Professional Documents

Culture Documents

Wind Calculation Sheet

Uploaded by

aauppalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wind Calculation Sheet

Uploaded by

aauppalCopyright:

Available Formats

72" Flare Stack - B3 U&O Package Reference / Remarks

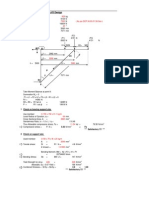

Vessel Geomatry

Vessel Diameter D = 1.83 m

Effective Diameter De = 2.56 m Piping without ladders (1.4*D)

Projected Area Af = 5.16 m2

Vessel Height h = 187.00 m

Vessel thickness t = 16.00 mm

Vessel mean radius Rm = 1814.00 mm

Ratios check Rm/t = 113.38 mm (if > 200, wind anaylsis is required)

h/D = 102.19 (if > 15 , wind anaylsis is required)

Stud Bolt / Nut Material High Strength Low Alloy Steel (ASTM A 193 Grade B7 / A 194 Gr. 2H)

Modulus of Elasticity Eb = 8.00E+02 Mpa ASME BPVC Sec II, Part D, Table TM-1

Poisson's Ratio b = 0.3 ASME BPVC Sec II, Part D, Table PRD

Yield Strength yb = 500 Mpa ASME BPVC Sec II, Part D, Table 1-A

Design Conditions

Basic Wind Speed Vbasic = 160 km/hr

Wind Speed converted to ft/sec. V = 145.81 ft/sec

Design Pressure P = 250 Mpa

Design Temperature T = 100 C

Allowable Stress for vessel material at design temperature S = 20000 Mpa ASME BPVC Sec II, Part D, Table 1-A

Allowable Stress for bolt material at design temperature Sb = 23000 Mpa ASME BPVC Sec II, Part D, Table 1-A

Allowable Stress for bolt material at atm. Temperature Sa = 23000 Mpa ASME BPVC Sec II, Part D, Table 1-A

Time Period Calculation

Weight, uniform w = 1000 kg/m

Modulus of Elasticity for shell material at design temperature E = 2.02E+11 Pa ASME BPVC Sec II, Part D, Table TM-1

Modulus of Elasticity for shell material at room temperature E = 2.02E+11 Pa ASME BPVC Sec II, Part D, Table TM-1

Moment of Inertia for shell area 3.14*(D/2)

3

*t I = 0.0385 m

4

Factor for first mode of vibration K = 1.79

Period of Vibration K(wh

4

/EI) T = 22.44 sec

Frequency of vibration f = 0.0446 Hz

Wind Force Calculation

Structual category III (Structures cotaining toxic or explosive substances)

Importance Factor I = 1.15 (Based on Structual category III)

Exposure Category C Open terrain with scattered obstructions

Gust Factor G = 0.85 (Based on Exposure category C)

Gust Response Factor (flexible vessels) Gf =

Equivalent height 'z' of vessel z = m

Intensity of turbulence at height 'z' Iz =

Velocity pressure coefficient at height 'z' Kz =

Topographic factor KzT = 1 Vessel is not located near or on an isolated hill

Mean hourly speed at height 'z' Vz = 1 ft/sec

Velocity pressure at height 'z' 0.0256KzKzTV

2

I qz = psf (1/2*(air density)*V

2

*I) = qz (when V in ft/sec)

Minimum design height zmin = m

Period of vibration T = sec

Fundamental natural frequency f = Hz

Background response Q =

Coefficient or Calculation Factors

Resonance response factor R =

Structure damping coefficient = 0.005 (0.005 for vessel on rock or pile foundation & 0.015 for vessel on soft soil or inside structure)

Coefficient factors = (Table 3-3 of D.R. Moss)

b = (Table 3-3 of D.R. Moss)

c = (Table 3-3 of D.R. Moss)

I = (Table 3-3 of D.R. Moss)

= (Table 3-3 of D.R. Moss)

