Professional Documents

Culture Documents

QA-111-J Audit Checklist - Control of Digital Product Definition and Model Based Definition

Uploaded by

Mani Rathinam RajamaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QA-111-J Audit Checklist - Control of Digital Product Definition and Model Based Definition

Uploaded by

Mani Rathinam RajamaniCopyright:

Available Formats

Goodrich Aerostructures Group

PROCESS AUDIT QA-111-J CHECKLIST

CONTROL OF DIGITAL PRODUCT DEFINITION (DPD) / MODEL BASED DEFINITION

(MBD)

(Assessment of a Goodrich Suppliers Digital Product Definition / Model Based Definition Capability)

SUPPLIER:

ADDRESS:

COUNTRY:

Q.C. MANAGEMENT:

DATE:

CITY:

ZIP:

PHONE:

FAX:

TITLE:

STATE

:

Notes:

Section 1.0 of the checklist is used to perform a basic DPD capability verification, Section 2.0 is used to

perform PCMS capability verification, and Section 3.0 is used for MBD capability verification.

The checklist for Section 2.0 and Section 3.0 is designed to build upon the basic DPD capability assessment

from Section 1.0, ensure that Section 1.0 is assessed prior to performing assessment for PCMS or MBD. The

Portable CMS and MBD sections may be N/A if the supplier does not require PCMS or MBD capability.

The person performing the DPD assessment should review contract language for DPD and Tooling

requirements prior to performing assessment (some questions may not be applicable based on contract

review).

1.0

Digital Product Definition (DPD)

DPD Definition: Digital Product Definition The Electronic data elements that specify the 3D

Computer Aided Design (CAD) geometry and all design requirements for a product (including

notation and parts list), and the use of this data throughout an integrated CAD/Computer Aided

Manufacturing (CAM) and Coordinate Measurement Systems (CMS).

1.1

Is there a process to control configuration of datasets from receipt throughout the manufacturing and

acceptance processes? (Ref. Section J2.1 & AS9100 Section 4.3 & 7.5)

1.2

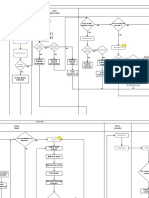

Is there a flow diagram of the complete documented DPD processes? (Ref. Section J2.3)

1.3

Does the documented DPD process require customer notification of changes to the process within 30

days? (Ref. Section J2.6)

1.4

Are documented DPD processes implemented with the defined authority for change control & maintenance?

(Ref. Section J2.7)

1.5

Is there a DPD process containing procedures for secure storage (with access control and archiving) for

customer supplied DPD data and derivative data? (Ref. Section J2.9.1 Item 3)

1.6

Are datasets derivatives traceable back to the current master dataset?

(Ref. Section J2.9.1 Item 4 & AS9100 Sections 4.3 & 8)

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 1 OF 12

7-22-08

Goodrich Aerostructures Group

PROCESS AUDIT QA-111-J CHECKLIST

CONTROL OF DIGITAL PRODUCT DEFINITION (DPD) / MODEL BASED DEFINITION

(MBD)

(Assessment of a Goodrich Suppliers Digital Product Definition / Model Based Definition Capability)

1.7

Does the supplier have a process to control configuration of dataset derivative media?

(Ref. Section J2.9.1 Item 4, J2.9.7 & AS9100 Sections 4.3, 7.5 & 8)

1.8

Does the supplier have a process that includes control of non current (obsolete) datasets and dataset

derivatives? (Ref. Section J2.9.1 Item 4 & AS9100 Section 7.3.7)

1.9

Does the planning package identify traceability to the current master dataset?

(Ref. Section J2.9.1 Item 5 & AS9100 Sections 4.3 & 8)

1.10

Is there a process in place to validate Product Acceptance Software (PAS) independent of the software

developer? (Ref. Section J2.9.2 Item 4 & AS9100 Sections 4.3 & 7.6)

1.11

Is there a documented process to require creation of plans and instructions for the building, configuration

management, loading and testing of Supplier Developed product acceptance software?

(Ref. Section J2.9.2 Item 5)

1.12

Does the internal quality audit procedure include auditing or reviewing all internal and sub-tier operations for

DPD data and related documentation? (Ref. Section J2.9.3 Items 1 & 2)

1.13

Does the suppliers documented procedure for corrective action include reporting, tracking and resolving all

transmission, hardware, software and dataset problems and deficiencies, (including GR/AG datasets)?

(Ref. Section J2.9.4 Item 2, AS9100 Section 8)

1.14

Does the supplier have a process to flow down DPD requirements to sub-tier suppliers who receive digital

data and does the process include GR/AG right of access? (Ref. Section J2.9.5 & AS9100 Section 7.4)

1.15

Does the supplier have a process to assess, monitor and control sub-tier compliance with DPD

requirements? (Ref. Section J2.9.5 Item 2 & AS9100 Section 7.4)

1.16

Does the supplier maintain certification/calibration requirements for:

CMS equipment?

(Ref. Section J2.9.6 Item 1)

NC equipment with inspection probe capability used for product acceptance?

Plotters used to produce drawings, mylars and inspection tooling media?

1.17

When CMS operations are performed in a non-controlled environment, does the process compensate for

environmental variation? (Ref. Section J2.9.6 Item 1 & AS9100 Section 7.5.1.3 & 7.6)

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 2 OF 12

7-22-08

Goodrich Aerostructures Group

PROCESS AUDIT QA-111-J CHECKLIST

CONTROL OF DIGITAL PRODUCT DEFINITION (DPD) / MODEL BASED DEFINITION

(MBD)

(Assessment of a Goodrich Suppliers Digital Product Definition / Model Based Definition Capability)

1.18

Is the supplier inspection media: (Ref. Section J2.9.7 Item 2)

Independently derived from and traceable to the authority dataset?

