy

industry. Now not so frequent as CIP Systems

and Chemicals improve.

Electropolishing diminishes the passive layer.

This must be restored to retain corrosion

resistance.

Installation QA Tasks

Materials certificated from supplier

Materials and equipment controlled at job site

Documented

Clean

In correct condition e.g. clean & dry

plant items.

Dispensed for installation.

Clean Installation protocol

Installation QA Tasks

Weld Log

Operator

Qualification

Checks/Certification

Equipment

Reference

Settings

Maintenance

Samples

Weld i/d

Installation QA Tasks

Installation Records

Specifications

Drawings

Components

Change control records

Installation QA Tasks

Inspection

Visual - Boroscope

Photograph

Samples

X-ray

Retained Samples

XIII. Commissioning and Validation

Commissioning Overview

Take equipment from installation to

operation

Incorporate a systematic method of testing

and documentation

Proper commissioning tests and

documentation satisfy many IQ/OQ

requirements

Differences between Commissioning

and Validation (1)

Commissioning Supplier

Responsibility

Validation User

Responsibility

Objective is to identify and

rectify problems

Demonstrate process is

as specified and under

control

Approved protocol not

required; link to validation

Must follow an

approved protocol

Typically operated by

supplier

Owned & operated by

user

Differences between Commissioning

and Validation (2)

Commissioning Validation

Not all data and

adjustments are

recorded & reviewed

All data & adjustments

must be

recorded/reviewed

No written report unless

specified

Written report is required

Reviewed for acceptance

by engineering/project

team

Reviewed and approved

by Quality Assurance

Commissioning Documents (1)

Generated by team

Vendors

Engineering firm

Construction contractors

Owner

GEP requirements

Timely Accessible

Witnessed Authorised

Commissioning Documents (2)

Lists :

Equipment (id; manufacturer; model.)

Piping (segment id; type; size & finish)

Valves (id; location; type size & finish)

Instruments (id; location; type , purpose,

critical/non-critical, range & calibration date)

Controllers and alarms

Filters (id; location; type; size; construction;

manufacturer; model & pore size)

Commissioning Documents (3)

Lists :

Process & utility connections.

System name

Supply pressure

Flow rate

Temperature

Electrical requirements

Materials of construction for product contact

Spare parts

SOPs (operation, maintenance, calibration,

monitoring)

Commissioning Documents (4)

Factory Testing Documents :

Equipment test procedures

Pressure tests

Safety checks

Calibration procedures & data sheets

PLC/PC testing

Sequence of operation testing

Commissioning Documents (5)

Weld Documentation :

Weld isometrics

Welder certification/qualification

Equipment certification

Weld inspection (logs, tapes, coupon id and

storage records)

Weld Procedures

Commissioning Documents (6)

Calibration Documentation :

Critical/non-critical instrument list

Critical instruments must be calibrated via

traceable methods before OQ

Non-critical instruments typically calibrated

prior to OQ

Calibration frequency of critical and non-

critical instruments may vary

Standard Operating Procedures

Should be drafted early as possible

Should include :

start-up/shut-down (normal/emergency)

sanitisation/cleaning

operation (including log)

sampling/testing

specific procedures

chemical addition, etc.

Commissioning Requirements (1)

Prepare equipment for operation

Start and verify operation of each component

Verify whole system

Use draft SOPs for start-up

Establish operation log

Commissioning Requirements (2)

Record actual system parameters and ranges

Perform statistical review if possible

Establish alert levels

Establish action levels

Review system readiness for balance of

OQ/PQ testing

Validation Overview

System Design (pre-validation)

Installation Qualification

Operational Qualification

Performance Qualification

Change Control

Regular Review (Annual system review)

This presentation will not deal with all the

normal validation steps. BUT PQ is special for

water systems

(Installation Qualification for Purified Water)

1.

1.1 Non-Return (Foot Valve)

1.2 Lowara CA200/35 3 2

1.3 UPVC 1

1.4 Non-Return

1.5 Power Supply 3 PH/ 380 V/ 50 Hz

2. 200

2.1 1

2.2 1

2.3

2.4

2.5 100

3. Ametek 20 /30

2

3.1 3/4

3.2 3/4

4. 38x120 .

