Professional Documents

Culture Documents

Manual Services 3126B PDF

Uploaded by

diony182Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Services 3126B PDF

Uploaded by

diony182Copyright:

Available Formats

La

direccin

no es

vlida

La URL no

es vlida y

no puede

ser

cargada.

Las

direcciones

web

se

escriben

normalmente

como

http://www.ejemplo.com

Asegrese

de

que

est

usando

barras

Ads by PlusHD.5 Ad Options

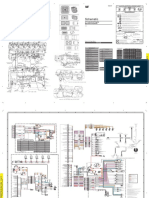

The Caterpillar 3126B HEUI Engine introduces a new era of the

diesel engine in the bus industry using the medium duty diesel

engine. The basic engine takes advantage of the 3116's best

features and years of experience and combines this with an

electronically controlled fuel system, larger displacement, and

other new features to produce the 3126B.

The fuel delivery system is controlled entirely by the Electronic

Control Module, hereafter called the ECM. The actual delivery of

the fuel into the combustion chambers is accomplished by the

Hydraulic Electronic Unit Injector system (HEUI), which will be

discussed later.

The ECM will identify short/open sensors or operating conditions

out of the normal range. It will alert the driver/mechanic through

the use of failure codes that are displayed on the dash.

At this point be advised that all subjects related to the operation

and maintenance of the engine are covered in the 3100 HEUI

manual provided with the chassis manual. Therefore no attempt

is made herein to cover engine repairs. Service and operating

instructions found in the Caterpillar manuals should be followed.

When in need of information concerning the engine, contact your

local Caterpillar dealer or distributor who is fully qualified and

capable of handling all engine warranty and service repairs.

Those responsible for operating and maintaining the buses

TL960 SERVICE MANUAL

Page 13-1

Caterpillar 3126B

HEUI Engines

powered by the 3126B engine are encouraged to read and study

the Caterpillar Operation and Maintenance manual at the

earliest opportunity. Certain operational characteristics should

be discussed with the bus operators to familiarize them on how

the ECM controls various functions.

Electronic Control Module

The ECM controls its various functions through signals from the

following sensors:

Injection Actuation Pressure

Turbo Boost Pressure

Engine Speed

Engine Timing

Coolant Temperature

Air Intake Temperature

Throttle Position

Vehicle Speed

The ECM provides total electronic control of the start and

duration of fuel injection. Data furnished by the sensors enable

the ECM to control the fuel injected into each cylinder, which

optimizes performance related to Normal and Cold weather

starting, warm up, emissions, noise, fuel economy, and

driveability.

Top Engine Limit

The ECM controls the top rpm of the engine, which is 2640 set

at the factory, by limiting the fuel to the injectors. The engine

does not have a mechanical governor.

Start-Up and Emission Control

White smoke is reduced by controlling injection timing and

delivery during cold operation and acceleration. The ECM uses

various sensor inputs to calculate timing and delivery that will not

produce smoke.

Vehicle Speed Limit

Maximum road speed is predetermined by the owner/operator at

TL960 SERVICE MANUAL

Page 13-2

La

direccin

no es

vlida

La URL no

es vlida y

no puede

ser

cargada.

Las

direcciones

web

se

escriben

normalmente

como

http://www.ejemplo.com

Asegrese

de

que

est

usando

barras

Ads by PlusHD.5 Ad Options

Ads by PlusHD.5 Ad Options

time of writing the specifications for the bus and is programmed

into the ECM by the factory. When the programmed speed limit

is reached the fuel to the injectors is limited, and will remain

limited until the bus slows to a speed below the limited speed.

Provisions have been made in the 3126B HEUI furnished by

Thomas to allow for the fuel to be gradually reduced as

maximum speed is approached, or about 2.5 mph before. This

process, called Soft Vehicle Speed Limiting, prevents a sudden

reduction of fuel at the top limit.

The soft vehicle speed limiting causes the engine to operate at

a reduced rpm while maintaining the desired maximum road

speed - a must if the best fuel economy is to be realized.

Engine Fast Idle

The engine is set to idle at 700 rpm by the factory; however,

provisions can be made for a fast idle of 1000 rpm on buses

operating in cold climates. This requires a dash mounted

ON/OFF switch with an "Enabled Indicator Light" on the switch.

Idle Shutdown Timer

The idle shutdown timer is designed to shut the engine OFF after

a predetermined period of idling. This can be between 3 minutes

and 60 minutes, depending on the initial programming.

The "Check Engine" light on the dash will begin to flash rapidly

90 seconds before the engine shuts down. The driver can

override the timer by depressing the brake pedal, if necessary,

by doing so while the light is flashing. This is only if idle

shutdown timer has been programmed to be overridden.

Engine Water Temperature Monitoring System

One of the features of the ECM system monitors the temperature

of the coolant. At 225

0

F (107

0

C) the "Check Engine" lamp will

come ON. If programmed, at that point the engine will gradually

"derate" in horsepower to a minimum of 120 hp, and road speed

will gradually reduce to 45 mph. This gives the operator ample

time to get off the road and prevent damage to the engine. All

drivers should be advised of this feature.

TL960 SERVICE MANUAL

Page 13-3

Note: All circuits powered by

the ignition switch will

remain HOT after the timer

shuts OFF. To avoid draining

the batteries the ignition

switch must be turned OFF

at that time.

Note: Excessive coolant

temperature will not shut

down the engine.

The ECM System Diagnostics

The ECM provides a flash code in the dash mounted "Check

Engine" lamp in the event of malfunction in or of some

component of the electronic control system. When the ECM

detects a problem the "Check Engine" light will come ON, or is

activated. At that time a failure diagnostic code will be entered

and stored in the ECM memory. The failure code can be

retrieved by 1) using the Caterpillar Electronic Control Service

tool, or 2) using the "Check Engine" light if the bus is equipped

with cruise control.

Check Engine Light Operation

When the ignition switch is turned ON, the lamp will illuminate for

5 seconds, which is a check to insure the lamp is working. The

ECM can be programmed to notify the driver of an active fault or

condition by blinking the lamp every 5 seconds after start-up.

The "Check Engine" lamp is also used to warn, by flashing

rapidly, that the "Idle Shutdown Timer" will shut the engine down

in 90 seconds. The driver can override the timer by depressing

the brake pedal, if necessary, by doing so while the light is

flashing. This is only if idle shutdown timer has been

programmed to be overridden.

Retrieval of a Failure Code

If the bus is equipped with Cruise Control the failure code can be

determined by the procedure outlined below. If not so equipped,

it will be necessary to use an Electronic Control Service tool that

is available from your Caterpillar dealer or from certain other

major tool suppliers. Use of the service tool will enable the

mechanic to retrieve codes stored in the ECM memory system

for periods longer than a day.