Contain graphics and text sufficient to illustrate inspection operation and result for each

product feature?

1.19

1.20

Does the supplier have a process to verify dimensional accuracy of derivative data outputs, including plotted

media, as compared to the master dataset? (Ref. Section J2.9.7 Item 3 & AS9100 Sections 4.3, 7.6 & 8)

Does the supplier have a process to ensure verification of all design requirements of the authority dataset?

(e.g., all defined by feature control frames, annotation, specifications, notes and other specified requirements in the authority

DPD dataset and associated parts list including dimensional and other properties)

(Ref. Section J2.9.7 Item 6 & AS9100 Section 8)

1.21

Is the suppliers CAD system software compatible with GR/AG design system software when required?

(Ref. QA-111-J Sections J2.9.1, J2.9.8 Item 1 & AS9100 Section 4.3)

1.22

Does the supplier verify dataset translations? (Ref. Section J2.9.8 Item 4 & AS9100 Section 4.3, 7.4)

1.23

Do procedures ensure release, acceptance, identification, secure access, and change control for tool

design, tool inspection datasets and digitally defined tools? (Ref. Section J2.9.9 Item 1 & AS9100 Section 7.5)

1.24

Is there a process to periodically verify accuracy and repeatability of digitally defined tooling used as media

of inspection? (Ref. Section J2.9.9 Item 2 & AS9100 Section 7.5)

1.25

Does the supplier define training requirements that: (Ref. Section J2.9.10 & AS9100 Section 6.2)

Assure competence and maintain employee training records, including on-the-jobtraining, for all DPD system users?

Respond to changes to the DPD process, equipment, or software?

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 3 OF 12

7-22-08

Goodrich Aerostructures Group

PROCESS AUDIT QA-111-J CHECKLIST

CONTROL OF DIGITAL PRODUCT DEFINITION (DPD) / MODEL BASED DEFINITION

(MBD)

(Assessment of a Goodrich Suppliers Digital Product Definition / Model Based Definition Capability)

2.0

Portable Coordinate Measurement Systems (PCMS)

PCMS Definition Coordinate Measurement Systems - Also known as Computer Aided Inspection

(CAI) and Computer Aided Measurement Systems (CAMS). Measurement equipment such as

Coordinate Measuring Machines (CMM), Laser Tracker, and numerical controlled machinery with

inspection probe capabilities which are used to support inspection activity.

2.1

If applicable, does the supplier have a process to control critical functions of the Portable CMS?

(Ref. Section J2.9.6 Item 2 & AS9100 Section 7.5.1.3)

a) Create acceptance criteria used by operator and quality assurance

b) Develop and use of scale factors to compensate measurements for coefficient of

thermal expansion and to verify accuracy

c) Establish, transform and manipulate coordinate systems

d) Establish data collection parameters and requirements

e) Establish special targeting and target adapter requirements

f) Equipment handling, equipment set-up, multi- Equipment handling,

equipment set-up, multi- station set-up, field checks and calibrations

g) Data analysis, format, storage and reporting

2.2

Does the supplier document inventory of all specific components used for PCMS measurements that affect

the integrity of data collection? (Ref. Section J2.9.6 Item 2 & AS9100 Section 7.6)

3.0

Model Based Definition (MBD)

MBD Definition: Is a GR/AG dataset containing the exact solid, its associated 3D geometry and 3D

annotation of the products dimensions and tolerances (and may include parts/notes list) to specify a

complete product definition. This dataset does not contain a conventional 2D drawing. MBD is one

possible format of DPD.

(Note: Model Based Definition provides a single-source of definition, and it reduces conflict between

CAD and paper drawings)

3.1

Does the suppliers CAD system have the ability to view annotation based on GR/AG site-specific

requirements? (Ref. Section J2.9.7 Item 5 & AS9100 Section 8)

3.2

Does the supplier have a process to create inspection planning from the authority dataset?

(Ref. Section J2.9.7 Item 5 & AS9100 Section 4.3, 7.5 & 8)

3.3

Is there a process in place to document First Article Inspections for product produced from MBD datasets?

3.4

Does the supplier have a process to assure sub-tier suppliers ability to work with MBD information?

(Ref. Section J2.9.7 Item 10 & AS9100 Section 8)

(Ref. Section J2.9.5 & AS9100 Section 7.4)

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 4 OF 12

7-22-08

Goodrich Aerostructures Group

PROCESS AUDIT QA-111-J CHECKLIST

CONTROL OF DIGITAL PRODUCT DEFINITION (DPD) / MODEL BASED DEFINITION

(MBD)

(Assessment of a Goodrich Suppliers Digital Product Definition / Model Based Definition Capability)

SUMMARY:

SURVEY CONDUCTED BY: (Print Name)

INITIAL SURVEY

CORRECTIVE ACTION:

FORM NO. E8131-3 QA-111-J Rev.AT

VCAR NO.

PERIODIC AUDIT

PAGE 5 OF 12

DATE TO BE COMPLETED:

7-22-08

COMPLIANCE GUIDANCE NOTES

For use as a guide when performing QA-111-J Control of Digital Product Definition (DPD)

Section 1.0 Digital Product Definition (DPD)

Question 1.1 (Ref. Section J2.1 & AS9100 Sections 4.3 & 7.5)

Documented processes that control GR/AG release authority dataset and other DPD/MBD derivates (i.e. NC

programs, Inspection plans, Tooling, etc.) from the point when the GR/AG authority dataset is received,

through derivate creation, performed programming, manufacturing planning (visual aids, in- process inspection,

final inspection), first article inspection and anything else that is applicable.

There must be a process to ensure the original authority datasets are secure, backed up and can not be

altered, and only the appropriate people have write access to part programs and inspection datasets.

Must have trained system administrator(s) with sole access to retrieve and store incoming customer datasets.

