Professional Documents

Culture Documents

04 PID Controllers

Uploaded by

Mansour AbdulazizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 PID Controllers

Uploaded by

Mansour AbdulazizCopyright:

Available Formats

Proportional-Integral-Derivative

PID Controllers

Cheng-Liang Chen

PSE

LABORATORY

Department of Chemical Engineering

National TAIWAN University

Chen CL 1

Outline

Proportional-Integral-Derivative Controller:

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

PID Control based on CurrentFuture Error with ConstantReset Bias

Chen CL 2

Steady Oset of PID when using Constant bias

Series PID Parallel PID

Response of PID Controllers to Typical Inputs

Operational Aspects of PID Controllers

problems of D action: sensitivity to noise

problems of I action: moving PB and reset windup

manual control requirement

bump-less transfer

Chen CL 3

PID Controller: A Survey

More Than 95% of Controllers Are of PID Type

Bialkowski (1993): paper mills in Canada

A typical mill has more than 2000 control loops

97% of loops use PI control

Only 20% of control loops were found to work well

and decrease process variability

Reasons for poor performance were

Poor tuning (30%)

Valve problems (30%)

Others (20%): sensor, bad sampling rates

Chen CL 4

PID Controller: A Survey

More Than 95% of Controllers Are of PID Type

Ender (1993)

30% of installed process controllers operate in manual

20% of loops use default parameters (factory tuning)

30% of loops function poorly because of equipment

problems (valves, sensors )

Chen CL 5

Why PID Controllers Are So Popular ?

Structure: simple

Easy for understanding

A few adjustable parameters, easy for tuning

Performance: good or acceptable level

Robustness: strong to uncertain operating conditions

Applicability: wide to dierent processes/industries

Chen CL 6

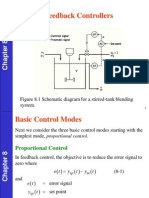

A Heat Exchanger with Feedback Control

Valve: AFC (ATO); Controller: Reverse Action

Chen CL 7

Simplest Controller: On-O Control

u(t) =

_

_

u

b

+ u if y(t) < y

sp

d

u

b

u if y(t) > y

sp

+ d

Problem: oscillatory response !

On-o cares about control direction only;

On-o gives same control action for dierent error magnitudes

Solution: control action considering error magnitude

Chen CL 8

Current-Error-Based P Control

with Constant Bias (SS value)

current control corrective action, u(t)

current error magnitude, e(t) y

sp

y(t)

u(t) e(t) y

sp

y(t)

u(t) = K

c

e(t) p(t) (K

c

: adjustable proportionality)

u(t) = K

c

e(t)

. .

u(t)

+ u

b

..

SS value

for e(t) = 0

Chen CL 9

Problem of Current-Error-Based P Control

u(t) = K

c

e(t)

. .

u(t)

+ u

b

..

SS value

for e(t) = 0

Too late to correct current error

It takes time to know eect of control on output

conservative action to guarantee stability

limited achievable control performance

Chen CL 10

Solution: Future-Error-Based P Control

Back to the Future

Control action based on future condition (error)

take control action in advance

better control performance

u(t) = K

c

e(t+T

d

)

. .

u(t)

+ u

b

..

SS value

for e(t) = 0

u(t) = K

c

e(t+T

d

)

. .

u(t)

+ u

b

..

SS value

for e(t) = 0

Chen CL 11

Future-Error-Based P Control

Gives Better Performance

HE: pulse decrease in input temperature

At t

1

: e(t

1

+ T

d

) > e(t

1

)

P control based on e(t

1

+ T

d

) has larger action

more steam smaller undershoot in T

( Pre-Act P)

..

K

c

e(t

1

+ T

d

) + u

b

> K

c

e(t

1

) + u

b

. .

( Normal P)

Chen CL 12

Future-Error-Based P Control

Gives Better Performance

HE: pulse decrease in input temperature

At t

2

: e(t

2

+ T

d

) < e(t

2

)

P control based on e(t

2

+ T

d

) has smaller action

less steam smaller overshoot in T

( Pre-Act P)

..

K

c

e(t

2

+ T

d

) + u

b

< K

c

e(t

2

) + u

b

. .