Using the Cruise Control to Determine a Failure Code

1. Start the engine.

2. Turn the Cruise Control switch to the OFF position.

3. Move the SET/RESUME switch to either position and

hold that position until the "Check Engine" lamp begins to

TL960 SERVICE MANUAL

Page 13-4

Ads by PlusHD.5 Ad Options

Ads by PlusHD.5 Ad Options

flash. The lamp will then flash to indicate a 2 digit code.

Release the Cruise Control switch at this point. Count the

first sequence of flashes to determine the first digit of the

failure code. After a 2 second pause the second digit of

the failure code will be flashed by the engine lamp.

If additional faults have occurred, the applicable failure code(s)

will then be flashed after a short pause.

Flash code 55 signals "No Detected Faults" have occurred since

the ignition switch was turned ON.

This subject is covered more in detail on pages 50 and 51 in the

3100 HEUI Operation and Maintenance Manual.

For various failure codes see the chart on page 13-11 for

Diagnostic Flash Codes/Engine Performance Relationship.

Initial Start-Up

When coolant temperature is below 64

0

F (18

0

C) the ECM

causes the engine to operate in a COLD MODE. During the

COLD MODE operation the engine will operate at the

predetermined FAST IDLE, 1000 rpm, horsepower is limited,

and under certain conditions the AIR INLET Heater may operate.

The engine should not be operated under full load until coolant

temperature reaches 160

0

F (71

0

C), which will reduce the

possibility of sticking valves due to a build-up of unburned fuel

on the valve stems.

Inlet Air Heater and Lamp

The Inlet Air system incorporates an Inlet Air Heater in the intake

manifold and a "MAN HTR" Lamp on the dash, connected in

parallel. When the heater is ON, the dash lamp is ON at the

same time.

The Inlet Air Heater is used to improve start ability in cold

weather and reduce white smoke. The ECM controls the heater

and lamp through a relay mounted beside the intake manifold.

Heater operation is determined during three stages of engine

operation: Power-up/Preheat, Cranking, and Engine Started

cycle.

TL960 SERVICE MANUAL

Page 13-5

The ECM is "powered-up" when the ignition switch is turned ON.

The heater lamp should glow for 2 seconds or so, regardless of

coolant temperature. If the combination of coolant temperature

and inlet air temperature is less than 77

0

F (25

0

C) the ECM will

turn the Inlet Air Heater and lamp ON for 30 seconds as a

preheat, and then go OFF. If the operator attempts to start the

engine during the "preheat" cycle the ECM will take over control

of the heater during the "cranking" cycle.

During the "cranking" cycle the heater will come ON if the

combined temperatures of the coolant and the Inlet Air is less

than 77

0

F (25

0

C) and will stay ON while cranking. If the engine

fails to start, the heater will resume the 30 second "preheat"

cycle.

After the engine has started the heater operation is still

determined by the combined temperatures of the coolant and

Inlet Air. The "engine started" cycle has two parts: a continuous

mode, followed by an ON/OFF cycle.

The "continuous mode" lasts for a maximum of 7 minutes. The

"ON/OFF" mode causes the heater to cycle ON and OFF at 10

second intervals. The "ON/OFF" mode can last up to 13 minutes.

Either of these modes can or will be interrupted when the

combined temperatures of the coolant and inlet air reaches 95

0

F

(35

0

C).

A failure or malfunction in either the inlet air sensor or the

coolant temperature sensor will show up as a flash code on the

"Check Engine" lamp.

Throttle/Fuel Control

The Electronic Control Module (ECM) controls the fuel flow to

the cylinders. Instead of a direct rod/cable from the accelerator

pedal to the fuel pump, the ECM receives a Pulse Width

Modulation (PWM) from a throttle position sensor which

incorporates a potentiometer. The sensor is located on the back

side of the accelerator pedal.

The ECM supplies 8 volts as input voltage to the potentiometer,

TL960 SERVICE MANUAL

Page 13-6

Ads by PlusHD.5 Ad Options

Ads by PlusHD.5 Ad Options

not 12 volts from the chassis system. The throttle position sensor

runs at a fixed frequency and amplitude. The 8 volts remain the

same, as does the frequency, throughout the full range of pedal

movement: the only thing that changes is the number of pulses

within an extremely short period of time. The internal circuitry in

the sensor causes a variation in the pulse width in the frequency,

depending on the position of the accelerator pedal.

The output signal from the sensor to the ECM is referred to as

the Duty Cycle or Pulse Width Modulation, and is expressed as

a percentage between 3 and 100%.

At Low Idle the sensor will produce a duty cycle of 10-22%. At

Full Throttle it will be 75-90%. This sensor-produced duty cycle

is translated in the ECM which determines the timing and

amount of fuel delivered to the cylinders.

Throttle Position Sensor Test Procedure

To test the TPS for being functional a meter that measures

frequency and duty cycle is required, such as the FLUKE model

87. This particular meter is also a volt/ohm meter.

1. Ignition switch must be OFF.

2. Disconnect the harness connector going to the throttle

sensor, not any other connector. (This connector is

located behind the left side windshield wiper motor

access door.)

3. Install a "breakout" T harness between the sensor and the

chassis harness.

4. Turn Ignition switch ON.

5. Set the meter to % Duty Cycle position. Measure the duty

cycle across Ground (pin B) and Signal (pin C).

6. Closed throttle reading should be 10-22%. Full throttle

should be 75-90%.

If the percentage figures fall within these ranges, the

sensor is good.

The same test can be made using the Caterpillar Electronic

Analyzer and Programmer toll, their model #8T9697 and tool

#8C9801 PWM Signal Adapter.

TL960 SERVICE MANUAL

Page 13-7

Caution: DO NOT

attempt to measure

resistance of the TPS. To do

so can cause catastrophic

damage to the sensor.

To make up a "breakout" T harness:

1. Join three 12" 10 AWG wires in the center of each with a

6" 20 AWG wire, making sure of 100% bond.

2. Place male Deutch connector #DT 04-3P-E004 on one

end of the three 12" wires.

3. Place a female Deutch connector on the opposite end

and on the 6" lead.

4. Using Caterpillar crimping tool, #1U5804, crimp the

terminals onto each wire. See Figure 1.

There may be times when it is more expedient to install a new

sensor or a new ECM in a process of elimination, which means

it would be wise to have one of each in stock.

Troubleshooting the Throttle Position Sensor System

Considerable training is required of the service technicians, and

investment must be made in some new sophisticated test

equipment, as well as, having on hand the appropriate service

and troubleshooting manuals from Caterpillar. The most critical

manual is Caterpillar Electronic Troubleshooting #7AS1-UP,

available from your area Caterpillar dealer. This manual goes

through a step-by-step sequence in checking any given fault

code that appears on the dash light.