A process for the supplier to check dataset integrity upon receipt.

Segregation of datasets by status (e.g., release, in-work and obsolete are minimum requirements)

Security (Password and access protection, regular back up for disaster recovery and archive storage).

Question 1.2 (Ref. Section J2.3)

There must be a flow diagram that documents the DPD processes and identifies the applicable procedure

references.

Flow chart should include reference to affected organizations such as (engineering, manufacturing planning,

tooling, inspection and procurement).

Question 1.3 (Ref. Section J2.6)

The supplier must have a process that notifies the customer when changes are incorporated into their DPD

process and impacts the customer (simple typographic errors need not apply)

Question 1.4 (Ref. Section J2.7)

Look for approval or signature page

Notification to affected personnel and sub-tier suppliers when changes occur.

Processes should be under document control

Question 1.5 (Ref. Section J2.9.1 Item 3)

When customers provide digital data, this data is type design data. The supplier must have a documented

process to protect type design data and ensure it is not altered.

There must be a process to ensure derivative datasets are secure, backed up and can not be altered.

Question 1.6 (Ref. Section J2.9.1 Item 4 & AS9100 Sections 4.3 & 8)

Traceability is looking at whether or not the derivative can be clearly tied back to its Authority dataset, such as

when visual aides or screen-prints are being used, they need to be traceable back to the current Authority

dataset.

Question 1.7 (Ref. Sections J2.9.1 Item 4, J2.9.7 & AS9100 Sections 4.3 & 7.5 & 8)

The derivatives/media must have a revision level process to keep the derivatives/media current with authority

dataset revisions that affects its configuration.

As an example look for these indicators:

o Creator/Date

o Sketch Revision Level

o Authority Dataset(s) Name, Location, Revision Level

o Other Derivative Dataset(s) Name, Location, Revision Level

o Feature Requirement(s) Identifier (e.g., GDT frame ID)

o Product identification

Note: Derivatives are modified copies or extracted data from the original authority dataset. (NC/CNC type programs,

visual aides, mylars, digital tool designs and tools, inspection datasets, FAI datasets, etc.

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 6 OF 12

7-22-08

COMPLIANCE GUIDANCE NOTES

For use as a guide when performing QA-111-J Control of Digital Product Definition (DPD)

Question 1.8 (Ref. Section J2.9.1 Item 4 & AS9100 Section 7.3.7)

The supplier must have a documented process and is compliant to make sure that the old (previous revision)

datasets (models) cannot be used as authority or inspection when an obsolete revision is no longer used.

Segregation and clear identification of current and past revision level datasets in suppliers directories.

Ensure compliance to contract data retention requirements.

Question 1.9 (Ref. Section J2.9.1 Item 5 & AS9100 Sections 4.3, & 8)

The supplier needs to have a documented process to ensure the planning is traceable to the correct authority

dataset.

o Planning used for route sheets, travelers, work instructions, NC programs, inspection, etc. will be

traceable to the authority dataset that controls the configuration being built.

o Verify there is a change control process that updates all derivative dataset elements (NC programs,

sketches / graphics, inspection plans, etc.) when the authority dataset is revised.

Question 1.10 (Ref. Section J2.9.2 Item 4 & AS9100 Sections 4.3 & 7.6)

A procedure independent of the software developer to determine that the software, and subsequent revisions,

accomplishes its intended function.

Supplier PAS validation or other party certification of software for each approved version level are documented

and records on file.

Training is provided and documented when new approved versions are installed.

When an artifact is used, a process must be in place for use to accept software functions and revisions.

Note: Typical applications for PAS are for Coordinate Measuring Machine (CMM), CAD translation

applications and analysis software.

Question 1.11 (Ref. Section J2.9.2 Item 5)

Software developed by suppliers requires plans and instructions for building, configuration management,

loading and testing of code.

Training is provided and documented when new versions are installed Process to control/identify current

software version released for production.

Secure storage of software version Authority copy.

Alternatively, the supplier has a documented process when an Artifact is used to accept software functions and

revisions.

Records of version level control of PAS validation

Question 1.12 (Ref. Section J2.9.3 Items 1 & 2)

Internal audit procedures identify DPD processes for review.

Review audit checklist for compliance.

Review internal audit records for evidence of having a completed internal audit for DPD processes.

Internal audit plan shall include provisions for audit of sub-tier supplier oversight.

Question 1.13 (Ref. Section J2.9.4 Item 2, AS9100 Section 8.0)

Processes to report dataset or software discrepancies to customer, OEM and all affected personnel.

Process to prevent use of discrepant datasets or software.

The supplier must have a documented process to disclose products inspected with discrepant media,

equipment, and/or tooling on items shipped to GR/AG and their customers.

Question 1.14 (Ref. Section J2.9.5 & AS9100 Section 7.4)

Supplier has contractual notes that flow GR/AG DPD/MBD requirements to all their approved sub-tier

suppliers.

Compare list of suppliers receiving datasets to list of suppliers approved to receive datasets.

Supplier has assessed sub-tiers and ensures the proper capabilities to manage and use the GR/AG DPD/MBD

datasets being provided.

Supplier has a documented process to manage changes and flow down DPD/MBD configuration changes.

When controlled datasets are provided to sub-tier suppliers, the supplier ensures sub-tier supplier is in

compliance to GR/AG ITAR, EAR and contract requirements prior to approval and release of DPD/MBD

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 7 OF 12

7-22-08

COMPLIANCE GUIDANCE NOTES

For use as a guide when performing QA-111-J Control of Digital Product Definition (DPD)

datasets.

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 8 OF 12

7-22-08

COMPLIANCE GUIDANCE NOTES

For use as a guide when performing QA-111-J Control of Digital Product Definition (DPD)

Question 1.15 (Ref. Section J2.9.5 Item 2 & AS9100 Section 7.4)

Supplier has assessed sub-tiers and ensures the proper capabilities to manage and use the GR/AG DPD/MBD

datasets being provided.