4.1 Multiport Autotrol 180/450

4.2 1

4.3 1

4.4

4.5 POWER SUPPLY 220 V

4.6 SAMPLING VALVE

5. S 37B

5.1 1

5.2 1

5.3 POWER SUPPLY 220 V

5.4 UV-MONITOR

-

-

6. REVERSE OSMOSIS 1500 L/Hr

6.1 1

6.2 3/4

6.3

6.4 ANTISCSLE / PE 100 / Chemical Pump

6.5 Power Supple 3 PH / 380 V / 50 Hz

6.6 VERTICAL MULTISTAGE PUMP 4

6.7 VESSEL FIBERGLASS 3 SETS + MEMBRANE 6 SETS

6.8 PRODUCT FLOWMETER

6.9 CONCENTRATE FLOWMETER

6.10 RECYCLE FLOWMETER

6.11 Controller ROF 900E

7. RO. 3,000

7.1 1 /

7.2 1 /

7.3 Manhole 18

7.4 VENT FILTER

8. 4HMS5 0.75 Mixed Bed 2

8.1 1

8.2 1

8.3 POWER SUPPLY 1 PH / 220 V / 50 Hz

8.4 Non-Return Valve

9. 38x185 .

9.1 - 1

9.2 PLASTIC DIAPHRAGM VAVE 1 8 / 1/2 6

9.3 STAGER CONTROLLER 1

9.4 AIR COMPRESSOR 1

9.5 SIGHT GLASS 2

9.6 1

9.7 SAMPLING VALVE

9.8 NaOH 50% TANK (PE)

9.9 EJECTOR () NaOH

9.10 HCI 35% TANK (PE)

9.11 EJECTOR () HCI

9.12 2,500

9.12.1 CHEMICAL PUMP Prominent ConB 1601 PP1

9.12.2 INLET / OUTLET

9.12.3 CHEMICAL PUMP Prominent ConB 1601 PP1

9.12.4 INLET / OUTLET

9.13 PH CONTROLLER HANNA HI981411-1

9.14 Lowara DOMO7 0.75

9.15 1

9.16 1

10. 20 / 5 1 / 1 1

10.1 1

10.2 1

11. LM-1

11.1 POWER SUPPLY 220 V 50 Hz

11.2 ELECTRODE SO-1 C=0.1

12. Sanitron S 50B

12.1 1 1/2

12.2 1 1/2

12.3 POWER SUPPLY 220 V

12.4 UV-MONITOR

-

-

13. 6,000

13.1 1 1/2 / 1 1/2

13.2 /

13.3 Solenoid Valve

13.4 Manhole 18

13.5 VENT FILTER

14. 2 INOXPA EFI 2340

14.1 1 1/2 (Sanitary Type)

14.2 1 (Sanitary Yype)

14.3 Non-Return Valve

14.4 POWER SUPPLY 3 Phase/380 V/50 Hz

14.5

15. 3 1 / 0.45 / 0.2

15.1 100

15.2 1

15.3 1

16. Sanitron S 50B

16.1 1 1/2

16.2 1 1/2

16.3 POWER SUPPLY 220 V

16.4 UV-MONITOR

-

-

17. CD 15/AD 4.5 /

17.1 AIR FLOW METER

17.2

17.3

17.4 INJECTOR MANIFOLD

17.5 STATIC MIXER

17.6

17.7 POWER SUPPLY 220 V / 50 Hz / 1.52 A

18. 1,500

18.1 1 / 1

18.2 /

18.3 Manhole 18

18.4 VENT FILTER

19. 2 INOXPA EFI 2340

19.1 1 1/2 (Sanitary Type)

19.2 1 (Sanitary Yype)

19.3 Non-Return Valve

19.4 POWER SUPPLY 3 Phase/380 V/50 Hz

19.5

20. 3 1 / 0.45 / 0.2

20.1 100

20.2 1

20.3 1

21. Sanitron S 37B

21.1 1

21.2 1

21.3 POWER SUPPLY 220 V

21.4 UV-MONITOR

-

-

22. M 15/AD 2.8 /

22.1 AIR FLOW METER

22.2

22.3

22.4 INJECTOR MANIFOLD

22.5 STATIC MIXER

22.6

22.7 POWER SUPPLY 220 V / 50 Hz / 1.52 A

23. 316L ( TEST )

Operation Qualification Purified Water

1. (1.1) 2 1 ..

2. 40 80 PSI ..

3. 30 (1.2) ..

4. Activated Carbon (1.3)

- Backwash ..

- Backwash ..

5. (1.4)

..

6. REVERSE OSMOSIS (1.5)

- Anti-Scale Feed 1 ..

- Inlet Pressure > 20 PSI Pre-Filter ..

- Low Pressure Switch

High Pressure Switch ..