Calculation factors Ni =

Nh =

Nb =

Nd =

Rh =

Rb =

Rd =

=

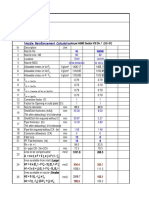

Gasket Type & Dimensions

Gasket Type & Material Spiral Wound Gasket (Stainless Steel, 304) with inner & outer ring

Basic gasket seating width b0 = 1 in. ASME Sec VIII, Div. 1, Appendix 2, Table 2-5.2

Conversion Factor Cb = 0.5 ASME Sec VIII, Div. 1, Appendix 2

Effective gasket seating width b = 0.500 in. ASME Sec VIII, Div. 1, Appendix 2, table 2-5.2

Mean diameter of gasket contact face = 67 in.

Outside diameter of gasket contact face = 68 in.

Diameter at location of gasket load reaction G = 67.00 in. ASME Sec VIII, Div. 1, Appendix 2

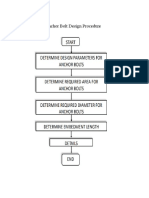

Design of Pressure Vessels under Wind Load in accordance with ASCE - 07

Min. gasket seating stress (SWG, Stainless steel) y = 10000 psi ASME Sec VIII, Div. 1, Appendix 2, Table 2-5.1

Gasket factor m = 3 ASME Sec VIII, Div. 1, Appendix 2, Table 2-5.1

Bolting Dimensions

Nominal stud bolt diameter a = 1.125 in.

Root diameter of thread ar = 1.1 in.

Cross sectional area at root of thread Ab = 0.95 in

2

.

Number of bolts = 56

Bolt Spacing Bs = 0.00 in. ASME Sec VIII, Div. 1, Appendix 2

Maximum Bolt spacing

Bsmax 2a+ [6t/(m+0.5)] = 2.25 in. ASME Sec VIII, Div. 1, Appendix 2

Loads Acting on Flange

Total hydrstatic end force H 0.785G

2

P = 563818 lbs. ASME Sec VIII, Div. 1, Appendix 2

Hydrostatic end force action on area inside of flange HD

0.785B

2

P = 0.00314 lbs. ASME Sec VIII, Div. 1, Appendix 2

Difference between two hydrostatic end forces HT H-HD = 563818 lbs. ASME Sec VIII, Div. 1, Appendix 2

Gasket Load HG W-H = 425716 lbs. ASME Sec VIII, Div. 1, Appendix 2

Total Joint contact surface compression load HP 2bx3.14GmP = 100982 lbs. ASME Sec VIII, Div. 1, Appendix 2

Minimum required bolt load for operating conditions Wm1 H+HP = 664801 lbs. ASME Sec VIII, Div. 1, Appendix 2

Minimum required bolt load for gasket seating conditions Wm2 3.14bGy = 1051900 lbs. ASME Sec VIII, Div. 1, Appendix 2

Flange design bolt load W = 989535 lbs.

Design of Bolting

Required bolt area for operating conditions Am1 Wm1 / Sb = 29 in

2

. ASME Sec VIII, Div. 1, Appendix 2

Required bolt area for gasket seating Am2 Wm2 / Sa = 46 in

2

. ASME Sec VIII, Div. 1, Appendix 2

Required bolt area Am = 46 in

2

. Greater of Am1 & Am2

Available bolt area Ab = 53.22 in

2

. Bolt cross section area x No. of bolts

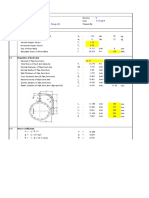

Flange Moments

Moment arm for HG hG (C-G)/2 = -33.5000 in. ASME Sec VIII, Div. 1, Appendix 2

Moment arm for HT hT (R+g1+hG)/2 = -16.7513 in. ASME Sec VIII, Div. 1, Appendix 2

Moment arm for HD hD R+0.5g1 = -0.0025 in. ASME Sec VIII, Div. 1, Appendix 2

Component of moment due to HG MG HGhG = -14261502 lb-in ASME Sec VIII, Div. 1, Appendix 2

Component of moment due to HT MT HThT = -9444663 lb-in ASME Sec VIII, Div. 1, Appendix 2