Other Items Related to Operating the 3126B HEUI Engine

As mentioned earlier, all who are involved in operating and

servicing this engine are encouraged to study the 3100 HEUI

TL960 SERVICE MANUAL

Page 13-8

Figure 1

Ads by PlusHD.5 Ad Options

Ads by PlusHD.5 Ad Options

Operation and Maintenance Manual furnished with the bus. Most

comments made herein are excerpts from that manual and are

intended only to provide a broad overview of what the ECM does

and how the 3126B differs from older engines, as far as the fuel

system is concerned.

1. Operating units with winterfront/shutters - refer to the

section related to the cooling system.

2. Fuel, lubricating oil, and coolant requirements are

covered in the Caterpillar manual.

3. Jump starting - no special precautions need to be taken

to protect the electronic system, other than what you

would normally do in any jump starting operation.

Welding on the Chassis

Before welding on this bus equipped with an electronically

controlled engine, the following precautions should be observed:

1. Disconnect all cables connected to the batteries.

2. Disconnect both electrical connectors at the ECM.

3. Do NOT use the ECM or engine ground stud for

grounding the welder.

Customer Specifications

The customer determines certain parameters when writing the

specifications for this bus. (See page 13-12.) At that time he or

she was given the option of programming a password into the

ECM. Unless the correct password is entered, it is impossible to

change the maximum engine RPM originally programmed. The

same thing applies to the Vehicle Maximum Speed limit and any

other parameters that the customer specified. Certain features of

the ECM system are controlled only by Caterpillar, consequently

Caterpillar has its own password. However, customer passwords

are not required for the engine to operate. The purpose is to

prevent unauthorized alterations of the system as originally set

up.

If the customer password(s) is (are) forgotten or misplaced,

arrangements have to be made with the Caterpillar dealer to

obtain the factory password if a change in one of the features is

desired.

TL960 SERVICE MANUAL

Page 13-9

Tamper Resistance

One of the features of the ECM is a programmed tamper

resistance. This prevents the vehicle from exceeding its preset

maximum road speed in the event the vehicle speed signal is

lost. Example: Assume the rear axle ratio would allow the vehicle

to run 72 mph at 2400 rpm; however, management wants a

maximum of 60 mph. This is programmed into the ECM by the

factory, which means the engine would be turning over only 1600

rpm. (These are only figures used for the purpose of explaining

how the Vehicle Speed Limit works.) IF the speed signal is lost,

the bus would run 72 mph without the tamper resistance feature.

With this feature, however, it will run only 60 mph, and under

greatly reduced power.

Caterpillar Hydraulic Electronic Unit Injector System

The Caterpillar Hydraulic Electronic Unit Injector (HEUI) system

uses the ECM to control the injection of fuel, using high pressure

engine oil to provide the "muscle" instead of a cam shaft. In a

conventional mechanical fuel system fuel injection pressures

increases proportionally with engine speed, whereas the HEUI is

electronically controlled independent of engine speed. Both the

start and end of injection are electronically controlled. Plunger

movement timing is NOT limited to the speed or shape of a

camshaft. The next several pages describe how the HEUI

system operates.

TL960 SERVICE MANUAL

Page 13-10

Ads by PlusHD.5 Ad Options

TL960 SERVICE MANUAL

Page 13-11

DIAGNOSTIC FLASH CODE/ENGINE PERFORMANCE RELATIONSHIP - 3100 HEUI DIESEL ENGINE

01 - Idle Shutdown Override

15 - Injection Actuation Pressure Sensor Fault

17 - Excessive Injection Actuation Pressure Fault (1)

18 - Injection Actuation Pressure Control Valve Driver Fault

19 - Injection Actuation Pressure System Fault

21 - Sensor Supply Voltage Fault (1, 2)

25 - Boost Pressure Sensor Fault (1)

27 - Coolant Temperature Sensor Fault (1, 2)

28 - Check Throttle Sensor Adjustment

31 - Loss of Vehicle Speed Signal

32 - Throttle Position Sensor Fault

34 - Engine RPM Signal Fault

35 - Engine Overspeed Warning

36 - Vehicle Speed Signal Fault

38 - Air Inlet Temperature Sensor Fault (1, 2)

41 - Vehicle Overspeed Warning

47 - Idle Shutdown Occurrence

49 - Inlet Air Heater Driver Fault (1)

51 - Intermittent Battery Power to ECM

55 - No Detected Faults

56 - Check Customer/System Parameters

59 - Incorrect Engine Software

61 - High/Very High Coolant Temperature Warning

71 - Cylinder 1 Fault

72 - Cylinder 2 Fault

73 - Cylinder 3 Fault

74 - Cylinder 4 Fault

75 - Cylinder 5 Fault

76 - Cylinder 6 Fault

42 - Check Sensor Calibrations

NOTE: An X indicates that the effect on engine performance WILL occur if the code is active.

An asterisk (*) mark indicates that effect on engine performance MAY occur if the code is active.

1. These Diagnostic Flash Codes may affect the system only under specific environmental conditions such as cold weather start-up of engine or cold weather operation at high altitude.

2. These Diagnostic Flash Codes reduce the effectiveness of the engine monitoring feature when active.

Shutdown Vehicle: Drive the vehicle cautiously off the road and get immediate service. Severe engine damage may result.

Service ASAP: Driver should go to the nearest qualified service location.

Schedule: Driver should have problem investigated when convenient.

DIAGNOSTIC FLASH CODE EFFECT ON ENGINE PERFORMANCE SUGGESTED DRIVER ACTION

Engine

Misfire

Low

Power

Engine Speed

Reduced

Engine

Shutdown

Shutdown

Vehicle

Service

ASAP

Schedule

Service

x * * *

* * *

x x x x

*

x

* * *

*

x

*

x

*

x x

*

* *

* *

* *

x x x

* *

* * *

* *

*

*

x

*

x x x

*

* *

x x

*

* * *

* * *

* * *

* * *

* * *

* * *

x

*

TL960 SERVICE MANUAL TL960 SERVICE MANUAL

Page 13-12

Diagnostic Flash Code/Engine Performance

Relationship Chart Inside

CAT 3126 CUSTOMER PARAMETER WORKSHEET

*To accompany each order or parameters will be defaulted.