( Normal P)

Chen CL 13

Implement Future-Error-Based P Control

As Current-Error-Based PD Control

Original P: u(t) = K

c

e(t) + u

b

PreAct P: u(t) = K

c

e(t + T

d

) + u

b

K

c

_

e(t) + T

d

de(t)

dt

_

. .

e

(t)e(t+T

d

)

+ u

b

Chen CL 14

u(t) = K

c

e(t + T

d

) + u

b

K

c

_

e(t) + T

d

de(t)

dt

_

. .

e

(t)e(t+T

d

)

+ u

b

Chen CL 15

Sub-Summary

P control based on current error with constant bias

e(t) e(t + T

d

)

P control based on future error with constant bias

u(t) = K

c

e(t + T

d

) + u

b

K

c

e(t) + T

d

de(t)

dt

(t)

+u

b

PD control based on current error with constant bias

Chen CL 16

Steady Oset for P (PD) Control

Non-zero Steady State Oset (I): Setpoint Change

Initial steady state: (all variables [0, 100%])

y = y

sp

= y e = 0 u = u

b

= u =

Chen CL 17

Case I: Setpoint change y

sp

: y y +

New steady state: y =?, u =?, e =?

(change in y) = K

p

{change in process input}

= K

p

{(change in CO) + (change in load)}

y y = K

p

_

_

_

u u

. .

change in CO

+

..

change in load=0

_

_

_

= K

p

_

K

c

e

..

_

_

(y + )

. .

new sp

y

_

_

+u

b

. .

u

u +

..

=0

_

_

y = y +

K

c

K

p

1 + K

c

K

p

. .

new steady state

= y +

. .

desired sp

Chen CL 18

Non-zero Steady State Oset (II): Load Change

Initial steady state: (all variables [0, 100%])

y = y

sp

= y e = 0 u = u

b

= u =

Chen CL 19

Case II: Load change : +

New steady state: y =?, u =?, e =?

(change in y) = K

p

{change in process input}

= K

p

{(change in CO) + (change in load)}

y y = K

p

_

_

_

u u

. .

change in CO

+

..

change in load=

_

_

_

= K

p

_

K

c

e

..

_

_

(y)

..

sp

y

_

_

+u

b

. .

u

u +

_

_

y = y +

K

p

1 + K

c

K

p

. .

new steady state

= y

..

desired sp

Chen CL 20

Current-Error-Based P Control

with Reset Bias

Question:

using P or PD control with constant bias,

how to guarantee zero steady-state oset ?

(at steady state: e = 0, y = y

sp

)

Answer: u = u

b

at SS

desired: e = 0 (y = y

sp

) at SS

u = u

b

at SS

Chen CL 21

Reset Bias for Zero SS Oset

Simplest Method

Simplest method to guarantee u = u

b

at SS:

Let u

b

(t) = u(t) for all t

then u

b

= u at steady state

e = 0 y = y

sp

P control based on current error with reset bias

via a unity-gain dynamics (not workable !)

Chen CL 22

Reset Bias for Zero SS Oset

Feasible Method

Feasible method to guarantee u = u

b

at SS:

desired: u

b

= u at SS

simplest method: u

b

(t) equals u(t) t

feasible method: u

b

(t) tracks u(t) t

u

b

(t) tracks u(t) with rst-order dynamics:

(use T

i

to adjust tracking velocity)

T

i

du

b

(t)

dt

+ u

b

(t) = u(t)

. .

equal

. .

tracking

Chen CL 23

P control based on current error with reset bias

via rst-order dynamics

Chen CL 24

Reset Bias Integral Action

(1) u(t) = K

c

e(t) + u

b

(t) (P with reset bias)

(2) u(t) = T

i

du

b

(t)

dt

+ u

b

(t) (u

b

(t) tracks u(t))

T

i

du

b

(t)

dt

= K

c

e(t) = p(t)

u

b

(t) u

b

=

1

T

i

_

t

0

p(t)dt

. .

change in bias

=

K

c

T

i

_

t

0

e(t)dt

. .

=u

b

(t)

Chen CL 25

(1) u(t) = K

c

e(t)

. .

p(t)

+

u

b

(t)

..