Supplier maintains records of sub-tier DPD capabilities (equipment and process)

Supplier has documented process to ensure sub-tier suppliers inspection planning is compliant when used to

accept GR/AG product.

Supplier documented processes ensure sub-tier datasets are verified when translations occur.

Supplier performs periodic review on their DPD/MBD sub-tier supplier to ensure they are in compliance to DPD

requirements, GR/AG ITAR, EAR and contract requirements.

Question 1.16 (Ref. Section J2.9.6 Item 1)

Look for procedures for certification requirements

Look for certification documentation and that Original Equipment Manufacturer (OEM) calibration/certification

has been met.

Plotters should have a validation process to verify repeatability and accuracy of plots.

Ply cutters should have a calibration process to verify repeatable and accuracy.

Question 1.17 (Ref. Section J2.9.6 Item 1 & AS9100 Section 7.5.1.3 & 7.6)

Suppliers in some cases cannot measure in a temperature controlled room, when this happens, the supplier

must have documented processes to:

- For CMM - Perform calculations to the measurements to compensate for the coefficient of thermal

expansion changes (i.e. Ambient air temperature, temperature of measured item, and measurement

equipment)

- Use of certified and calibrated gages/instruments

- For Portable Coordinate Measurement Systems (PCMS) see question of this task guide.

Question 1.18 (Ref. Section J2.9.7 Item 2)

Inspection media (paper inspection plans, inspection datasets, CMM programs, mylars, media of inspection

(MOI) tools, etc) needs to be traceable to the authority dataset.

If the inspection media is created by an organization other then supplier Quality Assurance, there needs to be a

documented process approved by QA.

Question 1.19 (Ref. Section J2.9.7 Item 3 & AS9100 Sections 4.3, 7.6 & 8)

A process to assure accuracy of derivative media (e.g. mylars, tools, CMS programs, NC programs) from

authority datasets.

Plotted mylar media should be validated at each point of use. Reference applicable document for plotted

media.

Question 1.20 (Ref. Section J2.9.7 Item 6 & AS9100 Section 8)

When planning measurements for product acceptance, the suppliers QA must verify that all design

requirements are identified and planned for inspection.

Note: Compliance for this process is best verified by reviewing FAI documentation for a specific product.

Measurement process must have guidelines to ensure the appropriate quantity of individual measurements are

taken on the feature being measured (i.e., quantity of surface points for measurement, CMM hits).

Process to ensure Key Characteristics identified on authority datasets are measured and the results are

recorded or every unit.

Question 1.21 (Ref. Sections J2.9.1, J2.9.8 Item 1 & AS9100 Section 4.3)

Supplier data exchange software compliant to GR/AG site requirements (e.g. encryption, file transfer protocol

(FTP), web connection, etc)

Ensure software levels and equipment matches the Data Exchange Survey Form 8087

If system is not compatible, there must be documented process to verify GR/AG received authority data is

acceptable before release.

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 9 OF 12

7-22-08

COMPLIANCE GUIDANCE NOTES

For use as a guide when performing QA-111-J Control of Digital Product Definition (DPD)

Question 1.22 (Ref. Section J2.9.8 Item 4 & AS9100 Sections 4.3, 7.4)

When translations of digital datasets occur between CAD systems or digital equipment, a process must be in

place to verify data. Examples of how this can be accomplished are using IGES_CHK, point cloud method or

other software validation processes.

Question 1.23 (Ref. Section J2.9.9 Item 1 & AS9100 Section 7.5)

There must be a documented process to review, revise and control tooling when authority dataset changes

affect tooling configuration.

There must be a documented release process and secure storage of released tool design datasets.

Digital definition of physical tooling (including templates, check fixtures) must conform to digital

engineering definition or approved tool design.

Tools and tool design/inspection datasets must be traceable to the authority dataset and the affected revision.

Question 1.24 (Ref. Section J2.9.9 Item 2 & AS9100 Section 7.5)

Media of inspection and other selected tooling is re-inspected for accuracy back to the digital tool definition

based on a frequency that will prevent nonconformance due to tool wear and stability, typically referred to as

periodic tool inspection (PTI)

Question 1.25 (Ref. Section J2.9.10 & AS9100 Section 6.2)

The supplier must have a documented process that ensures the appropriate quality assurance and other

affected personnel responsible for product acceptance have proper training to use DPD/MBD/Product

Acceptance Software for inspection planning, measuring and product/tool acceptance

The supplier must have a documented process that ensures other affected personnel responsible have proper

training to use DPD/MBD when it directly affects their job function.

The training must be formally documented and kept of file. This includes On Job Training when used as a

training tool.

Look for changes to the training program in response to changes to the DPD/MBD process, equipment, or

software.

Section 2.0 Portable Coordinate Measurement Systems (PCMS)

Question 2.1 (Ref. Section J2.9.6, Item 2 & AS9100 Section 7.5.1.3)

The supplier must have a documented process to perform acceptance of Portable CMS and the process must

cover each item a) through g) listed in checklist question.

The supplier must have a process to have all users trained utilizing the OEM manuals.

Question 2.2 (Ref. Section J2.9.6, Item 2 & AS9100 Section 7.6)

Supplier needs to have a documented process that controls the targets, target adapters, certified verification

lengths (commonly called scale bars) and all other components that affect the PCMS method of measuring.

The supplier calibration process controls all target, target adapters and certified verification lengths.

Supplier manufactured target, target adapters and certified verification lengths (scale bars) are design

controlled and have evidence of being accepted by quality assurance prior to use.

The supplier needs to have a process to remove any out of calibrated or suspect target, target adapters,

certified verification lengths and equipment from being used until it can be corrected.