Component of moment due to HD MD HDhD = -0.00000785 lb-in ASME Sec VIII, Div. 1, Appendix 2

Total Flange moment for operating conditions M1 Sum = -23706165 lb-in ASME Sec VIII, Div. 1, Appendix 2

Total moment for gasket seating conditions M2 W(C-G)/2 = -38121831 lb-in ASME Sec VIII, Div. 1, Appendix 2

Total Flange Moment Mo = -23706165 lb-in Greater of M1 & M2

Flange Geomatry Parameters

(Following factors found using Figures 2-7.1, 2-7.2, 2-7.3 & 2-7.3 of Appendix 2* ) (Following factors calculated using formulae, Article 2-3 of Appendix 2*)

F = 0.865 d = (U/V).h0g0

2

0.00

f = 1.1 e = (F/h0) #DIV/0!

T = 1.84 L = (te+1)/T+t

3

/d #DIV/0!

U = 9 K = A/B 0.00

V = 0.32 tx = 2g0 0.00

Y = 7.6 h0 = sqrt(Bg0) 0.00 in.

Z = 4 B1 = (B+g1) 0.01 in.

R = (C-B-2g1)/2 0.00 in.

h/h0 #DIV/0!

* Appendix 2 of ASME Sec VIII, Div. 1 g1/g0 #DIV/0!

Flange Stresses & Allowable Flange Design Stresses

Result

(ASME Sec VIII, Div. 1, Appendix 2, Article 2-7) (ASME Sec VIII, Div. 1, Appendix 2, Article 2-8)

Longitudinal Hub Stress SH fMo/Lg1

2

B = #DIV/0! psi SH < 1.5 Sf 30000 #DIV/0!

Radial Flange Stress SR (1.33te+1)Mo/Lt

2

B = #DIV/0! psi SR < Sf 20000 #DIV/0!

Tangential Flange Stress ST YMo/t

2

B -ZSR = #DIV/0! psi ST < Sf 20000 #DIV/0!

(SH + SR)/2 = #DIV/0! (SH + SR)/2 < Sf 20000 #DIV/0!

(SH + ST)/2 = #DIV/0! (SH + ST)/2 < Sf 20000 #DIV/0!

Flange Stresses Allowable Design Stresses

FEM Results

Analysis 1 Analysis 2

Longitudinal Hub

Stress (psi) 26904

Radial Flange Stress

(psi) 13047

Tangential Flange

Stress (psi) 5128

Combined Stress (S

H

+ S

R

)/2

19976 0 0

Combined Stress (S

H

+ S

T

)/2

16016 0 0

ASME BPVC

Calculations

4000

4500

5000

5500

Analysis 1 Analysis 2

ASME BPVC

Calculations

FEM Results

Tangential Flange Stress (psi)

Analysis 1

30000

Primary General

Membrane

P

m

10820

20000

Primary Bending P

b

11600

20000

Membrane + Bending Q 15870

20000

Total (including Peak) F 28920

20000

FEM Results

Allowable

Design Stress

Stress Category

12000

12500

13000

13500

Analysis 1 Analysis 2

ASME BPVC Calculations FEM Results

Radial Flange Stress (psi)

Analysis 2

10410 S

f

20000 Safe

12020 1.5S

f

30000 Safe

14300 1.5S

f

30000 Safe

24470 2S

f

40000 Safe

FEM Results

Stress Limit

Allowable Design

Stress (psi)

Result

25000

25500

26000

26500

27000

Analysis 1

ASME BPVC Calculations

Longitudinal Hub Stress (psi)

Longitudinal Hub Stress (psi) 26904 30000 Safe

Radial Flange Stress (psi) 13047 20000 Safe

Tangential Flange Stress (psi) 5128 20000 Safe

Combined Stress (S

H

+ S

R

)/2 19976 20000 Safe

Combined Stress (S

H

+ S

T

)/2 16016 20000 Safe

Flange Stresses

ASME BPVC

Calculations

Allowable

Design Stress

Result

Analysis 2

FEM Results

Longitudinal Hub Stress (psi)

r

g

0

=g

1

B

t

A

R

G

H

D

h

G

b

H

G

h

T

H

T

g

0

=g

1

R

C

g

0

/2

W

h

D

55.625 9.375 46.25

55.625 8.125 47.5

55.625 7.25 48.375

B

t

A

r

g

1

G

h

G

b

H

G

H

D

h

T

H

T

I

D

9

0

i

n

.