1

T

i

_

t

0

p(t)(t)dt

. .

u

b

(t)

+u

b

(PI)

= K

c

e(t) +

K

c

T

i

_

t

0

e(t)dt + u

b

= K

c

_

e(t) +

1

T

i

_

t

0

e(t)dt

_

+ u

b

Reset bias: interpreted as integral action

current-error-based P control with reset bias

(reseting bias according to integral of error)

= current-error-based PI control with constant bias

Chen CL 26

Reset Bias Integral Action

Chen CL 27

Chen CL 28

Future-Error-Based P Control with Reset Bias

P control based on future error

. .

PD

with reset bias

. .

PI

Interpreted As PD +PI (series PID ) Controller

e(t + T

d

) e(t) + T

d

de(t)

dt

e

(t)

Chen CL 29

u

b

(t) =

1

T

i

_

K

c

e

(t)dt + u

b

u(t) = K

c

e

(t)

. .

p(t)

+

u

b

(t)

..

1

T

i

_

K

c

e

(t)

. .

p(t)

dt +u

b

. .

u

b

(t)

Chen CL 30

Series PID Parallel PID

K

p

c

= K

c

_

1 +

T

d

T

i

_

K

c

= K

p

c

_

0.5 +

_

0.25

T

p

d

T

p

i

_

T

p

i

= T

i

_

1 +

T

d

T

i

_

T

i

= T

p

i

_

0.5 +

_

0.25

T

p

d

T

p

i

_

T

p

d

= T

d

/

_

1 +

T

d

T

i

_

T

d

= T

p

d

/

_

0.5 +

_

0.25

T

p

d

T

p

i

_

Chen CL 31

Series PID Parallel PID

p(t) = K

c

_

e(t) + T

d

de(t)

dt

_

u(t) = p(t) + u

b

(t)

T

i

du

b

(t)

dt

+ u

b

(t) = u(t)

P(t) = K

c

_

E(t) + T

d

dE(t)

dt

_

U(t) = P(t) + U

b

(t)

T

i

dU

b

(t)

dt

+ U

b

(t) = U(t)

P(s) = K

c

(E(s) + T

d

sE(s)) = K

c

(1 + T

d

s)E(s)

U(s) = P(s) + U

b

(s)

T

i

sU

b

(s) + U

b

(s) = U(s) U

b

(s) =

1

T

i

s+1

U(s)

Chen CL 32

U(s) = P(s) + U

b

(s) = P(s) +

1

T

i

s+1

U(s)

U(s) =

T

i

s+1

T

i

s

P(s)

=

T

i

s+1

T

i

s

K

c

(1 + T

d

s)E(s) (series PID)

=

K

c

T

i

s

_

T

i

T

d

s

2

+ (T

i

+ T

d

)s + 1

_

E(s)

= K

c

T

i

+T

d

T

i

_

1 +

1

(T

i

+T

d

)s

+

T

i

T

d

T

i

+T

d

s

_

E(s)

= K

c

_

1 +

T

d

T

i

_

_

1 +

1

T

i

1+

T

d

T

i

s

+ T

d

_

1 +

T

d

T

i

_

s

_

E(s)

= K

p

c

_

1 +

1

T

p

i

s

+ T

p

d

s

_

E(s) (parallel PID)

Chen CL 33

P Control Based on {Current, Future} Error

with {Constant, Reset} Bias

const. bias reset bias

current error P PI

future error PD PID

Chen CL 34

P Action to Step Error

Chen CL 35

PD Action to Step Error

Chen CL 36

PI (P-Reset) Action to Step Error

Chen CL 37

PID Action to Step Error

Chen CL 38

PD Action to Ramp Error

Chen CL 39

PID Action to Ramp Error

Chen CL 40

Problem of D Action (I):

Sensitive to High-Frequency Noise

Derivative action without lter:

Problem: sinusoidal input output mag. frequency

e(t) = Asin(t) D(t) = T

d

de(t)

dt

= T

d

A cos (t)

Chen CL 41

Solution: (rst-order) low-pass lter

T

d

N

dD(t)

dt

+ D(t) = T

d

de(t)

dt

. .