PARAMETER PARAMETER SETTING

Vehicle Speed Limiting ________________ MPH

If customer doesn't specify,

speed will be set at 65 mph

105 km. Actual maximum speed or

depends on axle ratio. Seventy

mph maximum speed allowed

on school bus models. ________________ KM

Vehicle Speed Limiting Protection Yes _______ No _______

Idle Shutdown Timer ________________ Minutes

3 to 60 minutes

Idle Shutdown Timer Override Yes ______ No _______

Maintenance Data Choose One:

PM Schedule _________ Hours or

_________ Mileage/KM

Customer Password ____________________

Up to 8 digits:

letters or numbers

Customer Name _______________________________

Address ______________________________________

City, State ____________________________________

Selling Distributor _____________________________

Distributor Order Number ______________________

Ads by PlusHD.5 Ad Options Ads by PlusHD.5 Ad Options

Ads by PlusHD.5 Ad Options

Caterpillar 3126B Product News

Higher Injection Pressures

An intensifier piston in the HEUI injector multiplies hydraulic

force on the plunger. By varying hydraulic input pressure,

injection pressure can be controlled in a range from 5,000 to

21,000 psi. These high pressures are available at idle as well as

high engine speeds. The higher injection pressures improve fuel

economy, performance, and emission capabilities.

HEUI System Components

1. Electronic Control Module (ECM):

The ECM is a microprocessor based system which

monitors various inputs and sensors from the vehicle and

engine as it controls the operation of the entire fuel

system. It contains information defining optimum fuel

system operational parameters. The ECM also has many

more external operational inputs than a mechanical

governor such as engine speed, timing, rail pressure,

boost pressure, etc. It can determine optimum fuel rate

and injection timing for any condition. It sends a precisely

controlled signal to energize the injector solenoid.

TL960 SERVICE MANUAL

Page 13-13

Electronic controls such as these are invaluable in

meeting new standards of exhaust emissions and noise

while maintaining excellent fuel economy. The ECM has

the ability to store data on mileage, fuel consumed, and

hours operated.

2. High Pressure Oil Supply Pump:

The hydraulic supply pump is a seven-piston fixed

displacement axial piston pump. It raises the system's oil

pressure level from typical engine operating oil pressure

of 40 psi to the actuation pressure required by the

injectors of 870 to 3300 psi. During normal engine

operation, pump output pressure is controlled by the

Injector Actuation Pressure Control Valve (IAPCV) which

dumps excess flow back to the return circuit. Pressures

for specific engine conditions are determined by the ECM.

3. Injector Actuation Pressure Control Valve:

The IAPCV is an electrically operated dump valve which

closely controls pump output pressure by dumping

excess flow back to the oil sump. A variable signal from

the ECM to the IAPCV determines pump output pressure.

Pressure while cranking a cold engine (below 50

0

F

[10

0

C]) is slightly higher because cold oil is thicker and

components in the injector move slower. The higher

pressure and advanced injection timing helps the injector

to fire faster until the viscosity of the oil is reduced.

4. HEUI Injector:

The injector uses the hydraulic energy of the pressurized

oil to cause injection. The pressure of the incoming oil

controls the speed of the intensifier piston and plunger

movement, and therefore, the rate of injection. The

amount of fuel injected is determined by the duration of

TL960 SERVICE MANUAL

Page 13-14

Ads by PlusHD.5 Ad Options

the pulse from the ECM and how long it keeps the

solenoid energized. As long as the solenoid is energized

and the poppet valve is off its seat, oil continues to push

down the intensifier and plunger until the intensifier

reaches the bottom of its bore.

Since the HEUI injector is the heart of the system, let's

look at its operation in detail.

Injector

The HEUI injector is hydraulically actuated by high pressure

engine oil supplied by the high pressure oil pump. It consists of

four major components:

1. Solenoid:

The solenoid is a very fast acting electromagnet which,

when energized, pulls the poppet valve off its seat.

2. Poppet Valve:

The poppet valve is held on its seat by a spring. In this

closed position, high pressure inlet oil is blocked and the

intensifier cavity is opened to drain. When the solenoid is

energized, the poppet is quickly lifted off its seat. The path

to drain is closed and the inlet for high pressure oil is

opened.

3. Intensifier Piston and Plunger:

When the poppet valve opens the inlet port, high pressure

oil enters the injector and acts on the top of the intensifier

piston. Pressure builds on the intensifier, pushing it and

the plunger down. The intensifier is six times larger in

surface area than the plunger, providing six times

TL960 SERVICE MANUAL

Page 13-15

multiplication of force. The downward movement of the

plunger pressurizes the fuel in the plunger cavity, causing

the nozzle to open. Thus 3,000 psi oil provides fuel

injection pressures of 21,000 psi.

4. Nozzle Assembly:

The nozzle assembly is of conventional design with the

exception of the fill check. This check ball seats and seals

during the downward stroke of the plunger to prevent

leakage of the high pressure fuel. During the return

stroke, it unseats allowing the plunger cavity to fill. The

nozzle valve is an inwardly opening type which lifts off its

seat when pressure overcomes the spring force. Fuel is

then atomized at high pressure through the nozzle tip.

Stages of Injection

There are three stages of injection with HEUI:

1. Fill Cycle:

During pre-injection all internal components have

returned to their spring loaded (non-actuated) positions.

The solenoid is not energized and the poppet valve is

TL960 SERVICE MANUAL

Page 13-16

Ads by PlusHD.5 Ad Options

Ads by PlusHD.5 Ad Options

blocking high pressure oil from entering the injector. The

plunger and intensifier are at the top of their bore and the

plunger cavity is full of fuel. Fuel pressure in the plunger

cavity is the same as fuel rail pressure, about 30 psi,

depending on conditions.

2. Injection:

When the ECM determines the injector should fire, the

following sequence of events occurs:

ECM sends signal pulse to injector solenoid,

Solenoid is fully energized almost instantly creating a

strong magnetic pull on the armature.

The armature is connected to the poppet valve. The

injection process begins when:

Magnetic pull of solenoid overcome spring tension

holding the poppet closed,

Poppet is quickly raised off its seat.

When poppet valve opens:

Upper poppet land closes off path to drain,

Lower land opens poppet chamber to incoming high

pressure oil,

TL960 SERVICE MANUAL

Page 13-17

High pressure oil flows around poppet to the top of

intensifier piston.

Pressure on the top of the intensifier forces it down along

with the plunger. The downward movement of the plunger

pressurizes the fuel in the plunger cavity and nozzle.

When the fuel pressure reaches Valve Opening Pressure

(VOP) of about 4,500 psi, the nozzle valve lifts off its seat

and injection begins.

As long as the solenoid is energized, the poppet remains

open and pressurized oil continues to flow in, pushing

down the intensifier and plunger. Injection pressure

ranges from 5,000-21,000 psi depending on engine

requirements. Injection continues until the solenoid is

deenergized, allowing the poppet spring to close the

poppet and shut off the high pressure oil.

TL960 SERVICE MANUAL

Page 13-18

Ads by PlusHD.5 Ad Options

Ads by PlusHD.5 Ad Options

3. End of Injection:

a. Drain Cycle

The end of the injection cycle begins when the ECM

terminates the electric pulse to the solenoid. The

following events occur:

The magnetic field of the solenoid collapses and

is no longer able to overcome poppet spring

tension to hold the poppet off its seat.