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 10 OF 12

7-22-08

COMPLIANCE GUIDANCE NOTES

For use as a guide when performing QA-111-J Control of Digital Product Definition (DPD)

Section 3.0 Model Based Definition (MBD)

Question 3.1 (Ref. Section J2.9.7 Items 5 & 6, Section J2.9.8 & AS9100 Sections 4.3)

Supplier data exchange software compliant to GR/AG site requirements (e.g. encryption, file transfer protocol

(FTP), web connection, etc)

Ensure software levels and equipment matches the Data Exchange Survey Form 8087.

Compatibility requirements may involve CAD systems or data exchange software.

Suppliers may need the same GR/AG CAD native software version or have the GR/AG approved LEV to view

the annotation.

Question 3.2 (Ref. Section J2.9.7 Items 5 & AS9100 Sections 4.3, 7.5 & 8)

Process to determine when manufacturing and/or inspection views/sketches are needed to supplement

authority dataset.

Question 3.3 (Ref. Section J2.9.7 Item 6 & AS9100 Section 8)

Process for reduced content datasets (MBD, RDD, etc.) to ensure all dimensioned, un-dimensioned features

and general / flag note requirements are planned for verification.

Unique identification of each feature is required. Various acceptable methods are available to manage this data

(e.g. 3D model, screen prints, sketches etc.)

Measurement planning must have guidelines to ensure the appropriate quantity of individual measurements

are taken on the feature being measured (i.e., quantity of surface points for measurement, CMM hits).

Note: Compliance for this process is best verified by reviewing FAI documentation for a specific product or concurrently

validating process.

Question 3.4 (Ref. Section J2.9.5 & AS9100 Section 7.4)

Supplier has assessed sub-tiers and ensures the proper capabilities to manage and use the GR/AG DPD/MBD

datasets being provided.

Supplier maintains records of sub-tier MBD capabilities (equipment and process)

Supplier has documented process to ensure sub-tier suppliers inspection planning is compliant when used to

accept GR/AG product.

Supplier documented processes ensure sub-tier CAD systems/format are verified when dataset translation

occurs.

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 11 OF 12

7-22-08

COMPLIANCE GUIDANCE NOTES

For use as a guide when performing QA-111-J Control of Digital Product Definition (DPD)

DEFINITIONS

AUTHORITY DATASET

This is the engineering definition provided in a 3D representation of the product, viewable on a Computer Aided Design (CAD)

system. In addition to the Authority dataset (aka CAD model), the entire product definition may typically include additional media

such as parts lists, part coordination documents, material specifications, etc.

The Authority dataset will exist in one of four possible formats.

1) The Authority dataset may include both the CAD model and fully dimensioned 2D drawing sheets.

2) It may include the CAD model and 2D drawing sheets having engineering requirements but not all linear dimensions.

3) Or the Authority dataset may only include the 3D model, with no 2D sheet and the engineering requirements displayed

as text within the 3D viewing area of the model.

4) Or the Authority dataset may only include the 3D Model and the engineering requirements displayed as text within the

3D viewing area of the model, as well as the remaining engineering requirements (in 2D form - notes list, part lists, etc.).

All four formats are considered Digital Product Definition (DPD). The second case is a reduced content format, and is sometimes

labeled as Reduced Dimension Drawing (RDD) or Simplified Drawing (SD). The third and fourth cases are termed Model Based

Definition (MBD).

The purpose of the DPD/MBD checklist is to verify that the supplier has processes to use any of these formats received from any

GR/AG site, to manufacture and inspect the product.

DATASET DERIVATIVE

The media created any time data is extracted from an Authority dataset for machine programming, visual aids, inspection aides,

FAIs, tool fabrication/measurement, plotting mylars, or what have you.

ACCEPTANCE SOFTWARE

This is software used during manufacturing that potentially affects product conformity where there is no further, downstream

verification of the product. (E.g., CAD, LEV, CMS, data handling/analysis, and in some cases, NC)

ENHANCED REFERENCE SYSTEM (ERS)

This is a permanent reference system usually for large assembly tools, with a large number of digitally-defined, fixed target

locations

readable by coordinate measurement systems. It provides better repeatability than conventional tooling datum features.

MACHINE TO NOMINAL

At many suppliers, the NC machining process creates parts with excess material that must be further worked. Machine to Nominal

controls seek to eliminate this practice, to improve flow, part fit and assembly.

IGES, STEP, DXF, PARASOLID

Standardized formats for CAD data that are readable by multiple systems.

COORDINATE MEASUREMENT SYSTEMS (CMS)

CMS devices check the 3D shape of products. Typical examples are the fixed Coordinate Measurement Machine (CMM), and

several portable devices, Theodolite, Laser Tracker, Photogrammetry (includes Videogrammetry), and Portable CMM.

LOW END VIEWER (LEV)

An entry level, visualization CAD system used to view, analyze, extract, and print dimensional and other required data from the

DPD dataset.

FORM NO. E8131-3 QA-111-J Rev.AT

PAGE 12 OF 12

7-22-08

You might also like

- NPI Job Responsibilities Detailed Jobs - Print 28-07-2021 - QADocument441 pagesNPI Job Responsibilities Detailed Jobs - Print 28-07-2021 - QAPirasanth VithuNo ratings yet

- SE:FY14 ReportDocument280 pagesSE:FY14 Reportbring it onNo ratings yet

- QRS-115 Requirements For Design & Development SuppliersDocument37 pagesQRS-115 Requirements For Design & Development SupplierscoralonsoNo ratings yet

- LO1 Operate CAD Software and Computer HardwareDocument176 pagesLO1 Operate CAD Software and Computer HardwareGretch D Ag0% (1)

- Requirements For Aviation, Space, and Defense Quality Management System Certification ProgramsDocument59 pagesRequirements For Aviation, Space, and Defense Quality Management System Certification ProgramsIsaac SamuelNo ratings yet