D action

. .

equal

. .

follow

Chen CL 42

Problem: (again)

derivative + ltering large inner signal (e

d

)

Solution: ltering derivative

Chen CL 43

Problem of D Action (II):

Bump Response to Step Input

Solution 1: D action on measurement

Derivative on measurement:

y(t + T

d

) y(t) + T

d

dy(t)

dt

e(t + T

d

) = y

sp

y(t + T

d

)

= y

sp

_

y(t) + T

d

dy(t)

dt

_

e(t) T

d

dy(t)

dt

For noise: ltering + derivative action

T

d

N

dy

f

(t)

dt

+ y

f

(t) = y(t) (y

f

(t) follows y(t))

D(t) = K

c

T

d

dy

f

(t)

dt

(derivative on y

f

(t))

Chen CL 44

Solution 2: ltering on setpoint signal

(use r(t) as the practical setpoint)

Solution 3: setpoint weighting (skip)

Chen CL 45

Problem of Reset (I):

Moving Proportional Band

(Reverse) P with reset bias: ([u

min

, u

max

] = [0%, 100%])

u(t) = K

c

_

y

sp

y(t)

+ u

b

(t) (K

c

> 0)

y(t) = y

max

= ? u(t) = K

c

_

y

sp

y

max

+ u

b

(t) = u

min

= 0%

y(t) = y

min

= ? u(t) = K

c

_

y

sp

y

min

+ u

b

(t) = u

max

= 100%

y(t) > y

max

u(t) < u

min

(saturation !)

y(t) < y

min

u(t) > u

max

(saturation !)

y(t) {y

min

, y

max

} u(t) {u

max

, u

min

} (normal operation)

Chen CL 46

Proportional Band: (for normal operation)

PB = [y

min

, y

max

] =

_

y

sp

+

u

b

(t)u

min

K

c

, y

sp

+

u

b

(t)u

max

K

c

_

=

_

y

sp

+

u

b

(t)0

K

c

, y

sp

+

u

b

(t)100

K

c

_

If y(t) PB, Then controller output is normal

width of PB: aected by K

c

y

max

y

min

=

u

max

u

min

K

c

=

100

K

c

%

position of PB: aected by K

c

, y

sp

, u

b

(t)

Chen CL 47

Example:

y

sp

= 50%, K

c

= 2, u

b

(t) = 50% t,

u

min

= 0%, u

max

= 100%

PB =

_

50 +

u

b

(t) 100

K

c

% , 50 +

u

b

(t) 0

K

c

%

_

= [ 25% , 75% ]

Chen CL 48

Moving PB due to Resetting Bias: Example

Process: G(s) =

_

0.016

3s+1

__

50

30s+1

__

1

10s+1

_

ZN-PI tuning: K

c

= 3.40, T

i

= 37 ( PB =

100%

K

c

%/%

= 29.4%)

Chen CL 49

Moving PB due to Resetting Bias: Example

Process: G(s) =

_

0.016

3s+1

__

50

30s+1

__

1

10s+1

_

Faster reset: K

c

= 3.40, T

i

= 18.5 ( PB =

100%

K

c

%/%

= 29.4%)

Chen CL 50

Moving PB due to Resetting Bias: Example

Process: G(s) =

_

0.016

3s+1

__

50

30s+1

__

1

10s+1

_

Slower reset: K

c

= 3.40, T

i

= 74 ( PB =

100%

K

c

%/%

= 29.4%)

Chen CL 51

Problem of

Reset (II)

Reset Windup

HE Example

Chen CL 52

Anti Reset-Windup:

Use A Saturation Model to Limit Control Signal

u(t) =

_

_

100% for v(t) 100%

v(t) for 0% v(t) 100%

0% for v(t) 100%

Chen CL 53

Anti Reset-Windup for Parallel PID

If v > u = u

max

Then e

s

= u v < 0

1

T

t

_

e

s

dt < 0 v until v = u

max

Chen CL 54

Modication of PID (I):

High-Frequency Noise

Problem of D Action: sensitive to high frequency noise

Solution: low-pass lter on D (P & D)

Chen CL 55

Modication of PID (II):

Anti Reset-Windup

Problem of Reset Action: reset windup (saturation)

Solution: limiter

Chen CL 56

Modication of PID (III):

Manual Control

Manual control: with an integrator

Chen CL 57

Modication of PID (IV):

Bumpless A/M Transfer

When in automatic control: m(t) (manual ) tracks u(t) (auto)

m(t): always ready to control

Chen CL 58

Modication of PID (V):

Bumpless M/A Transfer

Method 1: resetting bias during M/A (keep original y

sp

)

let u

b

(t) = m(t) K

c

e(t) (when M/A transfer)

thus u(t) = u

b

(t) + K

c

e(t) (auto control action)

= m(t) (nal manual action)

Chen CL 59

Method 2: set-point tracking (y

sp

(t) tracks y(t) when manual control)

T

s

dy

sp

(t)

dt

+ y

sp

(t) = y(t) (when manual control)

Disadvantage: y

sp

moved to undesired value ?