- Pressure Drop Pre-Filter RO < 5 PSI ..

- Pressure Pre-Filter > 20 PSI ..

- Membrane Pressure 130 250 PSI ..

- Product > 1,500 ..

- > 500 ..

- Circulate > 1,000 ..

- Automatic Flushing 24 ..

Flush

- Flush 3 ..

- Test Flush Conductivity ..

- Flush

..

- Conductivity

20 ....

- Concentrate ..

- Solenoid UV (1.4)

RO ..

7. (1.6) , (1.19) (1.12)

- ..

- ..

- ..

8. (17.) , (1.20) (1.12)

1 ..

9. Mixed Bed Stager

- Step Stager ..

- HCI (35%) ..

- NaOH (25%) ..

- Air Compresser ..

-

1 ..

- Test Solenoik Valve ..

Mixed Bed (1.8) Filter (1.9)

Conductivity Meter

( Conductivity 1 )

10. (1.11) , (1.17) ..

(1.24)

11. Test Ozone (1.25) , (1.18) ..

- Test Injector

() ..

12. Loop

2 Bars ..

Pressure Tank

(1.1) ( )

Activated Carbon

(Cl

2

) (ppm.) ---> ( 0.1 ppm.)

RO Pre-Filter (1.2)

Filter RO RO

Pre-Filter Membrane Flow (L/Hr)

Product Concentrate Circulate

Conductivity

(Microsiemens)

O3 (ppm)

pH value

TOC (ppb)

(CFU/ml)

Conductivity ()/

0

C

4 3 2 1 ................

(Installation Qualification for Water for Injection)

1. 500

1.1

1.2 FEED GRUNFOS CRN2-70

1.3

1.4 SENSOR

1.4.1 SENSOR , CONDUCTIVITY Loop 1

1.4.2 SENSOR 1

1.4.3 SENSOR , CONDUCTIVITY Loop 2

1.4.4 SENSOR 2

1.4.5 LEVEL SENSOR 1

1.4.6 LEVEL SENSOR 2

1.4.7 DI (1.12)

1.5 CONTROL PANEL

1.6

2. 4,000 (2.4)

2.1 6 KW 2

2.2 2 HP /3 PHASE

2.3 VENT FILTER

2.4 LEVEL PROBE

2.5 CIRCULATE

1 Self drain Dead leg Diaphragm

3. 1,500

3.1 6 KW 1

3.2 2 HP/3 PHASE

3.3 VENT FILTER

3.4 LEVEL PROBE

3.5 CIRCULATE

1 Self drain Dead leg Diaphragm

4. COOLING TOWER 40

4.1 1

4.2 380 V/50 Hz

4.3 PUMP CIRCULATE COOLING 380 V / 50 Hz

4.4 CIRCULATE COOLING

CONDENSOR BY-PASS VALVE

5. DRAIN ,

6. STEAM BOILER

6.1 FEED

6.2 FEED Anti-Corrosion

6.3 500 Kg / Hr

6.3.1 3

6.3.2 VENT VALVE

6.3.3 SAFETY VALVE

6.3.4 DRAIN

6.3.5 PRESSURE GAUGE 200 PSI

6.4 HEADER

6.4.1 SAFETY VALVE

6.4.2 PRESSURE GAUGE 200 PSI

6.4.3 STEAM TRAP

6.5 500

6.5.1

6.6

6.7 380 V / 50 Hz / 3 PH

7. STEAM

Operation Qualification Water For Injection

1. Boiler (2.2)

- Pressure 3-6 Bars .

- .

- .

2. (2.2)

- Feed .

- 80-98 .

- Conductivity < 1 .

- > 500 .

- 2 .

- Probe .

- Probe Loop 1 .

- Probe Loop 2 .

- Probe Conductivity

Loop 1 .

- Probe Conductivity

Loop 2 .

- Probe Loop 1 .

- Probe Loop 2 .

- Heated Vent (2.4) .

- Filter 100-120 .

- Heated Vent (2.7) .

- Filter 100-110 .

- Test Heater (2.4) .

- Test Heater (2.7) .

- Test 2.5 2.8

Loop 1 2 Bars Bars

- Cooing Tower

Condensor .

- Cooling Tower .

- Steam Generator

1) 1 Bar .

2) 3 Bars .

Water for Injection System Records

- ................................

- Conductivity < 1

- 100 CFU/ml

- TOC (ppb) at

0

C

- SIP ....................