- Configuration Management PresentationDocument91 pagesConfiguration Management PresentationVaibhav Gadhawe50% (2)

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDocument10 pagesFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoNo ratings yet

- Quality Tools and Techniques-Cause - and - Effect - Diagram - Fall20Document12 pagesQuality Tools and Techniques-Cause - and - Effect - Diagram - Fall20Ashik ShariarNo ratings yet

- Effective Auditing of Purchasing & Subtier Supplier Control ProcessesDocument40 pagesEffective Auditing of Purchasing & Subtier Supplier Control ProcessesJHBernardoNo ratings yet

- First Article Inspection FAI AS9102 PresentationDocument28 pagesFirst Article Inspection FAI AS9102 PresentationaldiNo ratings yet

- Manualul Calitatii Aviatie PDFDocument15 pagesManualul Calitatii Aviatie PDFStefan GrozaNo ratings yet

- Unified Thread StandardDocument4 pagesUnified Thread StandardFredNo ratings yet

- 9146:2016 Ballot Draft: Foreign Object Damage (Fod) Prevention Program Guidance Material March 2016Document26 pages9146:2016 Ballot Draft: Foreign Object Damage (Fod) Prevention Program Guidance Material March 2016María Ro DíazNo ratings yet

- BCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFDocument8 pagesBCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFMani Rathinam RajamaniNo ratings yet

- 9104 2a FormdDocument3 pages9104 2a Formdkarthi keyan100% (1)

- Meenakshi Molding Private Limited Process FMEA: O C C U RDocument4 pagesMeenakshi Molding Private Limited Process FMEA: O C C U Rilaya raja100% (1)

- PB 9104-1 enDocument49 pagesPB 9104-1 enVenkatesan KattappanNo ratings yet

- AS9100 Certification StatusDocument192 pagesAS9100 Certification StatusMani Rathinam RajamaniNo ratings yet

- 7.2.18 DFMEA-PFMEA-FMECA Comparison Guidance 13JUL2020Document4 pages7.2.18 DFMEA-PFMEA-FMECA Comparison Guidance 13JUL2020Moti Ben-ZurNo ratings yet

- Cnca C11-09-2014Document12 pagesCnca C11-09-2014raybchNo ratings yet

- Di Sess 81248BDocument2 pagesDi Sess 81248BBre TroNo ratings yet

- As9100D Gap Analysis Tool 9. Evaluation Gap Analysis QuestionnaireDocument6 pagesAs9100D Gap Analysis Tool 9. Evaluation Gap Analysis Questionnairechandravel sankarakumar100% (1)

- When To Conduct A First Article InspectionDocument4 pagesWhen To Conduct A First Article InspectionCloud RedfieldNo ratings yet

- FINETURN Feasibility FormatDocument1 pageFINETURN Feasibility FormatAyush NarangNo ratings yet

- Cast Designer FolderDocument2 pagesCast Designer Foldergui_nf6618No ratings yet

- Auditor Qualification CriteriaDocument10 pagesAuditor Qualification CriteriaMani Rathinam RajamaniNo ratings yet

- Drawing For Product Designers by Kevin HenryDocument209 pagesDrawing For Product Designers by Kevin Henryarbnor demajNo ratings yet

- Spira FOD Prevention Program 2 11 2021Document14 pagesSpira FOD Prevention Program 2 11 2021Tin NguyenNo ratings yet

- Iatf TrainingDocument10 pagesIatf TrainingAniket JadhavNo ratings yet

- As 9103 White PaperDocument3 pagesAs 9103 White PaperJoseph JohnsonNo ratings yet

- IATF - International Automotive Task ForceDocument10 pagesIATF - International Automotive Task ForceBeli NovareseNo ratings yet

- AL Problem Solving Process Manual - Updated 10 - May 2016Document74 pagesAL Problem Solving Process Manual - Updated 10 - May 2016Akshi Karthikeyan100% (1)

- 5G, (Gemba, Gembutsu, Genjitsu, Genri, Gensoku) ChekclistDocument2 pages5G, (Gemba, Gembutsu, Genjitsu, Genri, Gensoku) ChekclistMani Rathinam RajamaniNo ratings yet

- RIICWD601E Student Assessment Tasks AnswersDocument25 pagesRIICWD601E Student Assessment Tasks AnswersNavneet MehraNo ratings yet

- Maxsurf Booklet PDFDocument16 pagesMaxsurf Booklet PDFAnonymous NFsIMHyfLtNo ratings yet

- C TD - GRade 10 - LM - Module 4 Drafting Structural Layout and Details Corrected PDFDocument28 pagesC TD - GRade 10 - LM - Module 4 Drafting Structural Layout and Details Corrected PDFShayne Noelle Del RosarioNo ratings yet

- SRS DocumentDocument652 pagesSRS DocumentYudi ZulkarnaenNo ratings yet

- Puck Failure CriteriaDocument80 pagesPuck Failure CriteriaMateusz Duda100% (1)

- NO. PNB/DC-QAD-04/ ISSUE:2.0 / Revision: 00/ DATE:-01.04.16 Page 1 of 2Document2 pagesNO. PNB/DC-QAD-04/ ISSUE:2.0 / Revision: 00/ DATE:-01.04.16 Page 1 of 2sonnu151No ratings yet

- Patterns of DisruptionDocument34 pagesPatterns of DisruptionFred Nijland0% (1)

- Sae Geia-Std-0006a-2016Document18 pagesSae Geia-Std-0006a-2016wodonit136No ratings yet

- Robot Safety Standard Update: Roberta Nelson SheaDocument43 pagesRobot Safety Standard Update: Roberta Nelson SheaudbarryNo ratings yet