Chen CL 60

A Complete PID Controller (I)

Automatic control

Anti-reset windup

Bias tracking: bias tracks nal output u(t)

Manual tracking: m(t) tracks nal output u(t)

Manual setpoint adjustment

Chen CL 61

A Complete PID Controller (II)

Manual control

Anti-reset windup

Bias tracking: bias tracks nal output u(t)

Manual tracking: m(t) tracks nal output u(t)

(Manual setpoint adjustment)

Chen CL 62

A Complete PID Controller (III)

External setpoint (used in Cascade Control)

Anti-reset windup

Bias tracking: bias tracks nal output u(t)

Manual tracking: m(t) tracks nal output u(t)

Setpoint tracking:

Chen CL 63

A Complete PID Controller (IV)

Automatic control (used in Override Control)

Anti-reset windup

Bias tracking: bias tracks external signal z(t)

Manual tracking: m(t) tracks nal output u(t)

Setpoint tracking:

Chen CL 64

Thank You for Your Attention

You might also like

- Mathematical Formulas for Economics and Business: A Simple IntroductionFrom EverandMathematical Formulas for Economics and Business: A Simple IntroductionRating: 4 out of 5 stars4/5 (4)

- Process Control FundamentalsDocument923 pagesProcess Control FundamentalsAudrey Patrick Kalla100% (2)

- Controller PrincipleDocument24 pagesController PrinciplePortia ShilengeNo ratings yet

- Presentation On PID ControllerDocument26 pagesPresentation On PID ControllerSangramjit Sarkar100% (1)

- 05 Modeling Dynamic and Static Behavior of Chemical ProcessesDocument47 pages05 Modeling Dynamic and Static Behavior of Chemical ProcessesAsrul SaniNo ratings yet

- Dynamic Characteristics of Measuring SystemsDocument102 pagesDynamic Characteristics of Measuring Systemssunil48175% (4)

- Thermodynamics Summary NotesDocument11 pagesThermodynamics Summary NotesWong Jian MingNo ratings yet

- Thermo ReviewDocument7 pagesThermo ReviewdavidbehNo ratings yet

- EEE373 Electric Motor Drive: Asst. Prof. Dr. Mongkol Konghirun Ee, KmuttDocument16 pagesEEE373 Electric Motor Drive: Asst. Prof. Dr. Mongkol Konghirun Ee, KmuttTumenbayar LkhagvatserenNo ratings yet

- Ch20 Young Freedman2Document28 pagesCh20 Young Freedman2Andrew MerrillNo ratings yet

- Dynamic Charactorstics of An InstrumentsDocument30 pagesDynamic Charactorstics of An InstrumentsDhinakaran VeemanNo ratings yet

- Process Control CHP5Document29 pagesProcess Control CHP5Martha AlbaNo ratings yet

- 4-ITK-330 Steady State Nonisothermal Reactor DesignDocument37 pages4-ITK-330 Steady State Nonisothermal Reactor DesignadyckarockNo ratings yet

- Ce206 OdeDocument23 pagesCe206 OdeBorhan ShaikatNo ratings yet

- MIMO ArticleDocument11 pagesMIMO ArticleCesar GonzalezNo ratings yet

- Ilovepdf Merged-4Document118 pagesIlovepdf Merged-4رشا روروNo ratings yet

- Dynamic Characteristics of Sensors and Measurement SystemsDocument29 pagesDynamic Characteristics of Sensors and Measurement SystemsveenadivyakishNo ratings yet

- H2 and H∞ Optimal Control SolutionsDocument27 pagesH2 and H∞ Optimal Control SolutionsRiky Fitriadi100% (1)