................ 1 2 3 4

Conductivity ()

(CFU/ml)

TOC (ppb)

pH value

Performance Qualification

Activity expected by Regulator (but perform

for Company!)

Documented verification of proper system

operation in meeting predetermined

acceptance criteria

Follows IQ and OQ execution and resolution

of all critical deviations

Documentation Required to Write PQ

P & ID

User Requirement Specification

Pertinent regulations, guidelines and owner

specifications

Proven SOPs in place

PQ Sampling Program Objectives

Phase 1-- typical duration 2-4 weeks

Develop appropriate operating ranges

Develop and finalise operating, cleaning and

maintenance procedures

Demonstrate production and delivery of

product water of the required quality

PQ Sampling Program Objectives --

Phase 1 (Slide 1)

Sample after each step in treatment process

Sample at each point of use

Sample incoming feed water -- verify feed

water quality

FDA Water Guide suggests daily sampling --

alternate may be acceptable

PQ Sampling Program Objectives --

Phase 1 (Slide 2)

Chemistry testing specific to unit process

Microbiological testing for each unit process

At completion SOPs for operation,

maintenance and trouble shooting finalised

PQ Sampling Program Objectives --

Phase 1 (Slide 3)

Alarm response/action levels verified

Test failure process developed

Is failure localised? (specific port)

Define handling of different failure types

PQ Sampling Program Objectives

Phase 2

Typical duration 2-4 weeks

Demonstrate consistent operation within

established ranges

Demonstrate consistent production and

delivery of water of the required quality when

system operated to SOPs

Sampling scheme / duration same as Phase 1

PQ Sampling Program Objectives

Phase 3

Typical duration one year

Demonstrate extended performance

Ensure that potential seasonal variations are

evaluated and treated

Sample locations, frequencies and tests based

on established procedures

Change Control (1)

Assess potential impact of change

Determine required actions testing,

documentation changes and conditions for use

Provide audit trail for changes, testing and

approval

Change Control (2)

During design and construction -- GEP

During commissioning/validation -- eliminate

unnecessary signatures

Post-validation minor changes

use ongoing data

use Quality Assurance Assessment

Revalidation

Appropriate for major system changes

Determined via change control process

Periodic revalidation is not required

Perform regular review

Validation Summary (1)

Integrated approach

Document hierarchy clarifies document

purpose/relationship

Effective commissioning satisfies many

validation test requirements

Prepares the way for effective maintenance

and trouble shooting

Validation Summary (2)

Sampling program tailored to particular system

Change control methods may change during

project life cycle

Periodic revalidation not required

V-Model

User Requirement

(i.e. What)

Performance

Qualification

PQ Test Plan

Functional Design

(i.e. How as Schematic)

Operational

Qualification

OQ Test Plan

Design

Development

Detail Design

(i.e. How to make)

IQ Test

Installation

Qualification

Impact Assessment

Implementation

XIV. System Maintenance and

Troubleshooting

A natural progression from System Design &

Validation

Good design/validation

+ defined maintenance

= Few troubles

Need Troubleshooting strategy

System Maintenance and

Troubleshooting

No sytem 100 % reliable

Expect occasional quality problems

and mechanical failures

Plan a controlled response to the

unexpected

System for Troubleshooting

Know and understand your sytem

Consider Maintenance and

Troubleshooting at design/validation

stage

Develop standard approach to

Troubleshooting

Follow plan, avoid panic or short cuts

Know Your System

Understand contribution and operation of

each component and system parameters

How it works

Normal parameters

Sensitivity to change

Maintenance requirements

Troubleshooting Procedure

Methodical, no panic

Collect evidence

samples

Instrument readings

Compare with reference (validation) values

Identify source of problem

Take remedial action

Review, document, learning

Importance of Monitoring

Maintain product quality

Maintain equipment

Protect investment

Detect changes in incoming water

Maximise run time

Minimise service time

Historical tracking

Stringent Change Control

Factors to Consider (1)

Feed water quality

Change in supply

Sudden variations

Temperature

Seasonal

Adverse weather (floods, drought)

Monitor and trend quality of feed water

quarterly

Feed Water Parameters

Total dissolved solids (conductivity)

pH

Chlorine

Density index

Total Organic Carbon

Site specific contaminants silica, iron

Factors to Consider (2)

Final product water quality & quantily

Chemical attributes

Microbiological profile

Endotoxin content

Volume produced

Perform trending and address trends early

(Detailed monitoring programme, monthly

trending, annual review)

Final Water Quality/Quantity

Parameters

Flow rate

Conductivity

TOC

Microbial Count

Endotoxin level

Specific contaminants

Factors to Consider (3)

Equipment Considerations

Unit process

(ie individual component performance)

Maintenance history

Change Control

Parts

Feed water changes

Product water changes

Unit Process Monitoring

General Considerations

Understand individual components

Document current setting/ readings

Compare with original (validated)

Check maintenance requirements met

Review documented changes

Purified Water System validation

- Pressure Tank ..................................