- Chemical Compatibility ChartDocument13 pagesChemical Compatibility ChartManuel Mendez GomezNo ratings yet

- زنجيره تلرانسيDocument65 pagesزنجيره تلرانسيAmir HouNo ratings yet

- J STD 004bwam1Document4 pagesJ STD 004bwam1cdealmeida0% (2)

- Un-qd-ff-860 Fai ביצוע - engDocument6 pagesUn-qd-ff-860 Fai ביצוע - engmsy021yahoo.comNo ratings yet

- Is 1363 - 2 2002Document13 pagesIs 1363 - 2 2002Sourav HaitNo ratings yet

- Concepts of Model Verification and ValidationDocument41 pagesConcepts of Model Verification and ValidationMa'ruf NurwantaraNo ratings yet

- Formel Q-Capability Version 6.0 Supplier Training - Product AuditDocument11 pagesFormel Q-Capability Version 6.0 Supplier Training - Product AuditVijay LadNo ratings yet

- Engine MRO Overall ProcessDocument6 pagesEngine MRO Overall ProcessMihai ConstantinescuNo ratings yet

- Z-SCORE - Inter Lab Comparison of Mechanical TestingDocument2 pagesZ-SCORE - Inter Lab Comparison of Mechanical TestingAnubhav LakhmaniNo ratings yet

- Senthilkumars CMM Programmer Kumars CMM ProgrammerDocument2 pagesSenthilkumars CMM Programmer Kumars CMM ProgrammerSenthil Kumar0% (1)

- Mil STD 704Document25 pagesMil STD 704josebrigas4530No ratings yet

- Mil STD 1246CDocument36 pagesMil STD 1246COmNo ratings yet

- ISO4527 (2003) Metallic Coatings - Autocatalytic (Electroless) Nickel-Phophorus Alloy Coatings - Spec & Test MethodsDocument30 pagesISO4527 (2003) Metallic Coatings - Autocatalytic (Electroless) Nickel-Phophorus Alloy Coatings - Spec & Test MethodsWee Yaw LimNo ratings yet

- Surface Texture Measurement Fundamentals For Metrology Center Open HouseDocument54 pagesSurface Texture Measurement Fundamentals For Metrology Center Open HouseSushant VashisthaNo ratings yet

- Research Designs & Standards Organization: 1.0 Amendment HistoryDocument8 pagesResearch Designs & Standards Organization: 1.0 Amendment Historynvnrajesh123No ratings yet

- Master Form VDADocument4 pagesMaster Form VDAapi-3856433No ratings yet

- Houston Impact of J-STD-001F and IPC-A-610F ChangesDocument36 pagesHouston Impact of J-STD-001F and IPC-A-610F Changes安靖No ratings yet

- Qualkitdo SLVNV TQPDocument39 pagesQualkitdo SLVNV TQPJanos Kovacs100% (1)

- MAXXI 6 Sales Presentation 04-2016Document33 pagesMAXXI 6 Sales Presentation 04-2016Marty SchreckNo ratings yet

- Autoliv Material Specification: Flat Hot Rolled Steel For Safety Products - E116088Document4 pagesAutoliv Material Specification: Flat Hot Rolled Steel For Safety Products - E116088krishnamartial8269No ratings yet

- Lmi - Supplier Quality Requirements 2015 SQRM - Rev - UDocument31 pagesLmi - Supplier Quality Requirements 2015 SQRM - Rev - UJHBernardoNo ratings yet

- CSL STDDocument45 pagesCSL STDPuratchi VelanNo ratings yet

- Va 7.3-4eDocument4 pagesVa 7.3-4eshifaNo ratings yet

- 1363 3Document7 pages1363 3Shounak DeNo ratings yet

- I-Chart 8c RH August Ftq-2014Document1 pageI-Chart 8c RH August Ftq-2014Billa ManojNo ratings yet

- SMS/QMS Awareness Course: Icaa/Easa Amman, May 2017Document5 pagesSMS/QMS Awareness Course: Icaa/Easa Amman, May 2017Husam FNo ratings yet

- Interface control document The Ultimate Step-By-Step GuideFrom EverandInterface control document The Ultimate Step-By-Step GuideNo ratings yet

- TL 9000 Quality Management System Measurements Handbook NPR ExamplesDocument7 pagesTL 9000 Quality Management System Measurements Handbook NPR ExamplesMani Rathinam RajamaniNo ratings yet

- Product, Process, and Problem Analysis Quality SystemDocument25 pagesProduct, Process, and Problem Analysis Quality SystemMani Rathinam RajamaniNo ratings yet

- LSS Mani Rathinam RajamaniDocument2 pagesLSS Mani Rathinam RajamaniMani Rathinam RajamaniNo ratings yet

- ProgramDocument1 pageProgramMani Rathinam RajamaniNo ratings yet

- Payment Acknowledgment - 180604092233Document1 pagePayment Acknowledgment - 180604092233Mani Rathinam RajamaniNo ratings yet

- List of Certifications DiscontinuedDocument30 pagesList of Certifications DiscontinuedMani Rathinam RajamaniNo ratings yet

- Flight 1 Mon, Mar 4: Cathay PacificDocument6 pagesFlight 1 Mon, Mar 4: Cathay PacificMani Rathinam RajamaniNo ratings yet

- Fod Compliance & Findings - Bay 1Document2 pagesFod Compliance & Findings - Bay 1Mani Rathinam RajamaniNo ratings yet

- Letter of ParticipationDocument1 pageLetter of ParticipationMani Rathinam RajamaniNo ratings yet

- 3x5 Why Worksheet For SuppliersDocument1 page3x5 Why Worksheet For SuppliersMani Rathinam RajamaniNo ratings yet

- DoD PDR CheckList 18 April 2013Document87 pagesDoD PDR CheckList 18 April 2013Mani Rathinam RajamaniNo ratings yet