- Turbomachinery Equations SummaryDocument6 pagesTurbomachinery Equations SummaryMasood Ahmed KhanNo ratings yet

- PID Algorithms (Topic 26)Document20 pagesPID Algorithms (Topic 26)MustaphaRamziNo ratings yet

- Process Control CHP 5Document29 pagesProcess Control CHP 5dododoorNo ratings yet

- First Law of ThermodynamicsDocument27 pagesFirst Law of ThermodynamicsJanith DushyanthaNo ratings yet

- Feedback Controllers: Figure. Schematic Diagram For A Stirred-Tank Blending SystemDocument24 pagesFeedback Controllers: Figure. Schematic Diagram For A Stirred-Tank Blending SystemRama ChilpuriNo ratings yet

- Controllers - by Kenil JaganiDocument24 pagesControllers - by Kenil Jaganikeniljagani513No ratings yet

- Theorem 1 (Uniform Stability For Non-Autonomous Systems)Document18 pagesTheorem 1 (Uniform Stability For Non-Autonomous Systems)Jason ChiangNo ratings yet

- Dynamic System ModelingDocument53 pagesDynamic System ModelingDaniel SonNo ratings yet

- System Response System Response: Chew Chee Meng Department of Mechanical Engineering National University of SingaporeDocument33 pagesSystem Response System Response: Chew Chee Meng Department of Mechanical Engineering National University of SingaporeLincoln ZhaoXiNo ratings yet

- Material: To Be Able To Design and Analyze Antiwindup Schemes ForDocument5 pagesMaterial: To Be Able To Design and Analyze Antiwindup Schemes ForJesusChumbipumaNo ratings yet

- Thermodynamics Review of Energy Transfer and SystemsDocument130 pagesThermodynamics Review of Energy Transfer and SystemsJaimin Joshi0% (1)

- Feedback Controllers: Figure 8.1 Schematic Diagram For A Stirred-Tank Blending SystemDocument18 pagesFeedback Controllers: Figure 8.1 Schematic Diagram For A Stirred-Tank Blending Systeml7aniNo ratings yet

- Experiment 06: Study of Process Control-I: Mesbah Ahmad Lecturer Department of Chemical Engineering, BUETDocument18 pagesExperiment 06: Study of Process Control-I: Mesbah Ahmad Lecturer Department of Chemical Engineering, BUETMd Abid AfridiNo ratings yet

- 7 1Document18 pages7 1JohnNo ratings yet

- Chap 08 Marlin 2002Document37 pagesChap 08 Marlin 2002Audrey Patrick KallaNo ratings yet

- Experiment - 5: Temperature Control in A Mixing-Heating ProcessDocument13 pagesExperiment - 5: Temperature Control in A Mixing-Heating ProcessKalepu Navya ManishaNo ratings yet

- Boiling Film ExperimentDocument12 pagesBoiling Film ExperimentsquionkNo ratings yet

- Discontinuous Systems ExplainedDocument37 pagesDiscontinuous Systems ExplainedChernet TugeNo ratings yet

- 18 Ratio, Selective, Override ControlDocument66 pages18 Ratio, Selective, Override ControlSubodhNo ratings yet

- Assignment 1 Engineering Measurement Anandababu N PDFDocument14 pagesAssignment 1 Engineering Measurement Anandababu N PDFEdwin Yugcha100% (1)

- CHE3162 Lecture 8: Introduction to Feedback Control LoopsDocument33 pagesCHE3162 Lecture 8: Introduction to Feedback Control LoopsPhan NeeNo ratings yet

- Lect 7Document30 pagesLect 7ramiyaminNo ratings yet

- Chapter 4Document35 pagesChapter 4S S S REDDYNo ratings yet

- An Iterative Solution To The Finite-Time Linear Quadratic Optimal Feedback Control ProblemDocument2 pagesAn Iterative Solution To The Finite-Time Linear Quadratic Optimal Feedback Control ProblemFelipe Taha Sant'AnaNo ratings yet

- Chapter 5 - Section B - Non-Numerical SolutionsDocument9 pagesChapter 5 - Section B - Non-Numerical Solutionslight2618No ratings yet

- PID and P Controllers Formulas and EquationsDocument1 pagePID and P Controllers Formulas and EquationsPaul GomezNo ratings yet