C

g

1

78

104.5

g

0

H

T

W

h

D

H

G

7.3

71.25

66

78

15.16

104.5

r

Internal Pressure

W

h

T

h

G

Gasket

118

4.5

12

95

h

D

Internal Pressure

W

H

D

Stud & Nuts

Flange

111.25

r

12

4.5

90

6.75

Internal Pressure

Contact

Face

Stud & Nuts

W

h

D

H

D

Internal Pressure

H

D

You might also like

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Coupling Calculations and Ug-32 Unstayed Head CalculationsDocument9 pagesCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlNo ratings yet

- Platform - Bracing SupportDocument12 pagesPlatform - Bracing Supportpandiangv100% (1)

- Weldstrength Calc ProgDocument10 pagesWeldstrength Calc ProgSajal KulshresthaNo ratings yet

- Longitudinal Bending Stress: M1 Allowable Limit RemarkDocument16 pagesLongitudinal Bending Stress: M1 Allowable Limit RemarkSandal JepitNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- 350 V Pressure Vessel Strength CalculationDocument3 pages350 V Pressure Vessel Strength CalculationTanCM100% (1)

- Saddle Calc PD5500Document6 pagesSaddle Calc PD5500Vamsi SNo ratings yet

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyNo ratings yet

- Calculator - U Tubes - HSA & QtyDocument4 pagesCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- SEISMIC ANALYSIS KazzincDocument14 pagesSEISMIC ANALYSIS KazzincArees KhambattaNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Nozzle Reinforcement Calculation Excel SheetDocument3 pagesNozzle Reinforcement Calculation Excel Sheetramesh punjabiNo ratings yet

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNo ratings yet

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag50% (2)

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Document17 pagesNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoNo ratings yet

- ASME B16.5 2013 FlangeRating 1.0Document4 pagesASME B16.5 2013 FlangeRating 1.0sanjaysyNo ratings yet

- PVElite RefDocument6 pagesPVElite RefakhilNo ratings yet

- RoarkTable17 (Ring)Document5 pagesRoarkTable17 (Ring)tekstep7No ratings yet

- Welded Connection 1Document2 pagesWelded Connection 1engineeringyusufNo ratings yet

- Nozzle FEA CalculationDocument64 pagesNozzle FEA CalculationberylqzNo ratings yet

- Saddle v1-5: Fixed Saddle Sliding SaddleDocument9 pagesSaddle v1-5: Fixed Saddle Sliding Saddleduf fuNo ratings yet

- .Document7 pages.Darshan Panchal100% (1)

- Code Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsDocument1 pageCode Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsguravdrNo ratings yet

- Anchor Bolt CalculationDocument2 pagesAnchor Bolt CalculationNaresh KumarNo ratings yet

- 5.7 Asmeviii A-2 & Tema Split Backing RingDocument1 page5.7 Asmeviii A-2 & Tema Split Backing RingpastylNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Anchor Bolt (CSA) Rev1.1Document10 pagesAnchor Bolt (CSA) Rev1.1coolkaisyNo ratings yet

- Flange DesignDocument6 pagesFlange DesignDinesh VaghelaNo ratings yet

- SP by CantileverDocument18 pagesSP by CantileverPaldexNo ratings yet

- Sendai: Eversendai Consulting Engineers (P) LTDDocument6 pagesSendai: Eversendai Consulting Engineers (P) LTDfsijestNo ratings yet

- Design Calculation Anchor Flange - ASME VIII Div 1Document6 pagesDesign Calculation Anchor Flange - ASME VIII Div 1Johakim974No ratings yet