- Pre-Filter (1.2) ..........................

- Pre-Filter RO System ..........................

- Membrane RO System .......................

- Reverse Osmosis > 1,500 /

Conductivity 20

- Deionizer Mixed Bed Conductivity

Dei 1 2 1

- Deionizer Mixed Bed .3,000 /

- Filter 1.21, 1.22, 1.23, 1.14, 1.15 1.16 .......................

- Dei Circulate Loop Conductivity < 1

............

- CIP 100 CFU/ml ..................

- TOC < 500 ppb.

1)

400C

2) PRESSIRE GAUGE

() PRESSURE GAUGE

30-60 PSI () DRAIN

()

3)

6

4) ACTIVATED CARBON

(BACK WASH)

5) UV-MONITOR

0.4-10 () 0.4 ()

UV

QUARZT (WIPER) 2-3 DRAIN

DRAIN

6) REVERSE OSMOSIS PLC

AUTO FLUSHING FLUSH CONDU CTIVITY

FLUSH FLOW METER PRESSURE GAUGE

7) MIXED BED RESIN

(REGENERATE) 1 1

-

8) -

- -

-

- Carbon Filter

- Ozone, Conductivity DI

- Conductivity Mixed bed

- UV UV

- RO Pre-Filter Membrane

Product,

Circulate

- - Mixed Bed

-

-

- Anti-Scale Anti-Scale RO

-

NOTE : - Carbon Filter .......... ppm.

- ............ ppm.

- Conductivity Mixed Bed 1

- UV

-

References:

1) FDA,Guide to inspection of High Purity Water System July 1993

2) ISPE Baseline Pharmaceutical Engineering Guide, and Water and

Steam System

3) ISPE Baseline Pharmaceutical Water System

4) USP 28: 2005

5) BP 2002 ,Volume 1 and 2

6) Ph.Eur 4

th

,Edition

7) Gordon Farquharson: Pharmaceutical Grade Water Basis

8) Robert Chew : Commissioning and Qualification of Water

9) Antony Margetts: Validation Concept

You might also like

- From Start To Finish: Pharmaceutical Grade WaterDocument6 pagesFrom Start To Finish: Pharmaceutical Grade Watervenki_bee100% (1)

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Curto Regulatory Requirements Water SystemDocument40 pagesCurto Regulatory Requirements Water SystemAhmed Hamdy100% (1)

- Leachables and Extractables Handbook: Safety Evaluation, Qualification, and Best Practices Applied to Inhalation Drug ProductsFrom EverandLeachables and Extractables Handbook: Safety Evaluation, Qualification, and Best Practices Applied to Inhalation Drug ProductsDouglas J. BallNo ratings yet

- Analytical Methods for Drinking Water: Advances in Sampling and AnalysisFrom EverandAnalytical Methods for Drinking Water: Advances in Sampling and AnalysisNo ratings yet

- Engineering Processes for BioseparationsFrom EverandEngineering Processes for BioseparationsLAURENCE R. WEATHERLEYRating: 4 out of 5 stars4/5 (1)

- Pharmceutical Production WaterDocument16 pagesPharmceutical Production Waterthanhquang10010% (1)

- Lyophilization Competence06!11!2014 Tcm11 17173Document16 pagesLyophilization Competence06!11!2014 Tcm11 17173JPensacolaNo ratings yet

- Engineering Handbook: Steam Sterilization in PlaceDocument7 pagesEngineering Handbook: Steam Sterilization in PlaceVishal MistryNo ratings yet

- WP Pharma PureSteam CIP en 58087042 Mar15Document8 pagesWP Pharma PureSteam CIP en 58087042 Mar15itung23No ratings yet

- Schedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumDocument77 pagesSchedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumVivek PanchabhaiNo ratings yet

- Annex2 Who GMP Water For PharmaceuticalDocument23 pagesAnnex2 Who GMP Water For Pharmaceuticalpamy26250No ratings yet