The poppet closes, shutting off high pressure oil

from entering the injector.

When the poppet is seated, the upper land of the

poppet opens the poppet cavity to drain.

Pressurized oil in the intensifier chamber and

poppet chamber flows upward around the poppet

seat, through the vent holes in the poppet sleeve

and out the adapter drain hole.

The pressure of the fuel in the plunger cavity

exerts an upward force on the plunger and

intensifier. As the pressure of the pressurized

oil above the intensifier drops, so does the

downward force on the intensifier.

TL960 SERVICE MANUAL

Page 13-19

The upward force from the pressurized fuel

almost instantly becomes greater than the

downward force on the intensifier so the

downward motion of the intensifier and plunger

stops.

When the plunger stops, fuel flow also stops.

With the check still open, the remaining pressure

on the fuel pushes a tiny amount of additional fuel

out the orifice holes. This causes a large pressure

drop which lowers nozzle pressure below Valve

Closing Pressure (VCP) of 3,200 psi. Spring

tension on the check then reseats the check and

injection stops.

b. Fill Cycle

When the check closes, injection stops and the fill

cycle starts as follows:

The poppet and intensifier cavities are open to

atmospheric pressure through the poppet valve

and adapter drain hole.

Pressure drops very rapidly in the intensifier and

plunger cavities to near zero.

TL960 SERVICE MANUAL

Page 13-20

Ads by PlusHD.5

Ads by PlusHD.5 Ad Options

The plunger return spring pushes upward on the

plunger and intensifier forcing oil around the

poppet, through the holes in the poppet sleeve

and out the adapter drain hole.

As the plunger rises, pressure in the plunger

cavity also drops to near zero. The fuel rail

pressure unseats the plunger fill check, allowing

the plunger cavity to fill with fuel.

The fill cycle ends when the intensifier is pushed

to the top of its bore.

The plunger cavity is full and the fill check returns

to its seat.

Pressure in the intensifier and poppet chambers

is zero.

The injection cycle is complete and is ready to

begin again.

Engine Replacement

No attempt is made herein to cover subjects related to

maintenance and repairs to the Caterpillar Engine. These

services are covered in the engine manual furnished by the

Caterpillar. These instructions should be followed at all times.

Your local Caterpillar facility is dedicated and capable of

performing warranty repairs and other engine maintenance

repairs. Contact your local Caterpillar distributor on any

questions or problems related to engine performance.

Some basic suggestions should be considered when preparing

to remove the engine.

1. Place the bus on a clean, level, smooth floor to facilitate

easy movement of the floor crane (fork lift) and

transmission jack. Leave adequate room behind the bus

to allow for safe removal of the engine package.

2. Set parking brakes, chock rear wheels.

3. Disconnect battery cables. If the bus is to be idle for an

extended period, remove the batteries and place them on

a trickle charge, or use them elsewhere.

4. Close the heater shut-off valves to prevent draining the

entire system.

5. Drain coolant in a clean receptacle and store in a clean

container.

TL960 SERVICE MANUAL

Page 13-21

6. Drain engine oil, transmission fluid, hydraulic fluids and

dispose according to local ordinances.

7. If a new or rebuilt engine is installed, or coolant is

contaminated, remove the radiator and send it out for

cleaning and flow testing.

8. Important: Install identification tags on each electrical

circuit, harness connector, air lines, and hoses as they

are removed. This will save much time and confusion

later as the replacement engine is installed. The

electronically controlled engines have several harnesses

and hoses that are a part of the engine package, and can

be removed with the engine assembly. Removing them

and replacing them with the engine in place can be very

time consuming. Study these items before beginning the

engine removal process.

The following suggestions are intended to remove the engine

and transmission as a package, along with some of the hoses

and harnesses. The limited space between the engine and

frame rail on the right side makes access difficult to some of the

connections.

Some may elect to remove the transmission first, this is a local

decision.

Engine Removal

1. Observe the 8 steps listed above.

2. Remove the engine compartment rear door, if a fork lift is

to be used to remove the engine package.

3. Remove body rear bumper.

4. Remove chassis rear bumper and upper support bar.

5. Remove air conditioner drive belt, if so equipped.

6. Remove air cleaner hoses and piping.

7. Remove charge air-to-turbocharger pipe, remove support

bracket at rear lift eye with the pipe.

8. Remove radiator upper and lower pipes and hoses.

Tag the sensor connector on the upper pipe.

9. Remove the radiator module assembly for two reasons:

(See Cooling section.)

a. to facilitate access to the right side of the engine.

b. to send the radiator out for cleaning and testing if the

TL960 SERVICE MANUAL

Page 13-22

Ads by PlusHD.5 Ad Options

Ads by PlusHD.5 Ad Options

TL960 SERVICE MANUAL

Page 13-23

engine is being replaced or if the coolant was

contaminated with oil.

10. Disconnect heater hoses at the shut-off valves on the

engine.

11. Disconnect hoses at the water filter.

12. Disconnect block heater, if so equipped.

13. Disconnect fuel lines at the fuel filter.

14. Disconnect fuel return hose at rear of block.

15. Disconnect hydraulic supply hose at the hydraulic pump.

16. Disconnect power steering pressure hose at the hydraulic

pump.

17. Disconnect O-1 governor air line from the O-1.

18. Disconnect air compressor main discharge air line at the

compressor.

19. Remove the chassis harness connector from ECU.

20. Remove all cables from the starter.

21. If the bus has a retarder, remove the retarder oil cooler

from the chassis.

22. Disconnect oil pressure hose from block.

23. Disconnect battery, ground, and tachometer cables from

alternator.

24. Remove exhaust pipe from the turbocharger.

25. Remove transmission dipstick support at the hydraulic

filter assembly.

26. Disconnect transmission oil cooler hoses and

temperature sensor at the transmission.

27. Disconnect speedometer sensor at rear of transmission.

a. Disconnect speed sensor at lower front corner of

transmission.

b. Disconnect transmission harness from the

chassis harness at the connection on the left side

of the transmission.

c. Remove the harness mounting bracket at top of

transmission.

28. Remove drive shaft from transmission, tie up out of the

way.

29. The bundle of hoses and harnesses on the right side of

the engine can be confusing as to how they should be

handled. The following suggestions are offered:

a. Cut the tie wraps that hold this bundle together.

Some of the hoses and harnesses are attached to

the chassis, others to the engine. When the tie

Caution: Be sure to

tag each cable as it is

removed to insure it will go

back onto the proper

terminal on the starter

(positive and ground).

wraps are removed the various hoses and

harnesses can be separated from each other.

b. Once this is done, move the chassis related items

over the top of the engine and tie them up out of

the way.

30. Remove front and rear motor support bolts.

31. Place a transmission jack beneath the transmission,

taking care not to damage the oil pan, making sure the

transmission sets firmly on the jack.