- Calculation of PipeReinforcement ASMEB31 1Document4 pagesCalculation of PipeReinforcement ASMEB31 1threedlabsNo ratings yet

- Bolts Torque CalculatorDocument2 pagesBolts Torque CalculatorsopapilasNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Saddle SupportDocument12 pagesSaddle SupportrustamriyadiNo ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysisAntonio Perez Zornoza100% (1)

- Platform Cleat CalculationDocument1 pagePlatform Cleat Calculationmiteshpatel191No ratings yet

- Pressure Relief Valve (Open) Calculation Sheet: G T R G W F T R W FDocument1 pagePressure Relief Valve (Open) Calculation Sheet: G T R G W F T R W Fdj.4t67395No ratings yet

- Cdo CalcDocument3 pagesCdo CalcJeric FarinNo ratings yet

- 28 Roark Flat PlatesDocument4 pages28 Roark Flat PlatesJorge Silva100% (1)

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Stress at Junction of Shell & HeadDocument13 pagesStress at Junction of Shell & HeadRey Fiedacan100% (2)

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- Square Blind Flange With Stiffener ULDocument5 pagesSquare Blind Flange With Stiffener ULjoeriji100% (1)

- Calculo de Brida Segun ASMEDocument29 pagesCalculo de Brida Segun ASMEakarcz6731No ratings yet

- E4.5 Flange Cover CalcDocument10 pagesE4.5 Flange Cover CalcTanCM100% (1)

- Flange Leakage Test As Per Asme Boiler & Pressure Vessel CodeDocument12 pagesFlange Leakage Test As Per Asme Boiler & Pressure Vessel CoderssambhiNo ratings yet

- Towerwind Analysis - Anchoragebolt - Base PlateDocument14 pagesTowerwind Analysis - Anchoragebolt - Base PlateJoy lauriaNo ratings yet

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

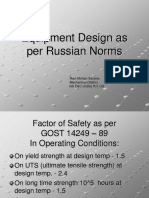

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- Crack Width BS 8110Document2 pagesCrack Width BS 8110nhulugallaNo ratings yet

- 1 Beam Fails Ub305x165x54Document4 pages1 Beam Fails Ub305x165x54Elencheliyan PandeeyanNo ratings yet

- Stored Energy CalculationDocument4 pagesStored Energy Calculationaauppal0% (1)

- Wind Engineering Latest ToolsDocument3 pagesWind Engineering Latest ToolsaauppalNo ratings yet

- Pressure Vessel Nozzle Calc - ASME VIII Div 1Document20 pagesPressure Vessel Nozzle Calc - ASME VIII Div 1aauppal100% (1)

- Wind Speed Table For Conversion of Knots, Beaufort, M/s and KM/HDocument4 pagesWind Speed Table For Conversion of Knots, Beaufort, M/s and KM/HaauppalNo ratings yet

- Tin 46 T out 36 delta T 10 V 54 m 54000 54 vel 2 7200 A 0.0075 D 97.720 4 C 4.2 ρ 1000 Q 2268000 630 179 COP 4Document2 pagesTin 46 T out 36 delta T 10 V 54 m 54000 54 vel 2 7200 A 0.0075 D 97.720 4 C 4.2 ρ 1000 Q 2268000 630 179 COP 4aauppalNo ratings yet

- Piping Stress AnalysisDocument51 pagesPiping Stress Analysissandygo100% (4)

- Bolt Torque CalculatorDocument9 pagesBolt Torque Calculatoraauppal100% (3)

- Solution: WE1 12 Nov 2008Document9 pagesSolution: WE1 12 Nov 2008aauppalNo ratings yet

- Tank CalibrationDocument12 pagesTank Calibrationmohamedyoussef1100% (2)

- Numerical Analysis PDFDocument15 pagesNumerical Analysis PDFaauppalNo ratings yet

- Numerical Analysis PDFDocument15 pagesNumerical Analysis PDFaauppalNo ratings yet

- Storage TankDocument4 pagesStorage Tankaauppal100% (1)

- Muffler TheoryDocument2 pagesMuffler TheoryMohit Mundra100% (1)