- System PrototypesDocument29 pagesSystem PrototypesYgor AguiarNo ratings yet

- TERMODINAMIKA PROSES DAN HUKUMDocument27 pagesTERMODINAMIKA PROSES DAN HUKUMAnonymous GTCOMvNo ratings yet

- Chapter 8 - Feedback ControllerDocument35 pagesChapter 8 - Feedback ControllerFakhrulShahrilEzanieNo ratings yet

- Peng ProsDocument112 pagesPeng ProsWahyuSatyoTriadiNo ratings yet

- PDC Chapter 8Document49 pagesPDC Chapter 8satya sagarNo ratings yet

- UO2016F Slide 1 - Basic Relations and Equations of Heat ConductionDocument20 pagesUO2016F Slide 1 - Basic Relations and Equations of Heat ConductionSushil KumarNo ratings yet

- Serv - Chula.ac - TH Tarporn 487 HandOut DynamicCDocument38 pagesServ - Chula.ac - TH Tarporn 487 HandOut DynamicCAaditya RoyNo ratings yet

- FORMULARIO PARÁMETROS OPERATIVOSDocument2 pagesFORMULARIO PARÁMETROS OPERATIVOSWildor Cordova SanchezNo ratings yet

- Thermodynamic PotentialsDocument22 pagesThermodynamic PotentialsShubham BansalNo ratings yet

- CHNG 2006 - PROCESS DYNAMICS AND CONTROL I TUTORIAL #1Document2 pagesCHNG 2006 - PROCESS DYNAMICS AND CONTROL I TUTORIAL #1Kiran VepanjeriNo ratings yet

- TER201 Lecture 6Document66 pagesTER201 Lecture 6lnxxNo ratings yet

- Introductory Differential Equations: with Boundary Value Problems, Student Solutions Manual (e-only)From EverandIntroductory Differential Equations: with Boundary Value Problems, Student Solutions Manual (e-only)No ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- V25n2a7 PDFDocument7 pagesV25n2a7 PDFDenis DominguezNo ratings yet

- Industrial Energy UseDocument180 pagesIndustrial Energy Usediego.lopez1870No ratings yet

- H OilRC ProcessDocument2 pagesH OilRC Processdiego.lopez1870No ratings yet

- SCH 4U The Structure of BenzeneDocument21 pagesSCH 4U The Structure of Benzenediego.lopez1870No ratings yet

- Future European Refining Industry June2012 PDFDocument23 pagesFuture European Refining Industry June2012 PDFdiego.lopez1870No ratings yet

- MS 075Document6 pagesMS 075diego.lopez1870No ratings yet

- The Future of Refining in Europe MMaugeri Dic-2011Document26 pagesThe Future of Refining in Europe MMaugeri Dic-2011diego.lopez1870No ratings yet

- Ind. End. Chem. Res. 2002, 41, 2248-2261Document14 pagesInd. End. Chem. Res. 2002, 41, 2248-2261diego.lopez1870No ratings yet

- Practice 3 Solutions PDFDocument4 pagesPractice 3 Solutions PDFdiego.lopez1870No ratings yet

- Distillation Ch1Document22 pagesDistillation Ch1conker4No ratings yet

- EVOS NOAA Hazmat Trajectory Model SequenceDocument7 pagesEVOS NOAA Hazmat Trajectory Model Sequencediego.lopez1870No ratings yet

- Pump Selection Guide Criteria PDFDocument7 pagesPump Selection Guide Criteria PDFrodriguez.gaytanNo ratings yet

- EVOS Resources For Teachers Students 3 16 09ppDocument36 pagesEVOS Resources For Teachers Students 3 16 09ppdiego.lopez1870No ratings yet

- 19 Feed-Forward ControlDocument50 pages19 Feed-Forward Controldiego.lopez1870No ratings yet

- 12 Tuning PID ControllersDocument139 pages12 Tuning PID Controllersdiego.lopez1870No ratings yet

- 12 Tuning PID ControllersDocument139 pages12 Tuning PID Controllersdiego.lopez1870No ratings yet

- PID Control - ARAKIDocument23 pagesPID Control - ARAKILuiz Carlos da SilvaNo ratings yet