- 2.PV Semisolid Fda PDFDocument37 pages2.PV Semisolid Fda PDFYuli SukmawatiNo ratings yet

- ECA Granulation TabletingDocument6 pagesECA Granulation Tabletingvaibhav rautNo ratings yet

- 3.1.4 Stilmas Multi-Effect StillsDocument2 pages3.1.4 Stilmas Multi-Effect StillsCastoriadisNo ratings yet

- 3.0 & 4.0 Basic Understanding of E&L - Addressing The Reg & Quality - JenDocument81 pages3.0 & 4.0 Basic Understanding of E&L - Addressing The Reg & Quality - JenKunalNo ratings yet

- Cleaning Validation Practices Using A Single Pot ProcessorDocument9 pagesCleaning Validation Practices Using A Single Pot Processorjljimenez1969No ratings yet

- Annex 2: WHO Good Manufacturing Practices: Water For Pharmaceutical UseDocument23 pagesAnnex 2: WHO Good Manufacturing Practices: Water For Pharmaceutical UsesakuraNo ratings yet

- Gea - STD Single Use Cip Sys - CipdDocument6 pagesGea - STD Single Use Cip Sys - CipdTBNo ratings yet

- Who TRS 970 Anexo 2 PDFDocument23 pagesWho TRS 970 Anexo 2 PDFAnonymous guhSjjNWdP100% (1)

- Compressed Gases in Pharmaceutical FacilitiesDocument7 pagesCompressed Gases in Pharmaceutical Facilitiesraju1559405No ratings yet

- Lyophilization of Parenterals FinalDocument25 pagesLyophilization of Parenterals FinalMostofa RubalNo ratings yet

- Application Note: Successful Wetting For Filter Integrity Testing in Volume-Restricted SystemsDocument13 pagesApplication Note: Successful Wetting For Filter Integrity Testing in Volume-Restricted SystemsSlavaNo ratings yet

- Water Treatment System (Sistem Pengolahan Air Spa)Document38 pagesWater Treatment System (Sistem Pengolahan Air Spa)Tjen MolynaNo ratings yet

- Comprehensive Quality by Design for Pharmaceutical Product Development and ManufactureFrom EverandComprehensive Quality by Design for Pharmaceutical Product Development and ManufactureGintaras V. ReklaitisNo ratings yet

- Extractables and Leachables Testing Services - Vimta Labs Ltd.Document10 pagesExtractables and Leachables Testing Services - Vimta Labs Ltd.Vimta Labs LtdNo ratings yet

- Sterile Filtration-Filter-Integrity-Test-TailinDocument15 pagesSterile Filtration-Filter-Integrity-Test-Tailinnawazash100% (1)

- Line Lubricant TestingDocument5 pagesLine Lubricant TestingPiyalarp LudeelerdNo ratings yet

- Seminar - IsPE Roughing in Pharmaceutical WaterDocument43 pagesSeminar - IsPE Roughing in Pharmaceutical WaterMohammad Fariz ikhsan100% (1)

- Production of Plasma Proteins for Therapeutic UseFrom EverandProduction of Plasma Proteins for Therapeutic UseRating: 3 out of 5 stars3/5 (5)

- Pilotplantscaleuptechniquesusedinpharmaceuticalmanufacturing 131002222820 Phpapp02Document73 pagesPilotplantscaleuptechniquesusedinpharmaceuticalmanufacturing 131002222820 Phpapp02Gautam SharmaNo ratings yet

- Complete Magnetic Filtration Mini-CatalogDocument19 pagesComplete Magnetic Filtration Mini-Catalog15 FFNo ratings yet

- Cobetter Lab Catalog 2017 PDFDocument51 pagesCobetter Lab Catalog 2017 PDFYilun LiuNo ratings yet

- Homo Mixer, View Homo Mixer, Ding Xin Product Details From Wuhan Dingxin Mechanical & Electric Equipment Co., Ltd. On Alibaba PDFDocument5 pagesHomo Mixer, View Homo Mixer, Ding Xin Product Details From Wuhan Dingxin Mechanical & Electric Equipment Co., Ltd. On Alibaba PDFtahera aqeelNo ratings yet

- Headspace Oxygen Measurement in Vials and AmpoulesDocument4 pagesHeadspace Oxygen Measurement in Vials and AmpoulesGhanta Ranjith KumarNo ratings yet

- Portfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesFrom EverandPortfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesPete HarpumNo ratings yet

- Media Fill Indicador de ColorDocument6 pagesMedia Fill Indicador de Colorsteven correaNo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)