- Effects of Poultry Manure Supplemented by NPK 15-15-15 Fertilizer On Cucumber (Cucumis Sativus L.) Production in Port Harcourt (Nigeria)Document7 pagesEffects of Poultry Manure Supplemented by NPK 15-15-15 Fertilizer On Cucumber (Cucumis Sativus L.) Production in Port Harcourt (Nigeria)tino3528No ratings yet

- C-11 - (13th) (POI) Paper 1 SOLUTIONDocument7 pagesC-11 - (13th) (POI) Paper 1 SOLUTIONRaju SinghNo ratings yet

- HFM Vatell SpecsDocument3 pagesHFM Vatell SpecsPro_td_Vivimos_9063No ratings yet

- CO2 Cueva BulakDocument7 pagesCO2 Cueva BulakCristian RiveraNo ratings yet

- Octahedral Molecular GeometryDocument24 pagesOctahedral Molecular GeometryAnonymous gUjimJKNo ratings yet

- Inspection of Heat ExchangersDocument37 pagesInspection of Heat ExchangersYoungmin Park75% (4)

- Heat Engine Apparatus ManualDocument23 pagesHeat Engine Apparatus ManualRomeo DequitoNo ratings yet

- Chapter10 Pharmacy CalculationsDocument34 pagesChapter10 Pharmacy CalculationsHal Edwards57% (7)

- Chapter 5 - NewDocument25 pagesChapter 5 - NewJW MNo ratings yet

- Marlex HXM 50100 PolyethyleneDocument1 pageMarlex HXM 50100 PolyethyleneBudyawan SaputraNo ratings yet

- Section A: Multiple Choice Questions (Compulsory)Document19 pagesSection A: Multiple Choice Questions (Compulsory)ivyNo ratings yet

- Estimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnsDocument10 pagesEstimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnssdddNo ratings yet

- Tpl-Kipl Jvkarnalstp-20cdd003 Design Docoments Part 1 Client 28-11-18Document1,057 pagesTpl-Kipl Jvkarnalstp-20cdd003 Design Docoments Part 1 Client 28-11-18navneet3bawa100% (1)

- 14 List of Products For Cert of Fitness (1) DNVDocument23 pages14 List of Products For Cert of Fitness (1) DNVCrywul Suitswitt FazhNo ratings yet

- Solar ChimneyDocument1 pageSolar Chimneyh_shrNo ratings yet

- Chemistry LabDocument49 pagesChemistry LabVishwas VermaNo ratings yet

- Proceedings of ICBC 2019Document499 pagesProceedings of ICBC 2019Mohanraj TNo ratings yet

- KLEN 2207 Cream CleanerDocument3 pagesKLEN 2207 Cream CleanerSneha Nagaokar100% (1)

- Análisis de Textura en Frutas CongeladasDocument9 pagesAnálisis de Textura en Frutas CongeladasJORGENo ratings yet

- Brochura PCP TiconaDocument84 pagesBrochura PCP TiconaFJNovaes454No ratings yet

- TankJet 65 Tank Cleaning CatalogDocument2 pagesTankJet 65 Tank Cleaning Catalogvalerian1988No ratings yet

- Material Design and Characterization of High Performance Pervious ConcreteDocument10 pagesMaterial Design and Characterization of High Performance Pervious Concreteqwefqwefqwe fqwefqwNo ratings yet

- Acids and Bases Lecture NotesDocument11 pagesAcids and Bases Lecture NotesmdonohueHGHSNo ratings yet

- Becogur enDocument2 pagesBecogur enRui Felizardo0% (1)

- Examples 1Document17 pagesExamples 1Nahom GebremariamNo ratings yet

- NSTSE Class 7 SolutionDocument5 pagesNSTSE Class 7 SolutionMota ChashmaNo ratings yet

- Work WsDocument5 pagesWork Wsapi-261954479No ratings yet

- Magnesium Lauryl SulfateDocument55 pagesMagnesium Lauryl SulfateNurul Nadia Ngah100% (1)