32. Connect engine lifting hoist (floor crane or fork lift) to a bar

or chain between the front and rear lifting eyes.

33. Lift the engine and transmission package slightly.

34. Remove the engine front support crossmember from the

chassis.

35. With adequate assistance, carefully pull the engine

package from the chassis, making sure all hoses, cables,

harnesses have been disconnected.

36. After removal, place the package on a secure and stable

mount.

37. If a replacement engine is to be installed, place it beside

the old engine and transfer all fittings, hoses, components

that are needed on the new engine. Make sure each is

installed in the same exact position as removed from the

old engine.

38. Depending on the service life of the major accessories

being moved, replace them with exchange units;

alternator, starter, hydraulic pump, air compressor, belts,

etc.

39. If the radiator has high mileage on it, or if it has

contaminated coolant in it, send it out to be cleaned and

tested. The same applies to the charge air cooler.

Removal and installation of the CAC is covered in the

Cooling section.

Engine Installation

Assuming all accessories, hoses, cables, etc. have been

installed in the same position as on the original engine, prepare

the engine package for installation. All loose or hanging hoses,

cables, harnesses should be tied securely against the engine to

prevent interference as the engine is moved into place.

TL960 SERVICE MANUAL

Page 13-24

Caution: When

pulling the package from the

chassis, make sure that all

hoses, harnesses, and

cables are disconnected

and secured from possible

damage.

Note: Be sure to tag each

hose, harness, and wire as it

is removed to be sure it is

reconnected correctly at

installation.

Caution: Make sure

not to damage transmission

oil pan with transmission

jack, and that the unit cannot

slip on jack.

Ads by PlusHD.5 Ad Options

La direccin no es vlida Ads by PlusHD.5 Ad Options

La direccin no es vlida Ads by PlusHD.5 Ad Options

Ads by PlusHD.5 Ad Options

1. Inspect the motor mount isolators for reuse, replace if in

doubt.

2. With the assistance of one or two aids, carefully move the

engine back in place in the chassis.

3. Install the front motor support crossmember. Torque

mounting bolts to 170 ft/lbs.

4. Lower engine onto the mounts, torque the mounting bolts

to 226 ft/lbs.

5. At this point, the most critical area lies in the proper

routing, connecting, and securing the various harnesses

and hoses to safeguard against interference or chafing

with other objects. Make sure all support clips are back on

the objects they were protecting.

6. Reconnect driveshaft to transmission.

7. Reinstall radiator module assembly, if it was removed.

8. Install all plumbing to engine and transmission.

9. Mount chassis rear bumper and upper support bar.

10. Attach rear body bumper.

11. Fill hydraulic reservoir, cooling system, and transmission.

12. After all the fluids have been installed, remove the fuel

solenoid wire from the solenoid. Rotate the engine with

the starter until pressure is registered on the oil pressure

gauge. Reconnect the solenoid wire, start the engine and

check for leaks.

13. Monitor the fluid levels immediately:

Check hydraulic reservoir. Do not allow it to empty,

otherwise, damage can be caused to the hydraulic pump.

Monitor the coolant level. Bleeding the system is outlined

in the Cooling section.

14. Attach engine compartment door.

15. Road test the bus for several miles; recheck for

performance and leaks.

TL960 SERVICE MANUAL

Page 13-25

Caution: When

moving the assembly into

the chassis, be careful to

prevent damage to hoses,

harnesses, cables, etc.

Caution: Take

extreme care to see that no

loose bolts, nuts, washers,

debris are inside any of the

pipes, hoses used in the

engine intake air system;

otherwise, severe damage

can be caused to the

turbocharger and inside the

combustion chambers.

TL960 SERVICE MANUAL

Page 13-26

Ads by PlusHD.5 Ad Options

Ads by PlusHD.5 Ad Options Ads by PlusHD.5 Ad Options

You might also like

- 3126B Serial DCS02760 Arr 2077523 Repair ManualDocument1,196 pages3126B Serial DCS02760 Arr 2077523 Repair Manualviemey1952100% (4)

- 3126Document5 pages3126Ebied Yousif AlyNo ratings yet

- Cat 3126e Service Manual: Read/DownloadDocument2 pagesCat 3126e Service Manual: Read/DownloadManabu Wakisaka40% (10)

- C15 Electronic Control SystemDocument5 pagesC15 Electronic Control SystemTakaNo ratings yet

- C12Document98 pagesC12Marcos Astete EgoavilNo ratings yet

- 3406 B Cat Engine Repair ManualDocument1 page3406 B Cat Engine Repair Manualibrahem0% (5)

- 3126E Commercial and Truck Engines and 3126B Engine-Maintenance IntervalsDocument91 pages3126E Commercial and Truck Engines and 3126B Engine-Maintenance IntervalsHazyDavey100% (1)

- ENGINE C15 (Torque de Bielas)Document4 pagesENGINE C15 (Torque de Bielas)Maquinaria Pesada ServisNo ratings yet

- SENR9525-00: 3126B Truck Engine Electrical SystemDocument2 pagesSENR9525-00: 3126B Truck Engine Electrical SystemSamuel Yogui Lara100% (4)

- SPN 5319 Fmi 31Document2 pagesSPN 5319 Fmi 31Terry33% (3)

- Cylinder Head: 3406E Marine EngineDocument3 pagesCylinder Head: 3406E Marine Enginemartinskaf100% (2)

- Cat C7 .Document4 pagesCat C7 .dionymackNo ratings yet

- Motor 3126 HEUIDocument128 pagesMotor 3126 HEUITiago Soares100% (2)

- C7 Cat - Dcs.sis - ControllerDocument2 pagesC7 Cat - Dcs.sis - Controllerrodinei80% (5)

- CAT C18 Connecting Rod Bearings - InstallDocument2 pagesCAT C18 Connecting Rod Bearings - InstallSayel MokhaimerNo ratings yet

- Fault Code 331 Injector Solenoid Driver Cylinder 2 Circuit - Current Below Normal, or Open CircuitDocument26 pagesFault Code 331 Injector Solenoid Driver Cylinder 2 Circuit - Current Below Normal, or Open CircuitAhmedmah100% (1)

- QuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualDocument2 pagesQuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualjengandxbNo ratings yet

- Cat 3176 Engine Manual: Table of ContentDocument2 pagesCat 3176 Engine Manual: Table of Contententreprise.tgctp2015100% (1)

- Valv CAT 3116Document8 pagesValv CAT 3116Tatiano Brollo100% (1)

- Catalogo Esco Cummins m11Document22 pagesCatalogo Esco Cummins m11Alexis Sanchez100% (1)

- C13, C15, and C18 Engines ARD Fuel Pressure Is HighDocument10 pagesC13, C15, and C18 Engines ARD Fuel Pressure Is HighRaphael Thorner100% (1)