- Month Wise NC TrendDocument2 pagesMonth Wise NC TrendMani Rathinam RajamaniNo ratings yet

- BCB 501 (O&G) - Competence Requirements For Inspection Bodies For Accreditation Against PNGRB Regulations PDFDocument10 pagesBCB 501 (O&G) - Competence Requirements For Inspection Bodies For Accreditation Against PNGRB Regulations PDFMani Rathinam RajamaniNo ratings yet

- Matecconf Imanee2018 08013Document6 pagesMatecconf Imanee2018 08013Mani Rathinam RajamaniNo ratings yet

- 09 - Chapter 3Document11 pages09 - Chapter 3Mani Rathinam RajamaniNo ratings yet

- Standards Made Available Free of Cost To Combat COVID-19Document4 pagesStandards Made Available Free of Cost To Combat COVID-19Mani Rathinam RajamaniNo ratings yet

- BCB 201 (IB) - Mar 2019 PDFDocument38 pagesBCB 201 (IB) - Mar 2019 PDFMani Rathinam RajamaniNo ratings yet

- CTS Ieic 03022012Document2 pagesCTS Ieic 03022012Mani Rathinam RajamaniNo ratings yet

- (CPL) Component Placement List (CPL) / Pick & Place File (PNP) / (XYRS) Required InformationDocument1 page(CPL) Component Placement List (CPL) / Pick & Place File (PNP) / (XYRS) Required InformationMani Rathinam RajamaniNo ratings yet

- Mani Rathinam Rajamani: Certificate of CompletionDocument1 pageMani Rathinam Rajamani: Certificate of CompletionMani Rathinam RajamaniNo ratings yet

- Audit Handbook Appendix A - Prime References 29 June 2019Document225 pagesAudit Handbook Appendix A - Prime References 29 June 2019Mani Rathinam RajamaniNo ratings yet

- Zero Defects Reference PFMEA IndexDocument2 pagesZero Defects Reference PFMEA IndexMani Rathinam RajamaniNo ratings yet

- 03 APQP Oberhausen PDFDocument32 pages03 APQP Oberhausen PDFMani Rathinam RajamaniNo ratings yet

- 05 APRSAF-26 Appendix-E Side Events PDFDocument2 pages05 APRSAF-26 Appendix-E Side Events PDFMani Rathinam RajamaniNo ratings yet

- TLE10 Q1 Mod2 - ICT-Technical-Drafting - Cad Working Environment v3Document28 pagesTLE10 Q1 Mod2 - ICT-Technical-Drafting - Cad Working Environment v3Alyssa Jean QuemuelNo ratings yet

- TRG CalendarDocument28 pagesTRG Calendarchandrakant chaudhariNo ratings yet

- Umesh Ahirrao: Personal ProfileDocument2 pagesUmesh Ahirrao: Personal ProfileUmesh AhirraoNo ratings yet

- NITM BTech ME SyllabusDocument31 pagesNITM BTech ME SyllabusMian yasirNo ratings yet

- Muhammad Khalil 18PWIND0528 Machine Design & CADDocument3 pagesMuhammad Khalil 18PWIND0528 Machine Design & CADMuhammad KhalilNo ratings yet

- CB Insights Report The Generative AI Market MapDocument24 pagesCB Insights Report The Generative AI Market MapSazones Perú Gerardo SalazarNo ratings yet

- 3D Rendering Workshop 2021 Olivier Campagne Import / Export GuidelineDocument7 pages3D Rendering Workshop 2021 Olivier Campagne Import / Export GuidelineAlex HeNo ratings yet

- CAD CAM Laboratory ManualDocument227 pagesCAD CAM Laboratory ManualGopinath B L NaiduNo ratings yet

- Chapter 4 Product and Service DesignDocument34 pagesChapter 4 Product and Service DesignLIU ZHONGKUN - FPEPNo ratings yet

- AptDocument86 pagesAptSreehari ViswanathanNo ratings yet

- CollabCAD Ebook 1 0Document262 pagesCollabCAD Ebook 1 0aryansolanki262923No ratings yet

- Broschure 5006ex e Final KomprDocument12 pagesBroschure 5006ex e Final KomprrajeshthorweNo ratings yet

- InRoads Tutorial V8.9Document206 pagesInRoads Tutorial V8.9meganutzzNo ratings yet

- Computer Aided Analysis and Design For Electrical EnggDocument3 pagesComputer Aided Analysis and Design For Electrical Enggmanish_iitrNo ratings yet

- EDU - Detailed - Drawings - Exercises - 2017-Solid DrawingDocument10 pagesEDU - Detailed - Drawings - Exercises - 2017-Solid DrawingAhmet Bülent BozdoğanNo ratings yet

- Autocad: CAD SOFTWARE For Drafting 2d and 3d ModelingDocument21 pagesAutocad: CAD SOFTWARE For Drafting 2d and 3d ModelingAkashNo ratings yet

- Render VertexDocument5 pagesRender VertexLautaro GonzalezNo ratings yet

- ADMP MCQDocument37 pagesADMP MCQSiddheswar BiswalNo ratings yet

- Online Documentation For Altium Products - Importing and Exporting Design Files - 2015-07-14Document7 pagesOnline Documentation For Altium Products - Importing and Exporting Design Files - 2015-07-14Ha Bui VietNo ratings yet

- 2015-Plant Business Case EbookDocument12 pages2015-Plant Business Case Ebookh_eijy2743No ratings yet

- Building Tech - BimDocument3 pagesBuilding Tech - BimZulaikha GazaliNo ratings yet

- Techfest 2K23 - Rules & RegulationsDocument3 pagesTechfest 2K23 - Rules & Regulationsvishal rathiNo ratings yet

- Frame Generator PDFDocument13 pagesFrame Generator PDFWilly PeralesNo ratings yet