- Jake BrackDocument6 pagesJake BrackDaniel DiazNo ratings yet

- Caterpillar Engine Service Training: 3126B HEUI UpdateDocument98 pagesCaterpillar Engine Service Training: 3126B HEUI UpdateEng-AhmedRashad100% (3)

- Engine Valve Lash - Inspect - Adjust... 3408E and 3412E Engines For Caterpillar Built Machines #I01625568 CaterpillarDocument4 pagesEngine Valve Lash - Inspect - Adjust... 3408E and 3412E Engines For Caterpillar Built Machines #I01625568 CaterpillarinduramNo ratings yet

- Cat - Dcs.sis - Controller 3056E 356 PDFDocument2 pagesCat - Dcs.sis - Controller 3056E 356 PDFДрагиша Небитни ТрифуновићNo ratings yet

- Caterpillar C7 - C9 - Sample EngDocument11 pagesCaterpillar C7 - C9 - Sample Engpp100% (4)

- C11 C13 WiringDocument14 pagesC11 C13 Wiringbenge henriqueNo ratings yet

- TSPG - Engine Tools 2-139 A 2-220 PDFDocument82 pagesTSPG - Engine Tools 2-139 A 2-220 PDFAKshay100% (1)

- 420F Backhoe Loader SKR00001-UP (MACHINE) POWERED BY C4.4 Engine (SEBP5986 - 55) - DocumentaciónDocument7 pages420F Backhoe Loader SKR00001-UP (MACHINE) POWERED BY C4.4 Engine (SEBP5986 - 55) - DocumentaciónRosa ChNo ratings yet

- Engine 3114, D6m Testing-and-Adjusting-injekktora I Ventila 3126-MeDocument63 pagesEngine 3114, D6m Testing-and-Adjusting-injekktora I Ventila 3126-Mezeljko100% (3)

- 320D CDocument16 pages320D CDwi Noviyanto100% (1)

- C11 Valves and InjDocument7 pagesC11 Valves and Injraymon1191No ratings yet

- E7 TiempoDocument12 pagesE7 TiempoJonatan Arango Gomez67% (3)

- 3126 OverhaulDocument2 pages3126 Overhaullalo11715100% (2)

- 301 12 PDFDocument13 pages301 12 PDFEduardo VillatoroNo ratings yet

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - Installhenry lavieraNo ratings yet

- 8YS1-Up, 9NS1-UpDocument60 pages8YS1-Up, 9NS1-UpKristen Holmes100% (1)

- Isb4.5 CM2350 FC 3741Document11 pagesIsb4.5 CM2350 FC 3741John MichaelNo ratings yet

- Transmicion de CF 500, CF 600 PDFDocument337 pagesTransmicion de CF 500, CF 600 PDFgusspeSNo ratings yet

- 2010-09-26 202624 NEHS0610-09 3100 Fuel Setting ToolingDocument32 pages2010-09-26 202624 NEHS0610-09 3100 Fuel Setting ToolingRoberto Manriques Estrada100% (3)

- 3304-3306 Medidas de Bielas y BancadasDocument3 pages3304-3306 Medidas de Bielas y BancadasJuan Carlos RivasNo ratings yet

- Especificaciones Motor Caterpillar C15Document2 pagesEspecificaciones Motor Caterpillar C15juan carlos rojas cadenaNo ratings yet

- C13 TDC InstallDocument4 pagesC13 TDC InstallEwgeny100% (1)

- Cat c7 Engine Serial Number Location PDFDocument3 pagesCat c7 Engine Serial Number Location PDFTerry Saxton0% (1)

- Electrical System C7 Industrial Engine: Harness and Wire Electrical Schematic SymbolsDocument4 pagesElectrical System C7 Industrial Engine: Harness and Wire Electrical Schematic SymbolsCésar Pérez100% (3)

- Cat 3126 EWD PDFDocument48 pagesCat 3126 EWD PDFAbdul Khaliq100% (1)

- C7 On-Highway Engine Electrical System: Kal1-Up SAP1-3955Document2 pagesC7 On-Highway Engine Electrical System: Kal1-Up SAP1-3955Selvin GalindoNo ratings yet

- Fault Code Cat c15Document4 pagesFault Code Cat c15Haris Prayogo100% (1)

- CAT 3126 Parts Manuals PDFDocument1,040 pagesCAT 3126 Parts Manuals PDFDavid B100% (5)

- Operation and Maintenance Manual: C11 and C13 Industrial EnginesDocument98 pagesOperation and Maintenance Manual: C11 and C13 Industrial Enginesaps100% (1)

- 3054 Engine Valve Lash - InspectAdjustDocument5 pages3054 Engine Valve Lash - InspectAdjusthenry lavieraNo ratings yet

- Cat 3126 ManualsDocument2 pagesCat 3126 ManualsElibey Cuadros Berbesi88% (25)

- Caterpillar 3126Document0 pagesCaterpillar 3126manuel12515100% (22)

- 3126 HeuiDocument26 pages3126 HeuiBradley LodderNo ratings yet

- Cat Eng-Er Serv PDFDocument25 pagesCat Eng-Er Serv PDFGiapy Phuc TranNo ratings yet

- Service 3126Document18 pagesService 3126jrrodrigueza293% (15)

- Caterpillar 3126 HEUI Engines: Mvp-Er Service ManualDocument6 pagesCaterpillar 3126 HEUI Engines: Mvp-Er Service ManualJesus Almanzar SantosNo ratings yet

- Caterpillar 3126 HEUI Engine: Mvp-Ef Service ManualDocument18 pagesCaterpillar 3126 HEUI Engine: Mvp-Ef Service ManualDarwin PerdomoNo ratings yet

- 303-03 Engine Cooling 2.3L EcoBoost - Description and Operation - System OperationDocument3 pages303-03 Engine Cooling 2.3L EcoBoost - Description and Operation - System OperationCARLOS LIMADANo ratings yet

- 3126e Comercial y 3126B PDFDocument20 pages3126e Comercial y 3126B PDFdiony1820% (1)

- Wiring Diagrams 3126 e PDFDocument2 pagesWiring Diagrams 3126 e PDFdiony18282% (11)

- Clean Gas Induction Cat C7 PDFDocument1 pageClean Gas Induction Cat C7 PDFdiony182No ratings yet

- Cat C15 Specifications PDFDocument30 pagesCat C15 Specifications PDFdiony182No ratings yet

- Kodiak C4500 y C5500 PDFDocument2 pagesKodiak C4500 y C5500 PDFdiony182No ratings yet

- Clean Gas Induction Cat C7 PDFDocument1 pageClean Gas Induction Cat C7 PDFdiony182No ratings yet

- Tier Epa EmissionsDocument5 pagesTier Epa Emissionsdiony182No ratings yet

- Cat C15 Specifications PDFDocument30 pagesCat C15 Specifications PDFdiony182No ratings yet

- Tier Epa EmissionsDocument5 pagesTier Epa Emissionsdiony182No ratings yet

- Top Kick T Series 2007Document24 pagesTop Kick T Series 2007diony1820% (2)

- Presentacion 797BDocument133 pagesPresentacion 797BgustavoNo ratings yet

- Kpit AutosarDocument74 pagesKpit AutosarChethanNo ratings yet

- DIAGRAMADocument2 pagesDIAGRAMALuis50% (2)

- Regenerative Braking SystemDocument16 pagesRegenerative Braking SystemTanvi KhuranaNo ratings yet

- Mmam 21me54 Module 4Document38 pagesMmam 21me54 Module 4ks2876261No ratings yet

- Bosch Motorsport Catalog 2015Document500 pagesBosch Motorsport Catalog 2015Shnawina Rhumis100% (2)

- Development of Virtual Dynamometer Using dSPACE ControlDesk - TCS PuneDocument13 pagesDevelopment of Virtual Dynamometer Using dSPACE ControlDesk - TCS PuneSiva ReddyNo ratings yet

- 2012 Ranger RZR 570 IntlDocument403 pages2012 Ranger RZR 570 IntlWendyNo ratings yet

- SMAN52730 - Wiring Diagram B11RaDocument58 pagesSMAN52730 - Wiring Diagram B11RaJonathan Nuñez100% (1)

- Cascadia Ceesg FD 2012Document220 pagesCascadia Ceesg FD 2012Jose Luis Calla Huanca95% (21)

- Suzuki Swift Sistema Direccion Asistida EPSDocument39 pagesSuzuki Swift Sistema Direccion Asistida EPSEduardomg Garage Mecanic88% (8)

- 2018-10-24 - UD Trucks Quester - UD HDE - Error CodeDocument39 pages2018-10-24 - UD Trucks Quester - UD HDE - Error CodeAhmad Salimin95% (20)

- Shift Control Mechanism 1. General: Chassis - A340E, A340F, A343E and A343F Automatic Transmissions CH-30Document3 pagesShift Control Mechanism 1. General: Chassis - A340E, A340F, A343E and A343F Automatic Transmissions CH-30Maxi SardiNo ratings yet

- 3 4 Anton Gerasimov OTADocument49 pages3 4 Anton Gerasimov OTAsaika_1982No ratings yet

- Caterpillar 775E - Specifications - AEHQ5457 (11-2001) PDFDocument28 pagesCaterpillar 775E - Specifications - AEHQ5457 (11-2001) PDFAndrea MinaNo ratings yet

- Toyota Avensis 2ad-Ftv FHV EngineDocument32 pagesToyota Avensis 2ad-Ftv FHV EngineGilbert Kamanzi100% (1)

- ТЕСТ ТОПЛИВОDocument14 pagesТЕСТ ТОПЛИВОАндрей ДубовецNo ratings yet

- Ds SeriesDocument56 pagesDs SeriesLeandro MesquitaNo ratings yet

- 2JZGTE VVTI InformationDocument25 pages2JZGTE VVTI Informationjonb42100% (1)

- 2007 LC4 690 LC8 990 Diagnostic Measurements Failure Codes PDFDocument49 pages2007 LC4 690 LC8 990 Diagnostic Measurements Failure Codes PDFEarl HarbertNo ratings yet

- Komatsu Hydraulic Excavator Pc228uslc 3 Eo Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc228uslc 3 Eo Shop Manualbianca100% (45)

- Perkins 400-2300 SeriesDocument6 pagesPerkins 400-2300 Seriesravikant8750% (2)

- Engine Performance - Hyundai Accent Gs 2008 - System Wiring DiagramsDocument7 pagesEngine Performance - Hyundai Accent Gs 2008 - System Wiring Diagramsbrosgaming007No ratings yet

- OMZ104746 - 7250, 7350, 7450, 7550, 7750 and 7850 Self-Propelled Forage Harvesters, Block File - ZX09263 - 0002ACA - 19 - 22JUL08.htm PDFDocument5 pagesOMZ104746 - 7250, 7350, 7450, 7550, 7750 and 7850 Self-Propelled Forage Harvesters, Block File - ZX09263 - 0002ACA - 19 - 22JUL08.htm PDFmuftah76No ratings yet

- 1K 2KD Fuel Injection Volume ValueDocument12 pages1K 2KD Fuel Injection Volume ValueJimmy100% (2)

- BypassGoldManual PDFDocument6 pagesBypassGoldManual PDFBrad FrancNo ratings yet

- CTC-070 Answerbook Oct13Document57 pagesCTC-070 Answerbook Oct13Giovanny Colorado100% (2)

- ECM Gran Vitara V6 H27Document6 pagesECM Gran Vitara V6 H27Alexa SaltosNo ratings yet

- CDS23008 GPR-DI M1 PackageDocument18 pagesCDS23008 GPR-DI M1 PackagehutaNo ratings yet

- 4M06 Spec Sheet RevbDocument4 pages4M06 Spec Sheet RevbIKNo ratings yet

- Automotive Electronic Diagnostics (Course 1)From EverandAutomotive Electronic Diagnostics (Course 1)Rating: 5 out of 5 stars5/5 (6)

- Why We Drive: Toward a Philosophy of the Open RoadFrom EverandWhy We Drive: Toward a Philosophy of the Open RoadRating: 4 out of 5 stars4/5 (6)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]From EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Rating: 5 out of 5 stars5/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceFrom EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVFrom EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVRating: 5 out of 5 stars5/5 (2)

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)From EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)No ratings yet

- The Official Highway Code: DVSA Safe Driving for Life SeriesFrom EverandThe Official Highway Code: DVSA Safe Driving for Life SeriesRating: 3.5 out of 5 stars3.5/5 (25)

- New Hemi Engines 2003 to Present: How to Build Max PerformanceFrom EverandNew Hemi Engines 2003 to Present: How to Build Max PerformanceNo ratings yet

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildFrom EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildRating: 5 out of 5 stars5/5 (1)

- Turbo: Real World High-Performance Turbocharger SystemsFrom EverandTurbo: Real World High-Performance Turbocharger SystemsRating: 5 out of 5 stars5/5 (3)

- Top 21 Hypercars: The Best and Fastest Car Ever MadeFrom EverandTop 21 Hypercars: The Best and Fastest Car Ever MadeRating: 3 out of 5 stars3/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Building Honda K-Series Engine PerformanceFrom EverandBuilding Honda K-Series Engine PerformanceRating: 5 out of 5 stars5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WFrom EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WRating: 4.5 out of 5 stars4.5/5 (6)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)